Chemical Risk Assessment

advertisement

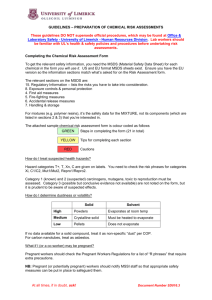

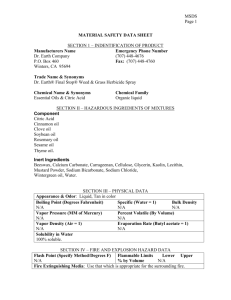

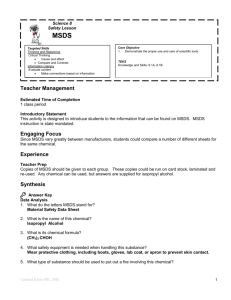

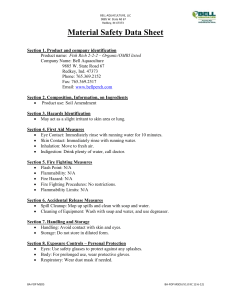

GUIDELINES – PREPARATION OF CHEMICAL RISK ASSESSMENTS These guidelines DO NOT supersede official procedures, which may be found at Office & Laboratory Safety - University of Limerick - Human Resources Division. Lab workers should be familiar with UL’s health & safety policies and procedures before undertaking risk assessments. Completing the Chemical Risk Assessment Form To get the relevant safety information, you need the MSDS (Material Safety Data Sheet) for each chemical in the form you will use it. US and EU format MSDS sheets exist. Ensure you have the EU version so the information sections match what’s asked for on the Risk Assessment form. The relevant sections on the MSDS are: 15. Regulatory Information – lists the risks you have to take into consideration. 8. Exposure controls & personal protection 4. First aid measures 5. Fire-fighting measures 6. Accidental release measures 7. Handling & storage For mixtures (e.g. polymer resins), it’s the safety data for the MIXTURE, not its components (which are listed in sections 2 & 3) that you’re interested in. The attached sample chemical risk assessment form is colour coded as follows GREEN YELLOW RED Steps in completing the form (21 in total) Tips for completing each section Cautions How do I treat suspected health hazards? Hazard categories T+, T, Xn, C are given on labels. You need to check the risk phrases for categories Xi, C1/C2, Mut1/Mut2, Repro1/Repro2. Category 1 (known) and 2 (suspected) carcinogens, mutagens, toxic to reproduction must be assessed. Category 3 (possible but conclusive evidence not available) are not noted on the form, but it is prudent to be aware of suspected effects. How do I determine dustiness or volatility? Solid Solvent High Powders Evaporates at room temp Medium Crystalline solid Must be heated to evaporate Low Pellets Does not evaporate If no data available for a solid compound, treat it as non-specific “dust” per COP. For carbon nanotubes, treat as asbestos. What if I (or a co-worker) may be pregnant? Pregnant workers should check the Pregnant Workers Regulations for a list of “R phrases” that require extra precautions. NB: Pregnant (or potentially pregnant) workers should notify MSSI staff so that appropriate safety measures can be put in place to safeguard them. At all times, if in doubt, ask! How do I reduce the risk if I decide it is unacceptable? The order of preference for improving safety is: Elimination Change the experiment to avoid using chemical or eliminate step Substitution Replace hazardous materials with safer alternatives. Can you buy in materials or outsource the job rather than attempting it yourself? Engineering Controls e.g. work in fumehood or glovebox Administrative Controls e.g. restricted lab access, hot-work permits Personal Protective Equipment e.g. chemical-resistant apron, safety boots, respirator. Only use these as a last resort. Its better to control risks than try to shield yourself from them! Frequently Asked Questions Q1: When do I need to complete a chemical risk assessment for my experiment? If you are conducting a procedure that: o uses chemicals o produces chemicals, either as an intended product or by-product If you routinely prepare stock reagents to be used in other procedures, this preparation can be assessed on a separate form. This cuts down on paperwork for you. Q2: Do I need to complete a chemical risk assessment if I order in a new chemical? No, the MSDS sheet provided by the supplier is the risk assessment for the chemical. o Make sure you get the correct MSDS sheet from the supplier. o Check the MSDS to ensure you store the chemical correctly. Q3: When do I have to review my chemical risk assessment? o At least once a year or o If there are significant changes to the work or o If the person doing the work changes, e.g. an FYP student repeats a procedure previously done by a postgraduate (page 2 of assessment form) o If the work is repeated in a different laboratory (page 3 of form) o If you have reason to suspect the assessment is no longer valid or o If the occupational exposure level (OLEV) for any of the materials used is exceeded Q4: What should be included in the chemical risk assessment? The assessment must take account of: o Starting materials in the form you will use them (e.g. 1M NaOH solution, not NaOH pellets) o Preparation of starting