Experimental study about the effect of scouring duration on the local

advertisement

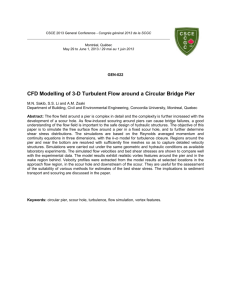

TIME EVOLUTION OF SCOUR AROUND SPUR DIKE ABOLFAZL SHAFAIE M.Sc Student Department of civil Engineering Amir Kabir University of Technology ,Tehran , Iran. SEYED MORTEZA SADAT-HELBAR Member of Iran water & Power Resources Development Company mortezasadat@yahoo.com HOSSEIN SHIRAZI Member of Iran water & Power Resources Development Company SUMMARY Spur dikes reduce the flow velocity near the river banks causing deposition of sediment and bank stability. One of the important problems in spur dike design is a local scouring at the head of spur dike. This phenomenon is derived by area contraction and powerful vortex. In this work it is presented measuring time and depth of several long duration clear-water scour laboratory tests around first spur dike with different discharges and two bed materials in the experimental flume constant slope; the time evolution of the erosion process is analyzed with respect to local souring and an empirical relation is developed. Four spur dikes with distance equal two times the first spur dike length and perpendicular to the flume wall were used in this study. The spur dikes were rigid, made of pressurized ply wood, straight and non-sub merged. Even though it appears that the scouring at the head of spur dike was continuing, but more than 80 % of the erosion has occurred at shorter time and after a short transient, depths increase almost linearly. Keywords: scour protection, erosion, open channel, laboratory test, flood control. 1 Introduction The flow hydraulic parameters have important effect on the erosion and protection of rivers. Increased velocity, discharge, shear stress and vortex cause bed and wall scouring [1], [2], [3]. One of the methods in coastal protection is building spur dikes and sub-merged Vanes structures that affect the streamlines and cause the flow toward thalweg of the river path [4]. Therefore, by reducing velocity impact from the shores it will increase the sediment aggregation on the river sides. Erosion phenomena are surely one of the most important factors in spur dike vulnerability: river structures are exposed to both contraction and local scour around spur dikes and abutments, especially at the time of heavy flooding [5]. The stability of the spur dike may be in danger and its structure may fail which will cause the river bank protection to be demolished [6]. Many spur dikes or other hydraulic instruction like bridges abutment either suffered severe damage or collapsed during recent years [7], [8], [9]). Researchers have investigated the cause of damage and local erosion at the head of spur dikes, Kuhnle et. al. [10,11] have studied the effectiveness of orientation of spur dike with river banks, which they assumed to be 90 degrees with river flow. Also Soliman et. al. [12] studied the effect of length of spur dike with respect to river morphology on the Nile river .Mohan et. al. [13] and Elawady et. al. [14] evaluated the minimum height to the impervious spur dike and the distance of submerged spur dikes for shore protection. Petersen [15] in her findings suggested distance between two consecutive spur dikes should vary between 1.5 to 6 times the lengths of the upstream spur dike. Using her suggestions for this study, the distance between spur dikes are fixed at 2L (L= spur 2 dike length) for the following experiments. Liu [16]; Baosheng [17]; Jain, S. C. [18]; Chang [19]; Franzetti and Wang [20] measured the maximum depth of scouring at the head of spur dike in a series of spur dikes. In spite of the considerable amount of studies on the subject in the scientific and technical literature, several hydraulic phenomena at spur dike crossings are not sufficiently defined; some problems may be easily solved when designing a new spur dike, by aggregating all uncertainties in safety factors, i.e. systematically choosing the safest model. When verifying existing spur dike, the adopted approximations appear too much conservative, so that the proper assessment of spur dikes vulnerability (absolute or relative) is extremely difficult and questionable. Therefore, better design criteria and validation methodologies for assessment of spur dike vulnerability are needed. Similarly, current national and international technical/scientific regulations do not appear adequate to a safe and rational design and validation procedure of spur dike. Different experimental results often do not match well; the dependence of phenomena on some parameters whose effect is probably not of secondary importance is still not well defined; the same is true for the temporal scour evolution. As a consequence, scour predictions for spur dikes can be affected by significant errors. Preliminary evaluations have shown that this procedure might significantly overestimate the actual scour depth. In this paper we present the results of several long duration scour laboratory tests around spur dikes; the erosion process was monitored by detailed measurements all around the obstacle. We will focus the analysis of results particularly on the predictability of scour with respect of its time evolution. 