GWD4_HO_Notes

advertisement

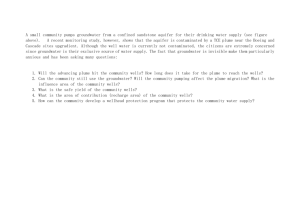

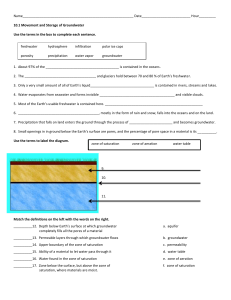

Session 3: Developing groundwater source(s) Wells and Bores Wells are holes in the ground that intersect an aquifer and allow groundwater to be extracted. Wells may be any depth depending on the geology and type of aquifer encountered. The depth of the well and the available yield depend on the aquifer Most wells are constructed by making a hole in the ground, by hand or with a machine, and installing a lining that supports the walls of the hole. The well is to provide access to the groundwater which is recovered by pump or by hand bailing. Shallow well and recovery vessel, Lao PDR - S House / ACF Temporary headworks for groundwater bore with submersible pump, generator discharge to bladders for temporary supply, Gouroukun, eastern Chad. Groundwater Drilling and Development _Session GWD 4 Page 1 Small diameter well with surface pump, Nias, Indonesia There is some difference of opinion on the use of the terms Bore and Well even amongst hydrogeologists and groundwater engineers. Generally in this course we make the distinction between a bore or a dug hole as being the drilled hole, while a well is the structure in the bore or the dug hole that actually provides access to the water. Participants should note that this distinction is not universal. In any country there may be particular terms that the participants are familiar with and prefer / need to use. Types of wells We have already seen that the local geology impacts the distribution of the aquifers, and the depth and ease of access to the groundwater. There are two general groupings of well types, based on the type of aquifer the well is in: Shallow, water table wells that are completed in the uppermost saturated aquifer at that location (the unconfined aquifer). These wells may be very shallow or tens of metres deep. Deep or confined wells tend to be sunk into an aquifer that is confined between two aquitards or aquicludes and the hydraulic head (measured by the water level in the well) is higher than the top of the aquifer. Such wells are said to be artesian, and if the hydraulic head is higher than the ground surface it is a "flowing" artesian well. Groundwater Drilling and Development _Session GWD 4 Page 2 The type of well is therefore related to the ground conditions and the tools and skills required to construct them. Wells are installed in the ground by hand (to generally shallow depths) or by using a variety of drilling techniques to drill a bore and construct a well in the borehole. Drilling techniques are typically simple hand drilling methods (such as augering and jetting), or machine drilling (rotary, percussion, down the hole hammer). Drilled wells can reach much greater depths and encounter a wider range of rock types than hand installed wells. NOTE: not all wells produce adequate water yields – some wells are dry Q: What could be the reason for this? A: the wells encounter low permeability materials eg Clays, hard rocks with no cracks intersected Groundwater Drilling and Development _Session GWD 4 Page 3 Well Siting Before excavation of bore or hand dug excavation, information about the geology, water table depth, seasonal fluctuations, recharge area and rate must be found. Develop a hydrogeological model of the site, using available information. This will determine the method for constructing the well, preferred location as well as skills and equipment needed Establishing groundwater wells Hand-made wells Wells can be dug by hand using two techniques – hand augering a small diameter hole and installing a narrow casing (to make a narrow diameter well sometimes called a tube well) and hand digging larger diameter holes. Installation of wells by hand can be effective in the first phase of an emergency as they may be implemented quickly and at low cost. In contrast to drilled bores, the necessary tools are readily mobilised, and can often rely on locally available skills. For installation of hand-made wells, the ground must be soft enough to dig either by hand or with a hand auger. In difficult ground, the construction of a hand dug well may be delayed and thus may not be a satisfactory option in an emergency. For hand-made wells the water table must be shallow. This limits the yield of a well as the well is likely to only touch the surface of the unconfined aquifer. Hand Auger Holes In some situations it is possible to install by hand auger in relatively soft ground. There is a range of hand augers suitable for different types of soil. As the hand auger hole becomes deeper, the diameter of the auger is reduced because smaller diameter augers are easier to turn in deeper holes. Generally it is difficult to continue hand augering a hole below the water table as the bore can collapse. Hand augers can be used to drill bores to limited depths (up to around 20m in suitable soils but usually much less). If the depth is greater than around 15m, and no water has been encountered, it is probably worth abandoning the site and