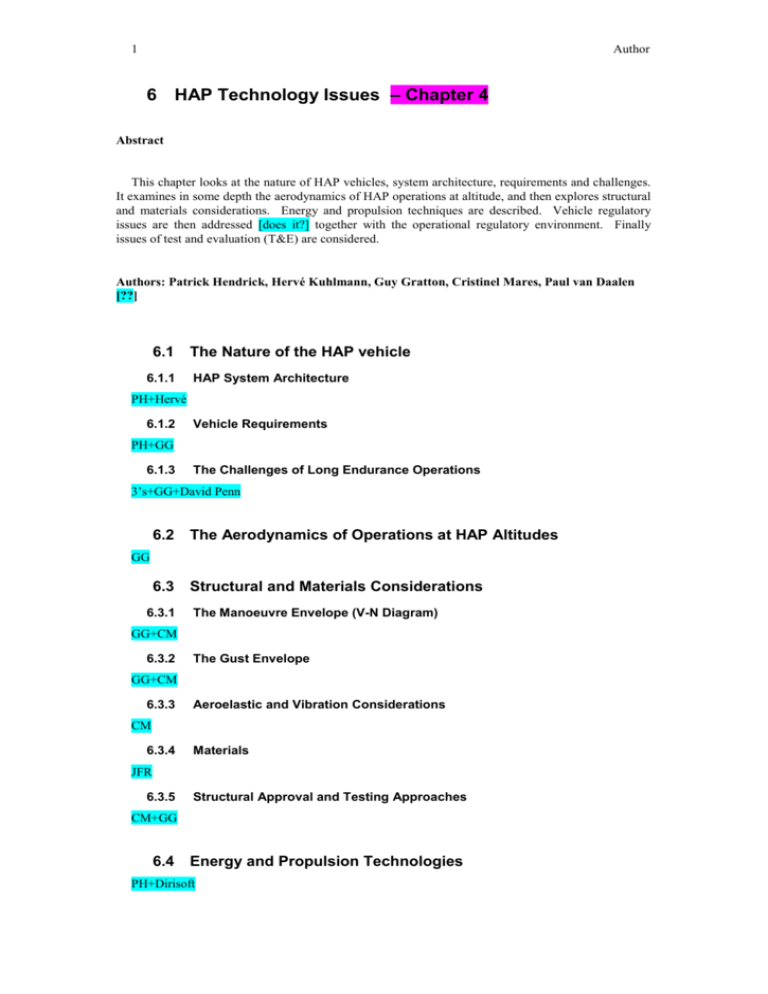

6 HAP Technology Issues – Chapter 4

advertisement

1 Author 6 HAP Technology Issues – Chapter 4 Abstract This chapter looks at the nature of HAP vehicles, system architecture, requirements and challenges. It examines in some depth the aerodynamics of HAP operations at altitude, and then explores structural and materials considerations. Energy and propulsion techniques are described. Vehicle regulatory issues are then addressed [does it?] together with the operational regulatory environment. Finally issues of test and evaluation (T&E) are considered. Authors: Patrick Hendrick, Hervé Kuhlmann, Guy Gratton, Cristinel Mares, Paul van Daalen [??] 6.1 6.1.1 The Nature of the HAP vehicle HAP System Architecture PH+Hervé 6.1.2 Vehicle Requirements PH+GG 6.1.3 The Challenges of Long Endurance Operations 3’s+GG+David Penn 6.2 The Aerodynamics of Operations at HAP Altitudes 6.3 Structural and Materials Considerations GG 6.3.1 The Manoeuvre Envelope (V-N Diagram) GG+CM 6.3.2 The Gust Envelope GG+CM 6.3.3 Aeroelastic and Vibration Considerations CM 6.3.4 Materials JFR 6.3.5 Structural Approval and Testing Approaches CM+GG 6.4 Energy and Propulsion Technologies PH+Dirisoft 2 Author 6.4.1 Launch and Station Keeping 6.4.2 Current Technologies 6.4.3 Future Developments 6.5 The (Likely) Vehicle Regulatory Environment EASA+PH 6.6 The (Likely) Operational Regulatory Environment EASA+PH 6.7 6.7.1 Test and Evaluation Introduction The test and evaluation (T&E) process has become fundamental to all aerospace product development, and indeed now within the aerospace professions is regarded as a separate discipline. This vital specialism will inevitably be extended to the development, approval and use of high altitude platforms. The main reasons why T&E needs to be formalised and regarded as important can be divided as follows: Basic safety establishment Both for purposes of professionalism, and inevitably insurance and public liability, it is essential that an acceptable level of safety is established and deemed to be acceptable. Risk Reduction Risk in this context is not that of safety, but technical risk – that of project or mission failure. It is likely that any competent vehicle customer will specify a minimum mission failure rate, but also the basic project success must be achieved within time and budget. Additionally, it is likely that as HAPs mature commercially, mission reliability will become an important sales factor to be established and improved upon. Performance characterisation The performance of the vehicle must be established. At the first order this will include climb, cruise and descent performance, range and endurance, and the range of flying speeds available at each operating altitude. This basic information however will also lead to derivation of mission profiles and in particular loiter turn radii – which will be fundamental to the design of most onboard and communicating ground-based equipment. A further consideration however is those topics which in a manned aircraft would be described as ‘stability and control’, ‘dynamic stability’ or ‘flying qualities’. All aircraft suffer to some extent oscillations about the planned steady flightpath, and these again will need to be understood in order to optimise associated equipment design. 3 Author Certification All spacecraft, and virtually all manned aircraft require some form of formal design certification. For aircraft the standards are laid down either by national military authorities, or by authorities who have delegated powers from ICAO – the International Civil Aviation Organisation, which was established by the Chicago Convention of 1944. In the latter case, for most projects based in Europe, EASA – the European Aviation Safety Authority – is likely to be the functioning delegated authority, although they may routinely delegate tasks to national organisations such as the CAA – the Civil Aviation Authority (UK), or DGAC – Directional General Aviation Civile (France). For the USA, the parallel organisation is the FAA – Federal Aviation Administration, whose rulings tend often to have significant global influence. Spacecraft certification tends to be administered by individual launch agencies, most notably ESA: European Space Agency, or NASA – the (US) National Aeronautics and Space Administration. Data must be obtained sufficient to satisfy the applicable authority or authorities (for international, or mixed military/civil operations, multiple authorities are likely) that certification requirements have been met. T&E itself will normally be divided into two primary sub-disciplines, ground and flight testing – although these have their own sub-sub disciplines, described below, and all of the four requirements above are likely to need to