Size resolution with Light Induced Dielectrophoresis

advertisement

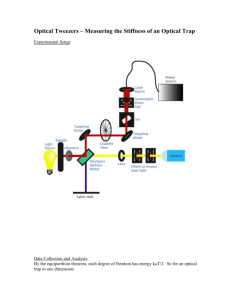

Spatial resolution of Light Induced Dielectrophoresis (LIDEP) SL Neale1, M Mazilu1, JIB Wilson2, MP MacDonald1, K Dholakia1 and TF Krauss1 1 School of Physics and Astronomy, University of St Andrews, North Haugh, St Andrews, Fife. KY169SS 2 School of Engineering and Phsyical Sciences, Heriot-Watt University, Edinburgh. EH144AS Sln2@st-and.ac.uk Abstract. A neutral particle in a non-uniform electrical field can experience a force, termed dielectrophoresis, due to the interaction of a dipole set up in the particle by the electrical field and the electrical field itself. Thus electrical field gradients generated by micropatterned metal electrodes can be used to move and trap particles such as colloid or biological samples. Recent work has shown a major step forward by using optical addressing of a photoconductive substrate to induce dielectrophoresis in a reconfigurable manner. This technique, Light Induced Dielectrophoresis (LIDEP), allows us to create virtual electrodes controlled by the incident light pattern. The forces generated in this way are up to five orders of magnitude greater than those generated directly by optical tweezers for the equivalent input power. This makes it possible to create vastly extended potential energy landscapes and permit sorting over large areas. In this paper we explore the mechanism of LIDEP and address the issue of size resolution. We simulate and experimentally measure the size of the trap it is possible to create by varying the optical spot size and discuss the effect of changing the sample cell thickness. 1. Dielectrophoreiss Dielectrophoresis is the force a neutral polarisable particle in a non uniform electrical field experiences due to the dipole set up within the particle interacting with the field. It was first described by Pohl [1] and follows the equation 1. FDEP 2 r 3 m Re[ K ( )]E 2 1) Where FDEP is the force due to dielectrophoresis, r is the radius of the particle, m is the permittivity of the medium, E 2 is the gradient of the square of the electrical field and Re[ K ( )] is the real part of the Clausius-Mossotti factor. The Clausius-Mossotti factor is given by equation 2. *p m* K ( ) * p 2 m* 2) Where m* and *p are the complex permittivities of the particle and medium respectively. This gives a frequency dependant response that attracts the particle to areas of high electric field gradient at some frequencies while repelling them at others. Figure 1 shows a dielectrophoresis experiment with one micron polymer colloid and metal electrodes creating areas of high electric field gradient, marked as red in 1A, with an area of low electric field gradient, marked in blue. Figures B and C show attraction to and repulsion from the high electric field gradient respectively and D shows the Clausius-Mossotti factor with the frequencies for B and C marked. Figure 1 Dielectrophoresis is shown in a chamber shown in A with areas of high field gradient shown in red and low filed gradient shown in blue. Attraction and repulsion are shown in B and C respectively and D shows the ClausiusMossotti factor. 2. Light Induced Dielectrophoresis (LIDEP) A recent advance has shown that dielectrophoresis can be demonstrated using a photoconductive surface [2, 3] in place of the traditional metal electrodes [4]. This gives some of the advantages of optical tweezing [5] as by changing the incident light pattern the electric filed pattern changes thus making it easy to control (see figure 2). An added advantage is the photoconductive surface requires much lower irradiance to activate than optical tweezers allowing the creation of larger area potential landscapes with the same power. Figure 2 A LIDEP chamber consists of a top component of ITO coated glass and a bottom component of ITO coated glass with layers of photoconductive a-Si and insulating Si3N4. A laser is focused onto the photoconductive surface causing a change in conductivity creating the shown field lines. The simulated gradient of the square of the electric fields are shown on the right for a chamber 5 micron high A) and 15 micron high B) 2.1 Spatial resolution with LIDEP When an optical spot is imaged onto the photoconductor the resulting electrical potential spot is larger than the optical spot due to the electric field diverging within the liquid. Figures 2A and B show that as the height of the sample chamber is changed the magnitude of the force changes but not the position of the maximum force, the trap size. To measure the size of the electrical trap the stage holding the LIDEP chamber was moved with respect to the optical spot. This creates a force on the trapped particle, proportional to the velocity of the stage, moving the particle within the trap (see figure 3). Figure 3 Particles trapped with LIDEP were tracked while moving the stage at A) 0.2 microns per second B) 1.6 microns per second. The forces on the particle were calculated and plotted as a function of position. For this experiment 5 micron polymer colloid was used with an optical spot size of 2.3 microns. The a-Si photoconductive layer was deposited by John Wilson of Heriot-Watt University to a thickness of one micrometer and a chamber height of 50 micrometers was used. The maximum velocity a particle could be trapped at was 1.8 micrometers per second. To find the position of the particle relative to the optical spot a particle tracking program, written in LabVIEW by Graham Milne and freely available form the Optical Tweezing group of the University of St Andrews website, was used. Figures 3A and B show the tracked trajectories of the particle as two different velocities, the maximum displacement and hence the trap size was measured to be 9.3 micrometers. 2.2 Trapping stiffness From the graph 3C the trap stiffness defined as the force it takes to move the particle a given distance in the trap (in N/m) can be calculated as the gradient of the best fit line. The force is calculated from the velocity of the particle and Stokes drag taking into account Faxen’s correction for a particle close to a surface, but not accounting for any friction with the surface that could cause the forces on the particle to be larger than accounted for here. From this the trap stiffness was 7x10-8 N/m with a power of 0.9mW giving an irradiance of 2.2x104 W/cm2. This compares to irradiances necessary for optical tweezers of 105 to 107 W/cm2 [3]. 3 Conclusions In this paper we have described a LIDEP setup where an electrical trap is created with an incident optical spot. The radius of the trap was measured for an optical spot size of 2.3 micrometers and found to be 9.3 micrometers. The trap stiffness was found to be 7x10-8 N/m with an irradiance of 2.2x104 W/cm2. This shows that although the electrical trap is larger than the optical spot, it is possible to create traps of similar size to cells with less power than is necessary for optical tweezing, a criteria that will be essential for large area cell sorting. References [1] H.A. Pohl, Dielectrophoresis, Cambridge University Press, Cambridge (1978). [2] P.Y. Chiou, A.T. Ohta and M.C. Wu, “Massively parallel Manipulation of single cells and microparticles using optical images,” Nature 436, 370-372 (2005). [3] P.Y. Chiou, A.T. Ohta and M.C. Wu, “Toward all optical lab-on-a-chip system: optical manipulation of both microfluid and microscopic particles.” Proc. Optical Trapping and Optical Micromanipulation SPIE Vol. 5514, 73-81. [4] M.P. Hughes, Nanoelectromechanics in engineering and biology, CRC Press (2003). [5] K. Dholakia and P Reece, “Optical micromanipulation takes hold,” Nano Today 1, 18 (2006).