Fig 2. Ammonia reactor with feedback control

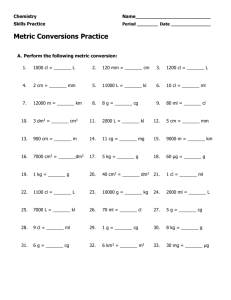

advertisement

Control of unstable ammonia reactor

Thomas Realfsen

Chemical Engineering, Norwegian Univ. of Science and Technology (NTNU)

Trondheim, Norway

November,2000

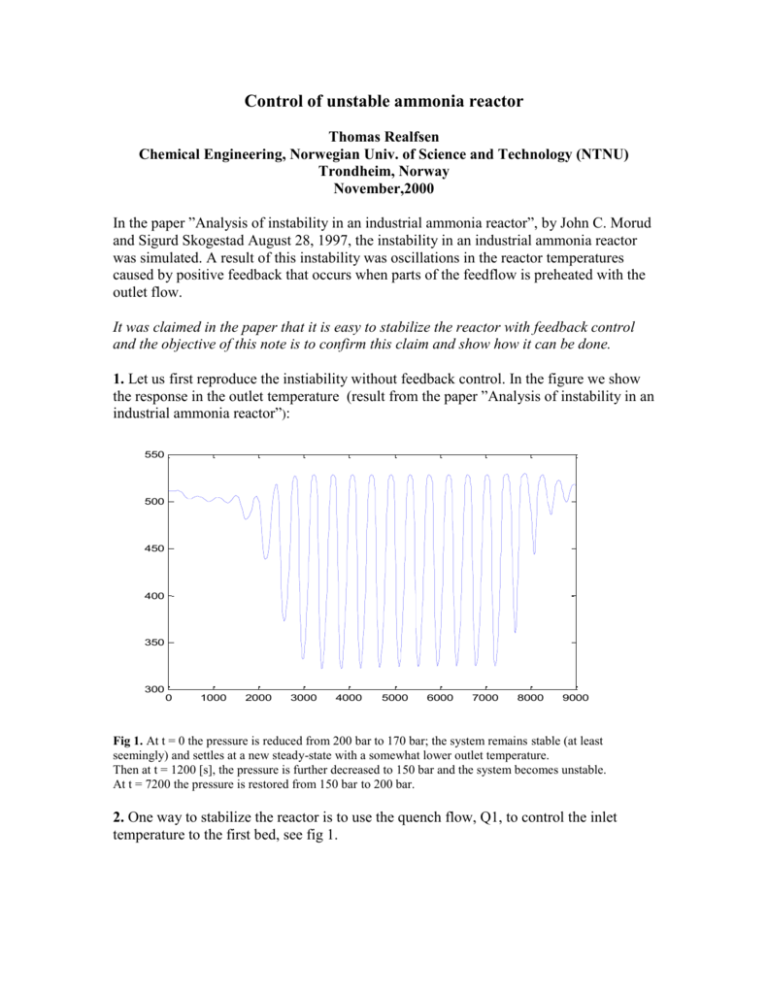

In the paper ”Analysis of instability in an industrial ammonia reactor”, by John C. Morud

and Sigurd Skogestad August 28, 1997, the instability in an industrial ammonia reactor

was simulated. A result of this instability was oscillations in the reactor temperatures

caused by positive feedback that occurs when parts of the feedflow is preheated with the

outlet flow.

It was claimed in the paper that it is easy to stabilize the reactor with feedback control

and the objective of this note is to confirm this claim and show how it can be done.

1. Let us first reproduce the instiability without feedback control. In the figure we show

the response in the outlet temperature (result from the paper ”Analysis of instability in an

industrial ammonia reactor”):

550

500

450

400

350

300

0

1000

2000

3000

4000

5000

6000

7000

8000

9000

Fig 1. At t = 0 the pressure is reduced from 200 bar to 170 bar; the system remains stable (at least

seemingly) and settles at a new steady-state with a somewhat lower outlet temperature.

Then at t = 1200 [s], the pressure is further decreased to 150 bar and the system becomes unstable.

At t = 7200 the pressure is restored from 150 bar to 200 bar.

