Geofin Shallow Drainage Core

advertisement

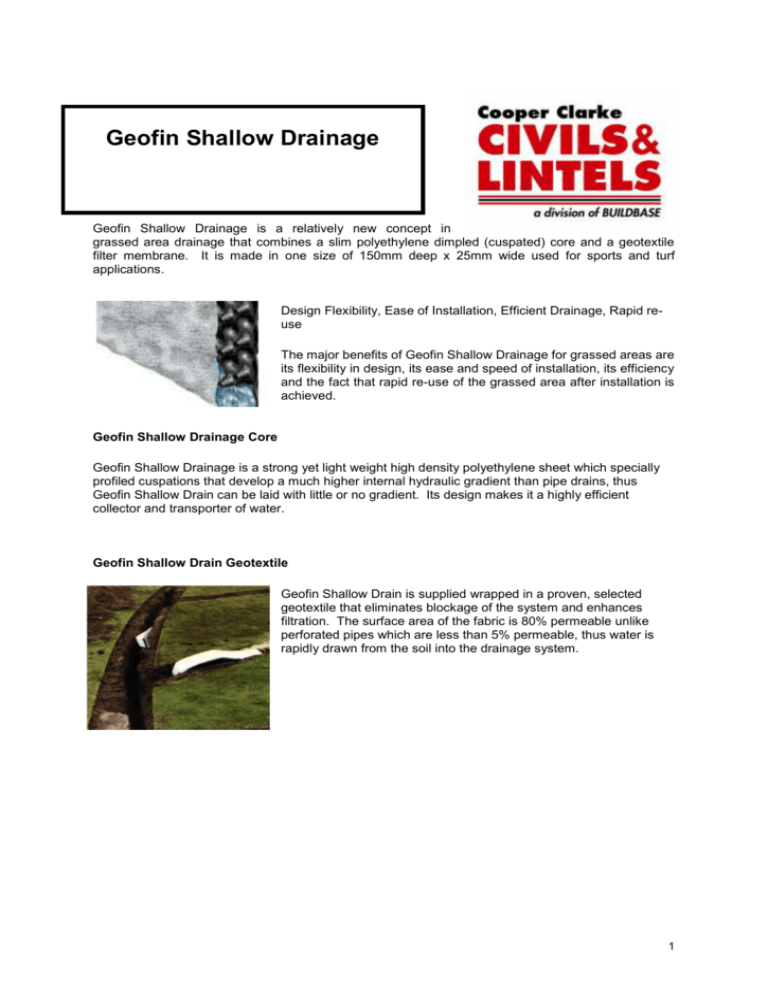

Geofin Shallow Drainage Geofin Shallow Drainage is a relatively new concept in grassed area drainage that combines a slim polyethylene dimpled (cuspated) core and a geotextile filter membrane. It is made in one size of 150mm deep x 25mm wide used for sports and turf applications. Design Flexibility, Ease of Installation, Efficient Drainage, Rapid reuse The major benefits of Geofin Shallow Drainage for grassed areas are its flexibility in design, its ease and speed of installation, its efficiency and the fact that rapid re-use of the grassed area after installation is achieved. Geofin Shallow Drainage Core Geofin Shallow Drainage is a strong yet light weight high density polyethylene sheet which specially profiled cuspations that develop a much higher internal hydraulic gradient than pipe drains, thus Geofin Shallow Drain can be laid with little or no gradient. Its design makes it a highly efficient collector and transporter of water. Geofin Shallow Drain Geotextile Geofin Shallow Drain is supplied wrapped in a proven, selected geotextile that eliminates blockage of the system and enhances filtration. The surface area of the fabric is 80% permeable unlike perforated pipes which are less than 5% permeable, thus water is rapidly drawn from the soil into the drainage system. 1 Back-Fill There is no specific requirement for graded back fill due to the filtering characteristics of the geotextile thus increasing the speed of installation and reducing costs. However, granular back fills are often recommended to enhance surface water collection. Sand can be used close to the surface without risk of injury to players and can provide a connection to treatments such as sand top dressing, core and mini-rolling. When wetted into the trench and consolidated the risk of settlement and rutting is minimised. Geofin Shallow Drainage Installation Being light Geofin Shallow Drain requires no specialised or mechanical handling. On small or inaccessible areas Geofin can be easily carried to site and installed manually. The narrow profile of Geofin Shallow Drain also makes it ideally suited to installation in conjunction with narrow trenching machinery which will produce slits 35mm wide. Some of the advantages of using Geofin Shallow Drain in narrow trenches include reduction in Disruption to the surface Excavated material and cart-away costs Imported fill costs Settlement over the trench Time and labour requirements Machinery size and therefore surface damage Re-vegetation after installation Geofin Shallow Drainage Jointing Jointing Geofin is quick and easy and requires no special tools or skills. Straight joints can be made by simply overlapping the core and taping the geotextile. Connections to conventional pipes can be made via purpose made prefabricated units. 2 Geofin Shallow Drainage Design Drainage problems and their solutions are diverse and therefore require careful design as well as careful installation and maintenance. A good drainage design will produce major benefits to the end user, such as Increased number of playing days (high utilisation) Improved playing surface through rapid removal of water Increased soil strength reducing treading damage Promoting healthy plant growth Promoting deeper root-take so reducing irrigation frequency in dry periods Geofin flexibility in design, high levels of performance and ease of installation all help to promote the benefits above in a cost-effective way. A type of Geofin Shallow Drain is commonly used beneath block paving to collect and drain the sand layer beneath the paving. When laid on impermeable substrate such as concrete, asphalt or roof drainage, it is critical to remove the water where there is traffic to prevent saturation and therefore deformation of paving structure. Percolated water seeping the sand layer if unable to escape will collect in the sand course layer. The permeability of paving sand has a low permeability and will soon become saturated. Sealing between block paving joints is soon damaged by sweeping and traffic movement; there, no reliance on water resistant sealed joints can be expected. Should the sand layer 30-50mm become heavily saturated by seepage between joints, the sand layer could liquefy and pump through joints causing displacement and heave (elephants foot). The solution would be to provide a positive drainage beneath the sand. By using the single cuspated Shallow as a flat back with geotextile wrapped geocomposite. Sand layer beneath block paved areas can be efficiently drained increasing the life of the traffic zone. Cooper Clarke Civils and Lintels, Bloomfield Road, Farnworth, Bolton, Lancashire. Tel: 01204 862222 Fax: 01204 795296 A trading division of Buildbase Limited Member of Grafton Group plc Registered in England No. 4725313 23 August 2007 Issue No4 3