materials used (e.g. drying of solvents) o Intermediates formed during the reaction o End products o By-products and waste generated. You must also consider: o Safe storage of materials o Safe disposal of waste o Are the appropriate controls, first aid and emergency procedures in place? Q5: The risks are minimal; parts of the form don’t apply to my experiment. Do I need to complete it? You must complete the form to show you’ve considered the risks and found the experiment is safe. Do not leave any section blank, mark it N/A (not applicable). Q6: I don’t understand what the form is asking me for. What should I do? If you don’t understand the information in the MSDS sheets or on the form, you’re probably not the right person to undertake the assessment. Ask for help. At all times, if in doubt, ask! 3. The assessment is specific to the location you assess it for. If you transfer the experiment to another lab, you have to repeat the assessment for that lab. 1. A chemical risk assessment must be completed for all experiments that involve chemicals. This includes procedures that produce chemicals as a by-product. 4. Review at least annually or o If work changes significantly o If OLEV is exceeded o If you have reason to suspect assessment is no longer valid UNIVERSITY of LIMERICK CHEMICAL AGENT RISK ASSESSMENT SHEET TITLE OF ACTIVITY:________________________________________________________________________________________________________________________________________ 2. This is your judgement of the experiment. Other workers may reach a different decision on the same procedure. ACADEMIC / PROJECT SUPERVISOR: ________________________________________________________ LOCATION:_____________ MODULE CODE:_____________________ (Room No.) (if relevant) End products 5B. From R phrases, MSDS Section 15 By-products Waste generated 5C. From R phrases, MSDS Section 15 OELV / BLV Number of people exposed Duration of Contact (Hr/Day) Dustiness or Volatility (high, medium or low) Amount Used (L or Kg) Ingestion Eyes Skin (Sk) Inhalation (Sen) 5D. Use your own judgement on what possible exposure routes could arise in proposed work 5F. For unknown solids, use OLEV figures for ‘dust’ from CoP. Treat CNTs as asbestos Intermediates formed in reaction Danger to environment (N) Flammable (F) Very Flammable F+ Repro 1 or Repro 2 Toxic Reproduction (Mut 1) or (Mut 2) Mutagenic or (C2) Carcinogenic Sensitising (Xi) Corrosive (C) Irritant (Xi) Harmful (Xn) 5A. From orange warning symbols on label or top of MSDS sheet and Section 15 – Regulatory Information EXPOSURE 5E. Powder = high, Crystalline solid = medium, pellet = low Starting materials Toxic (T) (C1) 5. List the following: Very Toxic (T+) LIST CHEMICAL NAMES ASSESSMENT REVIEW DATE:_____________________ OTHER HAZARDS HEALTH HAZARD CATEGORIES Explosive (E) (Use labels, Safety Data Sheets (SDS) & Chem. Agent CoP to complete this table.) ASSESSMENT DATE:______________________ Oxidising (O) ASSESSMENT UNDERTAKEN BY:_______________________________ NOTE OTHER SIGNIFICANT SAFETY CONCERNS: 6. If you have a concern that doesn’t fit elsewhere, note it here. E.g.: it is not required to report C3 carcinogens above, but it is prudent to be aware and treat them with care! Chemical Agent Risk Assessment Sheet 3 of 5 Document Number SF001.2 10. Only list control already in place here. New controls to be introduced go in the ‘additional preventative measures required’ column. PERSONS CARRYING OUT & DESCRIPTION OF THE ACTIVITY Persons carrying out activity (lecturer, technician, postgraduate or undergraduate student, maintenance, grounds, etc.): 7. Specify the grade of worker (e.g. FYP student, postgrad). You don’t need to name the person who will do it. 11. MSDS sheet for the chemical in the form you’re using it must be filed in lab. (e.g. NaOH pellets and 0.1M aqueous solution require separate MSDS sheets) CURRENT PREVENTATIVE & PROTECTIVE MEASURES ADDITIONAL PREVENTATIVE MEASURES REQUIRED STANDARDS & PROCEDURES (Name of relevant Departmental Safety COP, experimental procedures and/or other reference that controls the use of chemicals in this experiment or project): Relevant procedures are MSSI Safety Code of Practice and Laboratory Rules (posted in all MSSI labs) Safety Data Sheets (Are SDS’s available for each chemical?): YES NO CONTAINMENT FACILITIES (i.e. engineering controls, fume cupboards, etc.): Brief description of the activity and significant chemical hazards and risks involved: PERSONAL PROTECTIVE EQUIPMENT (i.e. protective clothing, gloves, eye protection, etc.): 