Papain-S1

advertisement

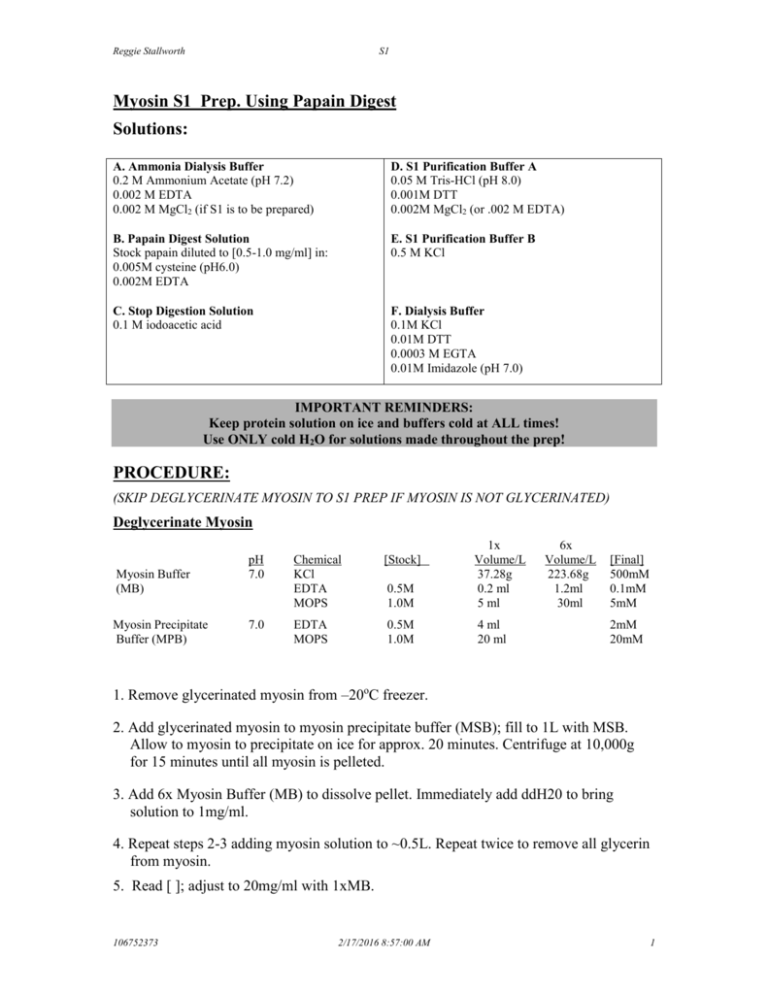

Reggie Stallworth S1 Myosin S1 Prep. Using Papain Digest Solutions: A. Ammonia Dialysis Buffer 0.2 M Ammonium Acetate (pH 7.2) 0.002 M EDTA 0.002 M MgCl2 (if S1 is to be prepared) D. S1 Purification Buffer A 0.05 M Tris-HCl (pH 8.0) 0.001M DTT 0.002M MgCl2 (or .002 M EDTA) B. Papain Digest Solution Stock papain diluted to [0.5-1.0 mg/ml] in: 0.005M cysteine (pH6.0) 0.002M EDTA E. S1 Purification Buffer B 0.5 M KCl C. Stop Digestion Solution 0.1 M iodoacetic acid F. Dialysis Buffer 0.1M KCl 0.01M DTT 0.0003 M EGTA 0.01M Imidazole (pH 7.0) IMPORTANT REMINDERS: Keep protein solution on ice and buffers cold at ALL times! Use ONLY cold H2O for solutions made throughout the prep! PROCEDURE: (SKIP DEGLYCERINATE MYOSIN TO S1 PREP IF MYOSIN IS NOT GLYCERINATED) Deglycerinate Myosin Myosin Buffer (MB) Myosin Precipitate Buffer (MPB) pH 7.0 7.0 Chemical KCl EDTA MOPS [Stock] 0.5M 1.0M 1x Volume/L 37.28g 0.2 ml 5 ml EDTA MOPS 0.5M 1.0M 4 ml 20 ml 6x Volume/L 223.68g 1.2ml 30ml [Final] 500mM 0.1mM 5mM 2mM 20mM 1. Remove glycerinated myosin from –20oC freezer. 2. Add glycerinated myosin to myosin precipitate buffer (MSB); fill to 1L with MSB. Allow to myosin to precipitate on ice for approx. 20 minutes. Centrifuge at 10,000g for 15 minutes until all myosin is pelleted. 3. Add 6x Myosin Buffer (MB) to dissolve pellet. Immediately add ddH20 to bring solution to 1mg/ml. 4. Repeat steps 2-3 adding myosin solution to ~0.5L. Repeat twice to remove all glycerin from myosin. 5. Read [ ]; adjust to 20mg/ml with 1xMB. 106752373 2/17/2016 8:57:00 AM 1 Reggie Stallworth S1 S1 Prep 1.Dialyze [myosin] 2% against Ammonia Dialysis Buffer overnight in 4oC (To ensure complete precipitation dialyzate is changed at least once- Total Volume of dialyzate 2L). 2. Bring myosin suspension to room temperature. 3.Digestion is started by addition of Papain Digest Solution to a final papain [ ] of .03mg/ml 4. Rxn is run for 7 minutes. 5. Stop rxn by addition of iodoacetate acid (Stop Digestion Solution) to a final [ ] of .001M. 6. Suspension is run for 90 minutes at 31,000rpms in 70 Ti. (27000 Beckman 30 rotor) to remove all insoluble digestion products. 7.Yield of S1 in supernatant is ~ 40% of the theo value. Mg.S1 is enriched in DTNB light chain-------EDTA S1 is deficient in that light chain Further purification of S1 Using ion-exchange chromatography 8. Solution of S1 (400-500mg) at 7-10 mg/ml is dialyzed against S1 Purification Buffer A and applied to a 2.5 x 60 cm column of DE-52 equilibrated in the same buffer. 9.Wash column with ~350ml and retained S1 is eluted with a linear KCl gradient. (S1 Purification Buffer B) S1 Purification DE-52 Column 0.6 0.5 0.4 Abs 0.3 0.2 0.1 -0.1 1 61 121 181 241 301 361 421 481 541 601 661 721 781 841 901 961 1021 1081 1141 1201 1261 1321 1381 1441 1501 1561 1621 1681 1741 1801 1861 1921 1981 2041 2101 2161 2221 0 -0.2 Time(secx10) 106752373 2/17/2016 8:57:00 AM 2 Reggie Stallworth S1 10. Collect and pool the fractions from the front 2/3 of the protein peak in 6-7 sections.. Collect 50 l of each section to run gel and determine the most concentrated section. Myosin std 1464sec 1518sec to to 1512sec 1584sec 1590sec to 1656sec Myosin std 1662sec to 1728sec 1734sec to 1800sec (sec x 10) 11. Further purify with ammonium sulfate fractionation. 12. Material precipitated at 47% is discarded. 13. Protein fraction salting out between 47-58% saturation is collected (Sorvall SS34 rotor, 15000 rpms, 20 minutes) 14.Protein is resuspended in a minimum amount of solution G. 15. Exhaustive dialysis against this buffer is required to ensure removal of traces of ammonium sulfate. 106752373 2/17/2016 8:57:00 AM 3