STGCL.SWP.63.1_Purification of Total

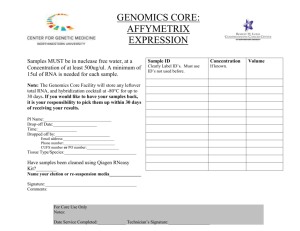

advertisement

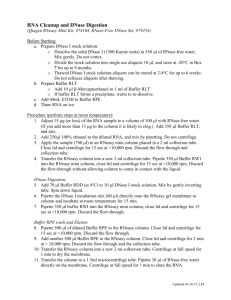

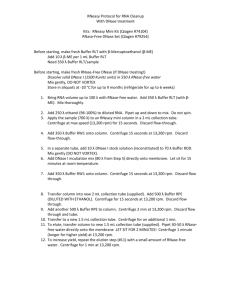

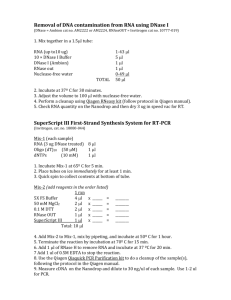

OHS026 Safe Work Procedure Faculty/Division Medicine/Immunology Medicine Document number Initial Issue date STGCL.SWP.63.1 28/04/2010 School/ Divisional Unit St George Clinical school Current version 1 Current Version Issue date 28/04/2010 Next review date 28/04/2012 The Writing Safe Work Procedures Guideline (OHS027) should be consulted to assist in the completion of this form. Safe Work Procedure Title and basic description Title: Purification of Total RNA from Cells Using RNeasy Mini Kit (QIAGEN) Description: Associated risk assessment title and location: STGCL.RA.63.1 Describe the activity or process This SWP outlines the procedure for Purification of Total RNA from Cells Using RNeasy Mini Kit (QIAGEN Cat#74104, 74106). All relevant MSDSs and the attached Risk Assessment must be read prior to the task being undertaken. Things to do before starting: Determining the correct amount of starting material It is essential to use the correct amount of starting material in order to obtain optimal RNA yield and purity. The minimum amount is generally 100 cells, while the maximum amount depends on: The RNA content of the cell type The RNA binding capacity of the RNeasy spin column (100 μg RNA) The volume of Buffer RLT required for efficient lysis (the maximum volume of Buffer RLT that can be used limits the maximum amount of starting material to 1 x 10^7 cells). RNA content can vary greatly between cell types. The following examples illustrate how to determine the maximum amount of starting material: COS cells have high RNA content (approximately 35 μg RNA per 10^6 cells). Do not use more than 3 x 10^6 cells, otherwise the RNA binding capacity of the RNeasy spin column will be exceeded. HeLa cells have average RNA content (approximately 15 μg RNA per 10^6 cells). Do not use more than 7 x 10^6 cells, otherwise the RNA binding capacity of the RNeasy spin column will be exceeded. NIH/3T3 cells have low RNA content (approximately 10 μg RNA per 10^6 cells). The maximum amount of starting material (1 x 10^7 cells) can be used. If processing a cell type there is no information about its RNA content, it is recommend starting with no more than 3–4 x 10^6 cells. Depending on RNA yield and purity, it may be possible to increase the cell number in subsequent preparations. Buffer preparation Add 10 μl β-mercaptoethanol (β-ME) to 1 ml Buffer RLT before use. Dispense in a fume hood and wear appropriate protective clothing. Buffer RLT containing β-ME can be stored at room temperature for up to 1 month. Buffer RPE is supplied as a concentrate. Before using for the first time, add 4 volumes of ethanol (96–100%) as indicated on the bottle to obtain a working solution. Procedure: 1. Harvest cells according to step 1a or 1a. 1a. Cells grown in suspension (do not use more than 1 x 10^7 cells): Determine the number of cells. Pellet the appropriate number of cells by centrifuging for 5 min at 300 x g in a centrifuge tube (not supplied). Carefully remove all supernatant by aspiration, and proceed to step 2. 1b. Cells grown in a monolayer (do not use more than 1 x 10^7 cells): Cells can be either lysed directly in the cell-culture vessel (up to 10 cm diameter). To lyse cells directly: Determine the number of cells. Completely aspirate the cell-culture medium, and proceed immediately to step 2. 2. Disrupt the cells by adding Buffer RLT. For pelleted cells, loosen the cell pellet thoroughly by flicking the tube. Add the appropriate volume of Buffer RLT. Vortex or pipet to mix, and proceed to step 3. 3. To homogenize the lysate Pipet the lysate directly into a QIAshredder spin column (QIAGEN Cat#79654) placed in a 2 ml collection tube, and centrifuge for 2 min at full speed. Proceed to step 4. Add 1 volume of 70% ethanol to the homogenized lysate, and mix well by pipetting. Do not centrifuge. 