Chapter 8 ADVERSE GROUND CONDITIONS: EFFECT ON

Chapter 8 ADVERSE GROUND CONDITIONS: EFFECT ON TUNNELLING

Introduction

The selection of a tunnelling machine to excavate in a given geological situation is based to a large extent on the machine giving satisfactory performance in the rock types anticipated to be prevalent mostly along the tunnel line. There is often the possibility of the tunnelling machine encountering adverse ground conditions, which have not necessarily been anticipated or the effects fully appreciated. In several tunnelling projects probing ahead and around the tunnel is carried out in order to try to detect adverse, and/or hazardous, ground conditions so as to implement appropriate control or ground improvement measures.

Effects of Adverse Conditions: General Appreciation

Tunnelling machines can respond differently to encountering adverse ground conditions. They can become trapped, buried or be even displaced physically back along the tunnel by the pressures exerted by wet unconsolidated materials flowing into the excavation. Some TBM machines can be designed, however, to counteract encountering inflow conditions by plugging the entire tunnel whilst remedial measures are carried out to subsequently allow normal tunnelling to proceed.

Adverse conditions can also arise should the tunnel drivage meet an unexpectedly high strength and abrasive rock type such as an igneous intrusion. This can create problems if the tunnelling machine type does not have the capability of excavating through such zones at satisfactory rates of progress.

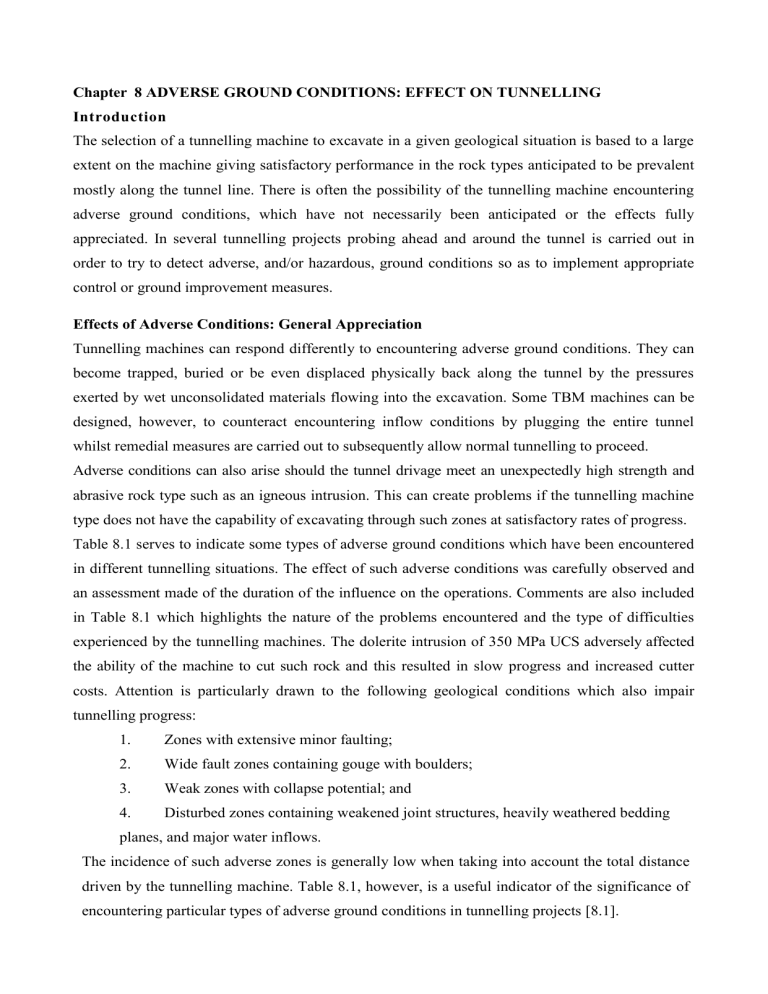

Table 8.1 serves to indicate some types of adverse ground conditions which have been encountered in different tunnelling situations. The effect of such adverse conditions was carefully observed and an assessment made of the duration of the influence on the operations. Comments are also included in Table 8.1 which highlights the nature of the problems encountered and the type of difficulties experienced by the tunnelling machines. The dolerite intrusion of 350 MPa UCS adversely affected the ability of the machine to cut such rock and this resulted in slow progress and increased cutter costs. Attention is particularly drawn to the following geological conditions which also impair tunnelling progress:

1.

