Plant-Made Pharmaceuticals Biopharming might be as easy as

advertisement

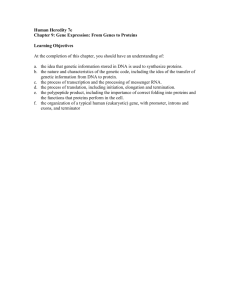

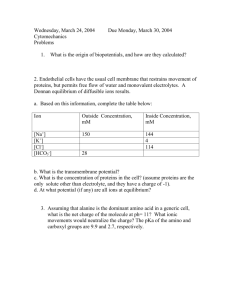

Plant-Made Pharmaceuticals Biopharming might be as easy as literally growing drugs on trees, if it wasn’t for the international regulations, technical challenges, and safety issues. Mariam Andrawiss, PhD Andrawiss is a freelance writer based in London During the September 2005 United Nations World Summit, Secretary-General Kofi Annan gave a ringing endorsement for advancing the Millennium Development Goals (MDGs). These goals, seeking to cure a host of global socioeconomic ills by 2015, form the basis of a mutual pact between developing and developed countries. Among the eight MDGs, two are directly related to vaccination and infectious diseases. A third seeks to provide access to affordable essential drugs in developing countries and to make the benefits of new technologies available in cooperation with the private sector. Millions of people die or suffer unnecessarily each year from diseases or conditions for which effective medicines or vaccines exist. Essential drugs can save lives and improve health, but only if they are accessible, affordable, and of good quality. Genetically modified alfalfa plants grow in a greenhouse. (All photos courtesy of A. Wigdorovitz, Instituto Nacional de Tecnologia Agropecuaria, Buenos Aires, Argentina) Recent studies suggest the promise of molecular farming, the production of pharmaceuticals in plants, as a successful way of making a range of proteins used in research and diagnostics. Producing pharmaceutical proteins in plants presents several advantages: the costs can be lower than traditional methods based on microbial fermentation, insect, and mammalian cell cultures. Some studies have suggested that recombinant proteins can be obtained at less than 10% of the cost of microbial fermentation systems and at 0.1% of the cost of mammalian cell cultures. When high-yield proteins are produced, the economic advantages of plants seem difficult to match. Another major advantage of drug production in plants is its potential for fast scalability. Biolex Therapeutics, Pittsboro, N.C., produces recombinant human therapeutic proteins in a small green aquatic plant called Lemna. "From the transformation event to the production of the transgenic plant, we can come out with a production line within three to four months," says Lynn Dickey, PhD, the company's research vice president. Plants as biofactories Using plants, it is technically possible to grow, harvest, and process pharmaceutical proteins on a large scale. The genetically modified crop containing edible vaccine, for instance, can be consumed raw or partially processed. By targeting protein expression into specific organs of the plant such as grains, one creates a stable storage system. By targeting the recombinant protein to subcellular regions of the cells, such as the endoplasmic reticulum, a favorable environment is created for its appropriate folding and Unripe Law & Order As early as in 1993, the US Patent and Trademark Office (USPTO) filed a patent for the invention of vaccines in edible transgenic plants that was finally issued in 1996 to Edible Vaccines Inc. (today Prodigene). Since then, many other applications have been registered (see www.uspto.gov). The granting of a patent does not automatically allow the patent holder to exploit the invention commercially. For that, specific national regulations need to be fulfilled. Although recombinant proteins obtained from plants are subject to the same set of marketing authorizations than any other drug of other origins, this technology requires the approval of farming of genetically modified (GM) crops, which varies from one country to another. The United States, Argentina, Australia, Canada, China, and South Africa are countries with the biggest transgenic crops areas. Intellectual property laws, health and safety regulations, and their enforcement differ greatly from nation to nation. The pace at which these norms are carried out does not satisfy molecular plant researchers. "If Pharma-Planta does not reach its milestones within these five years, the problem would have been our failure to reach an agreement with regulators, because the regulators so far have been really slow in putting down the rules," says Julian Ma, PhD, St. George’s Medical School, London, and scientific coordinator of the Pharma-Planta consortium (see "The Pharma-Planta Project" sidebar). Appropriate international legal agreements are required to control "biopiracy." Developing countries with less regulatory structures need help in the risk assessment of environmental impact, biosafety, and socioeconomic effects of GM crops. However, according to the Nuffield Council on Bioethics (www. nuffieldbioethics.org), the United States and other countries blocked the implementation of a Biosafety Protocol that had been examined by more than 100 parties to the Convention on Biological Diversity. The countries that rejected it already have extensive commercial GM crops. assembly, thus increasing the amount of recombinant proteins produced. Additionally, targeting the recombinant protein to the membrane concentrates the product. As a consequence, the cost of downstream purification is minimized. Finally, using plants for the production of drugs reduces the risk of contamination with human or animal pathogens, unlike production via animal or human sources. So far, pharmaceutical proteins produced in plants can be classified into three groups: human