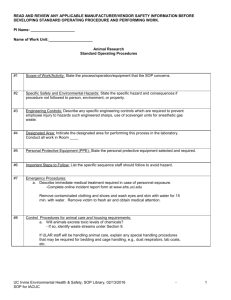

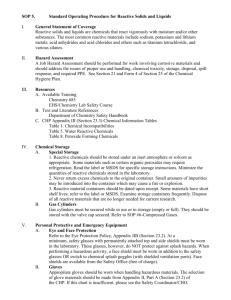

EHS Standard Operating Procedures Form

advertisement

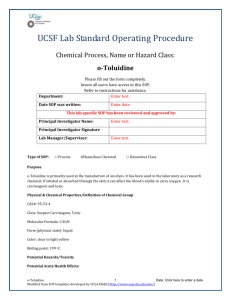

EHS Form # 002 Standard Operating Procedures Submit the completed SOP and any other associated materials (e.g. SDS [MSDS]) to your departmental safety committee that will then route it to EH&S. When approved place a copy in the lab with your laboratory safety documentation notebook. SOP Title: Supervisor/Principal Investigator: Department/Bldg/Room#: Section 1 – Process/Experiment Frequency : One time only Limited time only, End date: Ongoing with no pre-determined end date: Monthly Weekly Daily Irregularly Check here that a scaled-down experiment was considered: Check here that green alternatives were investigated: http://ehs.mit.edu/greenchem/ Check here that less hazardous procedures and/or chemicals were investigated: Describe (briefly) the process/experiment, including its purpose, Section 2 – Hazardous Chemicals Provide a list below of names of hazardous chemicals with CAS # to be used. If none, check here: Attach a copy of the SDS (MSDS). Each person using any of these hazardous reagents will be required as part of their training and certification to read a copy of the SDS (MSDS), to initial each section of the hardcopy, and sign and date the last page. Section 3 – Potential Hazards List any other non-chemical hazards here (biological, electrical, ergonomic, physical, etc.). If none, check here: Section 4 – Approvals Required Check all approval(s) required before students/staff start work on the process/experiment: Supervisor/Principal Investigator (required, others may be added at discretion ) Department Chair Departmental Safety Committee EH&S Other: Section 5 – Designated Area Processes may be done anywhere in the lab. Processes may be done only in specially delineated areas that are appropriately labeled. List these below. The Supervisor/PI will show these to the departmental safety committee. Section 6 – Special Handling Procedures and Storage Requirements Describe requirements for special storage and transport of hazardous chemicals. If none, check here: List special techniques/procedures required when handling chemicals/equipment. Include temperature Released/Revised: 10.23.2012; 01.09.2013; 7.19.2013 EHS Form # 002 controls; chemical incompatibilities; containment devices; access restrictions; special ventilation requirements. Section 7 – Personal Protective Equipment List PPE required: Gloves: Nitrile Neoprene Rubber None required Lab goggles/glasses Face shield Laser goggles Other: Lab coat Respirators. (if checked each individual will need EH&S certification). Other: Other: Section 8 – Engineering/Ventilation Controls No special engineering/ventilation controls are required. Biosafety cabinet Glove box Chemical fume hood Special exhaust chemical hood: Radioactive materials List any other engineering controls to be used. HF HClO4 Other: Section 9 – Spill and Accident Procedures/Decontamination No special spill and/or accident procedures are needed. Normal procedures will be followed: The following special spill and/or accident procedures are required: Section 10 – Waste Collection/Disposal No hazardous waste will be generated. Sharps container is required. Normal waste collection/disposal procedures will be followed. The following special waste collection/waste treatment/disposal procedures are required: Section 11 – Process Steps Process Steps Safety Measures (please also include specific laboratory techniques and PPE, safety indicators) Section 12 – Training Describe special training requirements. Place all documentation in appropriate folder in lab. SOP Prepared By (Name and Title): _________________________ Date: ___________ Departmental Safety Committee Approval: ________________________ Date: ___________ EH&S Approval: _____________________________________________ Date: ___________ Released/Revised: 10.23.2012; 01.09.2013; 7.19.2013