Advanced PM machine design

advertisement

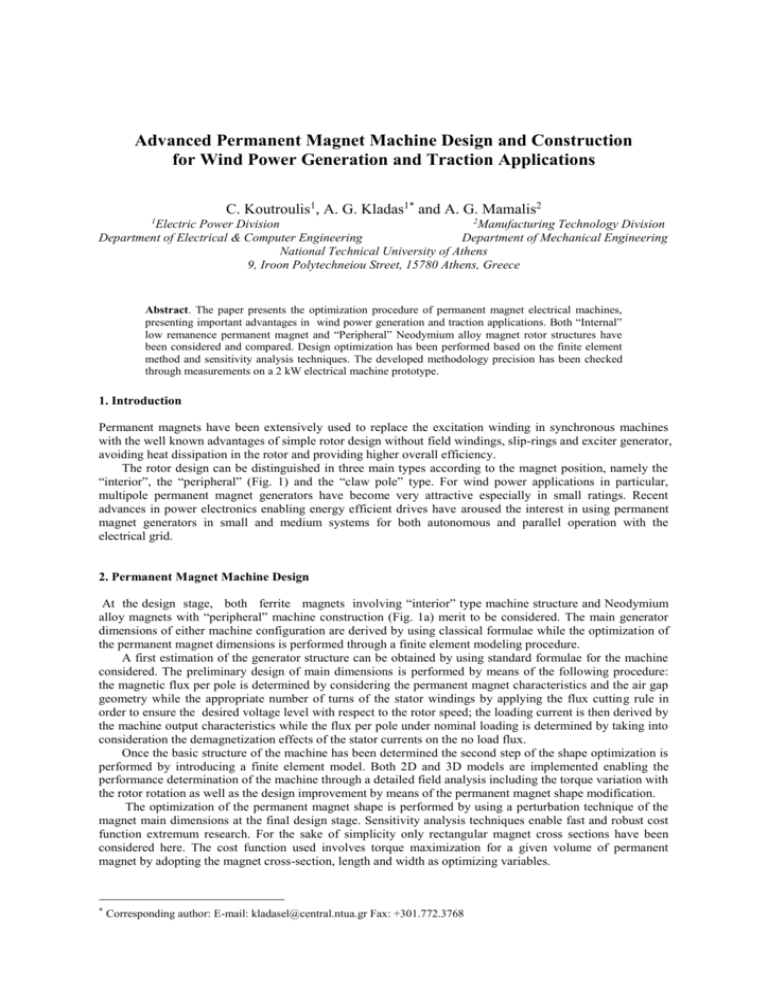

Advanced Permanent Magnet Machine Design and Construction for Wind Power Generation and Traction Applications C. Koutroulis1, A. G. Kladas1* and A. G. Mamalis2 1 2 Electric Power Division Manufacturing Technology Division Department of Electrical & Computer Engineering Department of Mechanical Engineering National Technical University of Athens 9, Iroon Polytechneiou Street, 15780 Athens, Greece Abstract. The paper presents the optimization procedure of permanent magnet electrical machines, presenting important advantages in wind power generation and traction applications. Both “Internal” low remanence permanent magnet and “Peripheral” Neodymium alloy magnet rotor structures have been considered and compared. Design optimization has been performed based on the finite element method and sensitivity analysis techniques. The developed methodology precision has been checked through measurements on a 2 kW electrical machine prototype. 1. Introduction Permanent magnets have been extensively used to replace the excitation winding in synchronous machines with the well known advantages of simple rotor design without field windings, slip-rings and exciter generator, avoiding heat dissipation in the rotor and providing higher overall efficiency. The rotor design can be distinguished in three main types according to the magnet position, namely the “interior”, the “peripheral” (Fig. 1) and the “claw pole” type. For wind power applications in particular, multipole permanent magnet generators have become very attractive especially in small ratings. Recent advances in power electronics enabling energy efficient drives have aroused the interest in using permanent magnet generators in small and medium systems for both autonomous and parallel operation with the electrical grid. 2. Permanent Magnet Machine Design At the design stage, both ferrite magnets involving “interior” type machine structure and Neodymium alloy magnets with “peripheral” machine construction (Fig. 1a) merit to be considered. The main generator dimensions of either machine configuration are derived by using classical formulae while the optimization of the permanent magnet dimensions is performed through a finite element modeling procedure. A first estimation of the generator structure can be obtained by using standard formulae for the machine considered. The preliminary design of main dimensions is performed by means of the following procedure: the magnetic flux per pole is determined by considering the permanent magnet characteristics and the air gap geometry while the appropriate number of turns of the stator windings by applying the flux cutting rule in order to ensure the desired voltage level with respect to the rotor speed; the loading current is then derived by the machine output characteristics while the flux per pole under nominal loading is determined by taking into consideration the demagnetization effects of the stator currents on the no load flux. Once the basic structure of the machine has been determined the second step of the shape optimization is performed by introducing a finite element model. Both 2D and 3D models are implemented enabling the performance determination of the machine through a detailed field analysis including the torque variation with the rotor rotation as well as the design improvement by means