Materials - Midlands State University

MIDLANDS STATE UNIVERSITY

FACULTY OF SCIENCE AND TECHNOLOGY

DEPARTMENT OF FOOD SCIENCE AND NUTRITION

FSN 107 & 204 FOOD CHEMISTRY LABORATORY

MANUAL

A. Physical properties of food

1.

Specific Gravity and Refractive index

To illustrate the use of hydrometers and refractometers in determining the absolute or relative concentration of a substance in a liquid.

Materials

Hydrometer (scale 1-2 or lactometer)

Refractometer

Skim milk

52% w/w sucrose solution

Saccharometer (Brix scale 30-60%)

Whole Milk

42% w/w sucrose solution

Procedure

a.

Bring whole egg and skim milk to the temperature at which the hydrometer is calibrated.Transfer samples to appropriate cylinders. Gently lower clean dry hydrometer into each sample. Read scale when bubbles are gone and hydrometer is at rest. b.

Use saccharometer to determine the percentage sucrose in a 42% sugar solution and a 52% sugar solution. c.

Use a refractometer to determine the soluble solid content of the same sucrose solutions as in step 2.

Questions

I.

What is the effect of butterfat concentration on the specific gravity of milk?

II.

What kind of dispersion is milk?

III.

When would it be advisable to use a saccharometer Vs a refractometer.

Dispersion Of Matter

Solutions

To illustrate the effects of solutes on two colligative properties.

Materials

Sucrose NaCl (reagent grade)

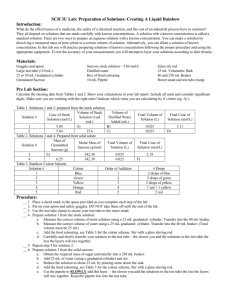

Procedure

1. Calibrate your themometer by determining the boiling point of deionised (D.I) water .

2. a) Prepare a solution with 30g NaCl and 300ml DI water in a 400ml beaker. b) Place beaker on burner over an asbestos wire pad. Suspend thermometer in beaker.

Heat to a boling point. c) Remove approx. 2ml into premarked tubes at each of the following temperatures,

101, 105, 106

0

C. Do not undershoot temperatures. Calculate the expected salt concentrations ( g solute/ g solvent) use the formula

T = K b or f

x wt of solute x 1000 x

of particles per molecule in a solution

wt of solvent M.W solvent

Convert the concentration (wt solute/ wt solvent) to % by substituting wt solute/ wt solvent in the formula with X x 100 where x = wt solute /wt solvent.

X + 1

Plot the boiling point vs soluble solids measured on the refractometer and the calculated

% solids extrapolated from the figure on the same graph.

d) Determine the % soluble solids with a refractometer.

3. a) Prepare a sucrose solution with 30g sucrose and 300g DI water in a 400ml beaker.

b) Place beaker on burner over an asbestos wire pad. Suspend thermometer, heat to a rolling boil.

c)Remove approx. 2ml solution into premarked tubes at the following temperatures

100.5, 101.5, 102 o C . Do not undershoot temperatures.

d) Determine % solids with refractometer.

4. a. Prepare a sucrose solution with 150g sucrose, and 150 ml water in a 400ml beaker.

b) Repeat the above

c)Repeat the above at temperatures 103, 106.5, 112, 114 and 130

0

C

d) Repeat above

5. Calculate the expected sucrose concentration from 3 and 4 above and graph the boiling point vs the expected and observed sucrose concentration on the same graph as described for salt in 2c.

6.a) Prepare 50g of 10% (W/W) solution of sucrose and a 10% of NaCl . b) Determine the freezing point of the 10% solutions by placing a thermometer in a test tube containing enough of the solution to cover the bulb. Place the test tube in a 4: 1 ice to NaCl mixture and observe the temperature at which the solution solidifies.

QUES

1. Why do the calculated and observed concentrations differ for sucrose but not for

NaCl?

2. Why is it not possible to reach a boiling point higher than 107 0 C for NaCl.

3. What is the boiling point for the thread? Soft ball stage? Hard ball stage? Hard crack stage? How does the final boiling point relate to the sucrose concentration and firmness of fudge or toffee.

4. Enumerate the characteristics of a true solution.

Emulsions

To demonstrate the effectiveness of various substances as emulsifying agents.

