Simulation of a Human Stomach as a Bioreactor

advertisement

Simulation of a Human Stomach as a Bioreactor

BSE-4126 Comprehensive Design Project

May 13, 2009

Purpose: The purpose of this report is to present the final paper, an updated executive

summary, project design, and conclusion on the bioreactor design.

Team: Proteinnovate

Group Members:

Marianita Avenida

Megha Maheshwari

Jennifer Kim

Kristen Pevarski

Advisors:

Dr. Zhang

Dr. Grisso

Executive Summary: Simulation of a Human Stomach as a Bioreactor

Due to rising costs of pharmaceutical testing and interest in the alternative delivery of

protein drugs, development of a device to test these proteins is essential. The harsh

environment of the stomach hinders the effectiveness of oral protein drugs by breaking

the polypeptides down into peptides. As a result, 98% of the protein is digested in this

process, making the subcutaneous route the most effective option. Injection has less

public appeal and increased chances of infections due to contaminated needles.

Furthermore, a lack of facilities and administrators to distribute these medications add

challenges for patients in developing countries. If pharmaceutical companies could

develop protein medications that could be taken orally, it would eliminate many issues

listed above.

Research and experiments are crucial in developing oral delivery protein drugs.

The bioreactor design by Proteinnovate will help resolve the issues involved with the

subcutaneous route of drug delivery by enabling drug developers to test what percent of

their potential oral protein drug is broken down during digestion. The bioreactor

includes: probes monitoring the pH, temperature, flow rate, and volume level, baffles,

stirrers, a stirrer motor, a cooling jacket, a conical bottom, and many other components.

The proposed design will monitor important parameters such as temperature, pH, flow

rate, agitation, and fluid level. Also, it will control them by changing the flow rate of

cooling water, adding hydrochloric acid, and changing the flow rate of the feed and

product. At the end of the bioreactor cycle, a SDS PAGE will detect the amount of

peptides. When an unprotected protein is inserted in the reactor, it will result in a 98%

digestion of the protein. Potential clients will be able to test their oral protein drug by

inserting it into the feed and measuring the unbroken protein. If clients believe the

amount of unbroken protein is sufficient enough to be taken by patients, they can start

producing them for the public.

The 2 1-liter bioreactors were calculated to cost approximately $100,000. This

figure can be compared to the cost of a previously constructed bioreactor made by British

scientists which was approximately $1 M. While the bioreactor by Proteinnovate has

2

fewer functions than its British counterpart, it is significantly cheaper to construct and

maintain.

Bioreactors that can be used as an artificial organ can be beneficial as shown

below. Animal testing of a chemical can cost from $0.5 M to $1.5 M. By using a

bioreactor, companies can significantly reduce the amount of money spent on testing.

They can aid in changing the way medicine is administered in a more public friendly

way. This will ultimately make medicine more accessible to patients in developing

countries.

3

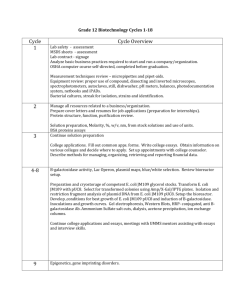

Table of Content: Simulation of a Human Stomach as a Bioreactor

Page

Problem Statement……………………………………………………………..

6

Connection to Contemporary Issues…………………………………………..

6

Scope of Work…………………………………………………………………..

6

Deliverables…………………………………………………………………..

7

Introduction…………………………………………………………………….

7

Design Criteria and Constraints……………………………………………….

8

Literature Review………………………………………………………………

8

Stomach

Physical…………………………………………………………………….

8

Chemical Environment…………………………………………………...

9

Digestion

Digestion Process………………………………………………………….

11

Mechanisms………………………………………………………………..

11

Drug Delivery

Oral…………………………………………………………………………

13

Bioreactors

Overview……..…………………………………………………………….

13

History……………………………………………………………………...

14

Types of Bioreactors….……………………………………………………

15

Safety and Standards………………………………………………………...

17

Preliminary and Alternative Designs

Continuous Bioreactor……………………………………………………….

20

Batch Bioreactor……………………………………………………………...

21

Project Design…………………………………………………………………..

22

Project Evaluation………………………………………………………………

26

Conclusion / Summary…………………………………………………………

28

Work Plan……………………………………………………………………….

28

Project Reflections……………………………………………………………… 30

4

References……………………………………………………………………….. 34

Appendix A

Bioreactor Design……………………………………………………………...

38

Appendix B

Figure 1. Stomach’s Structural Components………………………………... 39

Table 1: pH for Optimum Activity for Each Stomach Enzyme…………….

39

Figure 2: pH Ranges Through the Human Digestive Tract………………...

40

Figure 3. Flowchart of the Digestive Process………………………………...

40

Figure 4. Artificial Stomach…………………………………………………..

41

Figure 5. Continuous Bioreactor Operation Modes (with time)……………

41

Figure 6. Continuous Bioreactor Operation Modes…………………………

41

Figure 7. Turbulent Impellers………………………………………………..

42

Figure 8. A Dual-Membrane Hollow-Fiber Reactor………………………..

42

Figure 9: Serial CSTRs with Step by Step Feed A…………………………

43

Figure 10: PFR with Lateral Feed B…………………………………………. 43

Figure 11: Flow Pattern in a Batch Bioreactor with the Help of Baffles…..

43

Table 2. Decision Matrix………………………………………………………

44

Figure 12: Bioreactor Stages………………………………………………….

44

Figure 13: Gantt Chart Fall Semester………………………………………..

45

Figure 14: Gantt Chart Spring Semester…………………………………….

45

Table 3. Work Plan Fall Semester……………………………………………

46

5

Title: Simulation of a Human Stomach as a Bioreactor

Problem Statement: Due to rising costs involved with pharmaceutical testing, interest

in the development of artificial organs has increased. The team’s focus will be on the

simulation of an artificial stomach as a bioreactor. The design of the artificial stomach

allows for a better understanding of how protein drug molecules are absorbed in the

human stomach.

Connection to Contemporary Issues: Drug testing on animals is a controversial issue.

Animals are often abused and most are euthanized at the end of testing. Also, the test

subjects and the potential drug users have inconsistencies in the components of the

stomach which could lead to unexpected and adverse side effects while the drug is still in

the testing phase. Currently, proteins, such as vaccines, are taken subcutaneously and are

unable to be taken orally without the protein being degraded in the stomach. {More of the

problem than CI}

Scope of Work: The goal is to create a bioreactor design that mimics the stomach’s

processes. The bioreactor design should be able to be used by pharmaceutical companies

for testing of new oral protein drugs, which will increase the drugs’ public appeal,

efficiency in distribution, and reduce the amount of money spent on testing. Some

deliverables will include a flow diagram outlining the drug’s progression through the

digestion process, a bioreactor process flowchart, an economic analysis, sensors to

monitor the bioreactor’s simulated stomach environment, and a final bioreactor design.

The key measurable outcome will be a measurement of the percent of the original protein

broken down during digestion, which will measure the success and subsequent accuracy

of the bioreactor. The deliverables, listed above, will present the client with a bioreactor

that mimics the stomach’s digestive process. Clients will be able to use the bioreactor to

test new oral protein drugs, negating the use for animal and human testing. The client

will also receive a process flowchart of both the human and bioreactor’s digestive system

6

to better help them understand the process and an economic analysis to show why the

bioreactor is economically more feasible than human and animal testing.

Deliverables:

1. Flow diagram of the stomach’s processes

2. Bioreactor functioning as an artificial stomach {How would this be tested?}

3. Sensors to monitor the stomach’s environment (pH, temperature, etc)

4. Mass balance

5. Economic analysis

Introduction: Currently all protein drugs are taken administered subcutaneously.