3 Dimensional analysis The scour depth (d) at any point around a bridge abutment can be expressed in a nondimensional form as: b b L u g b t.U , , , * , , , obstacleshape, h B b u*c d 50 d 50 d (1) where the main geometrical quantities are defined in figure 1; flow parameters (flow depth h, average velocity U, Shields number u* ) refer to the position of the obstacle, for an undisturbed flow without the obstacle; d50 and g are respectively the median size and standard deviation of the granulometric distribution; t is time; u *c is the threshold value for u* . The characteristic length scale ( ) depends on the b/h ratio: typically b for small b/h values, while b for high values of the ratio [21,22]. For Melville sugg 1 < b/h < 25 (bh) 0.5 . Experiments shown here have b/h 7÷25 (see table 1), so that either b or (bh)1/2 may be chosen as the length scale. Some Reynolds number should be added in the control parameter list in (1) if turbulent effects do not dominate, so that fluid viscosity affects the phenomenon. The Froude number (possibly the densimetric Froude number) could substitute for either u* or b/d50 since the three non-dimensional groups is mutually correlated by h/b and u *c the resistance equation for a developed flow. In the following d will indicate scour depths in a generic point, ds is the absolute scour maximum for the hole, dst ,scour depth at the head of first spur dike. 4 Experimental set up and procedure All of the experiments were conduct in the National Laboratory of Soil Conservation and Water Management Research Center in Tehran. The experimental flumes have a length of 25m, width of 1.3 and 1.5m and depth of 0.8m.It has a constant slope of 0.001. The depth of water at downstream is regulated by flip gate having equal with the flume. The physical parameters of the flume are as follows: B is the flume width, b is flow concentration parameter (B-L) , L is the spur dike Length, dst is the scour depth at the head of first spur dike, X is the distance between spur dikes . Four spur dikes with distance equal two times the first spur dike’s length and perpendicular to the flume’s wall were used in this study. The spur dikes were rigid, made of pressurized ply wood, straight and non-sub merged. (Fig.1). To carry out each series of observation the straight hydraulic flume was partially filled with a layer of fine sand particles. To achieve the slope needed for the experiment,(0.001) the upstream end of the flume where the first spur dike is placed, had a thickness of about 0.206 m of particles and the downstream from the fourth spur dike was 0.20 m thick on section of reach with a length of 6m . This provides the slope of 0.001 for the experiment to be carried out. These particles have a density of ( s )2620kg / m 3 and a mean size diameter (d 50 ) of 1 and 3mm, and standard deviation of sediment grading, g as defined below equals 1.25mm . d g 84 d 16 0.5 (2) 5 Where, for example, d 84 is the size of sediment for which 84 percent of materials by weight are finer. Therefore, the grain size could be considered as approximately uniform size. To reduce the amount of disturbance at the surface when the water is entering the flume, for discharge greater than 30 liter per seconds, we placed a fiber glass on the water surface about 1 m before to the first spur dike. Also in the first 10 m of the flume, large sand and gravels were placed to increase the roughness, so that the approaching water was a uniform flow. For all experiments, at the end of each experiment the water was emptied in the stilling basin. Then, the local scouring at the head of spur dikes was measured. For the next experiment, the bed material was refurbished to the original state and the next experiments were performed. There is a moving rail on top of the flume and a graduated rod with an accuracy of 0.5mm for measurements of bed topography, with 3 degrees of freedom (longitudinal, latitudinal and vertical directional). The discharge was measured using a sharp cross rectangular weir located at upstream end of the flume with a maximum error of 0.4% and water level was measured using a point gauge with an accuracy of 0.1mm . Experiments were run near threshold conditions. Table 1shows test condition. Scour process and Time evolution A typical configuration for a spur dike scour hole shows that in head of the spur dike the hole has almost the form of a reverse cone that: whenever depth is deeper then cone’s radius is smaller, with a slope approximately equal to the sediment angle of repose in water and with the maximum close to the upstream corner of every spur dike; at the downstream side of the head of spur dike a channel can be recognized. 