Materials

Sudan red dye

Vegetable oil

Electric blender

Egg yolk

Sucrose ester (D. K ester F. 160)

Liquid detergent

Slides

Lecithin

Microscope

Test tubes

Sucrose ester (D.K ester F10 Bile

Polyoxyethylene Sorbitan mono palmitate (Tween 40)

Emulsifier Oil Water Liqiud For Dissoving

Emulsifier

O/W emulsions

Control – no emulsifier

Lecithin 0.5g

Egg yolk 0.5ml

Detergent 0.5ml

Bile 0.5g

Polyoxyethylene Sorbitan 0.5g

10

10

Sucrose ester (D. K ester F. 160) 0.5g 10

Sucrose ester (D.K ester F10) 0.5g 10

W/O emulsions

Control – no emulsifier

Lecithin 0.5g

Egg yolk 0.5ml

40

40

40 ml

10

10

10

10

Vegetable oil 0.5ml

Bile 0.5g

Polyoxyethylene Sorbitan 0.5g

40

40

40

Sucrose ester (D. K ester F. 160) 0.5g 40

Sucrose ester (D.K ester F10) 0.5g 40

Procedure

1. Colour oil with sudan red dye.

2. Mix emulsifier with liquid specified for your variation.

3. Put oil and water into sample cup of mixer.

4. Mix for 30sec on speed 5.

5. Pour into beaker and observe.

10

10

10

10

10

10

10

10

40

40

40

40 ml

40

40

40

40

-------- oil water water water oil

Water oil

----

Oil

Water

Water

Water

Oil

Water oil

6. Observe emulsions under microscope to determine whether you made a O/W or W/O emulsion.

QUES.

1. How does the type of emulsifier affect emulsion formation and stability for W/O or

O/W emulsions.

2. What chemical properties should a good emulsifier have?

3. How can emulsifiers be classified be classified by their hydrophilic Lipophylic balance

(HLB) number?

4. What kind of emulsion is butter? Cream? Margarine? Salad dressing?

5. Why are detergents good cleaning agents?

6. What is the role of bile in digestion and absorption of fats?

Foaming properties of Proteins

To compare the foaming abilities of various protein. To investigate the mechanism of foam formation and stability. To determine the effect of other chemical substsnces and temperatures on protein foams.

Materials.

Egg albumin

Soya albumen (soya Lacto)

Whey

Vegetable oil

Caseinate

Cornstarch

Sugar

NaCl

100ml graduated cylinders

Procedure

Mixer

1. Prepare 100ml of the following solutions; a.

0.5% caseinate b.

0.5% whey c.

0.5% egg albumin d.

0.5% Soy albumen e.

0.5% soy albumen + 0.5 % corn starch f.

0.5% soy albumen + 0.5% sugar g.

0.5% soy albumen + 0.5% veg. oil h.

0.5% soy albumen + 0.5% NaCl

2. Place 50ml into sample cup of electric mixer, mix at speed 5 for 30sec and place into 100ml graduated cylinder. Repeat for each.

3. Place containers at room temperatures and in a 40 0 C water bath.

4. Measure foam volume at 0.5 and 30sec after mixing.

QUES

1. Graph the loss of foam volume over time for each temperature for each solution.

2. Compare the volume and stability of the foams as a function of a) nature of protein present b) Type of ingredient in the presence of the protein c) Temperature

Carbohydrates

1. Qualitative Tests For Carbohydrates In Solution

Materials

Various carbohydrates in powder or granules

Test tubes

Molisch Test (for soluble carbohydrates) a.

Take 2cm

3 solution in a test tube, add a few drops Molisch reagent (alcoholic solution of alpha napthol). Mix well. b.

Add 1-2cm 3 concentrated sulphuric acid carefully, pouring down the inside of the tube to form a lower layer c.

Leave to stand then observe.

Iodine Test ( for carbohydrate polymers )

Take 2cm

3

of solution in a test tube, add a few drops iodine solution. Observe.

Fehlings Test (given by all reducing sugars )

To 1cm

3

solution in a test tube, add 1cm

3

of Fehlings solutions l and ll. Mix and heat in a boiling water bath for 2 mins.

Benedict’s Test

(given by all reducing sugars. It is similar to Fehlings but more specific and less sensitive)

To 1cm 3 of solution in a test tube, add 2cm 3 Benedict’s solution. Mix and heat for

2mins in a boiling water bath.