5. Transfer up to 700 μl of the sample, including any precipitate that may have formed, to an RNeasy spin column placed in a 2 ml collection tube (supplied). Close the lid gently, and centrifuge for 15 s at >8000 x g (>10,000 rpm). Discard the flow-through.* Reuse the collection tube in step 6. If the sample volume exceeds 700 μl, centrifuge successive aliquots in the same RNeasy spin column. Discard the flow-through after each centrifugation.* On-Column DNase Digestion with the RNase-Free DNase D1. Prepare DNase I stock solution before using the RNase-Free DNase Set (QIAGEN Cat#79254) for the first time. ___________________________________________________________________________________________________________ ___________ Page 1 of 4 Safe Work Procedure Date Effective: 01/01/2007 Uncontrolled document when printed Current Version: 1.2, 15/08/2007 Dissolve the lyophilized DNase I (1500 Kunitz units) in 550 μl of the RNasefree water provided. To avoid loss of DNase I, do not open the vial. Inject RNasefree water into the vial using an RNase-free needle and syringe. Mix gently by inverting the vial. Do not vortex.The RNase-Free DNase Set provides efficient on-column digestion of DNA during RNA purification. The DNase is efficiently removed in subsequent wash steps. D2. Add 10 μl DNase I stock solution (see above) to 70 μl Buffer RDD. Mix by gently inverting the tube, and centrifuge briefly to collect residual liquid from the sides of the tube. Note: Buffer RDD is supplied with the RNase-Free DNase Set. DNase I is especially sensitive to physical denaturation. Mixing should only be carried out by gently inverting the tube. Do not vortex. D3 Add the DNase I incubation mix (80 μl) directly to the RNeasy spin column membrane, and place on the benchtop (20–30°C) for 15 min. D4 Add 350 μl Buffer RW1 to the RNeasy spin column. Close the lid gently, and centrifuge for 15 s at >8000 x g (>10,000 rpm). Discard the flow-through.* 6. Add 500 μl Buffer RPE to the RNeasy spin column. Close the lid gently, and centrifuge for 15 s at >8000 x g (>10,000 rpm) to wash the spin column membrane. Discard the flow-through. Reuse the collection tube in step 7. 7. Add 500 μl Buffer RPE to the RNeasy spin column. Close the lid gently, and centrifuge for 2 min at >8000 x g (>10,000 rpm) to wash the spin column membrane. The long centrifugation dries the spin column membrane, ensuring that no ethanol is carried over during RNA elution. Residual ethanol may interfere with downstream reactions. 8. Optional: Place the RNeasy spin column in a new 2 ml collection tube (supplied), and discard the old collection tube with the flow-through. Close the lid gently, and centrifuge at full speed for 1 min. Perform this step to eliminate any possible carryover of Buffer RPE, or if residual flow-through remains on the outside of the RNeasy spin column after step 7. 9. Place the RNeasy spin column in a new 1.5 ml collection tube (supplied). Add 30–50 μl RNase-free water directly to the spin column membrane. Close the lid gently, and centrifuge for 1 min at >8000 x g (>10,000 rpm) to elute the RNA. 10. If the expected RNA yield is >30 μg, repeat step 10 using another 30–50 μl RNasefree water, or using the eluate from step 10 (if high RNA concentration is required). Reuse the collection tube from step 9. * Flow-through contains Buffer RLT or Buffer RW1 and is therefore NOT compatible with bleach. List all resources required including plant, chemicals, personal protective clothing and equipment, etc Cell lines (Classified as Risk Group 1 to the criteria of AS/NZS 2243.3:2002) Primarily cells (Classified as Risk Group 2 to the criteria of AS/NZS 2243.3:2002) PHYSICAL CONTAINMENT LEVEL 2 (PC2) REQUIRED 70% ethanol β-ME (Sigma) (Classified as T, N, R23/24/25 - R38 - R41- R43 - R50/53) Dispense in a fume hood and wear appropriate PPCE. Buffer RPE (QIAGEN) Per OSHA 29CFR1910.1200, Commonwealth of Australia [NOHSC:1005,1008(1999)], this products do not require a Material Safety Data Sheet (MSDS). They do not contain more than 1% of a component classified as hazardous and do not contain more than 0,1% of a component classified as carcinogenic. Therefore QIAGEN does not provide a MSDS for this products. Dear RNase-free water (QIAGEN) Per OSHA 29CFR1910.1200, Commonwealth of Australia [NOHSC:1005, 1008(1999)], this products do not require a Material Safety Data Sheet (MSDS). They do not contain more than 1% of a component classified as hazardous and do not contain more than 0,1% of a component classified as carcinogenic. Buffer RW1 (QIAGEN) (Classified as non-hazardous according to the criteria of Worksafe Australia) Refrigerated microcentrifuge Longsleeved lab gown Gloves Safety goggles List potential hazards and risk controls including specific precautions required Note: Wear PPCE throughout the procedure. Primarily cells (Classified as Risk Group 2 to the criteria of AS/NZS 2243.3:2002) PHYSICAL CONTAINMENT LEVEL 2 (PC2) REQUIRED 70% ethanol Flammable liquid and vapor. May cause central nervous system depression. Causes severe eye irritation. Causes respiratory tract irritation. Causes moderate skin irritation. Specific controls: Large quantities (2.5L) stored in flame-proof cabinet. Only small quantities (100mls) kept on bench ___________________________________________________________________________________________________________ ___________ Page 2 of 4 Safe Work Procedure Date Effective: 01/01/2007 Uncontrolled document when printed Current Version: 1.2, 15/08/2007 β-ME Hazard symbols T:Toxic, N:Dangerous for the environment R-phrase(s) R23/24/25 Toxic by inhalation, in contact with skin and if swallowed. R38 Irritating to skin. R41 Risk of serious damage to eyes. R43 May cause sensitization by skin contact. R50/53 Very toxic to aquatic organisms, may cause long-term adverse effects in the aquatic environment. S-phrase(s) S26 In case of contact with eyes, rinse immediately with plenty of water and seek medical advice. S36/37/39 Wear suitable protective clothing, gloves and eye/face protection. S45 In case of accident or if you feel unwell, seek medical advice immediately (show the label where possible). S60 This material and its container must be disposed of as hazardous waste. S61 Avoid release to the environment. Refer to special instructions/ Safety data sheets. 1. FIRST AID MEASURES General advice Consult a physician. Show this safety data sheet to the doctor in attendance. If inhaled If breathed in, move person into fresh air. If not breathing give artificial respiration Consult a physician. In case of skin contact Wash off with soap and plenty of water. Take victim immediately to hospital. Consult a physician. Sigma - M7522 www.sigma-aldrich.com Page 2 of 6 In case of eye contact Rinse thoroughly with plenty of water for at least 15 minutes and consult a physician. If swallowed Never give anything by mouth to an unconscious person. Rinse mouth with water. Consult a physician. 2. FIRE-FIGHTING MEASURES Suitable extinguishing media Use water spray, alcohol-resistant foam, dry chemical or carbon dioxide. Special protective equipment for fire-fighters Wear self contained breathing apparatus for fire fighting if necessary. 3. ACCIDENTAL RELEASE MEASURES Personal precautions Wear respiratory protection. Avoid breathing vapors, mist or gas. Ensure adequate ventilation. Evacuate personnel to safe areas. Environmental precautions Prevent further leakage or spillage if safe to do so. Do not let product enter drains. Discharge into the environment must be avoided. Methods for cleaning up Soak up with inert absorbent material and dispose of as hazardous waste. Keep in suitable, closed containers for disposal. 4. HANDLING AND STORAGE Handling Avoid contact with skin and eyes. Avoid inhalation of vapour or mist. Keep away from sources of ignition - No smoking. Take measures to prevent the build up of electrostatic charge. Storage Store in cool place. Keep container tightly closed in a dry and well-ventilated place. Containers which are opened must be carefully resealed and kept upright to prevent leakage. 