Concrete Cores and Beam Preparation

advertisement

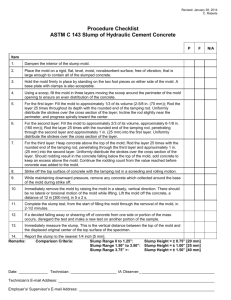

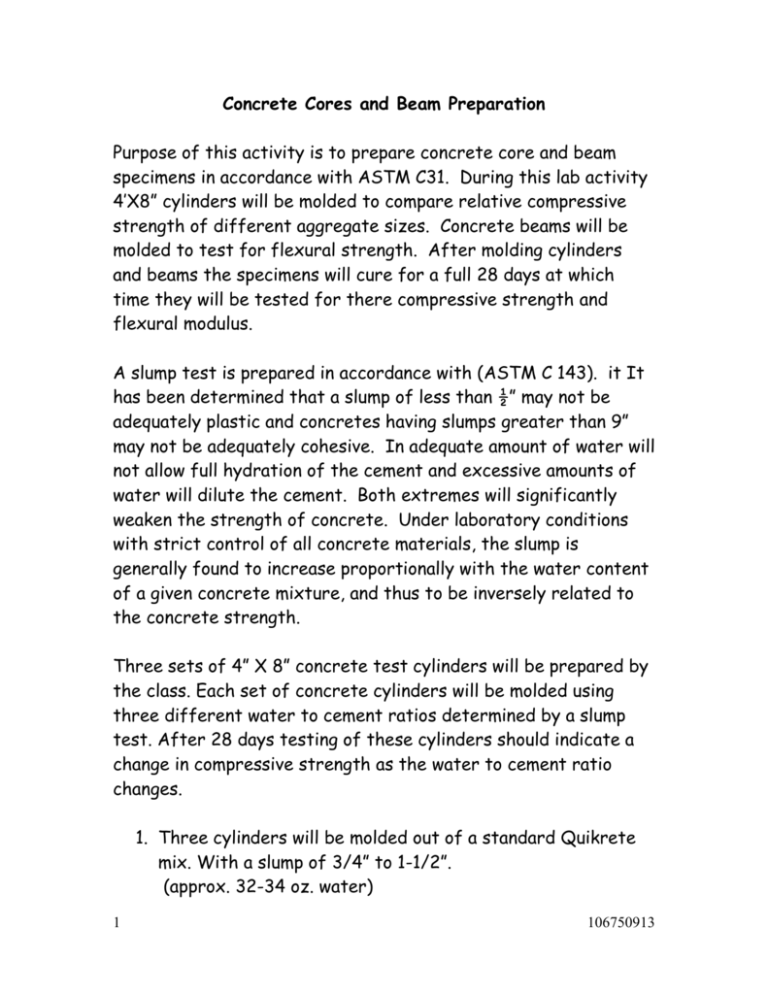

Concrete Cores and Beam Preparation Purpose of this activity is to prepare concrete core and beam specimens in accordance with ASTM C31. During this lab activity 4’X8” cylinders will be molded to compare relative compressive strength of different aggregate sizes. Concrete beams will be molded to test for flexural strength. After molding cylinders and beams the specimens will cure for a full 28 days at which time they will be tested for there compressive strength and flexural modulus. A slump test is prepared in accordance with (ASTM C 143). it It has been determined that a slump of less than ½” may not be adequately plastic and concretes having slumps greater than 9” may not be adequately cohesive. In adequate amount of water will not allow full hydration of the cement and excessive amounts of water will dilute the cement. Both extremes will significantly weaken the strength of concrete. Under laboratory conditions with strict control of all concrete materials, the slump is generally found to increase proportionally with the water content of a given concrete mixture, and thus to be inversely related to the concrete strength. Three sets of 4” X 8” concrete test cylinders will be prepared by the class. Each set of concrete cylinders will be molded using three different water to cement ratios determined by a slump test. After 28 days testing of these cylinders should indicate a change in compressive strength as the water to cement ratio changes. 1. Three cylinders will be molded out of a standard Quikrete mix. With a slump of 3/4” to 1-1/2”. (approx. 32-34 oz. water) 1 106750913 2. Three cylinders will be molded out of a standard Quikrete mix. With a slump of 2” to 3”. ( approx. 48 to 50 oz. water) 3. Three cylinders will be molded out of a standard Quikrete mix. With a slump of 6” to 8”. (approx. 64 to 68 oz. water) 4. Each cylinder shall be properly labeled on its lid stating, class section number and mix or slump and oz. of water. Each plastic cylinder mold will be filled ½ full then rodded 25 times with a rounded end rod. The cylinder will then be filled to the top and rodded an additional 25 times. Using a rod or trowel, the cylinders should be leveled off and made smooth. Cylinders should then be capped with a plastic lid and labeled. This process will be repeated for all nine cylinders. They then will b e placed on a plywood panel and stored for 28 days. Design mixes will be mixed by hand in a wheel barrow: 1. 2. 3. 4. 5. 2 Measure our six quarts of Quikrete for each batch of three cylinders. Start by adding the above recommended water. Mix thoroughly with shovel or hoe. Perform Slump test and add additional water to achieve desired slump. Record the actual total amount of water added to the mix on the lid and class section number. 106750913 Procedures for ASTM C-143 (Slump Test for Hydraulic Cement) 1. Start the test within 5 min. after obtaining the final portion of the mixed concrete sample. 2. Dampen the mold (inside) and place on the dampened base plate. 3. Hold the mold firmly in place during the filling and rodding operation (by the operator standing on the two foot pieces). 5. Fill the mold in three layers, each approximately one-third the volume of the mold. 5. Rod each layer with 25 strokes of the tamping rod. During filling and rodding the top layer, heap the concrete above the mold before rodding is started. 6. Strike off the surface by a screeding and a rolling motion of the tamping rod 7. Remove the mold immediately by raising it in a vertical direction. (Steps 2 through 7 should be completed in less than 2.5 minutes). 8. Place the empty mold (inverted) adjacent to the concrete sample and measure the vertical difference between the top of the mold and the displaced original center of the sample. This is the slump. 3 106750913 4 106750913 The concrete beams will be 6”X6”X20” in length. They will be molded using a standard Quikrete mix with a slump of between 2” and 3”. Mix up 3- 60lb. bags of Quickrete in a wheel barrow. Add 6 to 6-1/2 quarts of water and mix thoroughly. Perform a slump test. The desired slump should be between 2” to 3”. If slump is less than 2” add a small amount of water and re-mix. Check slump again. If mix is more than 3” add a small amount of Quickrete and re-mix. Check slump. If in the desired range fill beams as directed below. 1. One beam will be molded with no reinforcing bar. 2. One beam will be molded with a #3 reinforcing bar located centrally through the center of the beam. 3. One beam will be molded with a #3 reinforcing bar located below the neutral axis of the beam. All beam molds will be filled half full then rodded 25 times. The mold will then be filled completely and then rodded an additional 25 times. Using a trowel or bar, level the top surface even with the top of the mold. Place molds in storage to cure for 28 days. Be sure to rinse and clean all tools and equipment before returning to storage. 5 106750913