Zones with extensive minor faulting;

2.

Wide fault zones containing gouge with boulders;

3.

Weak zones with collapse potential; and

4.

Disturbed zones containing weakened joint structures, heavily weathered bedding planes, and major water inflows.

The incidence of such adverse zones is generally low when taking into account the total distance driven by the tunnelling machine. Table 8.1, however, is a useful indicator of the significance of encountering particular types of adverse ground conditions in tunnelling projects [8.1].

Table 8.1 Summary of case histories of machine tunnelling in adverse ground

Source: McFeat-Smith [8.1]

Case Machine type Geology

Tunnel dia.

Geological feature

Av. advance Delay to m/week progress

53 h A Roadheader Mudstones

(lightweight) & 30% coal

4m

15 m wide fault zone. 109

Minor water inflows

B Roadheader Soft sandstone Wide zone of quartzite 4 8

(med. weight) SE = 5 MJ/m

3

in sandstone near major

5m & 6-5m fault. SE = 14 MJ/m

3

50%

C Roadheader Mudstones,

(heavy weight) sandstones,

4 m siltstones,

thin quartzite

& limestone

Thin limestone in floor. 2 7* Several

SE = 29-1 MJ/m

3

, months

Quartzite in roof:

SE = 26-4 MJ/m removal

3 install- ation &

76 h D TBM Moderately

(med. weight) strong

3-5 m sandstones

23 m length of intensely jointed mudstone & sandstone

E TBM Dolerite sill 350 m of competent

(heavy weight) intrusion into dolerite sill,

3-5 m sedimentary sequence

350 MPa UCS

14 0

9 0

F TBM Pure mudstone 18 m length of soil

(heavy weight) at roof level infill zone in roof

3-5 m overlying limestone caused by solution effects of limestone

G TBM Sandstones,

(med. weight) mudstones

3-5 m

200 m throw fault giving 15 m clay gouge zone with boulders &

10 m shattered zone

9 0

120

60%

342 h

67 h

* potential never reached

Table 8.1 (continued) Case histories of machine tunnelling in adverse ground

Source: McFeat-Smith [8.1]

Case Tunnelling problems in adverse zone

Design aspects Comments

A

B

C

D

E

F

G

Generally minor.

Support: arches + lagging installed

Minor damage to boom jacks from falling lumps

Roadheader well designed for conditions

Slow cutting, drill & Machine rigidity on this Later models now blast used in sections; early type was a problem. capable of cutting sandstone: 24 m quartzite: 6-5 m

3

3

/h

/h

Good access available for blasting in this situation

Slow cutting, excessive Machine rigidity was a tool wear.

Limestone: 2 m 3 /h,

6-35 picks/m

3

.

Sandstone: 5 m

3

/h,

8-10 picks/m

3 problem, severe impact damage to saint attack picks. Machine withdrawn

Generally minor problems: arch supports used

Roadheader cutting system inadequate for installation

Reliable mucking system TBM well designed and easy access for support installation for conditions

Slow cutting.

Average progress

Triple button discs used although single reduced to 35 m/week. discs may nave been

Cutter costs very high better

Operation considered to be a success for such hard rock

Delays mainly for support and mucking

Long roof shield prevented installation of heavy due to collapse of roof temporary support,

Inadequate design features enhanced delays conveyors choked

Generally minor problems. Arch supports used; timber packing required for gripper pads

Suitable access for installation of arches close behind face. Single gripper pads most appropriate

TBM very well designed for this severe condition

Adverse Geology and TBM Tunnelling Problems

Adverse geological conditions give rise to a range of problems which include: rock fall-out and blockage at the face; rock failure in the proximity of the thrust jack gripper; the need for frequent cutter changes; the need for probe hole drilling to detect water and faults. These problems can significantly influence TBM potential penetration rates which under idealised rock conditions can be greater than 3 m/h and 50 m/day. Attention is drawn to the following adverse geological features with particular reference to TBM applications [8.21.

Hard, abrasive rock : Very hard, abrasive rock conditions may only marginally affect the drill and blast method, but TBM operation can be severely influenced. Some TBM's have been removed due to excavation difficulties in andesite or diabase dykes, pegmatite dykes, granites, siliceous dolomites, quartzitic sandstones etc. The problems or TBM operation in such conditions include: low penetration rates; excessive amount of time involved with carrying out cutter changes resulting in low machine availability time; and high cutter costs.