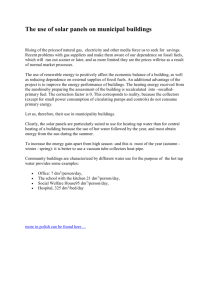

2. One way to stabilize the reactor is to use the quench flow, Q1, to control the inlet

temperature to the first bed, see fig 1.

Fig 2. Ammonia reactor with feedback control

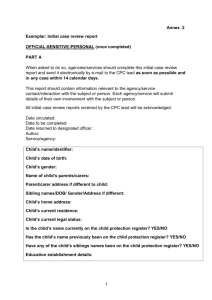

Simulation of the pressure reduction using this feedback structure with simple

proportional control shows that we have a stable system:

515

510

505

500

495

490

0

1000

2000

3000

4000

5000

6000

7000

8000

9000

Fig3. Feedback control of inlet temperature . At t = 0 the pressure is reduced from 200 bar to 170 bar; and

then at t = 1200 [s] the pressure is further decreased to 150 bar . The system remains stable!

At t = 7200 the pressure is restored from 150 bar to 200 bar.

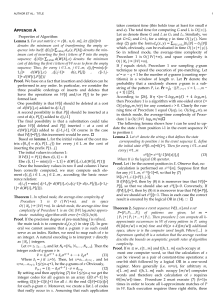

3. Now try another simulation (with feedback) where at t = 1200 [s] the pressure is

reduced from 200 bar to 150 bar. Again the system remains stable:

512

510

508

506

504

502

500

498

496

494

492

0

1000

2000

3000

4000

5000

6000

7000

8000

9000

Fig4. The outlet temperature stabilized at a new lower steady-state.

How to produce the results in figure 1,2,3 and 4:

Go to subdirectory control and see matlab files reguleringsim.m and concprof.m (the files

are also listed below)

.

-To reproduce the unstability in figure 1, the percentage signs in front of section 1 must

be deleted (let the percentage signs in front of section 2 and 3 remain).

-To reproduce the results from figure 3, the percentage signs in front of section 1 and 3

must be deleted (the percentage signs in section 2 must remain).

-To reproduce figure 4, the percentage signs before section 2 and 3 must be deleted (the

percentage signs in section 1 must remain).

To reproduce the results made in this paper it’s enough to make the changes in the matlab

file reguleringsim. The product concentration can also be produced, the changes above

must then also be made in the matlab file concprof (it’s done this way to prevent that the

concentration plot follows the iterations made in the ode-solver).

APPENDIX: FILES

main.m

clear all

startup

fcorr=0.5; epsnr=1.e-4;

%problems (fcorr=0.5)

% decrease fcorr if convergense

Tinit=linspace(360,510,30);

%To = 511.565

% gives upper steady-state ;

Tss1=ssnr(Tinit,fcorr,epsnr); % steady-state vector

t_start=0;

t_end=9000;

tspan=[t_start t_end];

[tid,T]=ode15s('reguleringsim',tspan,Tss1);

%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%

Cvec=[];

for i=length(tid):-1:1

c=concprof(tid(i),T(i,:)');

Cvec(i,:)=c(:)';

end

%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%

figure(1)

plot(tid,T(:,1))

figure(2)

plot(tid,T(:,30))

figure(3)

plot(tid,Cvec(:,30))

reguleringsim.m

function Tprime=reguleringsim(t,T)

global mc mh Cp Cpc Q1 Q2 Q3 Npoint Tf cf dm1 dm2 dm3 dHrx

u conc p

% comment: For simplicity we use rx((T(i),c(i-1)) rather

%than rx((T(i),c(i))

%section1.--Reconstruction of unstable ammonia reactor----%

if t<1200

p=170;

elseif (t>=1200 & t<=7200)

p=150;

else t>7200

p=200;

end;

%---------------------------------------------------------%

%section2.--New steady-state------------------------------%

%if t>1200

%

p=150;

%else

%

p=200;

%end;

%---------------------------------------------------------%

%section3.--P-controller----------------------------------%

%Kc=3;

%Q1=16.11+Kc*(T(1)-369.4); % positiv feedback, e=y-r

%mc=mh-(Q1+Q2+Q3);