Yellow or orange precipitate indicates reducing carbohydrates present.

QUES

1.What colour changes have you observed in the above reactions? What conclusions can you make out of these observations.?

2. What is a reducing sugar? What is the significance of the reducing ability of a sugar?

2. Draw the structure of each sugar tested and indicate the reducing potential of each sugar.

2. Quantitative Determination Of Concentration Of A Solution Known To Contain One

Reducing Sugar

Benedict’s Method

Reagents

Benedict’s quantitative reagent

0.3% glucose solution

Solution of named reducing sugar in unknown concentrations

Sodium carbonate- anhydrous

Method

1.

Pipette 10cm

3

benedict’s quantitative reagent into a small conical flask and add 2g anhydrous Na

2

CO

3.

2.

Add a piece of porous pot and heat the solution gently to boil.

3.

Keeping the mixture just boiling, run in the sugar solution in small amounts from a burette, boiling well after each addition until the blue or green colour disappears.

NB. The end point is reached when further addition of solution after boiling fails to cause any change in colour. When nearing the end point, boil gently for 30sec. After the addition of sugar to avoid overshooting. Read the burette to the nearest 0.05cm

3

and do at least two careful titrations to reach an agreement.

10cm 3 Benedict’s solution should be equivalent to:

-

20.0mg glucose

-

21.2mg fructose

-

20.6mg sucrose after hydrolysis

-

27.1mg lactose

-

28.2mg maltose

3. Microscopic Examination Of Starch Grains

Obtain specimens of starch extracted from different sources together with one from an unknown source eg. Laundry starch. Disperse minute quantities of each known starch in turn onto a microscope slide in a drop of water. Cover with a cover slip and observe under low and high power. Draw each indicating comparative sizes and characteristic features which allow for identification.

Examine unknown starches and make suggestions regarding their identity.

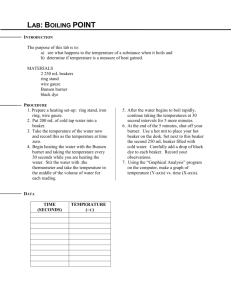

4. Gelatinisation Of Starch

Materials

180ml water

15g wheat flour

15g sorghum meal

15g maize meal

15g rice flour

Procedure

1.

Place of starch in a beaker. Add water slowly mixing well. No lumps.

2.

Heat slowly stirring all the time.

3.

Pour mixture into a large wetted crucible or petridish.

4.

Repeat with the other starches.

5.

Leave to cool for several hours or overnight. Compare the gels including any evidence of synerisis and record.

6.

Place a sheet of A4 size on the table. Place a sheet of carbon paper face down on the paper. Place a piece of grease proof paper on top of the carbon paper. Fix them to the table so that they will not move.

7.

Turn out the first mould on the left hand side of the grease proof paper. Continue across the paper with the other three moulds. Leave for 5mins to allow time to for any of the moulds to spread.

8.

Draw around the perimeter of each mould with a pencil. Press firmly so that the outline will appear on the plain paper.

9.

Carefully remove the moulds and grease proof paper. Write the name of the starch on the impression of the mould. Compare the impressions for size of spread.

QUES

Which starch would be suitable for thickening white sauce? Steak pie? Sauce to be frozen? Explain your answers.

LIPIDS

1. Detection Of Lipids In Foods

Grease Spot Test

Wrap a fragment in filter paper and leave in a warm place long enough to drive out any water. Observe stain.

Sudan lll Test for traces of lipids (use with fragments, powders, crumbs, gratings)

Sudan lll is a red dye used in alcoholic solution from which it is readily absorbed by lipids.

Method a. Place a standard amount (level spatula) of fragmented food in a test tube with 5cm 3 of

Sudan lll solution and shake thoroughly. b . Filter collecting the filtrate in another test tube. Repeat with an equivalent amount of lipid free material eg. Starch and compare the depth of colour of the filtrates. Record your observations.

2. Demonstration of Acrolein Formation

Heat 1 or 2 drops of glycerol in a dry hard glass test tube with an equal volume of potassium hydrogen sulphate crystals, a dehydrating agent. Note the characteristic smell.

Suggest where the smell could be coming from.