looking somewhere new VIEW Video of hand augering: http://www.youtube.com/watch?v=8aKOFCKAITE&feature=related In sandy soil in particular (such as in a river bed) it may be possible to install a slotted casing in the hand auger hole which allows access to the groundwater stored in the sand. This has been effectively done in Chad in Wadi (Dry River) beds by constructing shallow bores powered by suction pumps yielding up to 1L/sec. Groundwater Drilling and Development _Session GWD 4 Page 4 The example shows the auger set with a cutting bit on the bottom of the auger that passes through temporary casing (yellow), slotted polyethylene pipe is inserted through the centre of the auger at the maximum depth that can be reached, and the final discharge pipe connected to the casing and pump. Groundwater Drilling and Development _Session GWD 4 Page 5 In less permeable materials, the hand auger holes are less likely to be effective as pumping wells because they are unlikely to provide adequate pump yields, however they provide information on soil properties that may suggest siting of hand dug wells. Hand dug wells Wells can be constructed by hand using pick and shovel. In some cases they are dug simply by excavating the material by hand and using bucket and rope to remove the waste soil and no lining is used. In many operations, the wells are lined and may even be installed below the water table where there are adequate lining and availability of dewatering and sludge pumps. From Oxfam Manual on Hand Dug Well Equipment Groundwater Drilling and Development _Session GWD 4 Page 6 There are limitations on the construction of hand dug wells. As with hand augers, the ground must be soft enough to dig, and thus it can be dangerous to work in a hole. Hand dug wells are often lined with concrete casing or even stones to prevent them from collapsing. In difficult ground, the construction of a hand dug well may be delayed and thus may not be a satisfactory option in an emergency The water table must be shallow, and they cannot be dug much deeper than the water table because of the chance of collapse and filling with water. This limits the yield of a well as the complete aquifer cannot be encountered. However, with use of suitable well lining kits, which can be as simple as perforated corrugated iron as a temporary measure, or perforated and nonperforated concrete casing, and dewatering pumps to cope with inflowing groundwater, the depth may be increased. Completion of Hand dug wells ranges from simple holes that are readily accessed and offer little protection from contamination to those that are covered with sanitary surrounds and installed with a hand pump. Reference materials Details of construction of hand dug wells are well described in the Oxfam Technical instruction manual: “Hand dug well Equipment”. Further details are available in “Hand dug wells and their Groundwater Drilling and Development _Session GWD 4 Page 7 construction” S.B Watt and W.E Wood, IT Publications, 1995. These references provide details of the methods to install and construct liners. A good summary of low cost, rapid methods of drilling and well installation is http://www.wateraid.org/uk/what_we_do/sustainable_technologies/technology_notes/243.asp Bore Drilling The technique to drill a bore that will be made into a well, the equipment used and the depth to be drilled depends largely on the type of soils or rocks that are likely to be encountered, and on the groundwater depth and pressure in the aquifer . Hand operated drilling However there are a number of simple hand operated techniques in addition to hand augering that are commonly used to install narrow diameter (< 100mm diam) bores that are subsequently constructed as tube wells (narrow diameter production wells). These are shown in the following videos. VIEW YOUTUBE FILES Shallow percussion: http://www.youtube.com/watch?v=N3CUnUrMo6s&feature=related Shallow percussion in Senegal: http://www.youtube.com/watch?v=VWaTBNt0n9o&feature=related Deep well in Dhaka slums 200ft (>60m) deep: http://www.youtube.com/watch?v=nIvgg6QTKj4 Jetting Techniques Jetting techniques use water pressure forced down a drill pipe and through a nozzle to penetrate the soil and advance the bore to the required depth. The pressure disaggregates the soil and it is forced up the hole to the surface as a slurry. In tight soils that do not collapse, once the desired depth is reached, the hole can be inserted with casing and a screen. Groundwater Drilling and Development _Session GWD 4 Page 8 Source: Water for the World, Constructed Jetted Wells, Technical Note No RWS 2.C.3 Set up of jetting operation of 20m deep well, near Vermasse, Timor Leste Water surging from a jetted well, nearVermasse, Timor Leste Groundwater Drilling and Development _Session GWD 4 Page 9 A jetting operation in Ethiopia: http://www.youtube.com/watch?v=cHu5yFQn660&feature=related Jetting in Indonesia: http://www.youtube.com/watch?v=D-pmZe2aQuY&feature=related A backyard well in USA : http://www.youtube.com/watch?v=FbGUV7GQpMM&feature=fvw Some of