However, there are issues associated with contaminated needles, the invasiveness of

needles, the difficulty distributing vaccinations in underdeveloped countries, and the

costs associated with the administration of shots. Currently, there is research for new oral

protein drugs to replace the need for drug injection. The current problem is when

proteins go through the digestive system, the majority is denatured and broken down in

the stomach as a result of the stomach’s harsh environment, the physical breakdown by

muscles, and the enzymatic activity targeting proteins. Team Proteinnovate is creating a

bioreactor design to simulate the stomach’s digestion of proteins that can ultimately be

built and tested using oral protein drugs. During digestion, 98% of proteins are broken

down in the stomach. The design challenge is to design a bioreactor that will yield the

same percent of protein breakdown after the simulated digestion. A bioreactor intended

for this purpose does not currently exist; the bioreactor most similar in scope of work to

our design is a bioreactor created by British scientists that mimics the stomach’s digestive

system. While their design successfully simulates the whole digestion process, our

design focuses mainly on protein digestion, making it specifically for the testing of oral

protein drugs.

7

Design Criteria and Constraints: Some of the performance criteria include accuracy,

sensitivity, maintenance, and user-friendliness. Accuracy is defined by how well the

bioreactor follows the stomach’s process, i.e. 98% protein digestion. Our bioreactor

cannot produce too much physical breakdown as opposed to chemical breakdown; which

is shown as the bioreactor’s sensitivity towards the protein drugs. Due to the possibilities

of clients not having background knowledge in bioreactors, our design needs to be easy

to maintain and user-friendly. Other criteria include HCl, enzymes, and sensors to

monitor the pH and temperature of the bioreactor, smooth muscle simulation, and a

separation system. Design constraints include specific pH values during certain stages of

the digestion simulation and a temperature of 37 ºC. A successful design will need to

have a 98% protein digestion so that when clients input an oral protein drug, the stomach

will accurately simulate protein digestion. In order to be cost effective, the design will

need to cost less than $1 M. This number is in comparison to the $1 M that the British

stomach bioreactor cost and the $0.5 M to $1.5 M spent on animal testing per chemical.

Besides the above criteria, as yet, there are no additional design specifications.

Literature Review:

Stomach

Physical Environment

The stomach is only a part of the gastrointestinal system, which breaks down

particles of ingested food. Gastric juice is mainly composed of hydrochloric acid in the

stomach, which results in an environment with a pH that falls between 1 and 3 (Carter,

2004). The average temperature of the human stomach is approximately the same as the

body temperature of 37 ºC (Harvard Medical School, 2008). The stomach and its

different parts are depicted in Appendix B under Figure 1.

Waves of smooth muscle contractions along the stomach wall, known as

peristalsis, break food down into smaller pieces, mix it with the gastric juices produced

within the stomach lining, and move it through the stomach (Bowen, 2002). There are

three major regions in the stomach: fundus, corpus, and antrum. The fundus maintains

relatively constant intraluminal pressures with variable volumes and regulates the

8

emptying of liquids, while the antrum mixes liquids and grinds solids. The antrum is

more important in the emptying of ingested solids than of liquids (Smout et. al., 1980).

Epithelial tissues line the gastrointestinal tract (Louvard et. al., 1986). Spatial

asymmetry creates a concentration of certain cell-receptors at one pole or at the side of a

cell, creating polarization on the surface (Louvard et. al., 1986). This polarization and

differentiation among the different areas on the surface of the cells is associated with a

specific set of enzymes and antigens (Louvard et. al., 1986). The enzymes and domains

of the epithelial cell are then associated with a specific cell function (Louvard et.

al.,1986). Two types of junctions are found within the epithelial cells: the gap junction

and the tight junction (Louvard et al., 1986). Gap junctions are essential in that they

allow the passage of small molecules through them (Louvard et al., 1986). Three

structures are found within the gap junction that helps to create a chemical composition

that assist in preventing the diffusion of various proteins (Louvard et al., 1986). The

other junction associated with the epithelial cells is that of the desmosome which serves

somewhat as a staple that keeps the cells joined (Louvard et al., 1986).

Chemical Environment

The stomach environment is occupied by several different enzymes. Gelatinase is

a gastric enzyme which helps in the digestion of meat. Gastric amylase contributes to the

breakdown of starch, although it is of minor significance. Gastric lipase breaks down

tributyrin (almost exclusively), which is a butter fat enzyme. Rennin digests milk protein

into peptides (SAPN, 2006).

Protein-digesting enzymes break the protein down into peptide fragments within

the stomach. In order to function properly, the contents of the stomach need to be at a pH

around 2 (Champbell, 1987). Most proteins have a fairly stable tertiary structure, making

them difficult to be broken down by proteases (Foltmann, 1986). To prevent pepsin

from digesting the cells that make it, the cells needs to be synthesized into their inactive

pepsinogen form. Low stomach pH and hydrochloric acid levels are required to convert

pepsinogen into pepsin. Pepsin can only break proteins into shorter chains called

polypeptides. It cannot break the proteins completely down into amino acids. Trypsin and

chymotrypsin are produced in the pancreas for the purpose of further breaking the

polypeptides down in the small intestine. Each enzyme has a specificity towards certain

9

amino acids. Pepsin will only cleave to the N-terminal NH group that contains aromatic

amino acids (phenylalanine and tyrosine) and the C-terminal Co group of the dipeptidyl

unit (Tang, 1977). It will not cleave to bonds containing valine, alanine, or glycine.

Mucus, as one of the components that makes up gastric juice, is a “slimy”

material that protects the epithelial surfaces against acids and shear stresses and that is

produced by the mucous cells (Bowen, 1998). According to Forstner and Forstner (1986),

mucus functions as a “trap for the immobilization of enzymes, electrolytes,

microorganisms, products of digestion, and secretions”. Composed primarily of

glycopeptides, large mucin molecules bind together to form this layer of protection

(Forstner and Forstner, 1986). Mucus has several roles in its helping of the digestive

process. One is lubrication, mucus is able to lubricate nearby surfaces making them

easier to shear at the point of contact (Forstner and Forstner, 1986). Another function is

as a permeability barrier. Mucus has gaps in which certain nutrients and electrolytes are

able to pass through (Forstner and Forstner, 1986). In the intestinal tract, it protects the

outer linings for the high acid and is even able to stimulate gastrin mucin secretion

(Forstner and Forstner, 1986).

Hydrochloric acid (HCl), another component of gastric juice, is a strong acid that

makes sure the stomach maintains its acidic condition for proper digestion. HCl converts

pepsinogen to pepsin to break down proteins. The acidity also acts as an important barrier

to avoid infection caused by microorganisms (SAPN, 2006).

There are many important concentrations and rates that must be known in order

for the bioreactor to best be able to simulate the digestive process of the stomach. The

stomach secretes both H+ and Cl- ions against a concentration gradient. So, a great

amount of energy is required for the secretions. The energy to drive these two processes

is obtained from ATP hydrolysis. The concentration of hydrogen ions in the lumen of the

stomach can go up to 1.5*10-1 M. The concentration of chloride ions in the lumen of the

stomach can reach 170 mM (Smith & Morton, 2001). Gastric juice can reach up to 160

mM in the stomach. The gastric emptying rate has a large impact on the rate of drug

metabolism and the absorption of the drugs.

Stomach Concentrations and pH ranges

10

Enzymes are only operable within their optimum pH ranges. Table 1, found in

Appendix B, depicts the pH optimums of various enzymes. The hydrogen ion

concentrations can be found utilizing the following formula: pH = -log (H+)

Figure 2 depicts the various pH ranges and the time allotted to each organ of the

digestive tract `The upper stomach has a pH that ranges from 4.0 to 6.5 and the lower

stomach has a pH that ranges from 1.5 to 4.0.

Digestion

Process

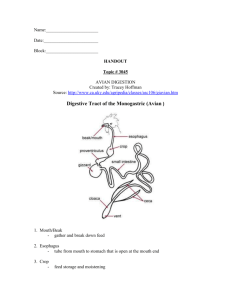

The digestive process begins in the mouth with the mastication or chewing of

food while the salivary glands secrete saliva to break down the carbohydrates and

starches. As shown in Figure 2, the nutrients then enter into the stomach where

simultaneously the stomach muscle physically breaks apart the proteins, the pH and

temperature denature the proteins, and specific enzymes target proteins for digestion.

