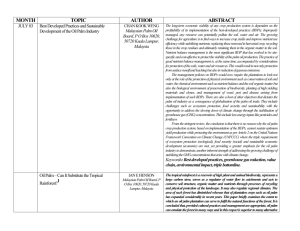

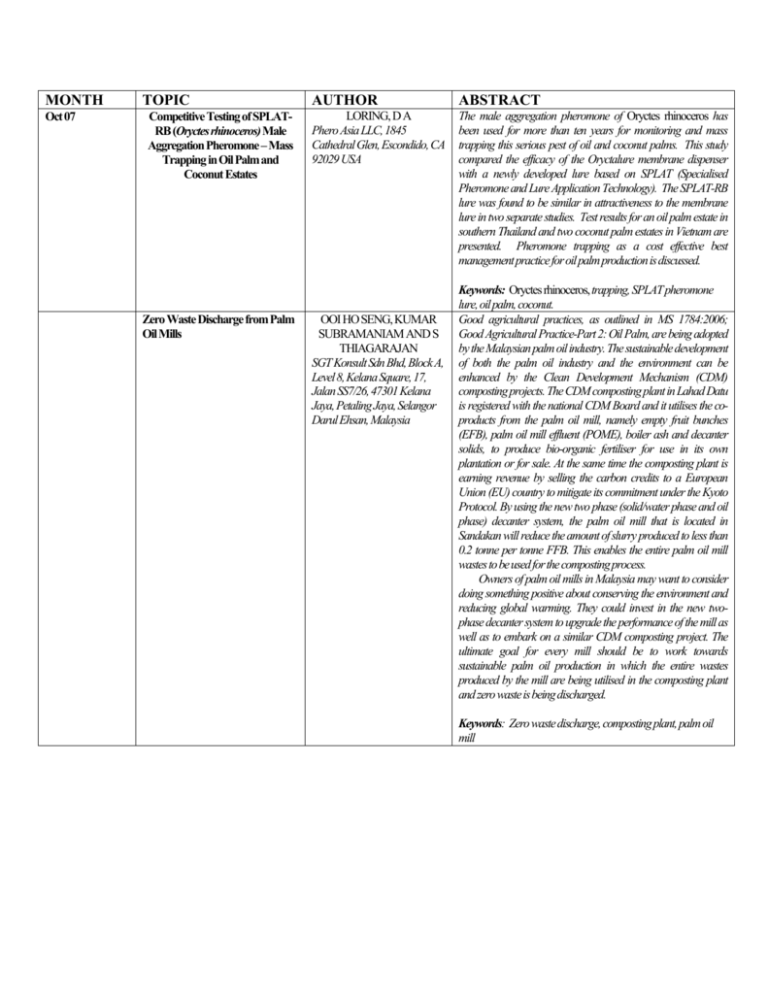

MONTH

advertisement

MONTH Oct 07 TOPIC Competitive Testing of SPLATRB (Oryctes rhinoceros) Male Aggregation Pheromone – Mass Trapping in Oil Palm and Coconut Estates Zero Waste Discharge from Palm Oil Mills AUTHOR ABSTRACT LORING, D A Phero Asia LLC, 1845 Cathedral Glen, Escondido, CA 92029 USA The male aggregation pheromone of Oryctes rhinoceros has been used for more than ten years for monitoring and mass trapping this serious pest of oil and coconut palms. This study compared the efficacy of the Oryctalure membrane dispenser with a newly developed lure based on SPLAT (Specialised Pheromone and Lure Application Technology). The SPLAT-RB lure was found to be similar in attractiveness to the membrane lure in two separate studies. Test results for an oil palm estate in southern Thailand and two coconut palm estates in Vietnam are presented. Pheromone trapping as a cost effective best management practice for oil palm production is discussed. OOI HO SENG, KUMAR SUBRAMANIAM AND S THIAGARAJAN SGT Konsult Sdn Bhd, Block A, Level 8, Kelana Square, 17, Jalan SS7/26, 47301 Kelana Jaya, Petaling Jaya, Selangor Darul Ehsan, Malaysia Keywords: Oryctes rhinoceros, trapping, SPLAT pheromone lure, oil palm, coconut. Good agricultural practices, as outlined in MS 1784:2006; Good Agricultural Practice-Part 2: Oil Palm, are being adopted by the Malaysian palm oil industry. The sustainable development of both the palm oil industry and the environment can be enhanced by the Clean Development Mechanism (CDM) composting projects. The CDM composting plant in Lahad Datu is registered with the national CDM Board and it utilises the coproducts from the palm oil mill, namely empty fruit bunches (EFB), palm oil mill effluent (POME), boiler ash and decanter solids, to produce bio-organic fertiliser for use in its own plantation or for sale. At the same time the composting plant is earning revenue by selling the carbon credits to a European Union (EU) country to mitigate its commitment under the Kyoto Protocol. By using the new two phase (solid/water phase and oil phase) decanter system, the palm oil mill that is located in Sandakan will reduce the amount of slurry produced to less than 0.2 tonne per tonne FFB. This enables the entire palm oil mill wastes to be used for the composting process. Owners of palm oil mills in Malaysia may want to consider doing something positive about conserving the environment and reducing global warming. They could invest in the new twophase decanter system to upgrade the performance of the mill as well as to embark on a similar CDM composting project. The ultimate goal for every mill should be to work towards sustainable palm oil production in which the entire wastes produced by the mill are being utilised in the composting plant and zero waste is being discharged. Keywords: Zero waste discharge, composting plant, palm oil mill