Non-Conforming Material Procedure

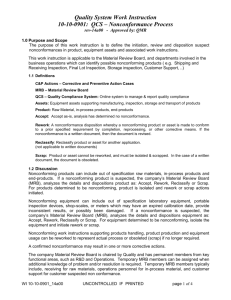

advertisement

Non-Conforming Material Procedure Owner is the Department Manager or designee responsible for maintaining this document. All functions marked with approval required must sign off on this document prior to publishing. As procedures are updated the cover page will change to the format below. The content format is grandfathered and does not require changing. Owner (mark w/ “X”) Function Mark w/ “X” if Approval Required Approval (Embed E-mail Approval) President Quality X Approve 04-000015-01.msg Marketing Sales Engineering X Operations X Approve 04-000015-01.msg Approve 04-000015-01.msg Finance Human Resources It is the user’s responsibility to ensure that this document is the current version. All Quality Management System documents are maintained within the Engineering Document Control System, (EDCS). For information on revision changes reference the Engineering Document Control System version history records. To view approval signatures click on the embedded approval email. Paper Version is for Reference Only – It is the users responsibility to Validate Current Version Online Microscan systems, Inc. – Confidential Form Name: QMS Procedure Format, Version 5 04-000015-01 Non-Conforming Material Procedure Version: 3 Page 2 of 6 Contents CONTENTS .................................................................................................... 2 PURPOSE ...................................................................................................... 2 Scope..................................................................................................2 DEFINITIONS/ACRONYMS ............................................................................... 2 REFERENCES ................................................................................................ 3 PROCEDURE ................................................................................................. 3 SECTION A. DISCREPANT M ATERIAL FROM RECEIVING INSPECTION ................. 3 SECTION B. DISCREPANT M ATERIAL FROM STORES........................................ 3 SECTION C. DISCREPANT M ATERIAL FROM PRODUCTION ................................ 4 SECTION D. REVIEW AND DISPOSITION OF DISCREPANT MATERIAL ................. 4 SECTION E. DISCREPANT M ATERIAL FROM SERVICE ....................................... 5 SECTION F. QUALITY RECORDS - DISCREPANCY NOTICE ................................ 6 Purpose The purpose of this procedure is to establish a method for identification, segregation and disposition of nonconforming material intended for manufacturing use. Items include: purchased parts, components and material assembled at Microscan or by suppliers. Scope Nonconforming material is defined as a deficiency in characteristic that renders the quality of a product or service unacceptable, indeterminate or not according to specified requirements. This can include but not limited to o materials that fail to conform to Engineering Drawing Specifications o materials that fail to conform to specifications on Purchase Orders o materials that fail to conform to Quality/Workmanship Standards Definitions/Acronyms MRB – Material Review Board; The purpose of this board is to provide directions aimed at minimizing the manufacturing scheduling and economic impact incurred as a result of nonconforming material. PPQD – Purchased Part Quality Database DN – Discrepancy Notice UAI – Use As Is RTV – Return to Vendor (Return to Supplier), Warehouse location DVR – Drawing Variance Record SCAR – Supplier Corrective Action Request CAR – Corrective\Preventative Action Request RT – Rejection/ Red Tag PO – Purchase Order ECR – Engineering Change Record IAW – In Accordance With MR – Material Review, Warehouse location for MRB ESDS – Electrostatic Discharge Sensitive Part – Refers to a “purchased” level component used in a sub-assembly. NR assembly – Refers to the sub-assembly or “70-level assembly that is Non-Re-workable. R assembly – Refers to the “70-,” “90-,” or “FIS” level assembly that is Re-workable. 04-000015-01 Non-Conforming Material Procedure Version: 3 Page 3 of 6 GEMBA – Gemba is a Japanese term meaning "the place where the truth can be found." Others may call it "the value proposition." In quality management, gemba means the manufacturing floor and the idea is that if a problem occurs, the engineers must go there to understand the full impact of the problem, gathering data from all sources. 80/20 rule – Also known as the Pareto principle, states that for many situations approximately 20% of the bugs cause 80% of the problems. Therefore, we should concentrate on the few bugs that cause most of the problems. References 04-000024 Corrective/Preventive Action Request Procedure 04-000267 Production Planning and Work Order Procedure 04-110014 Engineering Change Procedure (ECN) 04-000018 Electrostatic Discharge Control Procedure 04-200016 Stock Purge Procedure Procedure Section A. Discrepant Material from Receiving Inspection Responsibility Action Quality A-1 A non-conformance is identified on material in Receiving Inspection. Generate a Discrepancy Notice (DN) per A-2; a) If material is immediately needed for production, notify Quality representative for disposition. b) If there is no immediate need for non-conforming material, move the parts to the MRB holding area for MRB Review and Disposition. A-2 A Discrepancy Notice (DN) is created through the “DN Entry” module of the Purchased Part Quality Database (PPQD). A copy of the DN form is printed and attached to the discrepant material. A-3 Inventory Transaction to the discrepant material location is performed in Visual. Section B. Discrepant Material from Stores Responsibility Action Quality B-1 In case of identification of a nonconformity that can be presented in current stock, a stock purge is performed in accordance with Stock Purge Procedure (04-200016-01). B-2 Purged material is delivered to the MRB holding area. A DN is created per section A2. B-3 Material is held in the MRB holding area for MRB Review and Disposition. 