biopharmaceutical proteins, including growth hormone, human serum albumin, β-interferon, and erythropoietin; recombinant antibodies such as IgG1 and IgM; and recombinant subunit vaccines, from the hepatitis B envelope proteins and the rabies virus glycoproteins to the cholera toxin B subunit. High-expression levels of recombinant proteins determine the commercial viability of molecular farming. Yields are therefore crucial, as witnessed by the collapse of the US company CropTech in 2003, due to its inability to achieve the expression levels required for commercial feasibility. "Yield is a critical point," says Hilary Koprowski, MD, Thomas Jefferson University, Philadelphia, who pioneered the expression of animal proteins in plants. "You can overcome it by using larger amounts of plants, which are much easier to use than mammalian cells, but we still would like to increase the yields." In determining yield, the choice of plant for production is critical. Four groups can be distinguished: leafy crops such as tobacco, alfalfa, lettuce, and soybean; cereal and legume seeds; fruit and vegetables; and finally fiber and oil crops (see table below). Each of them has pros and cons and is generally chosen as a function of the recombinant proteins to be produced. Tobacco for proteins Tobacco is the most widely used species for the production of recombinant pharmaceutical proteins at the research laboratory level. Plant biotechnology company Chlorogen, St. Louis, chose this plant to produce its recombinant proteins. "Tobacco has been around for a long time; it is sort of a laboratory rat," said David Duncan, PhD, president and CEO. "It is easy to transform, and next to sugar cane, tobacco is one of the largest biomass producers on earth. Tobacco is also a plant that we can harvest up to five times per growing season and it grows back from the same plant. Another advantage of tobacco over other plants is that it is a self-pollinator, so even if an internal mechanism such as the maternal inheritance breaks down, the possibility of cross-contamination is limited." To introduce the gene encoding for the protein of interest, a process named transformation, two general methods are used. One is a vector, in which the plant parasite Agrobacterium tumefaciens operates to introduce the foreign gene into the host genome. The other is the gene gun, in which DNA-coated projectiles are accelerated into the plant tissues. After the transformation process, the efficiency of all stages of gene expression and protein stability needs to be maximized. Both the promoter sequence and the polyadenylation signal sequence are key elements for a high level of transcription. The strong and constitutive cauliflower mosaic virus promoter 35S (CaMV35S) is often chosen. Specific promoters, that is promoters that are only active in certain organs of the plant, have also been used and have the advantage of avoiding protein accumulation in vegetative organs, preventing both toxicity in the host plant and contact with nontarget organisms. Finally, inducible promoters allow the production of the desired protein only for a certain period of time. Subcellular targeting is another important factor influencing protein yields. Compartments within the cell can influence the processes of folding, assembly, and post-translational modification. These all affect proteins' stability and thus determine the final yield. Comparative targeting experiments have shown that targeting to the secretory pathway using N-terminal signal peptides derived from plant or animals is a suitable zone for folding and assembling for full-size immunoglobulins and single-chain Fv fragments. Several important factors for protein folding and assembly are indeed present in the endoplasmic reticulum: an oxidizing environment, a lack of proteases, and plenty of molecular chaperones. In the absence of a targeting signal, proteins accumulate in the extracellular space. Different stages of the alfalfa transformation. The recombinant binary vector was introduced in alfafa plants using the Agrobacterium tumefaciens system. Targeting chloroplasts Chloroplasts are alternative organs targeted in plants. Several examples of chloroplast-based molecular farming have been reported. The ability to genetically transform chloroplasts is significant for two important reasons. First, chloroplasts are inherited maternally and therefore are not transferred via pollen to other sexually compatible plants. This is vitally important given environmental concerns about gene transfer. Second, protein production using chloroplast transformation is several hundred times more effective when compared with the currently used nuclear transformation of plants. "Back in the 1980s, it was discovered that there are about 100 chloroplasts per cell and that there are about a hundred copies of DNA within each chloroplast," says Duncan. "In other words, it was discovered that you could have up to 10,000 copies on the foreign gene. This is what we call hyperexpression." However, chloroplasts are not able to perform many of the posttranslational modification tasks such as glycosylation. Plant-derived recombinant proteins tend to lack the terminal galactose and sialic acid residues normally found in mammals, but have the carbohydrate group α-(1,3) fucose, which has a (1,6) linkage in animal cells and β-(1,2) xylose, which is absent in mammals although present in invertebrates. This "foreign" glycan structure has affected the use and acceptance of plant-made proteins. To improve this, attempts have been made to humanize the