8. Include reaction scheme and equation where available. Is procedure exothermic or endothermic? How do you control a runaway reaction? How is it shut down in an emergency? ACCEPTABLE: UNACCEPTABLE: Note who is responsible to taking these additional measures and when they will be implemented by. NB: Experimental work should not begin until these additional measures are in place. Preventative Measures TRAINING (Describe training given to staff / students who will use these chemicals): LIST OTHER PREVENTATIVES AND PROTECTIVE MEASURES: RISK DECISION 19. If improvements are required, list them here. Note: specify the correct type of glove to wear. No one glove protects from all chemical types! 9. Include preparation of reagents used e.g. dilution of conc. acid to 0.1M solution If preparation is done by another worker, or stock solutions are used, these can be assessed in a separate risk assessment. (If needed to ensure that risks are kept at acceptable levels, list additional preventative measures to be used): If you have changed the process to make it safer, list the change(s) here e.g. substituting a safer solvent. This will save future work if another risk assessment is conducted on a similar procedure. In order of preference: 1. Eliminate the risk 2. Substitute a safer chemical or method for the risk 3. Engineering controls e.g. fume hood 4. Administrative controls e.g. restrict access to lab 5. Last resort: use PPE If, as a result of this risk assessment, the risk decision is found to be acceptable, then progress to the next page. If the risk decision is found to be unacceptable then the chemical agent / agents may not be used in the workplace. It may then be necessary to carry out a more detailed risk assessment. 20. Decide based on experience, hazards of materials used, quantities used, personnel exposed and safety controls in place. Chemical Agent Risk Assessment Sheet 4 of 5 Document Number SF001.2 FIRST AID (Location of showers, first aid arrangements, antidotes, Student Medical Centre contact details, etc.): SPILLS & OTHER EMERGENCY PROCEDURES (Describe emergency procedures in event of spill: including location of clean-up materials, emergency contacts & phone numbers, and the Departmental Emergency Plan): From MSDS - Section 4: First aid measures From MSDS – Section 8: Exposure controls & personal protection Section 5: Fire-fighting measures Section 6: Accidentla release measures Also consider first aid arrangements for out-of-hours work separately. Remember the medical centre is closed and no first aiders are at work in MSSI outside 9am-5pm Monday-Friday! WASTE (Specify if any special precautions should be taken when handling wastes and state the method of disposal): STORAGE (State the correct storage conditions for the various chemical categories being assessed.): This section should state the procedure you will follow in your lab to collect and dispose of waste. MSDS sheets often say “comply with local regulations”. This is not sufficient here! Know how you will dispose of the waste before you produce it – disposing of waste or unused chemicals is the most expensive part of running a chemistry lab! Aim to keep the amount of waste produced to a minimum. From MSDS - Section 7: Handling & Storage 21. Specify first aid, emergency, waste and storage procedures that apply in MSDS. You must take account of what provisions are made in the lab where you will perform the procedure. Ensure the correct safety equipment is in place (e.g. antidote, correct type of fire extinguisher). Note: If you repeat the experiment in a different lab, you have to reassess this page for the new location. I have completed this risk assessment and I am fully aware of the hazards involved in the above activity and of the essential safety precautions to be taken. I acknowledge with my signature here that I will comply with the safety precautions that this work requires. Signature of Assessor Researcher/Staff Date I have personally ascertained that the Assessor is aware of the hazards involved in the above activity and the precautions to be taken. I am satisfied that any hazards that were identified are adequately controlled and these controls will be regularly checked. This activity is deemed to be safe and has my approval. Signature of Supervisor: Senior Technician / Academic Staff / Head of Department Chemical Agent Risk Assessment Sheet Final responsibility for safe working lies with the supervisor, so check the assessment is done properly before signing on the dotted line! Date 5 of 5 Document Number SF001.2