HEP_24132_sm_suppinfo

advertisement

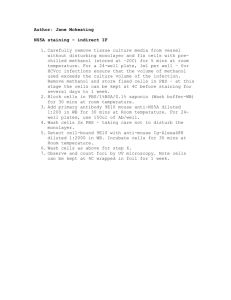

Supplement Analysis of Acetaminophen-Protein Adducts. Materials: Acetaminophen-cysteine (APAP-CYS) was obtained from Toronto Research Chemicals (North Rock, Canada) and norbuprenorphine-d3 was obtained from Cerilliant (Round Rock, TX). Bio-Spin® 6 Tris columns (6,000 Da Molecular Weight Cut-Off) were obtained from Bio-Rad Laboratories (Hercules, CA). High G-force microcentrifuge tubes were obtained from VWR (West Chester, PA). Ultrafree centrifugal filter devices (Durapore PVDF; 0.22 µm) were obtained from Millipore (Billerica, MA). Sodium acetate was obtained from J.T.Baker (Phillipsburg, NJ). Protease type XIV from Streptomyces griseus (~4.0 units/mg) was obtained from Sigma Aldrich (St. Louis, MO). Formic acid was obtained from Fisher Scientific (Fair Lawn, NJ). LC-MS grade acetonitrile and methanol were obtained from Honeywell Burdick and Jackson (Muskegon, MI). Aqueous solutions were prepared with deionized water purified by passage through a Milli-Q Plus filtration system (Millipore, Boston, MA). Preparation of calibrator, quality control (QC) and internal standard (ISTD) solutions: A 1.0 mmol/L stock solution of APAP-CYS was prepared in methanol with working solutions of 0.01, 0.05, 0.1, 0.5 and 1.0 ng/µL in methanol:water (50:50 v/v) prepared by serial dilution of the stock solution. Calibrator and QC solutions were prepared from separate APAP-CYS stock solutions prepared by different analysts. A 1.0 ng/µL norbuprenorphine-d3 solution in methanol, to be used as ISTD, was prepared by the serial dilution of a 100 µg/mL stock solution. Calibration standards were prepared by adding APAP-CYS to micro-centrifuge tubes containing 50 µL of analyte free matrix (cell lysate/media) to yield final concentrations of 2.5, 5.0, 10.0, 25.0, 50.0, 75.0, 100.0, 125.0, 150.0, 175.0, 200.0, 225.0, 250.0 ng/mL. Two additional matrix blanks (with and without internal standard) were prepared concurrently. QC samples at concentrations of 6.0, 100.0 and 210.0 ng/mL were prepared in duplicate from separate working solutions. Sample preparation and extraction: Aliquots (150 µL) of the cell lysate/medium samples were filtered four times through separate Bio-Spin 6 columns following the manufacturer’s instructions. A 50 µL aliquot of the filtrate was transferred to a clean labeled micro-centrifuge tube followed by 50 µL of protease type XIV enzyme in water (8 U/mL). Similarly, 50 µL of protease type XIV enzyme in water (8 U/mL) was added to the calibrator, QC and blank samples. All samples were digested by incubation at 37 oC for 24 hours in a thermostat controlled water bath. After digestion 20 µL of norbuprenorphine-d3 (1.0 ng/mL) was added to each tube followed by acetonitrile (600 µL) to precipitate the enzyme. Volumes of methanol:water (50:50 v/v) were added to each tube to bring the total volume to 750 µL. The samples were centrifuged at 16,000 rpm for 10 mins and the supernatant was evaporated to dryness at 40 oC using a Zymark Turbovap LV Evaporator operating at a pressure of 13 psi. The evaporated residue was reconstituted in 100 µL of 0.1% formic acid in water and vortex mixed for 30 seconds. The reconstituted solution was filtered by passage through an Ultrafree-MC centrifugal filter device at 10,000 rpm for 10 mins. The filtrates were transferred to clean labeled auto-sampler vials for LC-MS/MS analysis. Instrumentation and analysis: LC-MS/MS experiments were performed using a Thermo Finnigan Surveyor LC system (Thermo Electron Corporation, San Jose, CA) equipped with a YMC ODS-AQ column (50 mm L x 2.0 mm ID; 3.0 µm particle size, Waters Corp. Milford, MA), which was interfaced to a Thermo Finnigan TSQ Quantum triple-quadrupole mass spectrometer (Thermo Electron Corporation, San Jose, CA) using an electrospray ionization (ESI) source in positive ionization mode. Chromatographic separation was achieved using 0.1% formic acid in water (solvent A) and methanol (solvent B) at a flow rate of 0.25 mL/min. The gradient elution profile is as follows: hold at 98% A for 6 mins, decreasing to 50% A over 1 min, hold at 50% A for 6 mins and then returning to 98% A over 1 min. The total chromatographic run time was 20 mins. The ion source was operated with a capillary temperature of 280 oC while the ion spray voltage was set at 3.9 kV. Nitrogen sheath and auxiliary gases were set to 30 and 15 arbitrary units respectively. Selective reaction monitoring (SRM) experiments were performed utilizing collision induced dissociation (CID) with argon as the collision gas. The collision energy and molecular transitions were manually optimized for each analyte.