6 Sediments coming from upstream are mainly conveyed to the bottom of the channel, and could be either linked to the erosive effect of the wake detaching from the spur dike front corner, or to an alternation of active and stagnation regions within the vortex system from upstream. The erosion process typically begins at the spur dike upstream corner, the sediments being continuously displaced by the main flow which turns around the head of spur dike. After a few minutes, however, the maximum sediment activity progressively moves to the channel side, between spur dikes, while movements are less continuous; finally the erosion process becomes mainly impulsive, and the grains are clearly forced upstream and laterally by a vertical flow with a transverse horizontal axis (front region of vortex). The erosive process is apparently concentrated at the front of spur dike; lateral widening is caused by the consequent collapse of the hole sides. In spite of the low value of g for the granulometric distribution we could notice some minor armoring at the spur dike's downstream after the (4-5) hours of run. Sediment aggregation occurred between spur dikes noticeably. Typical time evolution trends for the maximum scour dst are plotted in figure 2. Erosion develops at an exponential rate during the first stage of runs, so that during the first hour the scour increased dramatically in logarithmic scale for time. Erosion continues at a decreasing rate. A lessening of the logarithmic scour rate can be recognized for tests approximately after half of time to equilibrium or 45005. In the following hours; after a short transient, depths increase almost linearly. These results indicate that the interactions among the main stream, the vortex system coming from the front and the wake from the corner generate a complex flow field in the constricted reach, whose scouring effects change with time. 7 Regression analysis based on the experimental observation and dimensional analysis shows the relation between d st and t to be as shown in equation.3 with R 2 0.95 . d st Lh 0.5 0.378( u 0.590 tu 0.378 ) Ln( ) uc ( Lh) 0.5 (3) We compared the measured increases in scour depths due to the constriction with literature formulas for constriction scour. The equations of selected previous studies carried out in Figure 3, presents resultant of this work with Cardoso and Bettes [23] and Kohli and Hager [24]. The comparison shows that the relation of time and scour depth proposed in this study gives a value approximately equal to Cardoso & Bettes [23] , while Kohli & Hager [24] can lead to a significant overestimation of the scour depth. Scour rate especially at the first stage of runs, in this work, does not comply with other methods. Conclusions In this work we presented the results of several long duration scour laboratory experiments around spur dikes; experimental conditions have been chosen so that with three different discharges and two bed materials at a time were varied. Detailed measurements of the erosion holes allowed the evaluation of scoured depth. The analysis of the results shows the following. 1. After several experimental tests were carried with long durations it was observed local scour depth near the spur dike strongly relies on duration of experiment and scour rate was occurring much slower rate after half of time to equilibrium. Even though it appears that the scouring at the head of spur dike was continuing, but more than 80 % of the erosion has occurred at shorter time and after a short transient, depths increase almost linearly. 8 2. Scour patterns show geometrical similarity along time and among different tests. As a consequence, all characteristics of the scour hole which could be significant for the spur dike stability (hole width, volume …) can be drawn with reasonable accuracy from maximum depths and/or from any other scour scale. 3. We observed significant effects of the constriction ratio on scour only for extreme values of the ratio (b/B = 0.30). If standard models are used to evaluate contraction erosion, the simple addition of contraction and local effects can lead to a significant overestimation of the total scour; a conceptual analysis of the results shows that the assumption of linear superimposition of contraction and local effects is not sound. As a general comment, we should stress that spur dike scour is less documented than other hydraulic instructions scour like pier and abutment scour, in spite of its importance on vulnerability of facilities on the shoreline. No comprehensive synthesis of experimental data is available. As a consequence, relatively large errors should be expected when predicting spur dike scour on the base of literature models of abutments or piers scour. Additional experiments are necessary to verify the present observations on a wider variety of flow conditions, especially for different b/B and h/d50 values. Notation B = Flume width; b = flow concentration parameter; dst = Scour depth at the head of first spur dike; ds = Maximum scour depth at the head of first spur; d 50 = Median grain size of sediment; d 84 = the size of sediment for which 84 percent of materials by weight are finer; d16 = the size of sediment for which 16 percent of materials by weight are finer;. Fr = Froude number; g = Standard deviation of bed material