glycosylation process by using purified human galactosyl and sialyl transferases to modify plant-derived protein in vitro. Finally, production costs of recombinant proteins depend on the required purity because more than 85% of expenditure reflects downstream processing rather than production per se. Plants are advantageous because several recombinant proteins can be used in raw or partially processed material, which decreases the costs significantly. click the image to enlarge Plants used as biofactories for the production of pharmaceutical proteins Several strategies at the molecular level have been developed to reduce downstream processing costs, such as concentrating the proteins to the membrane of the cell, which are then purified by membrane fractionation. Secretion systems are also advantageous because the recovery of proteins does not necessitate the disruption of plant cells. Market opportunities The fast scalability and the lower production costs of plant-made pharmaceuticals have scientists and the industry excited about the future of biopharming. "Once proper expression is achieved, this is just a win-win situation" says Kisung Ko, PhD, a collaborator of Koprowski working on the generation of clinical-grade monoclonals in tobacco. "I am very optimistic about this," adds Duncan. "I think we are turning the corner, even in Europe." Their enthusiasm is certainly shared by business analysts. For them, plant biopharming is emerging as a genuine competitive force in the large-scale production of recombinant proteins. Last December, consultants Frost & Sullivan published an analysis of the biopharming market, mostly focused on North America and Europe. Impelled by the growing demand for biopharmaceuticals and the general public acceptance of transgenic crops, North America is anticipated to become the largest market for plant molecular farming. Frost & Sullivan's report predicts that the US market alone might be worth $2.20 billion in less than a decade. "The gradual relaxation of the moratorium on transgenic crops in Europe is a good indication that the public and regulatory perception toward transgenic crops is improving, and this trend is expected to drive the market," the report states. Among pharmaceutical proteins, the remarkable success of therapeutic monoclonal antibodies (mAbs), which account for more than half of the mAbs approved by the FDA since 1997, has certainly prompted a frantic quest for new medical applications. In oncology alone, the NIH is currently recruiting participants to complete more than 250 clinical trials. Diverse needs, such as for lymphoma and melanoma anti-cancer treatments and Alzheimer's disease therapeutics, are increasing demand for these molecules. Routine immunizations need to be implemented in many regions such as Oceania, sub-Saharan Africa, and South Asia. However, as of June 2005, neither mAbs nor vaccines produced in plants are manufactured yet for any market. The Tufts Center for the Study of Drug Development in Boston has only one record of a plant-made therapeutic monoclonal antibody in clinical studies. This antibody is CaroRxe from Planet Biotechnology Inc., Hayward, Calif., which is used for prevention of dental caries. According to Tufts, only two companies are producing vaccines in plants that are in clinical studies. Large Scale Biology Corp., Vaccaville, Calif., has already achieved preclinical validation for its human papillomavirus vaccine program, and ProdiGene Inc., College Station, Texas, developed a vaccine against a virulent strain of E. coli. Tough competition Even though the academic and biotech biopharming community is using the most innovative and ingenious biotechnical means to turn plants into biofactories, competing effectively in the pharmaceutical market is still difficult. Most biopharming companies are not necessarily interested in developing their own products, says Janice Reichert, PhD, senior fellow The Pharma-Planta Project The Pharma-Planta project (www.pharmaplanta.org) is a consortium of 39 research groups from academic and industrial institutions in Europe and South Africa founded in 2003. Their goal is to enter plantmade pharmaceuticals into clinical trials. The Pharma-Planta scientists have signed a "Statement of Intent on Humanitarian Use" in which they agree that to the best of their ability, they will make knowledge that may be created by their program freely available for the achievement of humanitarian purposes. "I think this [statement] is a very important thing," says Julian Ma, PhD, St. George’s Medical School, London, and scientific coordinator of the Pharma-Planta consortium. "We have an enormous range of vaccines available in the United Kingdom that are not made available for the developing countries. When we think about the benefits of molecular farming, benefits in terms of the scale and the low cost of at the Tufts center. At the moment, they are just trying to come up with proof-of-concept for their diverse methods of plant expression. Reichert believes what they are currently lacking is another firm that has gone through the process of finding a right mAb candidate. "Most of these companies do not have their own mAb. What most of them need is a partner that wants to explore plant production." Sue Mayer, DVM, PhD, executive director of GeneWatch UK, a non-profit group that monitors developments in genetic technologies, says people often forget that the product has to work clinically. "People think all they need to do is to make a vaccine in a plant and they will be all right, but of course that vaccine