be met within each T&E sub-discipline. Considering the sub-disciplines within ground and flight testing, we have:- Ground Testing Ground testing will in the first and largest instance be for the purpose of demonstrating that a vehicle may reasonably be flight tested. This will generally divide into three primary components: structural testing (which will normally be a supplement to structural analysis); environmental testing (demonstrating in the lab environment that the vehicle should adequately function within the eventual operating environment); and system functionality. Flight Testing Flight testing is likely in the first instance to concentrate upon basic performance, controllability and reliability of the airborne vehicle. However, it must be recognised that the primary purpose of a HAP is the carriage of a mission payload, and hence once these early basics have been established, the flight test programme should increasingly concentrate upon systems integration: ensuring the utility of the basic mission systems, the operational safety management system, and the operator workstations and individual competences. Expertise in T&E exists at a high level, and it would be foolhardy for general programme teams to attempt to re-learn this without engaging with those specialist parts of the aerospace industry. In this regard there are two groupings of independent organisations who can be called upon for individual or published advice: the latter existing both through the format of manuals, and the more academic format of conferences and peer-reviewed journals. The first such grouping is of national and international aerospace organisations. The two largest of these are the American Institute of Aeronautics and Astronautics (AIAA), and the UK based Royal Aeronautical Society (RAeS): both contain substantial expertise on T&E and routinely publish documents and hold conferences covering various aspects of the field. The second such grouping is that of practitioner societies, who exist to share “lessons learned” and best practice. The oldest of these is the Society of Experimental Test Pilots [1], whilst also there is the SFTE [2]: Society of Flight Test Engineers. Both are headquartered in California, which is the historic centre of a large portion of global flight testing, but are represented internationally. These two organisations jointly also established the Flight Test Safety Committee [3], which publishes a great deal of basic advice. All three organisations hold numerous conferences globally, with one by each annually in Europe, rotating around the countries with the larger aerospace industries. It is likely that organisations lacking substantial existing T&E expertise may find what it requires within the memberships of either SETP or SFTE, both of whom have been concerning themselves with unmanned vehicle testing for some years. 4 6.7.2 Author Ground testing [4, 5] Ground structural testing The first consideration of airborne vehicle ground testing will certainly be the basic strength of the flight vehicle. At the time of writing, universal requirements for structural certification of a HAP have not been agreed, although at section 6c of this book, the authors venture their views on the most likely requirements. Fig. 6.1 below illustrates the likely envelope required of a HAP, which will most likely have characteristics around the following: N1 (maximum positive g limit) = 2.5 g N3 (maximum negative g limit) = -1.25 g VD (design maximum speed) = 51 m/s Gust loads: 7.62 m/s at VD, 15.24 m/s at VC VC gust line g 3 C A D 2 VD gust line 1 VA 0 VC VNE VDF VD Airspeed -1 -2 G -VD gust line E F -VC gust line BFSL 6 Fig. 6.1 Likely HAP flight envelope These will be used for determining the limit loads upon a structure, that is the maximum loads which it is expected to see through its service life. For approval purposes, these values must be multiplied within normal airworthiness practice by safety factors. At present there is insufficient maturity of HAP design and approval practice to define these; however there is little reason to believe that for operation above populated areas these may be reduced below those contained in the common civil airworthiness standards, which are summarised in Table 6.1. Table 6.1 Typical safety factors found in civil airworthiness standards 5 Author Usual Para 303 619 621 623 625 657 693 626 and 693 Reason Normal ultimate safety factor Composite primary structure Cast component Bearing at bolted or pinned joint Fitting factor (bolted or riveted joint) Hinge Rotating joint (except for cables, ball-bearings or roller-bearings) Cable systems, including joints Minimum factor 1.5 1.5 2.0 2.0 1.15 Overall factor not to be less than 6.67 Overall factor not to be less than 3.33 Overall factor not to be less