Once leaving the stomach, 98% of the proteins are broken down into peptides to enter

into the small intestine.

Each secretion supplies enzymes, whose function is to permit the hydrolysis or

breakdown of certain dietary proteins, carbohydrates, or lipids (Corring, 1983). The

digestion of proteins begins in the gastric lumen by pepsins and concludes in the small

intestine by pancreatic proteolytic enzymes (Corring, 1983). Carbohydrate digestion is

initiated by salivary alpha-amylase. Lipids are digested in the intestinal lumen by

pancreatic bile salts-lipase complex.

Hydrolysis of protein begins with the action of pepsins secreted in the gastric

juices in the inactive form of pepsinogens. These are activated by the HCl in the stomach

causing the pH to quickly rise from 2 to 4. The proteins become denatured due to the

harsh pH environment of the stomach leading to the formation of polypeptides (Silk,

1983). Intraluminal digestion is due to inactive proteolytic enzymes (trypsinogen,

chymotrypsinogen, procarbodypeptidases A and B, and proelastases). Trypsinogen

becomes active by the enterokinase forming trypsin which then activates the

chymotrypsinogen, procarboxypeptidases A and B, and the proelastases (Corring, 1983).

These cleave the peptide bonds around the L-amino acids. The chrymotrypsin plays a

11

significant role in the digestion of protein. After being broken down into small peptides,

the intestinal peptidases are further broken down. The majority of the absorption in

proteins takes place in the proximal jejunum while only small amounts are able to reach

the ileum for absorption (Silk, 1983).

Mechanisms

According to Silk and Keohane (1983), the following are two mechanisms

responsible for protein digestion: “transport of liberated free amino acids by group

specific active amino acid transport systems and the uptake of unhydrolysed peptides by

mechanisms independent of the specific amino acid entry mechanisms”.

Another important player in the digestive process is that of the salivary glands.

Secreting proteins, such as amylase, and mucin, along with water and electrolytes, saliva

has several important functions (Van Lennep et al., 1986). Along with wetting dry

nutrient, protecting mucus against dehydration, peroxidasing, and secreting lysozyme,

saliva is also important in the digestion of enzymes such as alpha-amylase and lingual

lipase (Van Lennep et al., 1986). According to Van Lennep et al. (1986), “the synthesis

of secretory proteins…is stimulated by beta-adrenoceptor activation but activation of

alpha-receptors inhibits synthesis.” Also able to inhibit the synthesis of certain proteins

is cycloheximide; however only when not stimulated with adrenaline or dibutyryl cyclicAMP (Van Lennep et al., 1986). Insulin, on-the-other-hand, is able to stimulate protein

synthesis (Van Lennep et al., 1986).

Starch is broken down by salivary alpha-amylase. The digestion of carbohydrates

also essentially begins in the lumen. The starch is broken down into maltose and other

forms. Starch digestion has its optimum capacity in a pH of 6.9, resulting in the stomach

not having as great of an effect. Some argue about whether or not starch is even broken

down in the stomach (Corring, 1983). Starch digestion mainly occurs in the small

intestine (Corring, 1983). In carbohydrate hydrolysis, brush border hydrolysis and the

use of the monosaccharide transport system is the primary method for digestion in

humans (Silk, 1983).

Lipids are also broken down in the lumen section of the stomach. The pH is also

relatively high for the optimum hydrolysis of lipids, resulting in a majority of the lipid

not being digested in the stomach (Corring, 1983). Chyme in the gastrointestinal tract

12

mixes, resulting in the dissolving of fat-soluble vitamins (Weber, 1983). These fat

droplets are then further broken down in the lumen into mixed micelles (Weber, 1983).

Lipase is essential in the step for the splitting of the dietary triglycerides into long-chain

fatty acids (Weber, 1983). Carboxylesterase and phospholipase are also important in the

hydrolysis of cholesterol ester and phospholipids (Weber, 1983).

Drug Digestion

Oral Delivery

Protein drugs’ efficiency is not maximized when taken orally, because of

protein’s high molecular weight, high hydrophilicity, and the likelihood of enzymatic

hydrolysis (Frokjaer and Hovgaard, 2000). However, an oral delivery of drugs has

caught the attention of some scientists. Due to invasiveness and possibilities of infections

while consuming insulin subcutaneously, some scientists have shown great interest in

oral delivery of insulin. Most of the insulin does not go into the bloodstream because it

gets broken down in the digestive system (Lin et al., 2008). In the study conducted by

Lin and other scientists in Taiwan, chitosan (CS) and poly-γ-glutamic acid (γ-PGA) was

developed to aid insulin to be taken orally. From the gastrointestinal tract to the small

intestines, the pH changes from acidic to alkaline. The authors used sodium

tripolyphosphate (TPP) and magnesium sulfate to make nanoparticles that can survive in

broader pH ranges (Lin et al., 2008).

Frokjaer and Hovgaard (2002) suggest that “the use of protease inhibitors,

adsorption enhancers, chemical modification, and special pharmaceutical formulations

can increase the bioavailability by bypassing enzymatic and absorption barriers”. The

authors indicate that aprotinin, amastatin, bestatin, boroleucine, and puromycin are

inhibitors that can be administered with the protein drugs. The major downfall of

protease inhibitors is that it has an effect on the absorption of other peptides and proteins

that are usually degraded in the system (Frokjaer and Hovgaard, 2000).

Bioreactors

Overview

13

Bioreactors are generally characterized as closed containers where biological and

chemical reactions take place. There are a variety of different structures and components

of a bioreactor for organs. Usually, the bioreactors consist of a human cell culture, a

support structure, a port for the inflow of the fluid which is going to go through

processing, a port for the outflow for the processed fluid, a chamber to gather the fluid

which will be processed, a second chamber to collect the processed fluid, two sets of

hollow capillary fiber bundles, one for the fluid coming in to be processed and one for the

processed fluid coming out (Galvotti, 2008).

According to the New England Anti-Vivisection Society (NEAVS, 2008), a

bioreactor is an apparatus for growing organisms such as bacteria, viruses, or yeast.

These are used in the production of pharmaceuticals, antibodies, or vaccines, or for the

bioconversion of organic wastes. The design of a bioreactor utilizes the basic principles

of conservation of mass (stoichiometry) and energy (thermodynamics), and relies on

knowledge concerning the rate at which the process is expected to take place (kinetics). A

typical bioreactor has a control system that monitors the conditions inside the vessel, such

as: mass flow rate, pH, temperature, dissolved oxygen level, gases present (i.e., air,

oxygen, carbon dioxide, nitrogen) and the agitation speed, which is controlled in order to

keep the contents uniformly mixed, and to allow for oxygen transfer (NEAVS, 2008). A

heat exchanger or a cooling jacket is also needed to keep the bioprocess operating at a

constant temperature.

History

In 1886, Dr. Mackenzie simulated the digestion of milk in the human body by

means of a catheter, a vessel which acts as the artificial cavity, and a milk strainer. The

primary purpose of the simulation of this process was to feed sickly patients through their

rectums. Dr. Mackenzie saw that the fluid undergoes digestion in the artificial cavity and

absorption in the rectum. He inserted a celluloid catheter two inches into the anus and

saw that the sphincter closed on the catheter (Mackenzie, 1886). The celluloid turned

soft, after encountering the body heat and could hardly be felt by the patient (Mackenzie,

1886). The catheter is put through a thick piece of India-rubber, before it is inserted into

the patient (Mackenzie, 1886). The India-rubber was made up of attached tapes, which

14

connected around the loins and which were tied fairly close to the anus (Mackenzie,

1886).

Dr. Mackenzie warmed up some milk and allowed it to sit for thirty minutes

before passing it through the strainer into the vessel. He observed that there was no curd

left on the strainer and that after straining, the milk flowed easily through the tubes

(Mackenzie, 1886). The milk in the vessel is elevated by about two feet above the bed of

the patient. It is observed that the milk passes through the rectum in about three hours,

which is an accurate period of digestion for milk (Mackenzie, 1886). The understanding

and construction of this early artificial stomach allows for the basis and inventions of

modern bioreactors.

