How to replace o-rings in your nailer

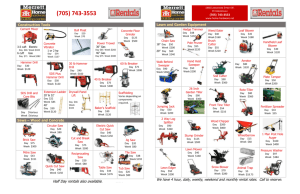

advertisement

How to replace o-rings in your nailer 1. First, make sure you have a workspace that will allow you to lay out all of your disassembled parts. 2. The tools that you will most likely need for this job are allen head wrenches, a straight pin or something similar to remove the o-rings, possibly snap ring pliers, degreaser/cleaner and o-ring lube. 3. Obviously, disconnect the nailer from the air hose! 4. Most o-ring kits include o-rings that are dynamic, that is, move and wear out most frequently. 5. Review the diagram that was included with your o-ring kit to determine which orings will be replaced. 6. Find your nailer exploded parts diagram first and print it out. 7. Make sure to lay out all of your disassembled parts in the order in which you removed them along with the fasteners. 8. Remove the cap or top of the nailer. This is usually held on by use of 4 allen head bolts. 9. Next, remove the cylinder, following the parts diagram to determine what is holding it in place. 10. Remove the piston/driver assembly. 11. If the trigger o-rings are included in your o-ring kit, then disassemble the trigger assembly per the parts diagram. 12. If you have a Bostitch nailer, usually, the trigger assembly is a separate kit which is replaced as one unit. 13. If you are working on a coil nailer, make sure that your new o-ring kit includes these prior to disassembly. 14. On coil nailers, there is a piston that advances the nails which includes several orings. Be sure to lay these parts in proper order as to not get them confused when reassembling. 15. Next, remove one o-ring at a time and find the corresponding o-ring in your new kit. 16. Before installing the new o-ring, clean the part in a parts cleaner suitable for this purpose. Hitachi makes a degreaser/cleaner. Do NOT use gasoline, kerosene or anything similar as these will melt your new o-rings! 17. Prior to installing your new o-rings, apply o-ring lubricant to the inside and outside of the new o-ring. Failure to do so, will cause your nailer to leak air. 18. Put each old o-ring in a discard pile so that you will know that these are old orings, not to confuse them with the new pile. 19. Repeat this process, steps 14-16 until you have installed all of the new o-rings. 20. Once all of the new o-rings have been installed, start reassembling your nailer in the reverse order in which you disassembled it. 21. Make sure to tighten any bolts snugly, but not to the point of stripping them. 22. Once your nailer is reassembled, squirt 3 or 4 drops of nailer lubricant into the end of your nailer where you attach your air hose. This will give your o-rings the needed lubricant for operation. (this step should be performed twice per day when using your nailer) 23. Insert fasteners into your nailer and test your nailer on a piece of scrap lumber. If you have installed your kit properly, your nailer should now show an improved amount of performance. 24. The most common source of leaks are: head valve leaks around these o-rings (air will escape from the top exhaust port or cap of the nailer) trigger valve leaks around these o-rings (air will escape from the trigger area of the nailer) driver misalignment due to improper re-installation of the piston/driver (air will escape from the nose of the nailer)