than 2.0 These factors are generally combined, so that for example in considering a composite wing mainspar for a +2.5 g HAP (the Altus HALE UAV shown in Fig. 6.2 Error! Reference source not found.is such an example), the total safety factor is likely to be 1.5 x 1.5 = 2.25. So, the total load that the mainspar is expected to demonstrate is proportional to 2.5 x 2.25 = 5.625 g. Fig. 6.2 NASA Altus HALE UAV - a lightweight airframe of primarily composite construction (Courtesy of NASA) This value, of limit load multiplied by total safety factor, is referred to as the ultimate load. This does not mean that it is expected to fail at this higher load, but that it is not expected to fail below this load. The actual load at which something has been proven or predicted to fail is the Failure load. A further concept is that of Proof Load, which is limit load multiplied by the proof factor; for most vehicles the proof factor will 1, so proof load = limit load, however this may not always be true and in particular the use of the concept of proof load and a reduced factor to get experimental vehicles initially airborne for evaluation purposes may be helpful – subject of-course to the agreement of any overseeing authority. It is a requirement that an aircraft structure must withstand the proof load indefinitely without permanent deformation, and the ultimate load for a short time (typically 3 seconds) without catastrophic deformation. The degree to which this last requirement is met, is defined by the Reserve Factor, RF, thus: Reserve factor = Failure load Ultimate load 3.1.1 (6.1) In American airworthiness practice, this may instead be stated as the Margin of Safety, where margin of safety = reserve factor – 1. Both are only quoted to three significant figures, since greater precision 6 Author would be misleading, and materials data is rarely, if ever, accurately available to a greater level of accuracy in any case. So, the structural reports into any aircraft structure must have the objective of showing throughout that RF ≥ 1. Depending upon the nature of evidence, to what extent RF must exceed 1, can be subjective and must be agreed between the proposing and approving engineers. For example, if it is intended to justify the strength of a complex component by use of a finite element (FE) model alone, then the inevitable uncertainty over the validity of an FE model (which is usually intended as a design, rather than a certification tool) must necessitate a larger value – usually greater than 1.3 although in extreme cases this might need to exceed 2.0. This is the reason why in practice FE (or other analytic methods) are almost invariably supported by test – if the computer model can be verified at a selection of points (or at the very least, at the most safety critical) then this allows a value of RF closer to 1.0 to be employed with good confidence. It is possible to interpret this as subjective, and it often is – except where it is possible to claim clear precedent with the same certifying authority (the engineering equivalent of case law), then it is invariably necessary for all parties to agree to the minimum values of RF that will be accepted for each part of a structure, approved to what method, before too great an expense has been incurred. Of course, the search (at least on the part of the designers) will always be for a value of RF that is as close to 1.0 as possible, since any value greater than that (or greater than can be agreed with the relevant authority) inevitably represents excess weight, which almost certainly degrades the aircraft’s performance in its designed role. Note: The terminology used above is that common in civil aircraft approvals in the United Kingdom. Inevitably other environments may use slightly different terminology, and readers should always ensure that they understand the terminology used in their own place of study or work – there is no absolutely correct terminology. There will be a large number of structural cases to be established, investigated and proven for any vehicle, but the main cases will normally be: 6.7.2.1 6.7.2.2 6.7.2.3 6.7.2.4 6.7.2.5 Main lifting surface (wing) structure, including attachments and fuselage carrythroughs Payload attachments (for flight, landing, and crash loads) Powerplant attachments (including torque loadings, thrust loadings and crash loads) Ground contact structure (undercarriage or similar, including take-off and landing cases) Stabilising structure (e.g. tailplane, canard, control surfaces – including critical extremes of weight and CG position, combined with speed). Ground environmental testing For the purposes of a HAP, there are two primary areas of ground environmental testing which must be considered: these relate to radiation/temperature and