pola26847-sup-0001-suppinfo

advertisement

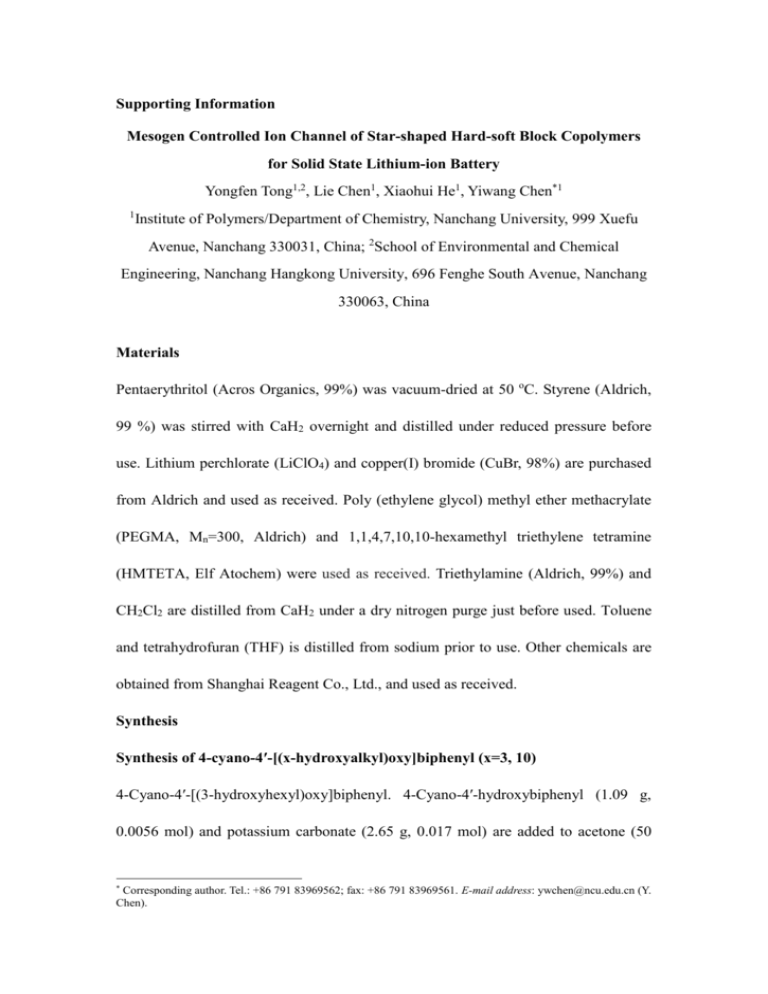

Supporting Information Mesogen Controlled Ion Channel of Star-shaped Hard-soft Block Copolymers for Solid State Lithium-ion Battery Yongfen Tong1,2, Lie Chen1, Xiaohui He1, Yiwang Chen*1 1 Institute of Polymers/Department of Chemistry, Nanchang University, 999 Xuefu Avenue, Nanchang 330031, China; 2School of Environmental and Chemical Engineering, Nanchang Hangkong University, 696 Fenghe South Avenue, Nanchang 330063, China Materials Pentaerythritol (Acros Organics, 99%) was vacuum-dried at 50 oC. Styrene (Aldrich, 99 %) was stirred with CaH2 overnight and distilled under reduced pressure before use. Lithium perchlorate (LiClO4) and copper(I) bromide (CuBr, 98%) are purchased from Aldrich and used as received. Poly (ethylene glycol) methyl ether methacrylate (PEGMA, Mn=300, Aldrich) and 1,1,4,7,10,10-hexamethyl triethylene tetramine (HMTETA, Elf Atochem) were used as received. Triethylamine (Aldrich, 99%) and CH2Cl2 are distilled from CaH2 under a dry nitrogen purge just before used. Toluene and tetrahydrofuran (THF) is distilled from sodium prior to use. Other chemicals are obtained from Shanghai Reagent Co., Ltd., and used as received. Synthesis Synthesis of 4-cyano-4′-[(x-hydroxyalkyl)oxy]biphenyl (x=3, 10) 4-Cyano-4′-[(3-hydroxyhexyl)oxy]biphenyl. 4-Cyano-4′-hydroxybiphenyl (1.09 g, 0.0056 mol) and potassium carbonate (2.65 g, 0.017 mol) are added to acetone (50 * Corresponding author. Tel.: +86 791 83969562; fax: +86 791 83969561. E-mail address: ywchen@ncu.edu.cn (Y. Chen). ml), and reflux for 2~3 h, followed by addition of 3-bromo-1-propanol (1.39 g, 0.01 mol). After refluxing for 24 h, the reaction mixture is poured into diluted HCl solution, and the precipitated product is extracted with chloroform. The combined chloroform extracts are washed with water and dried over anhydrous MgSO4. After filtration and concentration, the crude product is recrystallized from methanol to yield 1.05 g (76%) of white crystals, Mp. 113.5 ºC; 1H NMR (δppm, CDCl3): 1.03–1.51 (m, 2H, –CH2–), 3.68 (t, 2H, –OCH2OH), 4.1 (m, PhOCH2, 2H), 6.87–7.69(m, 8H, aromatic). IR (KBr): 2 224 (CN), 3 298cm-1(OH). 4-cyano-4′-[(10-hydroxyalkyl)oxy]biphenyl, which is obtained similarly with 4-cyano-4′-[(3-hydroxyalkyl)oxy]biphenyl. Mp. 78.5 ºC; 1H NMR (δppm, CDCl3): 1.01–1.99 (m, 16H, –(CH2)8–), 3.42 (t, 2H, –OCH2OH) 3.96 (m, PhOCH2, 2H), 6.89–7.65(m, 8H, aromatic). IR (KBr): 2 225 (CN), 3 288cm-1(OH). Synthesis of Monomers x-[(4-Cyano-4′-biphenyl)oxy]alkyl methacrylate MAxLC (x=3, 10) 3-[(4-Cyano-4′-biphenyl)oxy]propyl methacrylate (MA3LC). 4-Cyano-4′-[(3-hydroxyhexyl)oxy]biphenyl (7.59 g, 0.03 mol) is dissolved in a mixture of dry tetrahydrofuran (210 mL) and triethylamine (3.33 g, 0.033 mol). To this mixture a solution of methacryloyl chloride (3.13 g, 0.03 mol) in 50 mL of dry THF is added dropwise. The reaction mixture is stirred at room temperature overnight. The white solid which precipitated is removed through filtration and the solution evaporated at reduced pressure. The residue obtained is recrystallized from 96% ethanol to yield 7.15 g (74%) of white crystals. 1H NMR (δppm, CDCl3) :7.69 (d, 2H), 7.65 (d, 2H), 7.53 (d,2H), 6.99 (d, 2H), 6.10 (s, 1H), 5.56 (s, 1H), 4.16 (t, 2H), 4.02(t, 2H), 1.95 (s, 3H), 1.84 (q, 2H), Mp. 67 °C. 10-[(4-Cyano-4′-biphenyl)oxy]decatyl methacrylate (MA10LC), similarly obtained. Yield =73%. 