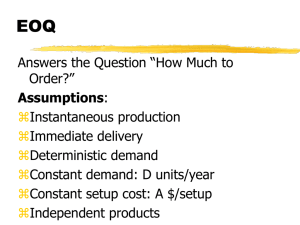

Deterministic Inventory Control Model

advertisement

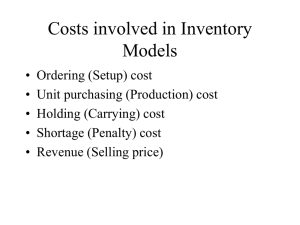

Created By: Rushabh Shah Deterministic Inventory Control Model Formulas 1. Model I(a) EOQ model with constant rate of demand 2 DCo Ch Q* Q* t D TVC * 2 DCo Ch TC * TVC DC 2. Model I(b) EOQ model with different rates of demand 2 DCo TCh Q* t * Q* D 2 DCo Ch T TVC DC TVC TC * 3. Model I(c) Economic Production Quantity Model when Supply (Replenishment) is gradual 2 DCo p Ch p d Q* Q* t D * TVC pd 2 DCo Ch p TC * TVC DC N* D Q* Here N=Optimal Number of production cycles Page 1 of 6 Created By: Rushabh Shah 4. p=rate of receipt of inventory d=rate of usage of inventory Model II(a) EOQ model with Constant Rate of Demand and Variable Order Cycle Time Q* M* 2 DCo Ch Cs Ch C s 2 DCo Cs Ch Ch C s Q* t D * TVC Cs 2 DCo Ch Ch C s R* Q* M * 5. Where R=maximum Shortage Units M=Optimal Stock Level Q=Economic Order Quantity Cs=Cost of shortage Model II(b) EOQ Model With Constant rate of Demand and Fixed Reorder Cycle Time Cs M Ch C s * D *t C * Cs TVC h * D *t C C s h 6. Model II(c) EOQ Model with gradual supply and shortage allowed Page 2 of 6 Created By: Rushabh Shah 2 DCo Ch Q* Ch C s Cs pd Q2* Q* p p p d Ch C C h s pd TVC 2 DC0Ch p C0 p d Cs Ch p Ch C s Q1* 2 D 7. Model III(a) EOQ model with Warehouse Space Constraint n fQ W Qi * 2 Di Coi Chi 2 f i i 1 8. Cs C C h s i i Model III(b) EOQ model with Investment Constraint n C Q i 1 i Qi * i F 2 Di Coi Chi 2 Ci where Chi r * Ci 9. Model III(c) EOQ model with average Inventory level Constraint n 1 Qi M 2 i 1 Page 3 of 6 Created By: Rushabh Shah 10. Model III(d) EOQ model with Number of orders Constraint Number of Orders per year = N * DC DC where N= specified number of orders DC= Demand in rupees 11. Model IV EOQ model with all units discounts available (i) Model with one price break (ii) Model with two price break Sums of Deterministic Inventory Control Model 1. I(a) 2. I(c) 3. I(c) The production department for a company requires 3600 K.g of raw material for manufacturing a particular item per year. It has been estimated that the cost of placing an order is Rs. 36 and the cost of carrying inventory is 25 percent of the investment in the inventories. The price is Rs. 10 per K.g. The purchase manager wishes to determine an ordering policy for raw material. A contractor has to supply 10,000 bearings per day to an automobile manufacturer. He find that when he starts production run he can produce 25,000 bearing per day. The cost of holding a bearing in stock for a year is Rs 2 and the set up cost of a production run is Rs. 180. How frequently should production run be made. A product is sold at the rate of 50 pieces per day and is manufactured at a rate of 250 pieces per day. The set up cost of the machines is Rs. 1000 and the storage cost is found to be Rs. 0.0015 per piece per day. With labour charges of Rs. 3.20 per piece, material cost at Rs 2.10 per piece and overhead cost of Rs. 4.10 per piece, find the minimum cost batch size Page 4 of 6 4. II(a) 5. II(c) 6. III(a) 7. III(b) Created By: Rushabh Shah if the interest charges are 8 percent (assume 300 working days in a year). Compute the optimal number of cycles required in a year for the manufacturing of this product. A commodity is to be supplied at a constant rate of 200 units per day. Supplies of any amount can be obtained at any required time, but each ordering cost Rs 50, cost of holding the commodity in inventory is Rs 2.00 per unit per day while the delay in the supply of the item induces a penalty of Rs 10 per unit per day. Find the optimal policy (Q,t) where t is the reorder cycle period and Q is the inventory after reorder. The demand for an item in a company is 18,000 units per year and the company can produce the item at a rate of 3,000 per month. The cost of one set up is Rs 500 and the holding cost of one unit per month is 15 paise. The shortage cost of one unit is Rs. 240 per year. Determine the optimum manufacturing quantity and the number of shortages. Also determine the manufacturing time and the time between set-ups. A small shop produces three machine parts 1,2,3 in lots. The shop has only 650 sq. m of storage space. The appropriate data for the three items are presented in the following table. Item 1 2 3 Demand(units per year) 5000 2000 10000 Set up Cost (Rs) 100 200 75 Cost per unit(Rs) 10 15 5 Floor space required (sq 0.70 0.80 0.40 ft/unit) The shop uses an inventory carrying charge of 20 percent of average inventory valuation per annum. If no stock outs are allowed, determine the optimal lot size of each item under given storage constraint. A shop produces three items in lots. The demand rate for each item is constant and can be assumed to be deterministic. No back orders are to be allowed. The pertinent data for the items is given in the following table. Item Carrying Cost(Rs. Per unit per year) Set up Cost (Rs per setup) Cost per unit(Rs) Yearly Demand (units) 8. III(c) 9. III(d) 1 20 2 20 3 20 50 40 60 6 10,000 7 12,000 5 7,500 Determine approximately the economic order quantities for three items subject to the condition that the total value of average inventory levels of these items does not exceed Rs. 1,000. Consider the data of above example no 6. with a constraint of limited storage space sufficient only for 560 units of all types of items instead of 650 sq. ft. of storage space. Determine the optimal number of units of each item separately so as to satisfy the given constraint. A company has to purchase four items A,B,C and D for the next year. The projected demand and the unit price in Rs are as follows Item Demand(units) Unit Price (Rs) A 60,000 3 Page 5 of 6 Created By: Rushabh Shah B C D 10. IV (one price break) 11. IV (two price break) 40,000 1,200 5,000 2 24 4 If the company wants to restrict the total number of orders to 40 for all the four items, how many orders should be placed for each item. The annual demand of a product is 10,000 units. Each unit cost Rs 100 if orders placed in quantities below 200 units but for orders of 200 or above the price is Rs. 95. The annual inventory holding cost is 10 percent of the value of the item and the ordering cost is Rs 5 per order. Find the economic lot size. A shopkeeper estimates annual requirement of an item as 2000 units. He buys from supplier at a cost of Rs 10 per item and the cost of ordering is Rs 50 each time. If the stock holding costs are 25 percent per year of stock value, how frequently should he replenish his stocks? Further suppose the supplier offers a 10 per cent discount on orders between 100 and 499 items, and a 20 percent discount on orders exceeding or equal to 500. Can the shop keeper reduce his costs by taking advantage of either of these discounts. Page 6 of 6