04-000015-01 Non-Conforming Material Procedure Version: 3 Page 4 of 6 Section C. Discrepant Material from Production Responsibility Action When non-conforming Parts or Non-Re-workable assembly (NR assembly) material is Manufacturing C-1 found in manufacturing, place in ESD safe bag. Mark the nonconforming material with rejection tag (RT), place in red bin. When non-conforming Re-workable assembly material is found in manufacturing; mark Manufacturing C-2 part with rejection tag, and place in rework bin. Note: Re-workable assemblies must be dismantled to a “Part” or “NR assembly” marking with rejection tag, and placing in red bin). Stores C-3 Removes non-conforming material from manufacturing red bins, transaction material to “Scrap” and place parts in MRB red bins. Quality or Mfg C-4 Performs “GEMBA” of MRB red bins, and reviews non-conforming material. Use 80/20 rule Engineer to determine if non-conforming material should be reviewed by MRB. Quality C-5 Non-conforming material designated for review shall be transferred from “scrap” to the “MR” location, and DN issued. Remaining non-conforming material shall be discarded in recycle bin (note, no DN required). Section D. Review and Disposition of Discrepant Material Discrepant material will be reviewed and disposition by the Materials Review Board (MRB) which consists of members from Manufacturing Engineering, Project Engineering (as required.), Purchasing, Quality and Manufacturing/Production Control. Responsibility Action Quality D-1 DN’s are reviewed for completeness, repetition, the need to contact suppliers, or the need to perform a stock purge. Designated Quality personnel will have the authority to execute a “Return To Supplier” disposition for non-conforming material provided the return is coordinated with Manufacturing/Production Control. In these cases, Quality and Purchasing will sign the DN. Material shall be returned in accordance with the Material Return and PO Update Procedure. The Quality representative will have the authority to execute a “Scrap” disposition on discrepant material from Production provided the cost associated with the DN does not exceed $100. In these cases, Quality signature is the only required disposition sign-off approval in a DN. D-2 All other dispositions shall be handled through the MRB and shall require disposition signoff approval from Quality, Manufacturing Engineering (or Project Engineer), Purchasing, and Manufacturing/Production Control. Note: The Project Engineer approves disposition on engineering material. Calls MRB Meeting to review and disposition discrepant material. This meeting is generally convened weekly. The MRB review may include drawing requirements, material planning requirements, and related or similar vendor issues. 04-000015-01 Non-Conforming Material Procedure Materials Review Board (MRB) D-3 Quality D-4 D-5 D-6 Version: 3 Page 5 of 6 Material are disposition as “Return to Supplier,” “Rework at Microscan,” “Scrap,” or “Use as Is.” The DN remains at a pending status until all members agree upon the final disposition and disposition approval signatures are obtained. If identified as part of the disposition, the MRB team will review the nonconformity, determine if nonconforming product has been delivered to the customer, and if so, inform Manufacturing Manager for impact assessment and appropriate action. Return to Supplier Discrepant material may be “returned to supplier” for rework, replacement or credit. Material and transactions will be processed in accordance with the Materials Return and PO Update Procedure (04-040010) Note: A copy of the completed DN will remain with the material for return. Rework at Microscan Discrepant material may be reworked. If necessary Rework Instructions will be created defining the scope and detail of the rework to be performed otherwise verbal instruction are acceptable. The rework instruction will require a verification of the rework upon completion. If the rework requires repair activity, the rework instructions will require engineering approval. Rework shall be executed by one of two means: 1. A rework work order in accordance with the Production Planning and Work Order Procedure (04-000267-01). 2. For very simple rework (i.e. Part marking or packaging issues), rework may be performed and verification of the rework will be documented on the associated DN. Scrap Disposition material “scrap” if the discrepancy is irreparable or the cost of rework exceeds the cost of replacement. Material that is scrapped will be disposed of. Inventory transactions will be performed in accordance with the Inventory Transactions and Adjustments Procedure. Note: All “scrap” material of a single part number that exceeds $250 shall have an additional sign off by VP of Operations or designated personnel. Use As Is “Use as Is” shall document material accepted for use in its current condition. A DVR (Drawing Variation Record) and ECR (Engineering Change Record) as required will support such action. Inventory transactions will be performed in accordance with Procedure 04-120003. Update the Disposition of the DN in the Purchased Part Quality Database. If MRB determines a Supplier Corrective Action Request (SCAR) is required, quality representative will generate and send in accordance with the Corrective\Preventive Action Request Procedure (04-000024-01) and/or inform the supplier of the DN. File hard copy of the DN by DN Number. Section E. Discrepant Material from Service Responsibility Action Service E-1 When non-conforming RTS (return to stock) Products or any ELF (early life failure) material is found in service: input failure data to defect tracking software and place in ESD safe Box. E-2 Complete a stock transfer record moving the product from RTN to MRB and deliver box and transfer record to stores. Stores E-3 Inventory transaction to the discrepant material location is performed. Material is physically taken to MRB discrepant material shelf. Quality E-4 Discrepant material is reviewed by MRB (material review board) and disposition as appropriate. 04-000015-01 Non-Conforming Material Procedure Version: 3 Page 6 of 6 Section F. Quality Records - Discrepancy Notice Responsibility Action Quality F-1 Collected: F-2 F-3 F-4 F-5 F-6 Indexed/Filed: Storage: Access: Retention: Disposal: Hard Copy signed, completed forms are maintained in the “MRB closed” file in the Q.A. file cabinet. Electronic copy located in the PPQD. Filed by Discrepancy Notice number. Hard copy In Q.A. file cabinet. Electronic copy in the PPQD. Open to all Microscan employees, available to customers by requests. A minimum of three (3) years from the date of closure. Discrepancy Forms may be disposed or recycled after the retention period.