these jetting techniques also allow the driving of casing simultaneous with the drilling process, with the nozzle and the drill pipe acting as the conduit for groundwater up the bore, eliminating the need to insert separate casing into the bore. This is a rapid technique although it requires sacrificial drilling rods and nozzles to be successful. It is more effective in permeable soil environments. A detailed description of the set up of a jetted well system is shown at: http://www.watersanitationhygiene.org/References/EH_KEY_REFERENCES/WATER/Drilling/Hand%2 0Drilled%20Boreholes/Constructing%20Jetted%20Wells%20(USAID).pdf Drilling techniques The previously described hand operated techniques are likely to be undertaken in the very first phase of an emergency where rapid action is needed and equipment can be mobilised quickly and in many cases produced from available materials. They are also relatively low cost although there are varying degrees of labour requirement. Often there is local expertise to undertake the work or training can be relatively quick. There are more sophisticated drilling techniques that are likely to provide a greater range of depth to aquifer and / or cope with more consolidated rock types. The equipment to undertake this drilling is usually mounted on trucks, and is expensive. Drilling rigs also require highly skilled crews, both of which would most likely require mobilisation of the equipment and the operating crew into the emergency area. In addition, drilling rigs present in the country where the groundwater is being investigated are often privately owned or perhaps owned by Government and both permits and contracts are likely to be needed. Equipment sourced internationally would require an even greater lead time. Different types of rigs are suitable for different rock types and groundwater conditions. These are generally either percussion rigs and rotary rigs depending on the rig technique. Percussion Rigs: Percussion rigs use a technique that crushes the rock under the weight of a tool dropped down the hole on a length of cable The technique is often used in unconsolidated and soft formations, generally less than 100m wells but can be greater. Percussion drilling is relatively slow as cable tool drilling requires the drilling action to be stopped so that the bore hole can be bailed or emptied of drilled cuttings. However it is a very successful method in enabling bores to be constructed. VIDEO: of cable tool operation :http://www.youtube.com/watch?v=vEIyPhQdqrw&feature=related Groundwater Drilling and Development _Session GWD 4 Page 10 Application in the Philippines: http://www.youtube.com/watch?v=mXAS0UUc7Ek&feature=related Rotary rigs: There is a range of rotary rigs but the common feature is that they have drill bits attached to the end of a segmented string of steel drilling rods and as the drilling rods rotate, the bit grinds through the soil and rock to advance the hole downward. Air and/or water is used as a circulation fluid to lubricate the hole, cool drill bits and provide a medium to move cuttings from the bottom the hole to the surface. In a form of rotary drilling termed mud rotary the drilling fluid is mud mixed on-site to density that is sufficient to prevent the groundwater pressure in th aquifer to collapse the side walls of the bore hole. Typically, boreholes drilled into solid rock are not cased until after the drilling process is completed, regardless of the machinery used. The Video shows a mud rotary rig in operation – note the size of the rig, rotation of the drill string and the mud emanating from the hole. VIDEO of a mud rotary rig http://www.youtube.com/watch?v=ZVlzCs3686s Some rotary rigs require no mud and are powered by air to activate the drilling bit. This is shown on the following video: http://www.youtube.com/watch?v=Qa0SL6h3pF8&feature=related Photo of Rotary rig, with drill bit and drilling rods visible – white tubing is PVC casing to be installed in the bore. Photo courtesy GHD Pty Ltd Groundwater Drilling and Development _Session GWD 4 Page 11 Drilling is a noisy, dangerous activity and is a highly skilled activity. During drilling the strata that are intersected are examined by geologist to identify the strata that may be the best aquifer and therefore have the highest yield Determining how to construct the well The highest flow of groundwater from an aquifer into a well is through the most permeable zones. This is again influenced by the geology – in this case the vertical variation that can be determined from information on the geological profile collected during drilling. In some case, detailed studies include drilling cores of rock and having it examined by a geologist. In the case below the basalt rock contained the large number of cracks was identified as the most productive aquifer. It is expensive to “cut cores” so usually the geologist will have to look at rock cuttings to identify potential aquifer zones. There are also geophysical tools that can help yet these require specialised equipment and potentially add another