System Analysis of Hydrogen energy chains

advertisement

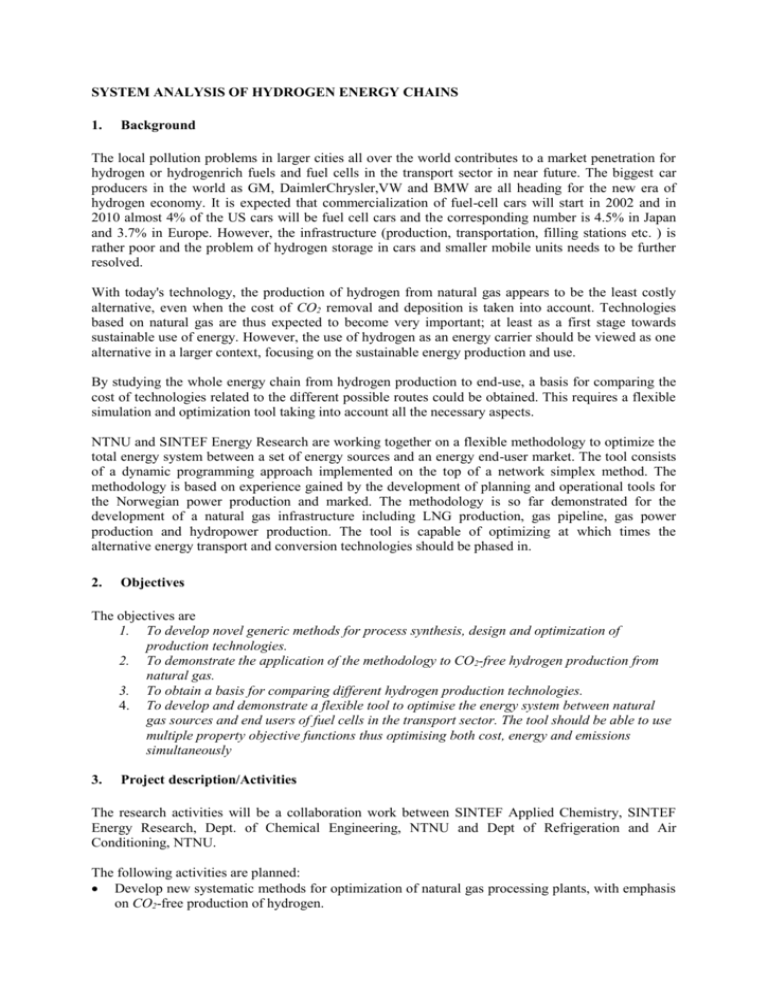

SYSTEM ANALYSIS OF HYDROGEN ENERGY CHAINS 1. Background The local pollution problems in larger cities all over the world contributes to a market penetration for hydrogen or hydrogenrich fuels and fuel cells in the transport sector in near future. The biggest car producers in the world as GM, DaimlerChrysler,VW and BMW are all heading for the new era of hydrogen economy. It is expected that commercialization of fuel-cell cars will start in 2002 and in 2010 almost 4% of the US cars will be fuel cell cars and the corresponding number is 4.5% in Japan and 3.7% in Europe. However, the infrastructure (production, transportation, filling stations etc. ) is rather poor and the problem of hydrogen storage in cars and smaller mobile units needs to be further resolved. With today's technology, the production of hydrogen from natural gas appears to be the least costly alternative, even when the cost of CO2 removal and deposition is taken into account. Technologies based on natural gas are thus expected to become very important; at least as a first stage towards sustainable use of energy. However, the use of hydrogen as an energy carrier should be viewed as one alternative in a larger context, focusing on the sustainable energy production and use. By studying the whole energy chain from hydrogen production to end-use, a basis for comparing the cost of technologies related to the different possible routes could be obtained. This requires a flexible simulation and optimization tool taking into account all the necessary aspects. NTNU and SINTEF Energy Research are working together on a flexible methodology to optimize the total energy system between a set of energy sources and an energy end-user market. The tool consists of a dynamic programming approach implemented on the top of a network simplex method. The methodology is based on experience gained by the development of planning and operational tools for the Norwegian power production and marked. The methodology is so far demonstrated for the development of a natural gas infrastructure including LNG production, gas pipeline, gas power production and hydropower production. The tool is capable of optimizing at which times the alternative energy transport and conversion technologies should be phased in. 2. Objectives The objectives are 1. To develop novel generic methods for process synthesis, design and optimization of production technologies. 2. To demonstrate the application of the methodology to CO2-free hydrogen production from natural gas. 3. To obtain a basis for comparing different hydrogen production technologies. 4. To develop and demonstrate a flexible tool to optimise the energy system between natural gas sources and end users of fuel cells in the transport sector. The tool should be able to use multiple property objective functions thus optimising both cost, energy and emissions simultaneously 3. Project description/Activities The research activities will be a collaboration work between SINTEF Applied Chemistry, SINTEF Energy Research, Dept. of Chemical Engineering, NTNU and Dept of Refrigeration and Air Conditioning, NTNU. The following activities are planned: Develop new systematic methods for optimization of natural gas processing plants, with emphasis on CO2-free