Blocky, slabby rock: The conditions tend to encourage blocks/slabs of rock to detach from the tunnel face, roof and side walls. Those rocks which are significantly jointed and exhibit weathering or chemical alteration and shearing/faulting weaknesses fall under this category. The orientations of joints and nature of the bedding are likely to dictate the occurrence of the most persistent fall-outs within the tunnel. Those fall-outs from the roof and side walls can be usually effectively dealt with by rock bolts and straps or by means of light steel supports, without undue influence on tunnelling progress. Rock fall-outs can give rise to potential blockage of the debris clearance system at the tunnel face, especially when large blocks need to be removed.

Squeezing ground: Stress-slabbing and squeezing ground deformation occurs mainly due to the stress magnitudes around the tunnel excavation exceeding the natural strength of such materials.

Although such problems commonly occur with clayey rock, squeezing and stress-slabbing behaviour are encountered with many rock types and especially those of poor quality which have been sheared or are heavily jointed.

Highly stressed conditions usually accompany such problems as is the case with tunnels at appreciable depth below the surface, but similar deformations and rock failure can occur where weak ground conditions are met at relatively shallow depths. Clay-shales, rocks with clay minerals generally, phyllites and volcanic tuffs are usually sensitive to free water. These can result in significant swelling which can exacerbate ground squeezing and flow into the tunnel excavation.

Table 8.2 Specific adverse geological features and their effect on tunnelling machine operations

Source: based on McFeat-Smith [8.3]

(a) Effect of ground conditions on TBM operations and design

Geological feature Effect on machine usage Selection of machine

1. Gouge, seatearth, Low utilisation due to support Machine design allowing completely mucking & steering operations easy access for installation weathered of support and mucking

2. Intense jointing

& shattering close to tunnel face.

As above but delays mainly for Experienced driver will support. High cutter costs in reduce steering problems. strong blocky rock

3. Sub-parallel Steering may be a problem if As above. Machine with one discontinuities bracing difficult. Support set of gripper pads arrangement again important preferable

4. High water inflows Delays for pumping, support, Waterproofed electrical

> 3000 m

3

/day mucking, track laying & equipment & large pumps, in short zones silting of tunnel Advance probing?

5. Hard & abrasive Controls machine penetration Machine cutter head rock rates and cutter costs. design important. Single

Accurate prediction important disc cutters preferable

6. Variable hardness Expected cutter wear should be Machine capable of cutting

& mixed face condition considered equivalent face of hardest rock to full hardest rock; non-carbide tools preferable. Increased maintenance desirable

7. Less intense Main areas for consideration These factors create poor condition of variable are support, and mucking and machine ground conditions; hardness & mixed

face than (6) including jointing etc. steering to a lesser extent whilst good access is the key to effective TBM design

(b ) Effect of ground conditions on roadheader operations and design

1. Gouge, seatearth, Main delays occur with Roadheader well adapted for completely supporting and mucking. tunnelling in soft or broken weathered Tracking may be difficult ground as good access is on soft floor available for most

2. Intense jointing operations. Selection of a

& shattering proven design is highly desirable

3. Sub-parallel Collapse of wedges may discontinuities require that large blocks have to be broken by pneumatic picks or secondary blasting

Standard designs of roadheaders should be normally adequate

Geological feature

Table 8.2 (continued)

Effect on machine usage Selection of machine

4. High water inflows As with TBM's. Tracking may As with TBM's. Inclusion of > 3000 m

3

/day be a problem machine mounted drill will in short zones assist probing

5. Hard & abrasive This is the main area for concern in roadheader tests can greatly help in selection. Prediction is

Specialist rock cutting rock reducing the risks of highly desirable if not a vital uncertainty regarding factor cutting

6. Variable hardness High vibration with less rigid Selection of rigid machine

& mixed face machines giving rapid wear with heavy duty cutter condition of machine components head, side stells and point attack picks recommended

7. Less intense Main items for consideration As with TBM's. Key to condition than (6) are support, mechanical & electrical maintenance & mucking respectively successful application is considered to be accurate prediction of cutting performance

Notes:

Geological feature:

1. Moisture content, and physical size and geometry are regarded as important.

2. The condition assumes a spacing of less than 0-15 m and non-cohesive joints.

3. The formation of thin wedges in the tunnel walls is taken account of especially in this condition.

4. The high water inflows are considered to occur over relatively short distances.

5. This condition includes rocks of high strength and associated with hardness and a high degree of abrasivity.

6. Anomalous variations in hardness such as the presence of nodules and hard bands etc. are taken into account in this condition.

