Syllabus

advertisement

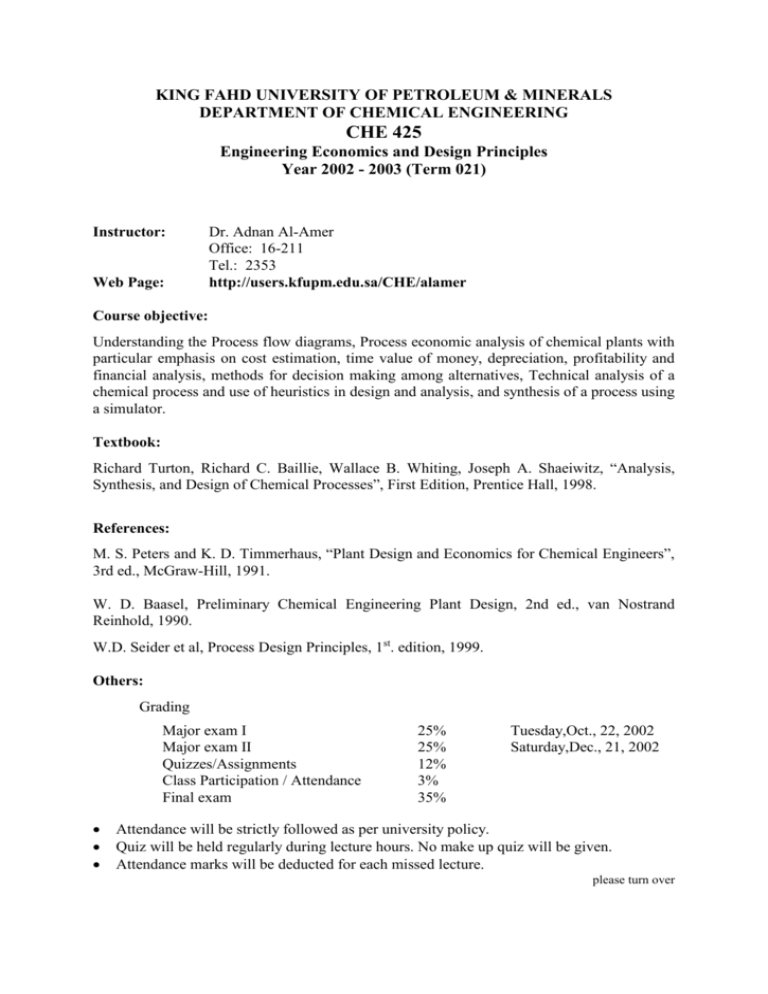

KING FAHD UNIVERSITY OF PETROLEUM & MINERALS DEPARTMENT OF CHEMICAL ENGINEERING CHE 425 Engineering Economics and Design Principles Year 2002 - 2003 (Term 021) Instructor: Web Page: Dr. Adnan Al-Amer Office: 16-211 Tel.: 2353 http://users.kfupm.edu.sa/CHE/alamer Course objective: Understanding the Process flow diagrams, Process economic analysis of chemical plants with particular emphasis on cost estimation, time value of money, depreciation, profitability and financial analysis, methods for decision making among alternatives, Technical analysis of a chemical process and use of heuristics in design and analysis, and synthesis of a process using a simulator. Textbook: Richard Turton, Richard C. Baillie, Wallace B. Whiting, Joseph A. Shaeiwitz, “Analysis, Synthesis, and Design of Chemical Processes”, First Edition, Prentice Hall, 1998. References: M. S. Peters and K. D. Timmerhaus, “Plant Design and Economics for Chemical Engineers”, 3rd ed., McGraw-Hill, 1991. W. D. Baasel, Preliminary Chemical Engineering Plant Design, 2nd ed., van Nostrand Reinhold, 1990. W.D. Seider et al, Process Design Principles, 1st. edition, 1999. Others: Grading Major exam I Major exam II Quizzes/Assignments Class Participation / Attendance Final exam 25% 25% 12% 3% 35% Tuesday,Oct., 22, 2002 Saturday,Dec., 21, 2002 Attendance will be strictly followed as per university policy. Quiz will be held regularly during lecture hours. No make up quiz will be given. Attendance marks will be deducted for each missed lecture. please turn over Chapter Title Lectures Introduction 1 Chapter 1 SECTION 0 CHEMICAL PROCESS DIAGRAMS Essential Flow Diagrams for Understanding Processes 4 Chapter 2 Chapter 3 Chapter 4 Chapter 5 SECTION 1: ENGINEERING ECONOMIC ANALYSIS OF CHEMICAL PROCESSES Estimation of Capital Costs 5 Estimation of Manufacturing Costs 5 Engineering Economic Analysis 6 Profitability Analysis 6 Chapter 6 Chapter 7 Chapter 8 Chapter 9 Chapter 17 Chapter 18 SECTION 2: TECHNICAL ANALYSIS OF A CHEMICAL PROCESS Structure of Chemical Process Flow Diagrams 1 Tracing Chemicals through the Process Flow Diagram 1 Understanding Process Conditions 3 Utilizing Experience Based Principles to Confirm the Suitability of a Process Design 5 SECTION 4: SYNTHESIS AND OPTIMIZATION OF A PROCESS FLOW DIAGRAM Synthesis of the PFD from the Generic BFD 2 Synthesis of a Process using a s Simulator and Simulator Troubleshooting 5 Review Note: The above is an approximate guideline. Office Hours: S, M, and W → 11– 12 1