A group of British scientists were actually successful in designing and

constructing the first artificial stomach in 2006. The chief designer of the artificial

stomach is man named Dr. Martin Wickham (The Assoc. Press, 2006). The artificial

stomach is larger than the size of a desktop computer and cost about $1.8 M to build (The

Assoc. Press, 2006). The two parts that make up the artificial stomach are a funnel and a

metal tube enclosed within a box. The mixture of digestive enzymes, food, and stomach

acids take place in the funnel section of the artificial stomach. The food then moves

down into the silver metal tube section of the stomach, where it is grinded into minute

particles (The Assoc. Press, 2006). Figure 3 depicts the two parts of the stomach.

There is software which controls the parameters of the artificial stomach. Examples of

these parameters include different hormone responses and the time it takes food to remain

in a specific part of the stomach (The Assoc. Press, 2006). The artificial stomach is

particularly unique in that the stomach utilizes specific digestion movements, such as the

contractions of the stomach which serve to break food down (The Assoc. Press, 2006).

This innovation is an important tool that will allow for many breakthroughs in various

researches dealing with the stomach, such as studying the process of nutrient absorption

in the stomach.

Types of Bioreactors

In a continuous bioreactor, the feed rate and product discharge rate or both are

held constant. Chemostat, an alternative name for a single Continuously Stirred Tank

Reactor (CSTR), is the simplest and the most widely applied design. The changes in

15

volume of the culture broth relative to elapsed time for continuous bioreactor can be seen

in figure 4.

When using the Chemostat design, an assumption that the growth rate is

determined by the supply rate of the growth-limiting substrate is made. This single

essential nutrient could be nitrogen, carbon, trace elements, or vitamins (Asenjo, 1995).

Cells are removed at a rate equal to that of their growth rate, and the growth rate of cells

is equal to the dilution rate (Shuler, 2001). According to Center of Applied Catalysts

(2002), a CSTR is “an adaptation of a batch reactor in which the substrate is added

continuously to the reactor while the reaction mixture is removed at the same rate.”

Since the substrate concentration throughout the whole reactor stays the same, the

product yield is usually lower than in a batch process. A batch process is a one step

system. It is the most widely used method in the biopharmaceutical industry because of

its versatility. Changes in volume of the culture broth relative to elapsed time for a batch

bioreactor can be seen in Figure 5.

A typical batch reactor consists of an agitator and a heating/cooling system.

Impellers commonly used in batch reactors are shown below. In a batch reactor, there are

four distinct phases: lag, exponential growth, harvesting, and new batch preparation

(Shuler, 2001). The basic elements that determine a reactor’s productivity, and thus the

size of the bioreactor, are the rate equation (usually includes yield values), cell

concentration, and the reactor’s flow characteristics (Asenjo, 1995).

According to Asenjo (1995), a membrane reactor is a flow reactor within which

membranes are used to separate cells or enzymes from the feed or product streams. In

membrane reactors, feed streams are delivered continuously, while products are removed

continuously, although in some applications they are collected intermittently or at the end

of the run. The most common membranes used in membrane reactors are ultra-filtration

and polymeric microfiltration. Microfiltration membranes have pore sizes between 0.1

and 5 µm, and they are used to confine cells within a reactor without restricting the

passage of soluble nutrients and products (Asenjo, 1995). Ultra-filtration membranes’

pore sizes typically range from 2 to 100 nm and can be used to exclude macromolecules

with molecular weights from 103 to 106 (Asenjo, 1995).

16

The most commonly used geometry for membrane reactors can be seen in the

hollow fiber design which is represented by Figure 7. This type of reactor was modeled

after the vertebrate circulatory system, wherein tissues are maintained by nutrients

provided through selectively permeable capillaries. A bundle of hollow fibers is sealed

into a cylindrical shell with epoxy or polyurethane resin. The thousands of hollow fibers

within the reactor provide a large surface area for mass transfer and cell adhesion

(Asenjo, 1995). The downside to using hollow fiber reactors is that cell observation and

harvesting can be problematic (Shuler, 2001).

One of the advantages of the membrane reactor is its ability to accomplish the

initial task of the membranes in a separation process within the body of the reactor.

Selective membranes can be used to facilitate both the removal of inhibitory metabolites

and the recovery of unstable products before degradation (Asenjo, 1995). Undesired

shear effects on protein are not significant except when gas-liquid interfaces are present,

assuming a Reynold’s number of less than 2300 and laminar flow of the fluid (Harrison,

2003). This denaturizing of protein at air-liquid interfaces is commonly encountered in

agitated vessels. This problem can be eliminated in a membrane reactor because the

enzymes are sequestered in a relatively quiescent region where they are protected from

mechanical damage and generally not in contact with air (Asenjo, 1995). The major

disadvantage of this system is the cost of the membranes and the need for their periodical

replacement (Chaplin, 2004).

Safety and Standards

The design project’s products will be a bioreactor and a testable protein drug.

When considering the testing process for this protein and the use of the bioreactor, certain

regulations must be observed. The following paragraphs review some of the pertinent

safety standards for the individuals handling the drugs that must be observed:

Drugs not in final form have additional protocol that must be followed during

the testing process. The Hazard Communication standard will be utilized throughout the

design. This standard is meant to enforce that all chemical hazards are looked at

carefully and the information about the risks of the hazards is sent to the employees and

employers who will be working with the chemicals. The standard also ensures the proper

17

labeling of all chemicals and that all employers make material safety data sheets available

to their employees. This standard will ensure the safety of the people working directly

with the protein drugs.

The Hazardous Waste Operations and Emergency Response standard will also be

followed throughout the design. This standard ensures the proper clean up of hazardous

chemicals, ensuring that the chemicals are removed or contained. If the proper waste

disposal procedure is not followed correctly, the laboratory will be at risk and might have

to shut down. In this case, refer to the TT OSHA Act of 2004, which discusses the

Industry Health and Safety. All chemical waste bottles must include Hazard Form

stickers with the start dates and the bottle contents. Since HCl is a strong acid, the bottle

must be labeled as Hazardous Waste and stored separately so that it may be carried out to

a proper hazardous waste management site. If a chemical is released and is not able to be

controlled quickly, an emergency response occurs, in which the fire department or some

other aid group comes to assist the employees (ACH, 2000).

The Access to Employee Exposure and Medical Records standard will give

employees, as well as the Assistant Secretary Representatives the right to look at medical

records. Access is needed by all of these people to ensure better detection, treatment, and

the prevention of diseases while working with these oral protein drugs.

In addition, the International Society for Pharmacoepidemiology has a set of Engineering

Pharmaceutical Innovation Standards and Practices and Guides that are used by

pharmaceutical and biotechnology professionals. These standards involve guidelines, as

to the testing and creation the drugs which would be pertinent to our design. The

environmental impact of the tested drugs would also need to be considered. The disposal

of the chemicals used in the creation of the drug and the composition of the bioreactor

would need to follow regulations set by the Environmental Protection Agency. The EPA

has numerous guidelines on the safe disposal of various chemicals and compounds.

The Federal Drug Administration also has many regulations for standard drug

quality. Some of the regulations include the Pharmacology/Toxicology standards, as well

as the Food and Drug Administration Amendment Acts of 2007 (CDER, 2003). The

Food and Drug Administration Act gives the FDA authority to regulate drugs, etc. The

team will have to follow the restrictions set forth by the FDA when obtaining drugs for

18

the bioreactor. In order to regulate new drugs, there are several trials that the FDA needs

to conduct. The trials consist of three different phases. Phase I consists of determining

the side effects and the testing safety of the drug. Phase II includes the credibility and

dosage range. Phase III consists of a comparison of the drug with a placebo and other

treatments, as well as the side effects on the patient (CDER, 2003). Other sources of

guidelines for drug testing include the U.S. Pharmacopeia, the EP Pharmaceutical

Standards, and other Pharmaceutical professional organizations. Standard laboratory

safety procedures would need to be observed, such as those written by the American

Chemical Society. The handling of hydrochloric acid and other chemical compounds can

potentially be hazardous and safety regulations must be observed.