delay in mobilisation and well installation Core of basalt from Rotary rig used to identify aquifer intervals (the zone with the largest number of fractures Spread out “cuttings” from drilled bore representing 3m sample intervals – the change in colour is an indication of change in material and assists in identifying the main aquifer Groundwater Drilling and Development _Session GWD 4 Page 12 Well Construction Methods (From Engineering in Emergencies) Method, well diameter and depth* Suitable formations for drilling and digging Unsuitable formations for drilling or digging Advantages Disadvantages Dug wells Diameter: > 1m Depth: < 30 m Clays, sands, gravels, small bounders Hard and soft rock Where depth to water > 30 m Low capital costs Quick mobilization Uses local skills Possible to maintain at village level Dangerous – large diameter hole Limited depth Time to dig and line Hand-drilled wells Diameter: 100 -200 mm Depth: < 30 m Clays, sands, fine gravels, Rock formations, cobbles, boulders Low capital cost Portable equipment Limited depth Limited range of suitable formations Jetted wells Diameter: 50 - 200 mm Depth: < 40 m Clays, sands, fine gravels, Rock formations, cobbles, boulders Very quick and easy in right conditions Low capital cost Portable Limited depth Limited range of suitable formations Water required to drill Percussion (cable too) Diameter: 100– 1100 mm Depth up to 500 m Soft rock, sands, gravels, silts and clays Running sand, flint (or chert), hard rock, boulders Reasonable capital and running costs. Simple maintenance Good sampling during drilling. Upto 30 m/day in soft rock Experienced drilled needed. Temporary castings needed in loose formations. Slow in hard rock may be 2 m/day Direct circulation rotary drilling. Diameter: 400-750 mm Depth: > 1000 m Soft rock, metamorphic and igneous rock Running sands, fractured rock, some shales, boulders Little drill casing needed 100-150 m/day in soft ground 10-20 m/day in rock High capital and operating costs. High demand on skill, maintenance and spares. Drilling fluid can damage aquifer Reverse circulation rotary drilling Diameter: 400-1750 mm Depth: upto 350 m Unconsolidated sediments, soft rock Hard rock, boulders 80-100 m/day in unconsolidated sediments. Drill casing not needed Heavy drilling equipment. Large quantity of water needed for drilling Down-the-hole hammer Diameter: 100-450 mm Depth: up to 400 m Hard rock Sands, gravels, clays, soft rock, loose boulders Up to 5 m/hr in hard rock Good sampling during drilling High skill, capital and maintenance From: Red R, Engineering in Emergencies, Davis and Lambert Construction of Groundwater Wells Having drilled or excavated the hole it must be lined and cleaned/cleared to provide an effective source of potable water. The construction of bores of any depth requires attention to the position of the most permeable zones in the geological profile. Groundwater Drilling and Development _Session GWD 4 Page 13 The well is a hole (generally vertical) that has been cut through the soil. Unless the bore has been drilled into very strong rock, in most cases, the walls of the well will need support. In hand dug wells this is the lining we spoke of earlier. In drilled bores it is known as casing. Most drilled Boreholes need Linings to make them stable and suitable for ‘development’ into well which can be sterilised and from which water can be extracted in as efficient a manner as possible and into which pumps can be installed. Casing of Wells Drilled wells are usually cased with a factory-made pipe. Lengths of pipe are connected and lowered down the hole. Installation of plastic casing in rotary drilled bore, Photo Courtesy GHD Pty Ltd The casing diameter is governed by the diameter of the drilled well and can be 300mm or more in a large diameter well. Typical materials are typically steel or plastic/PVC. Steel casing is very strong, although susceptible to corrosion. It is often used as surface casing and produces a straighter bore. Poly Vinyl Chloride (PVC) is used extensively for shallow low yielding bores and can be used where the water may be corrosive to steel. When exposed to direct sunlight for long periods, PVC will become brittle. Exposed surface casing should be protected. Plastics such as Polyethylene (PE) and Acrylonitrile Butadiene Styrene (ABS) casing are easy to handle, less brittle and low weight. They are less susceptible to corrosion than steel and more stable when stored in the open than PVC. PVC or plastic is typically welded and then lowered into the drilled well, vertically stacked with their ends nested and either glued or splined together. Opening the aquifer to the Well At the aquifer depth, there needs to be a pathway for the water in the aquifer to seep into the well for removal by a pump or by bailing it by hand. If the well is drilled into competent rock and there is Groundwater Drilling and Development _Session GWD 4 Page 14 no casing, this connection may be by direct seepage from the rock – the well is referred to as an “open hole” If the well has casing, there