5. EXPOSURE CONTROLS/PERSONAL PROTECTION We are not aware of any national exposure limit. Personal protective equipment Respiratory protection Where risk assessment shows air-purifying respirators are appropriate use a full-face respirator with multipurpose combination or type respirator cartridges as a backup to engineering controls. If the respirator is the sole means of protection, use a full-face supplied air respirator. Hand protection Handle with gloves. Eye protection Tightly fitting safety goggles. Faceshield (8-inch minimum). Skin and body protection Choose body protection according to the amount and concentration of the dangerous substance at the work place. Hygiene measures Avoid contact with skin, eyes and clothing. Wash hands before breaks and immediately after handling the product. Dispense in a fume hood and wear appropriate PPCE. Buffer RW1 contains a small amount of guanidine thiocyanate. Guanidine salts can form highly reactive compounds when combined with bleach. If liquid containing these buffers is split, clean with suitable laboratory detergent and water. If the spilt liquid contains potentially infectious agents, clean the affected area first with laboratory detergent and water, and then with 1% (v/v) sodium hypochlorite. MSDSs are available online in PDF format at www.qiagen.com/ts/msds.asp where you can find, view, and print the MSDS for each QIAGEN kit and kit component. 24-hour emergency information Emergency medical information in English, French, and German can be obtained 24 hours a day from: Poison Information Center Mainz, Germany Tel: +49-6131-19240 Refrigerated microcentrifuge Electrical appliance – electrocution hazard ___________________________________________________________________________________________________________ ___________ Page 3 of 4 Safe Work Procedure Date Effective: 01/01/2007 Uncontrolled document when printed Current Version: 1.2, 15/08/2007 Spinning rotor- physical injury hazard List emergency shutdown instructions For electrical appliances, the emergency cutoff switch (red button) is located on the wall near the entrance to the lab. In case ofβ-ME spillage:Evacuate personnel to safe areas. List clean up and waste disposal requirements The supernatant of cell culture must be treated by adding a 1% v/v of bleach for over 30 min and collected in the labeled tissue culture waste containers. All solutions should be disposed of in chemical waste containers. Contaminated solid waste should be disposed of through the biological and chemical waste stream. Ensure that contaminated solid waste is contained if placed into an open bin. β-ME This combustible material may be burned in a chemical incinerator equipped with an afterburner and scrubber. Should be disposed of in chemical waste containers. List legislation, standards and codes of practice used in the development of the SWP NSW OHS Act 2000 NSW OHS Regulation 2001 Code of Practice for the Labelling of Workplace Substances AS/NZS 2243.2:2006 AS/NZS 2243.3-2002. AS/NZS 2243.6-1990. AS/NZS 2243.7-1991. AS/NZS 2161.1:2000 Occupational Protective Gloves – Selection, Use and Maintenance AS/NZS 1336:1997 Recommended Practices for Occupational Eye Protection UNSW Hazardous Waste Disposal Procedure Supervisory approval, training, and review Supervisor: Prof S. Krilis Signature: Supervisor: Signature: Supervisor: Signature: Supervisor: Signature: Supervisor: Signature: Supervisor: Signature: Plant custodian: Prof S. Krilis Signature List competency required – qualifications, certificates, licencing, training - eg course or instruction: Training in this Procedure & Corresponding Risk Assessment SWP review date: 28/04/2012 Responsibility for SWP review: Kumiko Tanaka ___________________________________________________________________________________________________________ ___________ Page 4 of 4 Safe Work Procedure Date Effective: 01/01/2007 Uncontrolled document when printed Current Version: 1.2, 15/08/2007