In addition to required and necessary guidelines that should be followed in the

creation and testing of the pharmaceutical proteins and the bioreactor, certain ethical

issues must be addressed. Since the pharmaceutical’s aim is to eliminate the need for

human testing, that issue commonly addressed is obsolete. The common ethical issue

that is always addressed when introducing a pharmaceutical to the population is that it is

important to consider the side effects and whether the outcome is more important than the

negative side effects the drugs may induce.

Preliminary/Alternative Designs:

In order to design a bioreactor that can simulate the human stomach, the basic

principles that account for the main components of every bioreactor have to be

considered, after which the idea can be expanded to make the design more specific. Since

the environment of the stomach has to be kept constant, the design needs to include a pH

and temperature probe for monitoring, as well as a pH controller system and heat

exchanger or cooling jacket for pH and temperature control respectively. A method of

providing the reactor with gastric juices is also necessary. Gastric juices enable the

chemical breakdown of protein in the stomach, and are composed mainly of hydrochloric

acid (HCl), mucus, pepsin, and rennin. In order to place any proteins being examined into

the reactor and collect the product at the end of the process, there needs to be influent and

effluent openings. The stomach also needs to provide physical breakdown by shear stress

produced between reactor walls. Using a type of biomaterial that can act as a stomach

19

wall was considered, as well as using baffles and a stirrer to produce the same effect.

After the protein has been broken down by gastric juices, there needs to be a way to

measure how much of the protein has survived the harsh conditions. A separation system

will separate the broken peptides from the “intact” protein.

Three alternative designs have been considered for a reactor that could mimic the

human stomach. Each reactor has its own advantages and disadvantages which will help

to decide on which system will work the best for this particular project. The alternative

designs are:

Continuous Bioreactor

In a continuous bioreactor, the feed is put in continuously at the beginning and the

product is then collected at the end of the process. The changes in the volume of culture

broth with elapsed time for a continuous bioreactor can be seen in Figure 9.

The group chose two types of systems for the continuous bioreactor. One of the

systems incorporates a type of mixing device and one does not.

i) Continuously Stirred Tank Reactor (CSTR)

A CSTR is a tank to which reactants are continuously fed and products are

constantly withdrawn. In a CSTR, the tank is continuously agitated to reach a

specific output. To make the system even more efficient, the group considered

designing a CSTR in a series of steps, as shown in the figure below. The feed and

the product flow rate will be kept constant throughout the system, which will

create a simple general mass balance. The concentration of the effluent will be the

same from the beginning to the end. The stirrers in the serial CSTR will mimic the

natural mixing movements found in the stomach. Another important step is to find

the right paddles to use, so that the protein is not broken and biodegraded. The

protein breakdown mostly occurs by chemical means, not physical stress. The

continuous bioreactor is easy to load and unload. The feed goes in and the

product is collected at the end of the line. Since the feed is continuously fed to the

bioreactor, the product yield is a lot higher. However, if one part of the series has

contamination, the whole system will need to be turned off, which in turns creates

a great amount of down time for the industry.

ii) Plug Flow Reactor (PFR)

20

In a PFR, the feed is fed into a continuously straight tube or pipe. Just like

in a CSTR, the feed and product flow rate are assumed to be constant. However,

the reaction rate is inversely proportional to the distance traveled along the tube.

The reaction rate will be substantially higher on the upstream and decrease over

time as it reaches downstream. The flow in PFR only flows in the axial direction

(parallel to the tube), which does not ensure a proper mixing within the reactor.

To overcome this, the feed is put in the direction perpendicular of the stream, as

the figure below indicates.

The maintenance cost of PFR is slightly higher than the maintenance cost

of a CSTR. This can be overcome by placing the reagent at different locations in

the reactor. PFR can run for a long period of time without maintenance, and it

also has a higher efficiency than CSTR. The higher efficiency in a PFR indicates

that the reactor will have a larger percentage of completion in a PFR, than if

conducted in a CSTR. Another modification of PFR is the placement of a

membrane separation system within the tube. As the protein is being degraded by

the enzyme, the membrane can diffuse and separate the peptides with the “intact”

protein.

Batch Bioreactor

A batch bioreactor is a one step system. It is the most widely used method in the

biopharmaceutical industries, due to its versatility. Pharmaceutical companies can

choose a specific protein to test on without drastically altering the principles of the

reactor. This type of process also reduces contamination within the system. Unlike the

CSTR, if something wrong occurs, the bioreactor just needs to be shut down, sterilized,

and the whole process can be repeated. The changes in volume of a culture broth with

elapsed time for a batch bioreactor can be seen in figure below.

A batch bioreactor also contains a stirrer and baffles, which aid in proper mixing.

The baffles are usually placed along the side wall of the bioreactor and are utilized to

ensure uniform mixing. The mixture being stirred can only move in one radial direction.

The purpose of the baffles is to break the flow pattern, as shown in the figure below.

21

The major disadvantage of a batch bioreactor is the need for its’ periodic shutdown and start-up which makes for a loss of production time. Waste can be easily

accumulated within the reactor because the mixture just stays in one tank.

Semi-Continuous Bioreactor

After consideration of both reactors, a combination of the batch and continuous

bioreactors was desired. The human stomach closely resembles a semi-continuous

system where the initial feed is the batch portion and the enzymes and HCl are

continuously fed into the bioreactor making the continuous system essential.

When determining which design to pick, the team used the Decision Matrix found

under Table 2. As mentioned previously, the accuracy is the most important criteria for

our design. It is vital that the design simulates the human stomach as accurately as

possible; this means the stomach bioreactor must have a 98% protein digestion and have

the same environment as the stomach. In the digestive process, a small portion of the

protein digestion is a result of the physical breakdown of the drug. The design cannot be

too aggressive and make the physical breakdown a bigger portion of the digestive process

than the chemical reaction. The design team found the semi-continuous bioreactor the

best option to meet these criteria.

Project Design: The final design of a membrane bioreactor consists of two cylindrical

drums chambers, the first containing enough HCl to produce a pH range of 6.5 to 4, and

the second containing enough HCl for a pH of 1-3, a cooling jacket to ensure a constant

temperature of 37 °C, protein digesting enzymes such as protease and pepsinase, two

agitators for continuous stirring, baffles for even mixing, pH and temperature probes with

controllers, and a detection system that outputs the amount of peptides present after

digestion in comparison to the number of undigested proteins present. The design can be

found under Appendix A: Bioreactor Design. Since the digestive fluids will be

approximately 0.8 liters and the liquid needs to be 80% of the total bioreactor volume, the

bioreactor has a total volume of 1.00 liters. As seen on the bioreactor design in Appendix

A, the sensors will be attached to a computer monitoring the bioreactor and prepared to

counteract any change in the environment by changing the input into the system. The

sensors relaying information can be seen by the dashed lines connecting the sensors to the

computer.

22

The design incorporates a conical bottom to enable easier draining. The content

in the reactor will be recycled through the use of a peristaltic pump by collecting the

liquid at the bottom of the bioreactor and pumping it back to the top. This ensures that no

protein is accumulated on the bottom of the bioreactor. A second agitator is essential to

the design since in a typical 1-liter bioreactor there would be inconsistencies in the

concentrations and temperature of the solution. A second agitator placed slightly lower

than the first agitator will ensure the solution in the conical area will be of the same

concentration as the upper region of the bioreactor. To ensure the pH of the bioreactor

will also be as consistent as possible, there will be two inlets for the HCl. This is more

accurate since in the human stomach there are multiple areas for the digestive acid to

enter.