needs to be a perforation of the casing or specifically designed screen to enable the connection between the aquifer and the well. It is customary to place gravel around the screen (this is known as gravel or filter pack) so that fine material from the aquifer formation can be caught in the gravel pack and clean water can enter the well. In some bores no filter pack is necessary as sand and gravel formations can collapse against the screen naturally. Screens can be made of a variety of materials such as stainless steel, PVC or steel. Diameter of screens depend o n the diameter of the bore, and the size of the opening depends on the aquifer. Typical slotted PVC screen for production well Lengths of 200mm PVC casing and stainless steel screen for installation in production well Groundwater Drilling and Development _Session GWD 4 Page 15 A typical bore construction for groundwater development in Zambia is shown below, with the screens coinciding with the most permeable (potentially highest yielding) zones comprising mainly gravel. from Nkhoma and Baumle, (2007) As well as placing the casing and screen at the correct depth, the annulus between the wall of the bore and the casing needs to be filled. As noted above the interval opposite the screen is often comprised of a gravel pack. Typically the gravel pack is capped by a seal of low permeability material such as bentonite and the remainder of the annulus from the top of the bentonite seal to the surface filled with groutor cement. The bentonite seal and the grout provides protection of the wells from leakage from the surface down the side of the well. In addition, wells are typically capped at the surface with an engineered well cap. The construction of groundwater wells requires appreciation of the complexity of the design. There is often little room for error in the position of the screen, the dimensions of the pipe work in the well that will achieve the most efficient flow of water from the aquifer, or the incorrect materials that may result in corrosion or degradation of the well infrastructure. Groundwater Drilling and Development _Session GWD 4 Page 16 Furthermore, there needs to be an understanding of the different aquifer layers encountered in a bore, different aquifer pressures and the need to prevent leakage down the well from the surface with resulting potential for contamination. Typical well construction of a groundwater production bore Groundwater Drilling and Development _Session GWD 4 Page 17 Details of well constructions for a number of different aquifer types. Described in detail in Davis and Lambert Well constructed in unstable hard rock Well constructed in stable hard rock Design for a gravel packed well in an alluvial aquifer Well in naturally developed well in alluvial sediments Groundwater Drilling and Development _Session GWD 4 Page 18 Summary of Well types Modified From Wikepedia Note: A: dug well in shallow water table aquifer B: cased well screened in gravel aquifer (black) – note water level above top of aquifer C: well cased in lower strength clay, sand and gravel – open hole in the fractured rock D: dry well – no fractures intersected in rock – hole not established as a well Some key references on drilling: Descriptions of suitable drilling techniques for humanitarian purposes from the Merlin Website; http://www.watersanitationhygiene.org/References/Technical%20Resources%20%20Wells.htm Engineering in Emergencies, Davis and Lambert, RedR UK, 198 Driscoll, F.G (Ed), 1986. Groundwater and Wells, 2nd Edition, Johnson Filtration Systems Handbook of Ground Water Development, Roscoe Moss Company, John Wiley and Sons, 1989. Groundwater Drilling and Development _Session GWD 4 Page 19 Minimum Construction Requirements for Water Bores in Australia, Edition 2, ARMCANZ, 2003 Good descriptions are also shown on the following site http://www1.agric.gov.ab.ca/$department/deptdocs.nsf/all/wwg408 Groundwater Drilling and Development _Session GWD 4 Page 20 Well Development Well development is an essential part of well construction. After the well screen, well casing, and gravel pack have been installed, development is undertaken by surging or jetting water or air in and out of the well screen to clean out residual drilling fluid. It also allows the gravel pack around the well screen to settle. Development may take several days. Poorly designed and underdeveloped wells do not allow groundwater to easily pass through the screen into the well. This leads to excessive water level drawdown and poor well efficiency. Proper well design and good well development will result in lower pumping costs, a longer pump life, and fewer biological problems such as iron-bacteria and slime build-up. Poorly designed and underdeveloped wells are subject to more frequent pump failures because sand and fines enter the well and cause significantly more wear and tear on pump turbines. Note that well efficiency should not be confused with pump efficiency. The latter is related to selection of a properly sized pump, given the site-specific pump lift requirements