Table: Optimized processing parameters for SU

advertisement

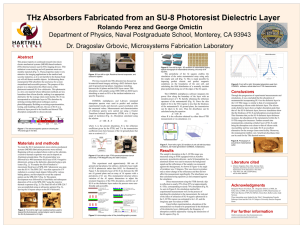

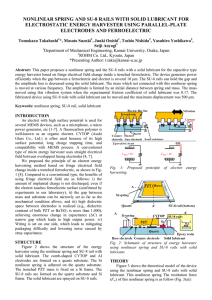

Characterization Results of SU8 Process (obtained in MSAL) Table: Optimized processing parameters for SU-8 layers with different thickness Thickness Resist grade Spin coating Pre-bake Exposure dose Post-bake Developing Resolution m rpm/sec C/min mJ/cm2 C/min min m 41.5 SU-8/50 500/15+3000/15 95/30 450 95/30 4 10 21.8 SU-8/50 500/10+4000/30 95/45 330 95/30 8 10 8.0 SU-8/5 500/10+1500/20 95/30 250 95/30 3 4 5.8 SU-8/5 500/10+2000/30 95/20 200 95/20 3 4 Note: If cracks are found in SU8 layers, you may bake them @100C for 5 minutes to reduce the number of cracks efficiently. Dimentional Change % The effects of exposure dose on dimensional change for different size transferred patterns 2 1.5 1 Structure A (500 um) Structure B (85 um) 0.5 0 -0.5 -1 -1.5 230 250 270 290 310 330 350 370 Dose (mJ/cm2) This figure shows the relative dimensional changes as the function of exposure dose for two different size patterns. For each structure size, there is a zero dimensional change exposure dose for this 8 m thick SU-8 resist. At lower dose, because of no sufficient photo-initialized acid to fully cross-link the resist, the material may be washed away by developer. On the other hand, at higher exposure dose, the enhanced acid concentration plus the enhanced diffusion will cause cross-link at vicinity area of the designed patterns resulting in the expanded SU-8 structures. Since the dimensional changes are relatively small, the results also suggest that if all structures in a mask have close dimensions, we can apply an optimized exposure dose applicable to whole wafer.