After the construction of the bioreactor, the client will input the oral protein drug

into the influent opening of the bioreactor. During the very first stage of the reaction, the

drugs will go through a pretreatment process. This process is meant to mimic the

physical breakdown by saliva as the drugs enter the human mouth. The pretreatment will

be very quick at approximately 12 seconds. A block diagram of the whole reaction

process can be seen in Figure 12. The drug will remain in the bioreactor for one hour, or

the average amount of time spent by proteins in the stomach. After digestion, the

membrane separator in the bioreactor will allow the gastric juices and other materials to

flow through while retaining the proteins. The proteins will then be put into a separation

system where the number of peptides versus undigested proteins will be calculated. This

process will take place in a pharmaceutical laboratory under standard laboratory safety

procedures. One assumption will be that the bioreactor will continue having 98% protein

digestion after construction. Another assumption is the amount of protein input into the

bioreactor is in small enough amounts to not interact with the HCl to produce a

significant change in pH or polarity in the bioreactor’s environment.

Different enzymes in the stomach operate under specific pH ranges. The

bioreactor will consist of a series of two stages that operate at different pH values. The

first stage will consist of the lipase, trypsin, and invertase enzymes operating at a pH

range of 4-6.5. After 60 minutes, the reactor will enter stage two by the addition of HCl,

23

creating a pH range of 1.5-4. Figure 14 depicts the two stages with their respective

enzymes.

As mentioned before, HCl will be used. The amount of HCl entering will be

determined by the pH meter. A diluted HCl solution of concentration 0.1 M will enter in

by drops. Since the reaction of the acid with the water is immediate, the pH will rapidly

change. The pH meter is connected to a computer that is also connected to the input of

HCl. Once the pH becomes in the range of 4.5 – 5.5, the computer will shut off the input

of HCl. Once the second stage of the process is begun, the computer will restart the

addition of the HCl until the pH becomes in the range of 2.5-3.5. This is in the middle of

the target range for the second process. A very small diameter of 0.005 m lab hose will be

used to deliver the HCl into the reactor. Since it is necessary to put in the acid in the form

of drops, a small valve will be put in the middle of the hose to control the flow. The valve

is connected to the sensor that sends a signal to the computer which will physically open

and close the valve. As the valve is closed, there will not be any acid flowing into the

reactor. When more acid is needed, the valve will open to allow some acid to go through

and lower the pH of the solution. To ensure the HCl does not react with the air in the

bioreactor, the air will need to be replaced with an inert gas. Since argon is one of the

most cost effective inert gases available, it was chosen for the bioreactor. While the

human stomach does not have argon, the argon will make no difference in the interaction

between the enzymes, pH, and temperature in breaking down the protein. In fact, it will

ensure that no unnecessary reactions will occur. Since the design will use argon, an air

sparger will be placed between the two agitators. The following is the procedure done by

the pharmaceutical company personnel to run the bioreactor:

Start-Up Procedure

Preparation of Media (must be done one lab period before-hand):

For the “Saliva” pretreatment:

In 10mL flask, mix:

-7 mmol/L Sodium Chloride

-10 mmol/L Potassium

24

-1.2 mmol/L Calcium

-2.5 mmol/L Bicarbonate

-1.4 mmol/L Phosphate

-9.5 mL DI water

-Equal part of Mucopolysaccharide, Glycoprotein, Hydrogen Peroxide,

α- Amylase, Lysozyme

Running the bioreactor:

1. Only authorized personnel with proper protective equipments such as rubber

gloves, lab coat, and safety goggles is allowed to operate the bioreactor.

2. Remove the lid and attached hosing from the bioreactor and dump the contents (a

mild water and bleach solution) down the drain. Spray the inside of the reactor as

well as the stirrer, sparger, sample port, etc. with bleach and rinse thoroughly with

DI water. Rinse for as much time as necessary until you no longer smell any

bleach in the bioreactor.

3. Reattach the bioreactor to the mounting base and connect the water jacket hosing.

4. Turn on the water supply to the bioreactor by opening the appropriate valves.

Also check if the cooling water is flowing properly. Connect the 10% HCl tube

into the reactor, make sure that the tube is not clogged and the flow meter is

working properly.

5. There are 2 bioreactors being used. On the first bioreactor, insert the pretreatment

content along with 2 mg of the chosen protein and note the starting time. Replace

the lid, and attach the condenser water in and out of line and attach the

temperature probe and the pH probe.

6. Set the temperature to 37 ºC at the temperature controller and enter pH range 7.5 6.5 at the pH controller. Run the reaction at the lowest speed setting for 12

seconds.

25

7. After 12 seconds, open the HCl valve and set the pH range to 6.4 – 4 and run the

reaction for 60 minutes.

8. After 60 minutes, continuously run the solution into the second bioreactor with

the same 37 ºC temperature and set the pH range to 4 - 1.5. Keep the 10% HCl

solution running constantly for 3 hours until the pH enters the set pH range.

9.

To collect samples, first connect a rubber bulb to the sampling port. Press a

sample tube tightly against the rubber seal on the collection port. Close the

sampling valve and squeeze the bulb. Slowly open the valve until a suitable

amount of sample has entered the tube.

Shutdown Procedure

1.

Stop the bioreactor by setting the control field of the agitator, temperature, etc. to

off. Switch off the main power supply.

2. Remove motor, all hosing, and attached probes from the bioreactor. Bring the

reactor to the sink.

3. Discard the contents to the designated drain area. Spray the inside of the

bioreactor including the sample port and all tubes with bleach solution twice and

rinse with water. Once everything has been thoroughly rinsed, fill the bioreactor

with enough water to cover the baffles and add approximately 150 mL of bleach.

4. Return the reactor to its base.

5. Make sure the area is clean for the next protein experiment.

After the digestive process is complete, the fluid inside the bioreactor will be run

through the SDS PAGE which will separate out the proteins by molecular weight. The

larger the protein the further it will travel towards the positive end of the gel following

electrophoresis which will enable the pharmaceutical companies to know what

percentage of the protein is still the original length and what percentage has been broken

down.

Project Evaluation: In promising the clients a dependable, accurate bioreactor that

emulates the human stomach, certain standards have to be met. After the construction of

26

the bioreactor, the physical environment has to consist of a temperature of 37 ºC, a pH

ranging from 6.5 to 1.5 over the course of four hours after the addition of HCl, and a size

of approximately 0.8L. After the input of a protein, the output on the SDS PAGE should

show approximately 98% breakdown of that protein.The economic analysis proves the

bioreactor’s competitiveness in the pharmaceutical market. The bioreactor’s digestive

process is not labor intensive due to a network of monitoring probes relaying data to a

computer which will change input conditions in order to maintain the preset design

criteria. The only labor associated with the process is in the initial construction, the input

of the materials, the cleaning of the bioreactor after completion of digestion, and reading

of the SDS PAGE to determine protein breakdown. While the two bioreactors together

cost approximately $60 K, the monitoring probes combined will cost under $2 K, the

specific computer software will cost minimum of $30 K, and the maintenance and

running costs will be well under $8 K, the total project is estimated to cost approximately

$100 K. This number is in comparison to the only other bioreactor designed to simulate

the human stomach which cost approximately $1 M after construction, fabrication, and

implementation. While the competitor bioreactor has a wider range of functions such as

producing vomit and monitoring all nutrients entering the bioreactor’s “stomach”,

Proteinnovate’s bioreactor design was created for a clientele solely interested in oral

protein drugs for a considerably less amount of money.

Certain areas of the design were speculated due to a lack of knowledge and

published material on oral protein drugs and an inability to construct the bioreactor to do

performance testing. One area of uncertainty was the size of the protein drug

administered. For the mass balance, a mass of 2 mg was used for the input protein since

oral protein drugs are still under development and there is currently no standard mass of

protein typically administered. The assumed 2 mg of protein, if substantially incorrect,

could result in insufficient amounts of enzymes put into the system. Another assumption

made was the amount of protein input into the system would not have a substantial

impact on the polarity or pH of the bioreactor’s chemical environment. If the amount of

protein typically administered were found to be a higher value than what was assumed,

this could result in a change in the stomach’s environment producing errors in the actual

pH of the system.