7. This condition considers less extreme variations in joint frequency, degree of joint opening, degree of inclination and roughness of joints, character of bedding, weathering, water inflows, and strength variations.

Potentially catastrophic conditions: Those conditions which are considered to be potentially catastrophic include tunnels encountering the following situations:

1. Saturated, debris-filled caverns in limestone;

2. Wide fault zones with clayey and sandy gouge under high water pressure;

3. Highly stressed rock with bursting potential when subjected to strain relief during excavation.

4. Pockets of noxious gases under high pressure which have the potential to burst or seep into the tunnel during excavation [8.2, 8.4].

Deere [8.2) has commented that the history of TBM's has seen several examples of such machines having become trapped or partially buried for weeks to months in fault-zone gouge or by squeezing ground. A tunnelling project in Guatemala which was being excavated by a 5-7 m diameter TBM became buried following driving into a solution cavern along a fault plane in limestone. This resulted in the release of 10,000 m

3

of debris which flowed into the tunnel accompanied by up to 3 m

3

/s of water. Around 250 m of the tunnel became plugged by the inflow of such wet deposits. Prior to the collapse, the TBM had driven around 7 km at rates of up to 9-12 m/day. The tunnel drivage was subsequently abandoned, but later bulk-headed and a permanent bypass excavated. Potentially catastrophic conditions should be sought and their risk determined at the tunnel design stage, and specifications frequently require probing holes to be drilled 10-30 m ahead of the tunnelling machine. Such probing can give advance warning of approach towards fault zones, water, caverns, or gas. It is recognised that such probe holes may delay tunnel drivage, but their aim is to assist in reducing the possibility of a potential catastrophe.

Tunnel cave-ins: general characteristics. Cave-ins are often associated with fault zones. As a

TBM drives into a wide fault zone containing soft in-fill, the debris is easily removed by the machine. This can readily encourage the formation of a collapse chimney above the TBM with the potential for further and more extensive collapse of weak ground or fault gouge which can result in burial of the tunnelling machine. These conditions are made worse with increased risk of tunnelling machine burial should water be present, and this is usually the case.

Encountering adverse ground conditions. Deere has drawn attention to the situation of a probe hole encountering a fault which possesses potentially catastrophic conditions. He argues that further proving should be carried out in order to establish the magnitude and orientation of the fault zone. Additionally, water pressure and outflow from the fault debris should be assessed.

References to Chapter 8

8.1 McFeat-Smith, I. (1987) Considerations for mechanised excavation of rock tunnels, 6th

Australian Tunnelling Conf., Melbourne, March, Vol.1, 149-157.

8.2 Deere, D.U. (1981) Adverse geology and TBM tunnelling problems, Proc. RETC

Eds. RJ. Bullock and H.J. Jacoby, San Francisco, SME, Vol.1, 574-586.

8.3 McFeat-Smith, I (1981) Machine tunnelling in weak and fractured rock conditions,

Proc. Int. Symp. Weak Rock, Tokyo, Pub. Balkema, 1075-80.

8.4 Deere, D.U., Merritt, A.H. and Cording, E.J. (1974) Engineering geology and underground construction,

Proc. 2nd Int. Congr. International Assoc, of Engng. Geology, Sao Paulo, Brazil, VII - GR1

- GR27.

8.5 Grandori, C. (1986) Fully mechanised tunnelling machine and method to cope with the widest range of ground conditions: experiences with a hard rock prototype machine, Proc.

RETC,"' Las Vegas, 355 - 376.

8.6 Merritt, A.H. (1974) Tunnel boring machines: geologic control, Proc. 2nd Int. Congr.

International Assoc, of Engng. Geology, Sao Paulo, Brazil, VII - PC - 2.1 - 2.7.

8.7 McFeat-Smith, I. (1984) Mechanised rock tunnelling in adverse conditions, Proc. Int. Conf. Case Histories in

Geotech. Engng., St. Louis, USA.

8.8 McFeat-Smith, I. and Tarkoy, P.J. (1980) Tunnel boring machines in difficult ground, Tunnels and Tunnelling,

January - February, 12, 15-19. 8.9

8.9 McFeat-Smith, I. and Tarkoy, P.J. (1980) Site investigation for machine tunnelling contracts, Tunnels and Tunnelling,

February, 12, 36-39.