and the desired pumping rate. Groundwater Pumping effects The volume of groundwater that can be pumped from a well is not limitless. Therefore it is important to understand the effect of pumping on an aquifer. Pumping from any groundwater well results in a decline in groundwater levels surrounding the bore. The decline in water level is referred to as the “drawdown cone” or “cone of depression” around the pumping bore. The drawdown decreases with distance from the bore and expands in size whilst pumping occurs until the pumping rate matches the inflow to the bore and drawdown ceases (ie when steady-state conditions are reached). The amount of drawdown in a properly designed well is related to the aquifer properties. However, if the well is not designed properly, the flow of groundwater into the well may be affected, and the drawdown may be greater than theoretically predicted. The details of this and resolving such problems require a thorough understanding of well hydraulics beyond the scope of this course. However, project managers need to be prepared to call upon specialist expertise to resolve these issues. Groundwater Drilling and Development _Session GWD 4 Page 21 What happens when a bore is pumped? Available Drawdown Drawdown Radius of Influence Static or pre-pum ping w ater level Cone of depression Pum p Aquifer The distance the drawdown cone extends depends primarily on the nature of the aquifer, the pumping rate and pumping duration. If the aquifer system consists of fractured rock, or is of odd shape, the shape and form of the cone may vary or extend further in certain preferential directions. If the drawdown cone extends such a distance from the pumping or production bore that it intersects other bores or in the case of unconfined aquifers, environmental features (e.g. creeks, rivers, coastline), it is said to have interfered with these features (i.e. interference has been manifested). The effect of interference is shown in the figure below, which schematically depicts a pumping bore, three neighbouring bores and a creek. Interference can become a significant issue because it can affect the amount of water pumped from a neighbouring bore, and can reduce environmental water flows in unconfined aquifers. The significance of the bore interference will depend on many factors, the most important being the impact on the available drawdown in the neighbouring bore. The available drawdown in a bore is defined as the distance between the standing water level and the pump intake. Interference reduces the size of the available drawdown in a bore. Groundwater Drilling and Development _Session GWD 4 Page 22 Bore Interference Neighbouring Bores Drawdown Drawdown Available Drawdown Drawdown Radius of Influence Static or pre-pum ping w ater level Drawdown Creek Cone of depression Aquifer Pum p If two bores are being pumped at the same time, the drawdown from one well bore will be superimposed on the drawdown from the other . Test pumping of bores Once the well is completed and developed, it is a good practice to conduct an aquifer test (or pumping test). The principles of the pumping test are based on the understanding of what happens when a well is pumped. A pumping test is a practicable and effective means of obtaining hydraulic characteristics of saturated geological formations and to determine the efficiency and capacity of the well. In terms of production bores, a pumping test is used to determine the performance of a bore, that is, the relationship between drawdown and flow. Knowing this relationship, a satisfactory pumping rate for a specified drawdown can be determined. The information about the pumping rate and resulting pumping water levels is also critical if you are to order a properly sized pump. Types of Pumping tests A step drawdown test is the preferred method of accurately determining the drawdown for any assumed pumping rate. The step drawdown test involves pumping the bore at typically three progressively higher constant rates for a period of time and monitoring the water level drawdown in the bore. Generally each pumping rate is held until groundwater levels begin to stabilise. The results can be used to identify a sustainable pumping rate for the bore over a set period, and a suitable pump set-up for the bore. The main disadvantage of a step test is that it is a short-term test, typically undertaken over 3-6 hours. The results therefore need to be extrapolated to estimate the long-term yield of the bore over months and years. The accuracy of the extrapolation of the results can be affected by the intersection of aquifer boundary conditions during long term pumping. To enable a better understanding of the impacts on yield with the intersection of boundary conditions, and to assess the performance of a bore over longer pumping periods and thereby provide suitable input for modelling proposed pumping scenarios, another type of test, a constant rate test is used. Groundwater Drilling and Development _Session GWD 4 Page 23 This test involves pumping from a bore at a constant rate