27

The bioreactor does not come with an air sparger because it is assumed that the

oxygen in the 20% reactor headspace and the dissolved oxygen contained in the water

would be enough to supply oxygen needed for the whole reaction. The group also

assumed that 100% of the feed protein is utilized and there no waste accumulation. With

this assumption, the following mass balance was obtained:

100% protein = 98% peptides + 2% protein

Conclusion/Summary: In order to create a bioreactor that would simulate the human

digestive system, three designs were considered. The CSTR, the semi-continuous, and

the batch bioreactor were all examined as possible reactor designs. The semi-continuous

bioreactor was considered to be the best design after much consideration and

comparisons with the other two reactors. The semi-continuous reactor was found to be

the best representation of the actual human stomach.

The semi-continuous bioreactor was designed with a conical bottom so that it

would be able to mimic digestion. Baffles, a cooling jacket, HCl, and enzymes were

added to simulate the physical and chemical environment of the stomach. The process

occurs in two stages after which the output is put through a SDS PAGE for the separation

of proteins by molecular weight to determine the protein digestion. The economic

analysis shows that the total cost of the bioreactor is around $100 K in comparison to the

only other bioreactor, costing approximately $1 M.

The deliverables that were promised at the beginning of the project included a

flow diagram of the stomach’s processes, a bioreactor functioning as an artificial

stomach, sensors to monitor the stomach’s environment, the mass and energy balance, as

well as the economic analysis. All of the deliverables, except for the energy balance,

were completed. The energy balance was not completed because the design is

theoretical, the group will not be able to physically test the accuracy of the bioreactor, so

it will be hard to determine the amount of energy needed to increase/decrease

temperature, etc. If the project were to be implemented, a possible environmental effect

would be that the waste would need to be distributed to the proper places, since strong

28

acid would be utilized. Team Proteinnovate’s bioreactor will hopefully be built

sometime in the future so that pharmaceutical companies will be able to reduce the cost

of testing as well as to reduce the invasiveness involved with needles.

Work Plan – Timeline – Design ScheduleSept. 25 - Finish and submit scope of work

Sept. 30 - Team meeting to possibly set a focus

Oct. 9 - Revision of cover page and scope of work

Submit project notebook

Oct. 23 - Submit Cover Page, Scope of Work, and References.

Nov. 6 - Turn in Project Notebook 2

Nov. 12 – Group Meeting: Revise Literature Review and Safety Standards

Nov. 13 - Submit Cover Page, Scope of Work, Resources, Safety, Regulatory, and

Environmental Considerations and Work Plan

Nov. 18 - Team meeting to discuss alternative designs

Nov. 20 - Turn in 3-Project Notebook, Finish and Submit Draft of Final report, Group

Meeting for outline update

Dec. 2 - Work on oral presentation and discussion.

Dec. 4 - Group Oral Presentation, Project notebook due

Dec. 16 - Revise final report

WINTER BREAK

Jan. 20 – Group meets to discuss new timeline and add necessary changes

Jan. 25 – Group discussion on gastric juice and research protein drugs

Jan. 26 – First class meeting of spring semester

Jan. 27 – Division of workload (chemical composition, protein drugs, paper editing)

Jan. 29 – Group meeting

Jan. 31 – Discussion of groups finding from previous research

Feb. 2 - Project notebook for spring semester due

Feb. 5 – Research on sensors

Feb. 7 – Research protein recovering method

29

Feb. 9 – Find exact concentration of stomach’s chemical composition

Feb. 13 – Discussion on bioreactor choice (multiple reactor in series or one reactor)

Feb. 14 – Completing midterm project report

Feb. 16 – Midterm project report due/Jenn’s presentation to team on sensor choices/

decide on sensors

Feb. 19 – Begin mass balances/energy equations

Feb. 23 - 2-Project notebook due/Finish mass balances/energy equations – individual

research to begin on separation systems

Feb. 26 – Discussion and decision matrix on different types of separation systems found/

decide on system

Mar. 2 – Work on final design report/conclusion and final design

Mar. 5 – Meet with advisor to discuss progress

Mar. 7 to Mar. 15 – SPRING BREAK

Mar. 16 – Cost/Economic analysis to be completed

Mar. 19 – Work on midterm oral presentations

Mar. 23 - 3:30-6:30 midterm presentation

Mar. 30 - 3-Project notebook due

April 1 – Group meeting

April 20 Draft of final report (not graded) due

April 27 - May 1 Poster Presentation of final report

May 4 Final Project notebook due.

May 7-12 - Individual oral exam

May 13 - Final report approved, graded, and signed by advisors.

The summary of the above dates is depicted below in our team’s Gantt chart found under

Figure 15. The team added more items to the timeline compared to the fall timeline. As

the project progressed, there were many unforeseen objectives that had to be completed.

These objectives include instrumentation research, bioreactor design using CAD, and

economic analysis. Researching inputs took longer than expected due to team’s

uncertainties regarding the reaction that may take during the bioreactor operation. After

consulting with multiple professors, Proteinnovate’s project came to a conclusion on

30

March 16 which is a month and a half later than the fall timeline in Table 3. The other

objectives were completed on time. The fall semester timeline and Gantt chart can be

found in Table 3 and Figure 15 respectively.

Project Reflections:

Kristen Pevarski: Overall, the project was a success. One of the things our group and I

learned early on was the need for time management. We had team meetings but there

were many times we got together as a team and got very little accomplished. I didn’t

realize at first that even for a meeting you have to do some preliminary work to make

sure the meeting runs smoothly and the work gets completed. I found that when we all

split up and did our individual parts then met again twice a week to go over what

everyone had done, things went much smoother. If I had to do this over again, I would

also ensure that we had better communication with our advisor. We were behind

schedule many times and got our reports or drafts into our advisor late, giving him very

little time to offer us constructive feedback. Other groups I talked with mentioned they

had met with their advisor at least once a week and I feel like that would have been a

good idea for us to make sure that we were on track. This is more in relation to what

happened the first semester when there was miscommunication and it turned out our

project focus was entirely off. I also feel like it would have been more efficient with

fewer people. Overall, I feel like it was a very positive experience and I have gained

invaluable insight into how I work and communicate with others and vice versa.

Megha Maheshwari: I greatly enjoyed this class for it allowed me to better understand

the design process and to utilize what I have learned over the past four years to create a

suitable design. I learned a great deal about the different components of the design

process, such as coming up with a suitable problem statement, actually constructing the

design and coming up with alternative solutions, while keeping the cost in consideration.

This design was a fairly new concept for the team because none of the members were

very familiar with proteins and their breakdown. A great deal of research had to be

conducted on protein drugs and the digestive system, in order to figure out how to best

simulate the stomach within a bioreactor, so that protein breakdown could be tested. So,

I also had the opportunity to learn a great deal about the different protein drugs and about

31

the components of a bioreactor. The team has amazing dynamics. All of the team

members were committed to the design and we worked well together. We kept up with

all of the tasks that were assigned to us periodically throughout the year. The design

helped to improve my time management skills because it required a great deal of work

that had to be completed on certain deadlines. If I were to do this project again, I would

love to actually build it because I think the building would allow us to better test the

design. Right now, the design is just theoretical. Some project management items that I

would do differently would maybe be to do less research and actually concentrate more

heavily on the design, because I feel the whole first semester was just dedicated to

research. In closing, I greatly enjoyed this class and my team dynamics. I know it will

help me in the future.

Veni Avenida: We have been doing this Stomach Bioreactor project for two semesters

and I learned so much about working with a group of people throughout the process. We

had to learn about each other’s learning styles and we had to learn to work with different

schedules and opinions. This project was fairly new and there were not a lot of references

to use, so we had to brainstorm quite often and develop new ideas. I think we did a very

good job with the project considering the limited resources that we had. The project itself

taught me how to think critically and it gave me chances to apply some of the technical

knowledge that I have gained from the BSE department. If there are things that I could

change however, I would love to actually build an actual bioreactor so that we can get the

laboratory experience. Also, I feel like some of the classes that are being taught during

this Spring semester should have been taught a little earlier to prepare us better for the

project. It would have been nice if we could actually contact a person from an actually

pharmaceutical industry as a co-advisor so that we would know if our design is feasible

for the industry or not. If I could go back and change our management item, it would be

to finish all the goals in our timeline. We did not get a chance to do an energy balance or

the design layout using a SuperPro. However, our design is not being jeopardized by not

completing these goals. Overall, the project was a success. I learned a lot in term of

working with other team members; managing my time better, and most importantly, now

I know how to apply my BSE knowledge to solve a real problem.