3. Visual evidence of invisible fat from foods

Materials

Potato chips

Groundnuts

Paper towel

Acetone

Microwave

Balance or scale

Rubber/ Latex gloves

Procedure

Foil

Acetone

100ml petri dishes

Hammer

100 and 600ml beakers

Safety goggles

Graduated cylinders

Potato chips i) Measure out 2g of potato chips and place on a paper towel. ii) Microwave on hogh for 25sec. iii) Fold the paper towel over the potato chips and crush the chips with a hammer. iv) Allow it to sit for 5mins. Open up the paper towel. Record your results.

Groundnuts i) Measure out 2g of groundnuts and put on a paper towel.

ii) Microwave for 25sec on high. iii) Fold the paper towel over the nuts and crush the nuts with a hammer iv) Allow it to sit for 5mins. Open up the paper towel. Record your results

4. Q uantitative Determination Of Lipids In Food

Extraction of fat

Materials

Potato chips Foil

Groundnuts

Paper towel

Acetone

Microwave

Balance or scale

Rubber/ Latex gloves

Acetone

Hammer

100ml petri dishes

100 and 600ml beakers

Face musks

Graduated cylinders

Glass rod

Procedure

1. Weigh out 5g of potato chips, crush with your fingures.

2. Label the beakers that you are using, one for chips the other for nuts. Record the weights of the labeled beakers.

3. Place the potato chips in the labeled beaker . Record the weight of beaker + chips.

4. Add 10ml of acetone to the crushed potato chips in the beaker.

5. Stir with a glass rod in a well ventilated area.

6. Carefully decant the acetone into the petri dish making sure the chips remain in the beaker.

7. Add 10ml of acetone to the chips and repeat steps 5 & 6.

8. Allow the acetone in the petri dish to dry overnight in a hood or well ventilated place to visualize the lipid that was extracted.

9. Allow the beaker with the chips to dry overnight. Weigh the beaker with the chips.

Ground nuts

1.Weigh out 5g of groundnuts. Crush the nuts between 2 pieces of foil with a hammer.

2. Repeat steps 2-9 in chips.

Tabulate your results under the following headings

Food, wt of beaker, wt of beaker with raw food, wt of raw food, wt of beaker with dried food, wt loss from food, % lipid extraction ie( wt lost from food/wt of raw food) x100

Ques.

Which lipid contained saturated and unsaturated fatty acids in this experiment?

Soxhlet Extraction

Weigh out 5g of the food into a dry Soxhlet thimble. Suspend the thimble in a beaker and dry it to constant weight in a steam oven. Place it in the Soxhlet condenser attached to a previously weighed flask containing sufficient ether to fill the thimble and half fill the flask. Attach the reflux condenser to the extraction tube. Heat the flask by means of a water bath or electric hot plate so as to keep the ether gently boiling. The ether vapour passes up the side tube of the extractor to the reflux condenser where it is condensed and runs back onto the food in the thimble. When the thimble is practically full, the ether is

returned to the flask by an automatic siphoning device, carrying with it some of the fat from the food. In this way, although a comparatively small quantity of ether is used, th food is being constantly extracted with fresh fat free solvent.

After siphoning over 24 times, stop the experiment just before the next lot of ether is on the point of syphoning over. The Soxhlet flask will the contain all the fat in a substance and little ether. The flask is then dried off in air and and weighed to constant weight. The fat is then washed out of the Soxhlet flask by a fat solvent, and then flask dried and weighed again. The percentage weight of fat in the food is then calculated.

Original weight of food sample = xg

Weight of flask + extracted liquid = yg

Weight of flask =zg

Percent lipid in food = y - z x 100 x

PROTEINS

1.

Thermal Decomposition Of Protein

Strongly heat some dry protein in an ignition tube held by tongs in a horizontal

Position. Note the typical smell and test the fumes emitted with: a) Moist red litmus paper b) Moist lead acetate paper

Note the colour changes and explain the reaction produced that colour.

What does the water vapour indicate? What causes the black residue?

2.

Water Solubility of Protein

Materials ;- A variety of powdered or fragmented protein.

Add a small quantity of protein in powdered or fragmented form to half a test tube of water. Shake thoroughly. Foaming is a sign of solubility, even if slight. If insoluble in cold water, try heating. a.) Classify the samples as l. Cold water soluble, ll. Hot water soluble and lll. Insoluble

QUES . What types of dispersions are formed?

Use the solutions for the next experiment. Tabulate your results for each test.

3.

