Transmission Maintenance & Work Management

advertisement

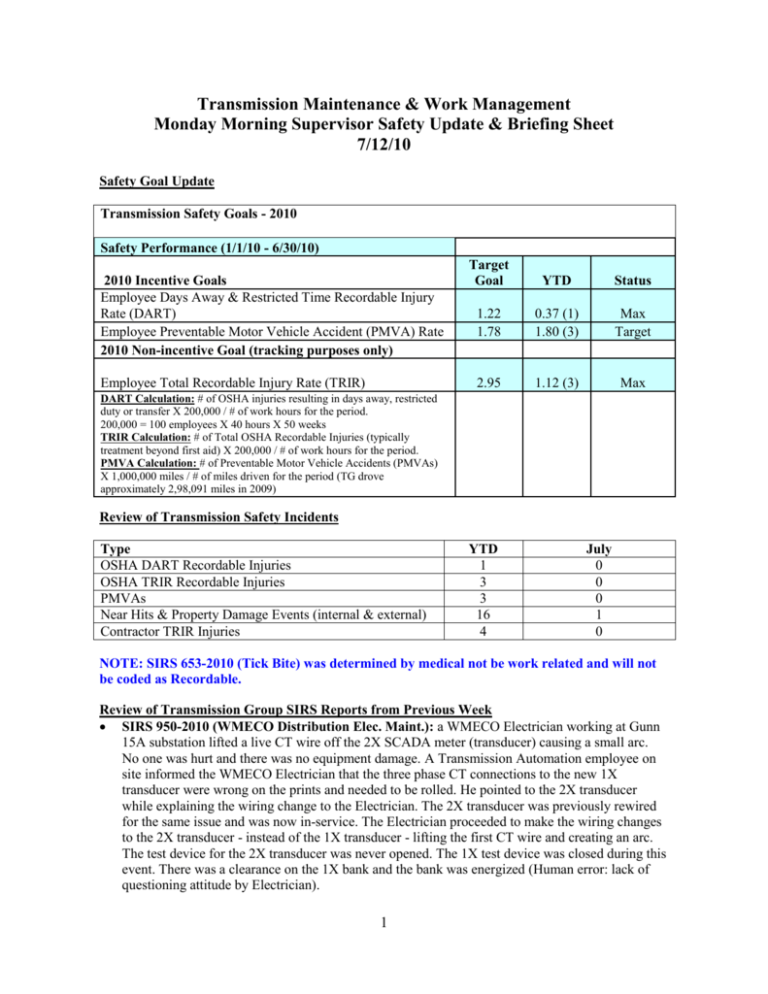

Transmission Maintenance & Work Management Monday Morning Supervisor Safety Update & Briefing Sheet 7/12/10 Safety Goal Update Transmission Safety Goals - 2010 Safety Performance (1/1/10 - 6/30/10) 2010 Incentive Goals Employee Days Away & Restricted Time Recordable Injury Rate (DART) Employee Preventable Motor Vehicle Accident (PMVA) Rate 2010 Non-incentive Goal (tracking purposes only) Employee Total Recordable Injury Rate (TRIR) Target Goal YTD Status 1.22 1.78 0.37 (1) 1.80 (3) Max Target 2.95 1.12 (3) Max DART Calculation: # of OSHA injuries resulting in days away, restricted duty or transfer X 200,000 / # of work hours for the period. 200,000 = 100 employees X 40 hours X 50 weeks TRIR Calculation: # of Total OSHA Recordable Injuries (typically treatment beyond first aid) X 200,000 / # of work hours for the period. PMVA Calculation: # of Preventable Motor Vehicle Accidents (PMVAs) X 1,000,000 miles / # of miles driven for the period (TG drove approximately 2,98,091 miles in 2009) Review of Transmission Safety Incidents Type OSHA DART Recordable Injuries OSHA TRIR Recordable Injuries PMVAs Near Hits & Property Damage Events (internal & external) Contractor TRIR Injuries YTD 1 3 3 16 4 July 0 0 0 1 0 NOTE: SIRS 653-2010 (Tick Bite) was determined by medical not be work related and will not be coded as Recordable. Review of Transmission Group SIRS Reports from Previous Week SIRS 950-2010 (WMECO Distribution Elec. Maint.): a WMECO Electrician working at Gunn 15A substation lifted a live CT wire off the 2X SCADA meter (transducer) causing a small arc. No one was hurt and there was no equipment damage. A Transmission Automation employee on site informed the WMECO Electrician that the three phase CT connections to the new 1X transducer were wrong on the prints and needed to be rolled. He pointed to the 2X transducer while explaining the wiring change to the Electrician. The 2X transducer was previously rewired for the same issue and was now in-service. The Electrician proceeded to make the wiring changes to the 2X transducer - instead of the 1X transducer - lifting the first CT wire and creating an arc. The test device for the 2X transducer was never opened. The 1X test device was closed during this event. There was a clearance on the 1X bank and the bank was energized (Human error: lack of questioning attitude by Electrician). 1 Review of Significant NU SIRS Reports from Previous Week: SIRS 947-2010 (CL&P Line Dept.): While switching out to make the DB pad on research pkwy dead, in order to replace it, a switching error occurred. The lead splicer and splicer had a tailboard and both understood the steps and were wearing full PPE. The splicer was parking the primary from Pad 63 to Pad 45(the one needing replacement) he pulled and parked phase 3 and 2, when he went to pull and park phase 1 he installed it in the phase 2 energized bushing. Once the crossphase occurred they heard 2 loud noises but no flash occurred. They went and checked the pads on either side of this location for damage. SIRS 887-2010 (CL&P Elec. Maint.): Planned switching was underway at South Naugatuck 21L s/s. The task was to isolate a section of the bus to allow for repairs to the damaged 21L5-4 switch. In the process of the switching the crew opened a set of disconnect switches thought to be associated with the 21L6 circuit however the switch was actually on the 21L4 circuit. When the switch was opened the 21L4 circuit was de-energized resulting in an outage to a single large customer (note: both disconnects were on the same pole and there was no nomenclature). The Supervisor recognized that the wrong switch had been opened and contacted Dispatch to restore the 21L4 circuit. The customer was out for about 30 minutes. At this point the EM Supervisor made a decision to back out of the original planned switching and repair the 21L5-4 switch at a later date. In the process of the go back switching the crews inadvertently closed the 21L5-2 breaker into workman's grounds. A full analysis will follow. Weekly Safety Topic – Top Three Myths about Workplace Injuries Top Three Myths about Workplace Injuries - And What YOU can do to Bust Them by Dr. Deb Potter and Carl Potter, CSP How many times have you heard people saying something completely ridiculous or that you know just isn’t right? You don’t have to go very far these days to encounter such statements. With everyone having their say on blogs, YouTube, and even the nightly news, you probably hear things that you just don’t agree with or that you know are fabricated several times a day. Safety is not immune. We’ve been hearing “myths” about safety for years. We took an informal poll recently, and here are our top three safety myths – you’ve probably heard them or something similar a time or two in your career. Myth #3 You cannot create a hazard-free