1H NMR (δppm, CDCl3) :7.69 (d, 2H), 7.65 (d, 2H), 7.52 (d,2H), 6.99 (d, 2H), 6.13 (s, 1H), 5.56 (s, 1H), 4.15 (t, 2H), 4.02(t, 2H), 1.94 (s, 3H), 1.81 (q, 2H), 1.69 (q, 2H), 1.21-1.56 (m, 12H) Mp. 64°C. Synthesis of ATRP Initiator Pentaerythritol Tetrakis(2-bromoisobutyrate) (PERBr4) Under N2 atmosphere, to a dried, two-neck, 100-mL flask equipped with a magnetic bar, 2-Bromoisobutyryl bromide (36.8 g, 0.16 mol) was slowly added to a solution of pentaerythritol (2.72 g, 0.020mol) and triethylamine (16 g, 0.16 mol) in dry THF at 0 o C. The solution was stirred for 24 h and allowed to reach room temperature slowly. The mixture was then transferred to a separation funnel with 350 mL of dichloromethane and rinsed successively with 10% HCl, 5% NaHCO3, and then deionized water. The organic phases were dried over MgSO4, and the solvent was removed by rotary evaporation. The raw product was dissolved in a small amount of dichloromethane and recrystallized in methanol. Yield: 79%. 1H NMR (δppm, CDCl3): 4.32 (s, 8H); 1.92 (s, 24H). Synthesis of the Star Macroinitiator 4PS-Br4 (4PS) via ATRP 0.18 g of PERBr4 (0.24 mmol), 0.021 g of CuBr (0.144 mmol), 0.033 g of HMTETA (0.144 mmol) and 16.0 g of styrene (154 mmol) were added to an ampoules bottle. The bottle containing reactants was fully degassed with three freeze–pump–thaw cycles and sealed under vacuum. It was subsequently immersed in a thermostated oil bath at 100 oC under stirring to allow polymerization of styrene. After reaction for 6 h, the system was cooled down to room temperature. Finally, the mixture was washed by a large excess of methanol repeatedly. The white copolymer product was then dried in vacuum. 1H NMR (δppm, CDCl3): 7.4–6.5 (m, 5H, aromatic), 3.7 (s, CHBr), 1.2–2.1 (m, CH2 and CH of PS). Synthesis of the Star Macroinitiator 4PS-PEGMA-Br4 (4PS-PEGMA) by ATRP In a typical polymerization, a Schlenk flask is charged with macroinitiator, 4PS-Br4 (1 g, 0.09 mmequiv. Br), PEGMA (3g, 10 mmol), distilled toluene (10 mL), and ligand HMTETA (23mg, 0.1mmol) and degassed before CuBr (14.3 mg, 0.1 mmol) under nitrogen. The solution is degassed three times with freeze-pump-thaw cycles. For a given reaction time the flask is immersed in an oil bath preheated at 85 °C. After 4 h of polymerization, the Schlenk flask is dipped into liquid nitrogen to stop the polymerization. The solution is diluted with THF and passed through a column of neutral alumina to remove the copper salts. The product is precipitated from an excess of ether twice, filtered, and vacuum dried to give a colloidal product of 4PS-PEGMA-Br4 3.36 g. 1H NMR (δppm, CDCl3): 7.4–6.5 (m, 5H, aromatic), 4.1-3.42 (m, -OCH2CH2O-), 3.38 (s, -OCH3), 0.81–2.1 (m, CH2 and CH of PS, CH2 and CH3 of methacrylate main chain). Synthesis of the Star Copolymers 4PS-PPEGMA-PMAxLC The synthesized 4PS-PPEGMA-Br4 macroinitiator (2 g, 0.016 mmol), CuBr (0.01 g, 0.064 mmol), distilled toluene (10 mL) and MA10LC (1.5g, 0.003 mol) were added into a dried round-bottom flask. HMTETA (0.014 g, 0.064 mmol) was then poured into the flask. The polymerization reaction was then allowed to proceed at 85°C. At 24 h from the initiation of the polymerization, heating was stopped. The obtained polymer was then isolated and purified by reprecipitation using a similar method as that used for the 4PS-PPEGMA-Br4 macroinitiator. 