Chemical Mechanical Polishing of Copper

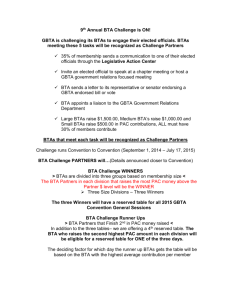

advertisement

Chemical Mechanical Polishing of Copper by Mitch Anderson Advisors Dr. S.V. Babu and Sachin Pandija Chemical Engineering Department Chemical Mechanical Processing, CMP, is the process by which the surface of a material is polished by a slurry in order to obtain a uniformly flat layer. This is useful in order to polish the surfaces of metals and semiconductors to increase their conductivity and resistivity for such uses as computer chip parts. The polishing is done with a machine which includes a feed line which allows the slurry to be added to the sample surface at a constant rate, pad which spins at a constant rate in order to physically remove surface molecules from the sample, and a head to hold the sample in place at a known pressure, which may or may not spin to add to the physical polishing. A slurry is a water based solution which is the main ingredient in this polishing. It contains chemicals and physical abrasives which plane and polish the surface of the sample. There are generally three main categories of chemicals involved in a slurry: the complexing agent, the oxidizing agent and the inhibiting agent(s). The complexing agent makes the surface of the sample more soluble and more easily removed with the abrasives. The oxidizing and inhibiting agents create protective layers on the surface molecules and help to control the rate at which the surface molecules are removed to ensure uniform and undamaged surfaces. For my research, I experimented with different slurries and polishing pads to study how different chemnicals affect the removal rate of the surface of a copper disk. I made slurries in which only one change was made at a time to measure the effect of each individual change. I changed the complexing and inhibiting agents, the weight percent oxidizing and inhibiting agent, and the pad used to polish the disk. For complexing agents, I used either 0.13M Glycine, 0.13M gamma Aminobutyric Acid, 0.13M Acetic Acid or 0.13M beta Alanine. The oxidizing agent was always Hydrogen Peroxide, and I used 1 wt%, 5 wt% or 10 wt% in the slurries. The inhibiting agents were 0.5 mM ADS, 1mM ADS, 2mM ADS, 1mM BTA, 5mM BTA or a combination of 1mM ADS and 1mM BTA. For pads I used either IC-1400 or Polytex surfaces. The controls that I did not change were the 3 wt% Fumed Silica as an abrasive in each slurry, the pressure added by the head of the polisher as 2.5 psi, the pad rotation speed was kept at 90 rpm, the head rotation was 0 rpm, and each experiment ran for two minutes. The goal of my research was to determine which combination of these chemicals will yield the optimized removal rate of the surface of the Cu disk with the least damage to the surface. BTA is a known inhibiting agent in CMP slurries. However, due to the characteristics that BTA exhibits when exposed to Cu, it was advisable to search for an alternative inhibitor. BTA forms an extremely strong bond with Cu, such that polishing the surface of Cu with a protective layer of BTA bonded to it will actually tear off the surface molecules of Cu, creating significant scratches and deformations on the surface of the sample. In addition, BTA bonds at an angle on the surface of Cu such that there are gaps in this protective layer. Therefore we examined the utility of ADS as an inhibitor. ADS is a common surfactant in slurries. A surfactant is a soap-like compound which reduces the surface tension of liquid. This causes the liquid to spread across the surface of the sample and more easily penetrate the molecules of the solid. We hope to discover the efficiency of ADS as an inhibiting agent so that we might replace BTA as an inhibiting agent in our experiments to remove the negative effects BTA has on the Cu surface. However, we also were curious to see if ADS could be added to slurries containing BTA to fill in the holes on the Cu surface left by BTA in order to create a more thorough protective layer and to see if any reactions occured between BTA and ADS that would yield a better removal rate or negate the scratches that BTA caused on the Cu surface. Class of '08 Chemical Engineering Honors Program Mentor: Dr. S.V. Babu Oral Presentation