workplace It is shocking how many people believe that no workplace can be made free of hazards. We had one person tell us that it just isn’t possible to have a workplace without hazards so he might as well lock the front door to the manufacturing plant where he was the safety director. Certainly situations change over time, sometimes even very quickly, making it difficult to identify and control hazards. It requires discipline and diligence to recognize and mitigate every hazard. “We don’t work in a dangerous environment. We work in a hazardous environment that we make dangerous by not following safe work procedures and wearing our PPE.” -Brad Miles When we understand what it takes to create an injury-free workplace, we are able to hit the target more than not. Hazards are the reason people get hurt, without the hazard there is no injury. When we fail to follow safety procedures and or wear our personal protective equipment we increase the risk of an injury. A hazard-free workplace is created by actively identifying, evaluating the risk and applying controls to physically protect employees. 2 Myth #2 Being safe takes too much time and money When people say that it takes too much time or money to be safe, they obviously don’t understand the power of a cost/benefit analysis. Have you ever considered the direct and indirect cost of even a minor injury? And, the thought of pain and agony that an injury causes should be enough to make anyone do everything they can to stay safe. "I think of attitude as an inward feeling expressed by outward behavior." -John Maxwell If you feel that being safe takes to much time and money you have an attitude problem. In our work we continually meet individuals who have been injured and by their own admission, the cost of recover and lost wages is substantial. A personal injury impacts the productivity of the company, the earning power of the individual who is injured and takes valuable quality time away from families. Myth #1 Accidents just happen Research shows that over 99% of all accidents are preventable. If you think that accidents just happen, then what allows you to drive down the road, walk down the sidewalk, or even live in your home without great fear. The reality is that you have a great deal of control over the circumstances around you. "Fate is the hunter for those least prepared." -Ernest K. Gann In the high-risk environment of electric utilities it is vital that workers understand the importance knowing how to prevent personal injuries. Any utility worker who thinks that working safe is a matter of fate is a danger to themselves and co-workers. Fate is the hunter, but the worker who prepares by learning everything they can about working safe is less likely to be injured. When conducting a job briefing the fates are dismissed by taking time to identify any hazards. When the worker believes that they have no control they are likely to miss a hazard and in turn miss preparing themselves to hit the goal of nobody gets hurt. "Remember, people will judge you by your actions and not your intentions." -Carl Potter Safety is an action word, but most of the time we treat it as something passive. Be Safe, have a safe trip or make safety your first concern. To make something safe takes action and requires one to do something. That something is to recognize what can cause an injury (hazard) and then take steps to control it in a manner that ensures nobody gets hurt. Many leaders think that leading people to work safe means showing support by flipping burgers at the annual safety meeting. This is great to help show servant leadership, but that is not what people in the field want to have happen. They want leadership! A leader is one who knows how to rally the people behind a cause and is willing to walk the talk. Employees want a leader who will challenge them to continually be better at working safe. A leader who says, "I don't want you to get hurt producing, transmitting or distributing our product and I am willing to work with you to make sure that happens." Creating a workplace that targets zero-injuries is not a gimmick or a new safety program, it is a workplace where everyone cares enough to engage in the safety process. To create such a workplace the organizations need leadership and leadership is at all levels. Will you take action to engage and challenge the people you work with or are you just talking about safety? Carl Potter, Certified Safety Professional and Deb Potter, PhD are Certified Management Consultants who work with organizations that want to create an environment where nobody gets hurt. As advocates of a zero-injury workplace, they are speakers, authors, and consultants to industry. As a general aviation pilot, Carl enjoys infusing aviation safety principles into his workplace programs. For information about the Hazard Recognition and Control Workshop, contact them at. 800-259-6209 or www.HazardRecognitionWorkshop.com 3