has to work and has to stimulate the right immune response. Our feeling is that it is the biggest challenge." production, clearly the main beneficiaries will be those in developing countries." "Most of the targets that we are looking at for Pharma-Planta are mostly relevant for the developing world," says Ma. "In the UK, one person died of rabies last year. But if you go to Southeast Asia or Africa, rabies is a serious danger, killing thousands of people every year." The program still has three years to accomplish its objectives. Other therapeutic molecules have been freely licensed before in developing countries. Merck, for instance, has been providing its antiretroviral treatments in Africa for free. However, lengthy research projects, strict biosafety regulation check ups, expensive clinical trials, and costly processing of patents and licensing are undoubtedly going to make Pharma-Planta’s goals difficult to attain. Koprowski thinks the biopharming community needs to gain the confidence of the pharmaceutical industry and investors. "When the pharmaceutical industry realizes the possible future of growing vaccines in plants, then the community will gradually gain confidence and be able to produce them," he says, adding that profits will make them confident. "The first year, profit of a vaccine is very low. You have to gain market share. You have to educate doctors and veterinarians to use it. But in my opinion, these are the vaccines of the future." But Reichert says more needs to be done: "I was in Montreal early last year for the Plant-Made Pharmaceuticals Conference, and even among themselves they were not convinced they can actually do plant production yet. There is potential, but there are serious issues that need to be addressed." Indeed, one important constraint for cost-effective biopharming is good manufacturing of the final product. The quality of the final product is measured by its structural authenticity and to its homogeneity across bushels, given that conditions of soil and weather will change from crop to crop. Another major constraint are multiple biosafety concerns that need to be addressed, as with other genetically modified crops. Although pharmaceutical proteins produced in plants are generally considered safer than those of microbial and animal origin because they lack endotoxins and pathogens, biosafety concerns include the potential co-purification of pesticides and the unpredictable consequences of using viral DNA sequences employed in the transformation of the plant. Environmental threats The possibility of huge amounts of recombinant protein being infiltrated into soil and groundwater is a major concern among environmentalists. Cross contamination could also occur between the genetically modified plants and their wild-type counterparts, leaving microorganisms in the soil, insects, and animals. "I would not advocate growing plants that produce vaccines in open fields. These plants should be grown in greenhouses. Then you can hold all your safety problems there," says Koprowski. "If they use the economical argument, the advantage starts to go away if you have to build a contained greenhouse," says Reichert. Mayer agrees: "It is very cheap to grow something in the fields, but production in high-containment facilities is far from sustainable. I think people have exaggerated the potential cost savings if you are going to do it in a way that has a good safety control. I think it is extremely unlikely that licensing will be given to grow genetically modified crops outdoors." Even though regulatory and safety issues need to be addressed, molecular farming has much to offer for developed and developing countries. Two years ago, the European Community funded the Pharma-Planta project (www.pharma-planta.org). The Pharma-Planta scientists have signed a "Statement of Intent on Humanitarian Use" in which they express their intention to develop products that specifically solve health needs of the poor in developing countries. This year, the Bill and Melinda Gates Foundation set up a The Grand Challenges in Global Health intiative and a committee of medical specialists. The experts indentified the urgent need for needle-free delivery systems and heat-stable preparations as particularly pressing. Molecular farming could be the way to overcome obstacles like storage, transportation, and delivery to developing countries. The latter could produce their own plant-based vaccines and distribute them. "Vaccines seem like a better fit for the plant-made pharmaceuticals," says Reichert. Vaccines that could be produced and administered through edible plants seem like a science-fiction dream to prevent disease in rural African areas. But in Western countries, where the market for vaccines is roughly a hundredth of the market for therapeutics, it seems unlikely that biotech companies would look into tackling these issues without the support of either public or nonprofit funding. "I think there are indeed niche opportunities. They complement and maybe fill a few unmet needs, like perhaps production in developing countries," says Reichert. "I do not think they will ever displace normal grounds of production, like E. coli and CHO cells. Not unless there are major-major advances in the efficiency of the production of the material" Mayer says GeneWatch thinks that people should not use food crops. "It is just asking for troubles. We do think that containment is important, and if trials are going to go head outdoors, serious attention needs to be made on the potentially adverse environmental effect."