production of hydrogen. Apply this methodology to develop an optimized hydrogen production process. Develop a basis for comparing different hydrogen production processes, and to make a comparison of the different technologies. Examples of such processes are: - H2 from natural gas - H2 from electrolysis of water - H2 from bio-mass - Photo-electrochemical (PEC) H2-production - Photo-biological production The energy system optimization tool, mentioned earlier, will be developed further to also include hydrogen as an energy carrier. The optimization tool can handle optimization with multiple objective functions. Usually, cost minimization is used, but the tool will also be capable of maximizing chain energy efficiency or emission minimization. A multipurpose objective function will be designed, which would make a reasonable compromise between cost, efficiency and environmental aspects. Such concept could be used to evaluate different taxation strategies. 3 Ph.D. research projects are included in the project: 1. Ph.D. work 1 (Supervisor: Professor Sigurd Skogestad/Professor N.N.): Develop methods for large-scale optimization of hydrogen production processes. Develop systematic methods for designing reaction systems, and for designing overall processing plants. This is a continuation of previous works by Professor Kristian Lien and coworkers. Estimation of uncertainty in process models. Technical calculations in connection to new technology are always uncertain. It is nevertheless necessary to deal with such uncertainty, and to estimate its effects. 2. Ph.D. work 2 (student: Audun Røsjordet. Supervisor: Professor Signe Kjelstrup): Entropy minimization of chemical processes. A method for entropy minimization and a tool for entropy analysis of chemical processes will be further developed. The method is based on irreversible thermodynamics and the principle of minimization of entropy. An entropy analysis is valuable as a tool for making chemical processes more energy efficient, and frequently uncovers better process designs and operating conditions. The focus of the Ph.D. work is on the method development. This work will be financed by STATOIL for 2 ½ years starting from January 1., 2001. 3. PhD.work 3 (student Kåre Gether. Supervisor Professor Geir Owren): The PhD work will follow closely the activities at SINTEF Energy Research. Mathematical models for relevant energy converters in the hydrogen chain (from "well to wheel") will be developed. The models will provide information about unit cost, unit efficiency and emissions. Simulations and optimizations on selected scenarios will be performed. The Ph.D. work will be strongly integrated in the SINTEF activity. This is motivating for the students, and gives valuable inputs for the SINTEF activity. 4. Organisation and key personnel Project manager and SINTEF Research scientist: Hanne M. Kvamsdal, SINTEF Energy Research, Thermal energy SINTEF Research scientist: John Morud, SINTEF Applied Chemistry, Process technology Ph.D. candidate 1: NN. Supervisors: Professor Sigurd Skogestad/Professor N.N., Dept. of Chemical Engineering, Group for Process Systems Engineering, NTNU Ph.D. candidate 2: Audun Røsjordet. Supervisor: Professor Signe Kjelstrup, Dept. of Physical Chemistry, NTNU Ph.D. candidate 3: Kåre Gether. Supervisor: Geir A. Owren, Professor at Department of Refrigeration