sediment; L = spur dike Length; s = Particle's density; R 2 Regression coefficient; 9 S = Bed slope; X = Distance between spur dikes; h = Flow depth; u = Average velocity; uc = The threshold value for u ; u* = Shields number u *c = The threshold value for u* ; t = Time; T = Dimensionless time; = Obstacle shape; and = The characteristic length scale. Acknowledgments The authors would like to acknowledge the Iran Water and Power Resources Development Company for financial support. References [1] Azinfar, H; Kells, J. A., Jan 2007. Backwater effect due to a single spur dike Canadian Journal of Civil Engineering; 34, 1; ProQuest Science Journals pg. 107. [2] Giuseppe Oliveto and Willi H. Hager, F. 2005. Further Results to Time-Dependent Local Scour at Bridge Elements, Annual Journal of Hydraulic Engineering, JSCE, vol. 131, No.2, pp. 97-105. [3] Pinter. N. 2005. Technical review of the upper Mississippi River flow frequency study. Southern Illinios University . http://65.108.172.154/Issues/ Flood plains/ Rpt –Pinter Final. pdf. [4] Ettema, R., and Muste, M. 2002. Scale-effect trends on flow thalweg and flow separation at dikes in flatbed channels. IIHR Rep. 414, IIHR–Hydroscience and Engineering, The Univ. of Iowa, Iowa City, [5] Hager, W. H., and Oliveto, G. 2002. Shields’ entrainment criterion in bridge hydraulics. J. Hydraul. Eng., 128(5), 538–542. [6] Kothyari, U. C., and Ranga Raju, K. G. 2001. “Scour around spur dike sand bridge abutments. J. Hydraul. Res., 39(4), 367–374. [7] Morris J.L., Pagan-Ortiz J.E. (1997), "Bridge Scour Evaluation Program in the United States", Proceedings of the 27th IAHR Congress, S. Francisco, Theme A, 110-115. [8] Ballio, F., Orsi E. (2000). "Time evaluation of scour around bridge abutments" .Water Eng. Res .NO. 2, PP. 243–259. [9] Yeo W.K. (1998), "Field Investigation of Bridge Scours in Korea", Proceedings 3rd International Conference on Hydro-science and Engineering ICHE '98, Cottbus 31 Agosto – 3 Settembre . [10] Kuhanle, et.al. 1999. Geometry of scour holes associated with 90 Engineering, Vol.129, No.9-pp 635-646. [11] Kuhnle, R. A., Alonso, C. V., and Douglas Shields, F., Jr. 2002. Local scour associated with angled spur dikes. J. Hydraul. Eng., 128(12),1087–1093. 10 0c spur dikes J. of Hydraulic [12] Soliman, M.M., Attia, K.M , 1997. Spur Dike Effect on the River Nile Morphology After High Aswan Dam, Congress of the International Association of Hydraulic Research, IAHR, Vol.120 No.9-pp125-146. [13] Mohan,J. and Agrawal, A.K., 1979. Efficacy of Submerged Spurs in Protection of Banks, CI (1) Journal –CI, Vol.59. [14] Elawady, E., Michiue, M. and Hinokidani, O. 2000. Experimental Study of Flow Behavior Around Submerged Spur-Dike on Rigid Bed, Annual Journal of Hydraulic Engineering, JSCE, vol. 44, pp. 539-544. [15] Petersen. M.S, 1986. River Engineering, Published by prentice- Hall, Englewood cliffs, printed in U.S.A . [16] Liu. J &Tominaga. A & Nagao. M, 1994. Numerical simulation of the flow around the spur dikes with certain con figuration and angles with bank, Journal of Hydraulic Engineering. Vol.12, No.2, November 1994, pp. 85-100. [17] Baosheng Wu, M. Guangqian Wang; Jiming Ma; and Ren Zhang. 2005. Case Study: River Training and Its Effects on Fluvial Processes in the Lower Yellow River, China, Annual Journal of Hydraulic Engineering, JSCE, vol. 131, No.2, pp. 85-96. Breusers H.N.C., [18] Jain, S. C. 1981. Maximum clear-water scour around circular piers. J.Hydraul. Div., Am. Soc. Civ. Eng., 107(5), 611–626. [19] Chang, F. and Davis, S., 1999. Maryland Sha Procedure for Estimating Scour at Abutment, Part I- Live Bed Scour, H J. of Hydraulic Engineering, Vol.125, No.9. [20] Franzetti et al, 1999. Effect of Time and Channel Geometry on Scour at Bridge Abutment, J.Hyd., Vol.125, No.4 [21] Melville B.W. (1997), "Pier and Abutments Scour: Integrated Approach", Journal of Hydraulic Engineering, Vol. 123, n. 2, 125-136. [22] Melville B.W. (1992), "Local Scour at Bridge Abutments", Journal of Hydraulic Engineering, Vol. 118, n. 4, 615-631. [23] Cardoso, A H., Bettess, R. (1999). "Effects of time and channel geometry on scour at bridge abutments". J. Hydraulic. Eng., Am. Soc. Civ. Eng.NO.125, PP. 388–399. [24] Kohli, A., and Hager, W. H. 2001. Building scour in flood plains. Water and maritime engineering, Institution of Civil Engineers, London,148, 61–80. 11 Table 1: test conditions. Test B (m) d 50 (mm) S1 S2 S3 G1 G2 G3 1 1 1 3 3 3 1.3 1.3 1.3 1.5 1.5 1.5 L (m) h (m) u (m/s) uc (m/s) 0.39 0.39 0.39 0.45 0.45 0.45 0.035 0.045 0.055 0.076 0.098 0.117 0.220 0.256 0.280 0.263 0.306 0.342 0.320 0.320 0.320 0.680 0.680 0.680 12 10mm X=2L FLOW dst Fig.1. Definition sketch. 13 L B/2 100% 90% 80% (dst/ds)% 70% 60% S1 50% S2 40% S3 30% G1 20% G2 G3 10% 0% 0% 10% 20% 30% 40% 50% 60% 70% 80% 90% (t/T)% Figure 2. Time evolution of maximum scour depth. 14 100% 0.14 0.12 dst(m) 0.1 0.08 0.06 Present study 0.04 Cardoso & Bettes (1999) 0.02 0 100 Kohli and Hager (2001) 2500 4900 7300 9700 t (sec) Figure 3. Comparison of time evolution of maximum scour depth with previous studies. 15