32

Jennifer Kim: Senior design offered a different experience compared to all the other

group projects. Since the design project lasted a whole year, we were able to fix most of

the mistakes we made during the first semester. During the first semester, I only met

with the team members once a week. Every time the team had to turn a project item in, I

felt rushed. Since there are four members, it was very difficult to schedule a meeting due

to time conflicts. We managed to overcome this by splitting into two smaller groups

during the spring semester. The team operated more efficiently this way. Furthermore,

to resolve the issue of feeling overwhelmed, we met at least twice a week. Our frequent

meetings helped me accomplish more and get more feedback from other members. I

think better communications between team members and advisors would have helped

during the design process. In the beginning of the semester, our team’s focus was

completely different than what our advisors expected of us. Also, there were a few times

when team members got confused as to where to meet. In the future, I will make sure

that there is a clear understanding of expectations between supervisors and coworkers.

I wish our plant design took place during the fall semester. It provided a great

amount of information regarding instrumentation, designing a plant, and cost analysis. If

we had learned about it sooner, we would have been able to provide a more detail and

accurate cost analysis. Nevertheless, we were able to add information as the plant design

class went on. We were also able to get feedback from Dr. Agblevor on our

instrumentation.

If I had to redo this process, I would choose a team with fewer members or try to

find a more efficient way to work with many people. Also, I would have liked to have a

project that we could actually build. During in-class presentations and poster

presentations, I envied the fact that there were groups that were trying to solve problems

by visiting sites and growing bacteria to see if their project was feasible. During the first

semester, we took a wrong path. I ended up doing a lot of research on different drug

delivery methods. Although it was irrelevant to our final project, I learned so much from

research. Overall, I enjoyed the experience. Our group overcame our time constraints. I

got a feel for what working with others would be in the real world. I also learned a lot of

chemistry, biology, and CAD design from other members.

33

References:

AAS. Zoology Archive – Stomach Acid. Newton. Ask A Scientist. Available at:

http://www.newton.dep.anl.gov/askasci/zoo00/zoo00114.htm. Accessed 28

January 2009.

ACH. 2000. Laboratory waste management and Disposal. AnalChem. Available at:

http://delloyd.50megs.com/hazard/labwaste.html#act. Accessed 1 May 2009.

Asenjo, J. A., and J.C. Merchuk. 1995. Bioreactor System Design. New York, N.Y.:

Marcel Dekker, Inc.

Bowen, R. 2002.Gastrointestinal Motility and Smooth Muscle. Colorado State

University. Fort Collins, CO. Available at: http://www.vivo.colostate.edu.

Accessed 26 October, 2008.

Bowen, R. 1998. Mucus and Mucins. Colorado State University. Fort Collins, CO.

Available at: http://www.vivo.colostate.edu. Accessed 27 October, 2008.

CAC. 2002. Center for Applied Catalysis. South Orange, NJ: Seton Hall University.

Available at http://artsci.shu.edu/chemistry/cac/faccontinuous.htm. Accessed 10

December 1008.

Campbell, N. 1987. Biology, 1st Ed. Menlo Park, CA. Benjamin/Cummings Publ. Co,

Inc.

Carter, J. S. Atoms, Molecules, Water, pH: 2 November 2004. Batavia, OH University of

Cincinnati Clermont College. Available at:

http://biology.clc.uc.edu/courses/bio104/atom-h2o.htm . Accessed 27 October

2008.

34

CDER. 2003. Drug Applications. U.S. Food and Drug Administration. Center and Drug

Evaluation and Research. Available at:

http://www.fda.gov/cder/regulatory/applications/laws.htm. Accessed 1 May

2009.

Chaplin, M. 2004. Membrane Reactors. Enzyme Technology: 20 December 2004.

London, London: London South Bank University. Available at:

http://www.lsbu.ac.uk/biology/enztech/membrane.html. Accessed 13 December

2008.

Corring, T, and Rerat, A. 1983. A Survey of Enzymatic Digestion in Simple-Stomached

Animals. In Digestion and Absorption of Nutrients. Jouy-en-Josas, France: Hans

Huber Publishers.

Desnuelle, P., ed. 1986. Molecular and Cellular Basis of Digestion. New York, NY:

Eslevier.

Dubois, A. and Castell, D.O. 1984. Esophageal and Gastric Emptying. Florida: CRC

Press.

Foltmann, B. 1986. Pepsin, chymosin and their zymogens. In Cellular and Molecular

Basis of Digestion. New York, NY: Elsevier Science Publishers.

Forstner G.G and Forstner, J.F. 1986. Structure and function of gastrointestinal mucus.

In Molecular and Cellular Basis of Digestion. New York, NY: Elseiver Science

Publishers.

Friedman, M.H.F, ed. 1975. Functions of the Stomach and Intestine. Baltimore, MD:

University Park Press.

Frokjaer, S., Hovgaard, L. 2000. Pharmaceutical Formulation: Development of Peptides

and Proteins. 189-205. Philadelphia, PA. Taylor & Francis Inc.

Galavotti, D. 2008. Bioreactor, particularly for bioartifical organs. U.S.

Patent 7371567

Harrison, R.G., P. Todd, S.R. Rudge, and D.P. Petrides. 2003. Bioseparations Science

and Engineering. New York, N.Y.: Oxford University Press.

HMS. 2008. Normal Human Body Temperature: 2000-2008. Harvard Health

Publications. Harvard Medical School. Available at:

http://www.health.harvard.edu. Accessed 27 October 2008.

Jacobson, E.D., ed. 1972. Gastrointestinal Physiology. Physiology Series 1(4).

Baltimore, MD: Buttersworth University Park Press.

35

HMS. 2008. Normal Human Body Temperature: 2000-2008. Harvard Health

Publications. Harvard Medical School. Available at:

http://www.health.harvard.edu. Accessed 27 October 2008.

KW. The Real Secret to Better Health Digestive Enzymes. Elite-Zyme Pro. Kangen

Water. Available at: http://www.yourzymes.com/. Accessed 28 January 2009.

Lin, Y. H. 2008. Multi-ion-crosslinked nanoparticles with pH-responsive characteristics

for oral delivery of protein drugs. Journal of Controlled Release, doi:

10.1016/j.jconrel.2008.08.020.

Louvard, D., Reggio, H., and Coudrier, E. 1986. Cell surface

asymmetry is a prerequisite for the function of transporting and secreting

epithelia. In Molecular and Cellular Basis of Digestion. New York, NY: Elsevier

Science Publishers.

Mackenzie, J. D. 1886. Continuous Rectal Alimentation; An Artificial Stomach. The

British Medical Journal: 1161.

NEAVS. 2008. Project R & R Glossary. Release and Restitution for Chimpanzees In U.S.

Laboratories. Boston, MA: New England Anti-Vivisection Society. Available at

http://www.releasechimps.org/resources/glossary/. Accessed 10 December 2008.

SAPN. 2006. Digestive Enzymes. Biology-Online.org: Scientific American Partner

Network. Available at: http://www.biologyonline.org/articles/digestive_enzymes.html. Accessed 27 October 2008.

Scheele, G. 1986. Early Biochemical events in the biogenesis and topogenesis of

secretory and membrane proteins. In Molecular and Cellular Basis of Digestion.

New York, NY: Elsevier Science Publishers.

Shuler, M.L., and F. Kargi. 2001. Bioprocess Engineering Basic Concepts. 2nd ed. New

York, N.Y.: Prentice Hall

Silk, D.B.A, and Keohane, P.P. 1983. Digestion and Absorption of Dietary Protein in

Man. In Digestion and Absorption of Nutrients. Jouy-en-Josas, France: Hans

Huber Publishers.

Smith, E. Margaret and Morton, G. Dion. 2001. The Digestive System. Elsevier Health

Sciences.