and Air conditioning, NTNU, Associate advisor: Hanne M. Kvamsdal The activity on design and optimization of hydrogen production will be part of the activity at PROST, which is the strong point center for Process Systems Technology at NTNU/SINTEF. PROST was established in 1994, and was awarded by the Norwegian University of Science and Technology (NTNU) and SINTEF in recognition of the strong international standing of the group. About 50 persons are associated with PROST. This includes six professors with about 25 Ph.D. students from three NTNU departments. The group has many years of experience in the fields of process design (synthesis) and process optimization. These technologies are invaluable for developing systems for sustainable use of energy in particular, as well as for the process industries in general. The Chemical Engineering department at SINTEF Applied Chemistry (part of PROST) has many years of experience in performing technical and economic evaluations of hydrogen production technologies. 5. Budget and time schedule The NTNU cost is primary related to the 3 doctoral projects, each running for about 3 years at an annual rate of NOK 400 000. One of these (the project on entropy minimization of chemical processes) will be sponsored by STATOIL for 2 ½ years starting from January 1., 2001. Cost (in KNOK) 2001 2002 2003 2004 Total Scholarship 3 Ph.D. 1000 1200 1000 200 3400 SINTEF 1500 1500 1500 1500 6000 Travels, computer costs. etc. 20 50 100 30 200 Sum 2520 2750 2600 1730 9600 Financing NFR Norsk Hydro Statoil Sum 6. 1720 400 400 2520 1950 400 400 2750 2000 400 200 2600 1230 300 200 1730 Cost distribution 2001 2002 2003 Industry 32 % 29 % 23 % NFR 68 % 71 % 77 % 9600 100 % 100 % 100 % 2004 29 % 71 % 100 % Total 28 % 72 % 100 % Sponsors Norsk Hydro, ref. Elizabeth Baumann Ofstad Statoil, ref. Arne Grislingås 7. 1. 2. 3. 4. 5. 6. 7. 8. Selected references Sogge, J., Strøm, T. and Sundset, T., Technical and economic evaluation of natural gas based synthesis gas production technologies. SINTEF Applied Chemistry, February 1994, STF21 A93106. S. Skogestad, Prosessteknikk. Tapir forlag 2000. Tørvi, H. and T. Herzberg, Methods for evaluating uncertainties in dynamic simulation results—a comparison of performance. ESCAPE 8, Brügge, Belgium, May 1998. Kjelstrup, S., Sauar, E. and Lien, K.M., Equipartition of forces. Review of a new principle for process design and optimization. Periodica Polytechnica Ser. Chem. Eng. 1, 1997. Strøm, T., Pettersen, T., Sundset, T. and J. Sogge. Use of membrane reactor in production of synthesis gas— process options. The First European Congress on Chemical Engineering, Florence May 4-7, 1997 Andersen, T., Bakken, B.H., Gustavsen, B., Røynsand, J. and Vist, S., “Analyse av transportsystemer med multiple energibærere, SINTEF-report, TR A5128, 2000, a project professionally advised by Prof. Geir Owren Kvamsdal, H.M., Andersen, T. and Bolland, O., (2000), Natural Gas Fired Power Plants with CO 2-capture – Process Integration for high fuel-to-electricity conversion efficiency, in proceedings of the 10 th European Sumposium on Computer Aided Process Engineering (ESCAPE-10) conference, Florence, Italy, May 2000, edited by Pierucci, S., Elsevier, Milan Kvamsdal, H.M. and Ulleberg, Ø., (2000), “Hydrogensamfunnet – en nasjonal mulighetsstudie”, SINTEF report TRA5197, ISBN No. 82-594-1811-8