vibration/flutter. Thermal testing In the case of radiation and temperature extremes, the first and most obvious case will be of solar radiation. Equipment must function under high altitude solar radiation levels which are likely to approach 1.4 kW/m²[ 6 ]: providing both the opportunity for power generation and the penalty of heating. Testing is likely to require a flight-representative vehicle – not necessarily fit for flight (so this can for example be dual-roled with a structural test specimen which will not be flown), but with representative thermal and system characteristics. The design and provision of testing facilities may be non-trivial since the external atmospheric and radiation characteristics of a typical ground-based laboratory will not be representative of the conditions at altitude and a degree of engineering judgement will be required in provision of these test facilities. It is likely that the most efficient manner in which this aspect of T&E can be carried out is initially through analysis of the system boundary thermodynamics during operational use, allowing construction of a conservative physical simulation of 7 Author operating conditions using reasonably affordable ground based facilities – representing reasonably accurately the radiation profile falling on the vehicle, the vehicle’s power consumption and operation of systems, and the surrounding atmospheres insulative/conductive properties. This will, inevitably be unrepresentative to some extent, hence the requirement to justify testing through thermodynamic analysis and to include a degree of conservatism in test planning. Additionally to this however, the HAP operating environment will be within the lower stratosphere or middle stratospheres (see Fig. 6.3), where temperatures are likely to be in the region of -40°C to 60°C (233 – 253 K). Within the core structure of the vehicle, around heat-wasting systems these low temperatures will not be experienced, but at extremes – in particular load bearing control or lifting surfaces at the extremes of the HAP structure – these low temperatures will be experienced which will modify materials properties and may reduce their strength below acceptable limits. To some extent, this may be resolvable using already published materials data, but in many cases physical testing to destruction of discrete pieces of HAP structure may be needed, in order to establish integrity at extremes of operating condition. 100,000 Altitude, feet 80,000 60,000 40,000 20,000 0 -80 -60 -40 -20 0 20 40 Air temperature, °C Fig. 6.3 temperature variation with altitude (International Standard Atmosphere: temperate conditions) [source/ack?] Vibration testing There are two primary sources of oscillatory excitation available within a HAP vehicle in flight. These are the engine, and von-Karman vortex shedding. Any propulsive device will contain moving parts of some description, either reciprocating or rotating, and this motion will create vibration within the vehicle structure, probably at multiple frequencies, each a function of the powerplant’s operating frequency. Additionally, behind any structure in a fluid flow (in this case, that is part of any flying structure of a vehicle in forward flight) there is potential for von-Karman vortex shedding, as illustrated in Fig. 6.4 below on a larger scale. Either may generate frequencies which coincide with natural resonant frequencies within the structure and this coincidence may cause damage. Where this is within the internal structure it is normally referred to as resonance, or within an aerodynamic shape excited as von Karman shedding, as flutter. Testing can be conducted to some extent on the ground through instrumentation of a flight vehicle for vibration. By running powerplant and/or systems it is possible to identify the frequencies generated, most likely by reference to powerplant or reciprocating system operating speeds (e.g. 3 per rev, 7 per rev, etc. - known generically as “N per rev vibrations”). There are tools available to attempt prediction of von Karman vortex shedding at given operating conditions (based upon estimates of the Reynolds and Strouhal numbers[7, 8, 9]) but in practice these are estimating methods with significant uncertainty 8 Author of outcome. At the same time, it is relatively straightforward to determine the main airframe / vehicle structural resonant frequencies by applying a percussive load to the structure and measuring the resonant response. So far as can reasonably be established, it should be ensured that airframe resonant frequencies do not closely coincide with either frequencies due to powerplant and systems, or due to predicted vonKarman shedding from major airframe components. (There is likely to be a requirement for further flutter testing in flight, which is