4PS-PPEGMA-PMA3LC, similarly obtained. Preparation of Star Copolymer /LiClO4 Electrolytes In a typical procedure for preparing the electrolyte, copolymers and LiClO4 salt are dissolved in acetonitrile and stirred for 24h, varying amounts of copolymers and LiClO4 salt to achieve the desired [O]/[Li] ratios (Z). After the solution was stirred, it was cast onto an aluminum foil; and the solvent is slowly evaporated at room temperature for 24 h. Then, the material is heated to 60 °C under vacuum for 24 h. The film is about 100μm thick and had a smooth surface without pinholes. Characterization Methods The nuclear magnetic resonance (NMR) spectra are collected on a Bruker ARX 400 NMR and Bruker AV 600 NMR spectrometer with deuterated chloroformor as the solvent and with tetramethylsilane (δ=0) as the internal standard. The infrared (IR) spectra are recorded on a Shimadzu IR Prestige-21 Fourier transform infrared (FTIR) spectrophotometer by drop-casting sample solution on KBr substrates. The gel permeation chromatography (GPC), so-called size-exclusion chromatography (SEC) analysis, is conducted with a Breeze Waters system equipped with a Rheodyne injector, a 1515 Isocratic pump and a Waters 2414 differential refractometer using polystyrenes as the standard and tetrahydrofuran as the eluent at a flow rate of 1.0mL/min and 40 oC through a Styragel column set, Styragel HT3 and HT4 (19mm×300mm, 103 +104 Å) to separate molecular weight (MW) ranging from 102 to 106. Thermogravimetric analysis (TGA) is performed on a TA Mettler TG 851 for thermogravimetry at a heating rate of 10 oC /min under nitrogen with a sample size of 8–10mg. Differential scanning calorimetry (DSC) is used to determine phase-transition temperatures on a Shimadzu DSC-60 differential scanning calorimeter with a constant heating/cooling rate of 10 ºC /min. Texture observations by polarizing optical microscopy (POM) are made with a Nikon E600POL polarizing optical microscope equipped with an Instec HS 400 heating and cooling stage. The X-ray diffraction (XRD) study of the samples is carried out on a Bruker D8 Focus X-ray diffractometer operating at 30 kV and 20mA with a copper target (λ= 1.54 Å) and at a scanning rate of 1o/min. The surface image of the membranes were investigated by scanning electron microscope (SEM), using an Environmental Scanning Electron Microscope (ESEM, FEI Quanta 200). Transmission electron microscopy (TEM) images were recorded using a JEOL-2100F transmission electron microscope and an internal charge-coupled device (CCD) camera. The samples for TEM investigation were prepared as follows: the liquid crystalline copolymers were prepared by dropping a 2 g/L tetrahydrofuran (THF) solution on copper grids, then heated and annealed at the desired temperatures for 2 h. Electrochemical measurements are made in a standard three-electrode cell by an electrochemical analyzer. Alternating current (AC) impedance measurements of the polymer electrolytes are performed using CHI660 electrochemical workstation (CH Instruments) over a frequency range of 10 Hz-1MHz with an amplitude of 10 mV. All the specimens are sandwiched by two polished stainless steel blocking electrodes for conductivity tests. These measurements are performed in the temperature range of 10-100 ºC, and the system was thermally equilibrated at each