and monitoring the water level drawdown generally both in the pump bore and in nearby observation bores. Typically constant rate tests are undertaken over longer periods of several days to weeks. The objective of a pumping test is to determined estimates of the aquifer hydraulic parameters transmissivity and storativity which are used in determining sustainable pumping rates. Pumping Test Set Up Ideally a pumping test involves monitoring the pumping rate from a well and monitoring at frequent intervals the water decline in water levels in observation bores located at distances from the pumping well. This to help determine the properties of the aquifer and the long term yield of a bore, but also the impact on surrounding wells or water ways if they are in the vicinity. An example of a pumping test taking into account the distribution of surrounding pumping wells, observation bores and wells that may be affected is shown in the figure. The test showed that the well could be pumped without seriously affecting the adjacent wells or the nearby water way. The duration pumping for water supply would need to be managed to eliminate excessive drawdown in the well or having an effect on the water level i surrounding wells. Layout of wells around a proposed pumping well (red) Water levels were measured in aa number of wells during the pumping test Specific capacity test A specific capacity test consists of measuring the ‘drawdown’ (the drop in water level from before pumping starts) at a given pumped discharge rate and establishing the ratio of drawdown to discharge. Blocked screens or perforations or other damager will decrease specific capacity so if a specific capacity test is carried out once a year it is possible to monitor the bore’s performance; to check if the bore is deteriorating. The specific capacity should be established early in the life of the bore. The pump-test prior to installing the production pump will be a reference against which future tests can be compared. Groundwater Drilling and Development _Session GWD 4 Page 24 Relevance of the Bore Drilling, Construction and Testing to an Emergency If available drilling resources are readily available, well drilling is an opportunity to provide more secure groundwater sources in the vicinity. However while there may be time constraints in the first phase of an emergency of setting up and undertaking well drilling other than perhaps shallow hand installed or jetted wells, there may be existing wells in an area that may provide a source for the emergency. Understanding the details of such wells is essential in planning for the use of the water source at the outset. The ability to undertake and assessment of the well condition and to undertake well redevelopment may be valuable in that existing bores in an area that may be a potential water source for an emergency in the short term, particularly if extra demand is to be placed on existing wells. In addition, the potential investigation and development of available groundwater resources is also a basic part of water resource longer term planning for later stages of the emergency. Groundwater Drilling and Development _Session GWD 4 Page 25 Springs Springs occur when groundwater within an aquifer naturally flows out at the ground surface. A key factor in the development of springs is knowing the flow rate, the variation of flow with time and the catchment area. It ios also useful to understand current usage and potential risks from taking spring water. Spring water may be harvested in a number of ways. In very large springs with high discharge volumes, natural pools may exist, and infrastructure to collect from these is relatively extensive, has relatively high capital cost and will take time for suitable design and construction. For smaller springs, the spring development is commonly based around construction of a protective box that enables collection of water either for collection by hand or by discharge to a tap for collection at the well or via a discharge pipe for distribution downhill. Enhancement of the flow by excavation is often required and gravel and sand is placed in the excavation to act as a filter. In addition, filters are often placed on the top of discharge pipes . Where there is sloping ground and drainage, where possible excess surface runoff should be prevented from entering the spring collection site, by constructing a ditch on the uphill side Further information on developing a protecting spring sources is available in http://www.oxfam.org.uk/resources/downloads/emerg_manuals/draft_oxfam_tech_brief_springpr otect.pdf as well as the references therein. A good brief summary is presented in Davis and Lambert (Engineering in Emergencies) From Oxfam technical brief Groundwater Drilling and Development _Session GWD 4 Page 26 From Oxfam technical brief Spring being protected, Zaire - S House / WEDC Groundwater Drilling and Development _Session GWD 4 Page 27 Spring box with discharge pipe leading down hill, Nias, Indonesia Groundwater Drilling and Development _Session GWD 4 Page 28