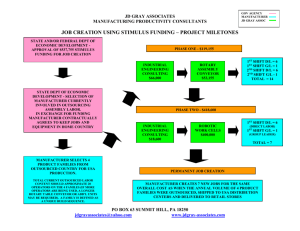

Professional Letter

advertisement

MASTERSPEC BOND&SEAL – DRY-LAID PAVERS Section 07180 – Water Repellent 1. PART 1 GENERAL 1.1 SCOPE A. Water repelling, penetrating coating and bonding agent, which is to be, applied to exterior and interior dry-laid paver systems and jointing sands. 1.2 QUALITY ASSURANCE A. B. 1.3 QUALIFICATIONS A. B. 1.4 C. D. E. F. Apply coating to 24 sq. ft area of each surface to be waterproofed, where directed by Architect. WARRANTY A. 1.8 Convene a pre-installation conference one week prior to commencing work of this Section. Review installation procedures and coordination required with related work. FIELD SAMPLE A. 1.7 Submit product data information. Include details of product description, tests performed, limitations to coating, cautionary procedures required during application, and chemical properties Submit manufacturer’s installation instructions. Submit manufacturer’s certificate that products meet or exceed specified requirements and that their application was according to manufacturer’s recommendation. Submit manufacturer’s certificate that products supplied comply with local regulations controlling the use of volatile organic compounds (VOC). Submit manufacturer’s test and inspection reports. PRE-INSTALLATION CONFERENCE A. B. 1.6 Manufacturer: Company specializing in manufacture of water repellent coatings with five years minimum experience. Applicator: Certified and approved by manufacturer. SUBMITTALS A. B. 1.5 Perform work in accordance with manufacturer’s printed instructions. Maintain one copy of document on site. Provide manufacturer’s 5-year warranty for materials. REGULATORY REQUIREMENTS A. Comply with all current federal, state, and local volatile organic compound (VOC) regulations. 1.9 2. ENVIRONMENTAL REQUIREMENTS A. Do not apply coating when ambient temperature is lower than 40 degrees F or higher than 100 degrees F. PART 2 PRODUCTS 2.1 ACCEPTABLE MANUFACTURERS A. 2.2 EPRO Services, Inc. 800-882-1896. MATERIALS A. BOND&SEAL, a low viscosity, pre-polymer, hydrocarbon based urethane sealant. Appearance - uncured, cured Initial Cure Final Cure Elongation UV Resistance Resistance to solvents & fluids Resistance to de-icing Bonding 3. ASTM D 412 Clear 1 hr 24 hrs (substrate/weather) 100% Excellent Excellent Excellent Excellent PART 3 EXECUTION 3.1 INSPECTION A. B. C. 3.2 PREPARATION A. B. C. D. E. 3.3 Remove loose particles and foreign matter. Remove oil or foreign substance with a cleaner, which will not affect coating. Protect adjacent surfaces not scheduled to receive coating. If applied on unscheduled surfaces, remove immediately, by approved method. All jointing sands must be compacted and damp, with excess sand removed from the surface of paver. FIELD QUALITY CONTROL A. B. 3.4 Verify all pavers are secure and level. Verify surfaces to be coated are dry, clean, and free of efflorescence, oil, or other matter before application of coating. Beginning of installation means acceptance of substrate. Field inspection and testing will be performed. Manufacturer of water repellant coating shall provide the inspection services as required. APPLICATION A. B. Delay work until substrate is dry to touch but jointing sand is still damp. Do not install in dry sand joints. Apply coating in one liberal flood application, with excess material by use of an industrial foam squeegee being forced into the sanded joints to ensure maximum saturation. 3.5 PROTECTION AND CLEANING A. B. C. Protect adjacent surfaces from damages and stains. Clean materials from surfaces where inadvertently applied. Protect finished installation.