Pinion Canyon Wash Bay Structural Narrative

advertisement

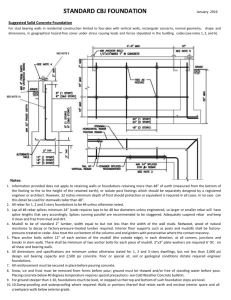

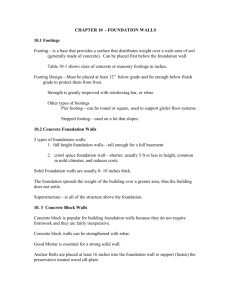

July 2012 Preliminary Structural Schematic Design Narrative for: Pinion Canyon Wash Bay, Fort Carson, CO Solicitation No: W9128F-12-R-0038. The structural scope of service for the referenced project are to include the design of a concrete sedimentation tank, supply basin maintenance ramp, hose towers, slabs on grades, concrete islands, trench drains, and drainage channels. The respective elements will be designed per the codes/loads as listed in Section 01 83 00, sub section 1.4. It is anticipated that all concrete used on the project shall be 4,500 psi with an entrained air content of 4-7% and a maximum w/c ratio of 0.45. Note: Additional team clarification is needed for the construction of the sedimentation tank/basin. The below narrative is assuming the tank is a rectangular, formed concrete box with approximate plan dimensions of 8’x80’ within an “overflow” basin. This assumption is based on section 01 83 00, sub section 1.3.2 which states that the walls are to be designed as cantilevered which tends to imply a vertical construction scenario. Should the entire base and overflow pond be concrete, option 2 below would be most likely with a 12” slab with a minimum reinforcing of #3 at 10”o.c. each way, top and bottom and 8” walls with #4 at 12” o.c. each way, minimum. Additional discussion will be required. Sedimentation Tank The sedimentation influent tank will be constructed of concrete with water tight joints (i.e. water stop) and shrinkage resistance mix designs. There will also be ramped access for cleaning. The walls of the basin will be designed as cantilevered walls and will include considerations for fluid, earth, seismic, and maintenance loads. (Additional information will be required with regards to proposed equipment used for maintenance loading.) Pending additional design requirements, it is anticipated that both the walls and slab will consist of 12” thick concrete with two layers of reinforcing. Due to expansive soil conditions, special foundation considerations must be made. Based on the available limited geotechnical information, there are two proposed methods for addressing the expansive soils. 1. Drilled Piers: The walls will be designed as integrated grade beams that will span between 18” diameter x 26’ long (minimum) drilled straight shaft piers. It is expected that the top of the piers/bottom of walls be at least 36” below finish grade due to frost consideration. It is anticipated that 4 piers will be required per side of the tank with a total of 8 piers. A 6” void space will need to be included beneath the structure to allow for the expansion of native soils. (We will be pricing footings in lieu of piers) 2. Over Excavation: Pending additional site investigations, over excavation and the installation of compacted structural fill may be a viable option in conjunction with a mat footing configuration. Based on the limited soils information, it is assumed that a minimum of 3’ of over excavation/structural fill will be required. It is also recommended that a sub-base drainage system be used to minimize the risk for future soil expansion due to water infiltration. Page 2 Note: Additional coordination is needed for the interaction of the pond liner and tank foundations especially if the sedimentation tank is an independent structure within the basin requiring support by piers with an expansion void. Supply Basin Maintenance Ramp It is assumed that the primary construction of the supply basin will consist of a lined soil pond with a concrete access ramp for maintenance. It is anticipated that the ramp will have vertical curbs/walls which would be 12” thick with two layers of reinforcing and extend a minimum of 36” below grade. Based on the available limited geotechnical information, there are two proposed methods for addressing the anticipated expansive soils. 1. Drilled Piers: The walls/curbs will be designed as integrated grade beams that will span between 18” diameter x 26’ long (minimum) drilled straight shaft piers. It is expected that the top of the piers/bottom of walls be at least 36” below finish grade due to frost consideration. It is anticipated that 2 piers will be required per side of the basin with a total of 4 piers. A 6” void space will need to be included beneath the structure to allow for the expansion of native soils. 2. Over Excavation: Pending additional site investigations, over excavation and the installation of compacted structural fill may be a viable option. Based on the limited soils information, it is assumed that a minimum of 3’ of over excavation/structural will be required. It is also recommended that a sub-base drainage system be used to minimize the risk of future soil expansion due to water infiltration. Note: Additional coordination is needed for the interaction of the pond liner and tank foundations especially if the ramp is an independent structure within the basin requiring support by piers with an expansion void. Hose Towers: The hose towers will be custom designed as cantilever steel structures capable of supporting the required hose system and associated loads. Such loads would include water thrust, wind, seismic, and anticipated operation loads associated with movement. The tower will be supported on an isolated footing separate from the surrounding slab/island. Based on the available soils information it is anticipated that the tower will need to be supported with an 18” diameter by 26’ long (minimum) drilled straight shaft pier. Slab on Grade: With the anticipated vehicle loading, it is proposed that all slabs on grade for this project be 12” thick with a minimum #3 bars at 10” o.c. each way top and bottom. All edges of the slabs are to have a turned down edge a minimum of 3’-0” below finished grade. This configuration will help to minimize the horizontal migration of surface water under the slab as well as provide the recommended frost protection. Based on the available limited soils information, it is assumed that the slab will need to be constructed on 3’ of structural fill. It is recommended that the sub base drainage system be used to minimize the risk of future soil expansion due to water infiltration. If additional over-excavation procedures are not allowed per additional geotechnical information, a post and beam system with 18” diameter by 26’ long straight shaft piers may be required. Concrete Islands: It is anticipated that the concrete islands will be construction in a similar manner as those required for slab on grade with additional reinforcing as required. Page 3 Trench Drains/Drainage Channels: It is anticipated that the drains/channels will be constructed with 8” thick concrete walls and a 12” thick bottom. For conditions with adjacent slabs, the slab should be run over the top of the trench walls in a capping arrangement. Water stop should be used at all construction joints. Sub-grade support/preparation is expected to be similar to those described for slab on grade. For covered trench locations, it is anticipated that the edge of the slab be notched and reinforced with an appropriate bearing angle (vertical leg up) as required to support the selected trench covers. This approach would be consistent for both a proprietary trench drain or custom designed system.