of the permanent magnet shape modification. The optimization of the permanent magnet shape is performed by using a perturbation technique of the magnet main dimensions at the final design stage. Sensitivity analysis techniques enable fast and robust cost function extremum research. For the sake of simplicity only rectangular magnet cross sections have been considered here. The cost function used involves torque maximization for a given volume of permanent magnet by adopting the magnet cross-section, length and width as optimizing variables. * Corresponding author: E-mail: kladasel@central.ntua.gr Fax: +301.772.3768 3. Results and Discussion The presented methodology has been applied to design a generator to be connected to a six step diode rectifier bridge. At the preliminary design stage an air-gap width of 1 mm has been chosen while a multipole “peripheral” machine structure has been adopted. Fig. 1a gives the mesh employed for the rotor part simulation in the 3D finite element model, comprising 15.000 nodes and 70.000 tetrahedra. The comparison of the field calculation by the 2D and 3D models has shown a very good agreement except in the region very near the end of the air gap due to the flux leakage. A reduced scale prototype of 2 kW permanent magnet generator has been constructed in order to check the method validity. The measured output characteristics of the generator supplying a six diode rectifier are in good agreement with the those calculated as shown in Fig. 1b. a 350 300 250 Vdc ( V) 200 150 100 50 0 0 1 2 3 4 6 5 Idc (A) 7 8 9 10 11 12 b Fig. 1 Discretization of the machine in finite elements. a: 3D mesh of the rotor part. b: Output characteristics of the p.m. generator connected to a rectifier, ___ : simulation results, o o : measured results 4. Conclusion A methodology for the design of permanent magnet electrical machines for wind power generation and traction applications has been presented. This technique comprises a preliminary design stage by means of standard formulae and an optimization stage involving finite element models. The method results are validated through measurements on a prototype. References [1] A. G. Mamalis, G. N. Gioftsidis and J. Prohaszka, “Manufacturing of thin rectangular plates by explosive compaction of copper powder”, Proceedings Instn. Mech. Engrs., vol. 204, pp. 237, 1990. [2] A. G. Kladas and J.A. Tegopoulos: "A new scalar potential formulation for 3d magnetostatics necessitating no source field calculation", IEEE Transactions on Magnetics, vol. 28, no 2, pp. 1103-1106, March 1992. [3] P. Di Barba, A. Kladas, P. Neittaanmaki, M. Rudnicki, A. Savini, “Application of global optimization strategies to the shape design of a transformer winding”, Advances in Engineering Software, No 19, Elsevier Science Ltd, pp. 121-125, 1994. [4] T. Higuchi, J. Oyama, E. Yamada, E. Chiricozzi, F. Parasiliti and M. Villani, “Optimization procedure of surface permanent magnet synchronous motors”, IEEE Transactions on Magnetics, Vol. 33, no 2, pp. 1943-6, 1997. [5] A. G. Kladas, M. P. Papadopoulos and J. A. Tegopoulos, “Multipole permanent magnet generator design for gearless wind power applications”, Proceedings ICEM’98, Istanbul, pp. 2055-9, 1998. [6] S. B. Yoon , I. S. Jung, D. S. Hyun, J. P. Hong, Y. J. Kim, “Robust shape optimization of electromechanical devices”, IEEE Transactions on Magnetics, vol. 35, no 3, pp. 1710-3, May 1999.