selected temperature for at least 1 h. Complex impedance plots are computed from the raw experimental data. The intersection in the imaginary impedance at low frequency with the real impedance axis corresponds to the ionic conductance of the samples and hence the conductivity values (σ) are obtained from the equation σ= (1/Rb) (t/A), where Rb represents the bulk resistance, t is the thickness and A is the area of the sample. The lithium transference number (t+) was determined by using a combination method of dc polarization and ac impedance measurements. The sample was sandwiched between two 0.5 mm-thick lithium foils (Alfa) as non-blocking electrodes and assembled in a standard 2032 coin-cell holder in an argon gas-filled glove box. The dc voltage pulse applied to the cell was 10 mV. The electrochemical stability of the hybrid electrolytes was determined by linear sweep voltammetry (LSV) using stainless steel (SS) as a working electrode and lithium as counter and reference electrodes for a Li/electrolyte/SS cell at a scan rate of 2 mVs-1 from 1 to 8 V vs. Li/Li+. FT-IR Analysis of Polymers The FT-IR spectra of macroinitiator 4PS, 4PS-PPEGMA and copolymer 4PS-PPEGMA-PMA10LC are shown in Figure S1. The component absorption bands can be easily observed in the FI-IR spectra of the star liquid crystalline copolymer, which shows the absorbance peak of a –Ph groups at 1597 cm−1 derived from 4PS and a –C-O-C- groups at 1107 cm−1 derived from PEGMA, a weak band at 1737 cm−1 associated with the –COO- stretch, and an obvious band of cyano functionality at 2223 cm-1 implying the presence of cyano biphenyl mesogens. 4PS-PPEGMA-PMA10LC 2223 1107 4PS-PPEGMA 4PS 1597 PER-Br4 1737 4000 3500 3000 2500 2000 Wavenumbers (cm 1500 1000 500 -1 ) Figure S1. FT-IR spectra of the macroinitiator PER-Br4, 4PS, 4PS-PPEGMA and copolymer 4PS-PPEGMA-PMA10LC. H2 C CH a COO CH2CH2 O CH3 m CH3 CH2 C cBr CH2 C b CH3 COO CH2 10 O CN H2 C CH a CH 3 CH 2 C Br b CO O CH 2 CH 2 O CH 3 m H2 C CH a Br 8.0 Figure S2. 7.0 1 6.0 5.0 4.0 3.0 2.0 1.0 0.0 ppm H NMR spectra of the polymers 4PS, 4PS-PPEGMA and 4PS-PPEGMA-PMA10LC. 4PS-PPEGMA-PMA3LC 4PS-PPEGMA-PMA3LC o intensity (a.u.) annealing at 150 C 4PS-PPEGMA-PMA10LC 4PS-PPEGMA-PMA10LC o annealing at 150 C 200 Figure S3. UV 250 spectra 300 350 Wavelength (nm) of the polymers 400 450 4PS-PEGMA-MA3LC and 4PS-PEGMA-MA10LC as-cast films and annealing from their liquid crystalline states on a quartz plate. 100 80 60 40 4PS-PPEGMA (a) 4PS-PPEGMA-PMA3LC (b) 4PS-PPEGMA-PMA10LC (c) 20 (b) (c) (a) 0 0 100 200 300 400 500 600 Figure S4. TGA thermogram of copolymers recorded under nitrogen at a heating rate of 10 oC/min (c) Heating Flow Endo (a) (b) -58.8 -53.4 Cooling Heating (b) (c) -49.5 (a) -50 0 50 o Temperature ( C) 100 Figure S5. DSC thermograms of 4PS-PPEGMA-PMA10LC with various [O]/[Li] ratios [Z = (a) 30, (b) 20, (c) 10] recorded under nitrogen during the second heating scans at a scan rate of 10 oC /min. Table S1. VTF parameters and Tg for electrolytes studied. Copolymer electrolytes 4PS-PPEGMA /LiClO4 4PS-PPEGMA-PMA3LC/LiClO4 4PS-PPEGMA-PMA10LC/LiClO4 Z,[O]/[Li] Tg(K) T0 (K) A (Scm-1K0.5) Ea (kJ/mol) 30 20 10 30 20 10 30 20 10 217.2 222.3 226.1 215.6 228.5 235.4 214.2 219.6 223.5 167.2 172.3 176.1 165.6 178.5 185.4 164.2 169.6 173.5 2.17 1.94 1.78 0.87 2.13 1.06 0.37 1.01 0.77 7.81 6.34 6.13 4.12 5.31 4.25 5.39 4.67 4.31