discussed later). A good example of such a programme, albeit for a manned aeroplane, is shown at reference [10]. Fig. 6.4 von Karman vortex shedding in cloud from satellite image (courtesy of NASA/ GSFC/ LaRC/ JPL) Ground testing for systems demonstration and integration The basis for most ground systems testing is what is colloquially known as the “iron bird” – a lab based systems assembly which can be used in order to determine the controllability and interoperability of all systems. The HAP environment presents some interesting challenges here, since it is very likely that the payload and flight vehicle will be developed entirely separately with a degree of necessary secrecy between airframe and payload development teams, and thus it may require managerial direction to force these together. Failure to do so has significant potential to result in programme failure, and has been known to occur in both manned and unmanned aerial vehicle programmes. It is likely that an iron bird simulator programme will parallel the ground structural investigation programme but may also be in series with the development and testing of operator ground stations, since these can be inter-operated in order to maximise the realism of both, in particular using evaluation of the operator workstation to ensure that the spectrum of operation of the iron bird is as realistic as possible. The iron bird should, as far as possible, represent the true collection of flight systems components, so that any failures or incompatibilities which might occur in flight can be identified and corrected before the commencement of flight testing. This may often seem like a delaying and expensive luxury, particularly to designer and programme managers with a high degree of confidence in their design process. However, compared to the cost of a failure during a flight test programme it is invariably a relatively inexpensive insurance measure within the development of any complex vehicle. A further component of ground testing here is EMC: Electro Magnetic Compatibility testing. EMC testing need not be an expensive part of the programme, and is likely to be conducted using the actual flight vehicle late in its development but before first flight. EMC testing is conducted by operating all systems, with each non-essential system (mostly payload systems) being shut-down then restarted in turn whilst overall systems operation is monitored. This is essential, particularly in order to ensure that payload systems, which may well have their own external communications role, cannot interfere with flight management systems – ultimately flight management systems must be protected since without their continued and continuous operation, an unacceptable potential to lose the entire vehicle exists. There has been one recent high profile instance of a low altitude UAV prototype being lost in such a manner[11], and the risks to HAPs are identical. This requirement for EMC testing in HAPs must be 9 Author regarded as an absolute, with a repeat requirement at the change of any internal or external radio frequency or electromagnetic characteristic. This should not be an onerous requirement since often a full test can take less than an hour, with all flight facilities available, and it is achievable on the day of a test flight. 6.7.3 Flight testing 6.7.4 Through life testing Bibliography [1] [2] [3] [4] [5] [6] [7] [8] [9] [10] [11] http://www.setp.org http://www.sfte.org http://www.flighttestsafety.org/ Dr. Guy Gratton, Brunel (University) Flight Safety Laboratory and Facility for Airborne Atmospheric Measurements Dr. Cristinel Mares, Brunel University. Pidwirny, Michael (Lead Author); Kevin Vranes (Topic Editor). 2008. "Solar radiation." In: Encyclopedia of Earth. Eds. Cutler J. Cleveland (Washington, D.C.: Environmental Information Coalition, National Council for Science and the Environment). [First published in the Encyclopedia of Earth October 20, 2006; Last revised December 2, 2008; Retrieved May 15, 2009]. Kim, K. J. and Durbin, P. A. (1988) Observations of the frequencies in a sphere wake and drag increase by acoustic excitation, Physics of Fluids, 31, pp. 3260-3265. Sakamoto, H. and Haniu, H. (1990) A study on vortex shedding from spheres in uniform flow, Journal of Fluids Engineering, 112(December), pp. 386-392. White, Frank M. Fluid Mechanics 4th edition 1999, McGraw Hill, ISBN 0-07-116848-6 MW Kehoe and DF Voracek, Ground vibration test results of a JetStar airplane using impulsive sine excitation, NASA TM-100448 dated February 1989. S Swartz and A Fabiszak, Lessons Learned From a Scan Eagle UAV Inadvertent Departure From Controlled Flight Shortly After Take-off While on Autopilot, presentation to the 29th San Diego Symposium of the Society of Experimental Test Pilots, March 2009