%---------------------------------------------------------%

m1=mc+Q1;

m2=m1+Q2;

m3=m2+Q3;

% Conc. in bed 1:

c(1)=cf+dm1*rx(T(1),cf)/m1;

for i=2:10

c(i)=c(i-1)+dm1*rx(T(i),c(i-1))/m1;

end

% Quench 2:

cin2=m1/m2*c(10)+Q2/m2*cf;

% Conc. in bed 2

c(11)=cin2+dm2*rx(T(11),cin2)/m2;

for i=12:20

c(i)=c(i-1)+dm2*rx(T(i),c(i-1))/m2;

end

% Quench 3:

cin3=m2/m3*c(20)+Q3/m3*cf;

% Conc. in bed 3

c(21)=cin3+dm3*rx(T(21),cin3)/m3;

for i=22:30

c(i)=c(i-1)+dm3*rx(T(i),c(i-1))/m3;

end

%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%

% Quench 1:

Ti=hx(T(30),Tf); Tin1=mc/m1*Ti+Q1/m1*Tf;

% dTdt in bed 1:

dTdt(1)=(m1*Cp*(Tin1-T(1))+dm1*rx(T(1),cf)*dHrx)/(dm1*Cpc);

for i=2:10

dTdt(i)=(m1*Cp*(T(i-1)-T(i))+dm1*rx(T(i),c(i1))*dHrx)/(dm1*Cpc);

end

% Quench 2:

Tin2=m1/m2*T(10)+Q2/m2*Tf;

% dTdt in bed 2:

dTdt(11)=(m2*Cp*(Tin2T(11))+dm2*rx(T(11),cin2)*dHrx)/(dm2*Cpc);

for i=12:20

dTdt(i)=(m2*Cp*(T(i-1)-T(i))+dm2*rx(T(i),c(i1))*dHrx)/(dm2*Cpc);

end

% Quench 3:

Tin3=m2/m3*T(20)+Q3/m3*Tf;

% dTdt in bed 3:

dTdt(21)=(m3*Cp*(Tin3T(21))+dm3*rx(T(21),cin3)*dHrx)/(dm3*Cpc);

for i=22:30

dTdt(i)=(m3*Cp*(T(i-1)-T(i))+dm3*rx(T(i),c(i1))*dHrx)/(dm3*Cpc);

end

Tprime=dTdt;

conc=c;

Tprime=Tprime';

concprof.m

% This function are used only for plotting concentration

%out of reactor

function c=concprof(t,T)

global mc mh Cp Cpc Q1 Q2 Q3 Npoint Tf cf dm1 dm2 dm3 dHrx

u conc p

% comment: For simplicity we use rx((T(i),c(i-1)) rather

%than rx((T(i),c(i))

%section1.--Reconstruction of unstable ammonia reactor----%

if t<1200

p=170;

elseif (t>=1200 & t<=7200)

p=150;

else t>7200

p=200;

end;

%---------------------------------------------------------%

%section2.--New steady-state------------------------------%

%if t>1200

%

p=150;

%else

%

p=200;

%end;

%---------------------------------------------------------%

%section3.--P-controller----------------------------------%

%Kc=3;

%Q1=16.11+Kc*(T(1)-369.4); % positiv feedback, e=y-r

%mc=mh-(Q1+Q2+Q3);

%---------------------------------------------------------%

m1=mc+Q1;

m2=m1+Q2;

m3=m2+Q3;

% Conc. in bed 1:

c(1)=cf+dm1*rx(T(1),cf)/m1;

for i=2:10

c(i)=c(i-1)+dm1*rx(T(i),c(i-1))/m1;

end

% Quench 2:

cin2=m1/m2*c(10)+Q2/m2*cf;

% Conc. in bed 2

c(11)=cin2+dm2*rx(T(11),cin2)/m2;

for i=12:20

c(i)=c(i-1)+dm2*rx(T(i),c(i-1))/m2;

end

% Quench 3:

cin3=m2/m3*c(20)+Q3/m3*cf;

% Conc. in bed 3

c(21)=cin3+dm3*rx(T(21),cin3)/m3;

for i=22:30

c(i)=c(i-1)+dm3*rx(T(i),c(i-1))/m3;

end