Qaulitative Tests For Protein

Biuret Test (for compounds with two or more peptide linkages)

Mix 5cm 3 2M Sodium Hydroxide and three drops 1% copper sulphate. Reserve some of this mixture for colour comparisons. Add 1cm

3

Biuret mixture to an equal volume of solution/ suspension under test and leave to stand.

Millon’s Test ( for compounds containing the hydroxy–phenyl group, C

6

H

4

OH)

N.B

Millon’s reagent (Mercury dissolved in nitric acid) is poisonous use minimum quantities.

Add 2 drops Millon’s reagent to about 2cm 3 of solution or suspension under test and heat in a water bath. Observe results.

Xanthoproteic Test ( For compounds containing the phenyl group, C

6

H

5

)

Add about 2 drops concentrated nitric acid to about 2cm

3

of solution or suspension under test and heat in a water bath. Cool and neutralize by adding an ample amount of ammonium hydroxide solution.

Sakaguchi Test ( for all known proteins)

To 3cm

3

of solution/suspension under test, add 1cm

3

2M sodium hydroxide, 2 drops 1% alcoholic alpha naphthol and 3 drops 10% sodium hypochloride. Mix well and allow to stand. Repeat on a blank, ie. a test tube containing water instead of test solution/suspension.

Sulphide Test (For sulphur containing amino acids)

Add 2cm

3

of dilute sodium hydroxide to to 1cm

3

of solution or suspension under test.

Boil thoroughly in a water bath noting dissolution of insoluble protein. Either add a few drops of lead acetate solution or dip in lead acetate test paper.

QUES a) What are the specific reactions involved in producing the colour in each of the tests. b) What difficulties might be encountered in the amount of protein using the same colour reaction.

3.

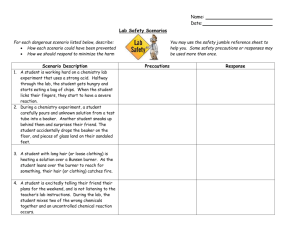

Denaturation of Protein

Experiment 1

Materials

Egg white

0.1M Sodium chloride solution 0.1M Calcium chloride solution

0.1M ferric chloride solution

1.0M sucrose solution

0.1M Hydrochloric acid solution

0.1M sucrose solution

0.01M Hydrochloric acid solution

Distilled water

Procedure

Dilute 1 egg white (slightly beaten) with 3 volumes distilled water, stir slowly but thoroughly and filter. To each test tube add 10ml albumin solution and 5ml of each of the solutions listed above, including distilled water. Record the pH of the solution containing distilled water and 0.01M and 0.1M hydrochloric acid. Place all in a beaker of water, heat slowly and note the temperature at which opalescence develops.

Experiment 2

Materials

2% egg albumin solution

4cm

3

industrial spirit (alcohol)

2cm

3

mercuric chloride solution (poisonous)

2cm 3 tannin acid solution

NB. If instead, egg white is used, (albumen) make up a 10% solution and filter off insoluble globulins.

Procedure

Place approx. 3cm

3

of albumin solution in each of the three test tubes.

In the forth test tube, heat gently at first and then bring to the boil.

Record results describing any coagulum that forms

While these apply in particular to egg albumin, the effects of organic solvents, salts of heavy metals, alkanoids, eg. Tannin acid and heat are similar for most soluble proteins.

Using this information, explain the following. a.

pickling of anatomical specimens in alcohol b.

swallowing egg white as an antedote for lead poisoning c.

applying tannic acid ointment to burns and why this is no longer advocated. d.

Destroying enzymes by heat.

Maillard Reaction

To evaluate the aroma and colour of heated amino acid – glucose solutions.

Materials

Glucose

Aspartic acid

Lysine

Phenylalanine

Valine

Procedure

Methionine

Leucine

Proline

Arginine

1. To 50g of glucose, add 50mg of an amino acid in a test tube, add 0.5ml distilled water. Mix thoroughly.

2. Smell each mixture and record any sensations.

3. Cover each test tube with heavy aluminium foil, heat solutions in a water bath at

100 0 C for 45mins. Cool to about 25 0 C in a water bath. Record the odour sensations for each solution eg. choc-like, potato-like.

4. Record the colour as; 0=none, 1=light yellow, 2=deep yellow, 3=brown.

QUES

What factors influence the degree of maillard browning?