Delivery of inhaled medication in adults

advertisement

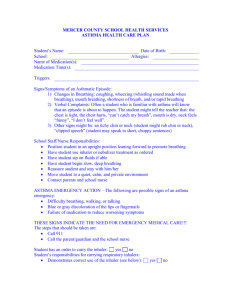

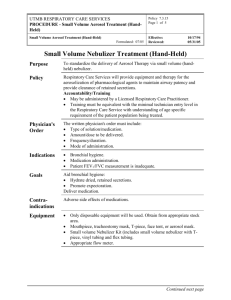

Delivery of inhaled medication in adults Dean Hess, RRT, PhD UpToDate performs a continuous review of over 375 journals and other resources. Updates are added as important new information is published. The literature review for version 15.1 is current through December 2006; this topic was last changed on January 8, 2007. The next version of UpToDate (15.2) will be released in June 2007. INTRODUCTION — The inhalation of therapeutic aerosols is an effective method of drug delivery frequently applied to the management of respiratory disease. Inhalation (or aerosol) therapy can be employed with a range of medications using a number of different techniques. Examples include: Inhaled beta agonists and anticholinergic bronchodilators are used to treat chronic obstructive lung diseases Inhaled steroids have a central role in the management of asthma Inhaled antibiotics and mucokinetic agents are therapies for cystic fibrosis and bronchiectasis Inhaled pulmonary vasodilators are used to manage pulmonary hypertension [ 1] In the future, patients with nonrespiratory disease may benefit from aerosol delivery of drugs, including insulin and opiates [2] OVERVIEW — Three principal types of devices are used to generate therapeutic aerosols: nebulizers, metered dose inhalers, and dry powder inhalers. All three generate aerosols using different mechanisms. In many cases, clinicians must choose the most appropriate device for drug delivery as well as the appropriate therapeutic agent [3]. In addition, the patient technique for proper use differs among these devices. The patient-aerosol generator interface is an important, but often overlooked, component of patient compliance and therapeutic response. Ineffective use of any of these devices will result in suboptimal drug deposition. As a result, patient instruction and compliance are crucial aspects of prescription and use of these devices. All three types of devices can be used to efficiently deliver medication to spontaneously breathing patients. Only nebulizer systems and metered dose inhalers can be used in intubated patients; dry powder inhalers should not be used in intubated patients. NEBULIZERS — The basic design and performance of pneumatic (or jet) nebulizers have changed little over the past 25 years (show figure 1). Nebulizer performance is affected by both technical and patient-related factors (show table 1) [4,5]. Jet nebulizers are often considered interchangeable. However, differences in performance among nebulizers produced by various manufacturers have been reported, some of which have clinical implications [ 6,7]. This may be less important for inhaled bronchodilators, although newer nebulizer designs should be considered for more expensive formulations where precise dosing is required. ( See "New nebulizer designs" below). In addition to differences in design, the performance of nebulizers is influenced by several common factors, including mechanism, use of mouthpiece or facemask, and drug formulation. Mechanism — The operation of a pneumatic nebulizer requires a pressurized gas supply, which acts as the driving force for liquid atomization. Compressed gas is delivered as a jet through a small orifice, generating a region of negative pressure above the medication reservoir. The solution to be aerosolized is first entrained, or pulled into the gas stream and then sheared into a liquid film. This film is unstable, and rapidly breaks into droplets due to surface tension forces. A baffle placed in the aerosol stream allows formation of smaller particles and recycling of larger droplets into the liquid reservoir. The aerosol is entrained into the inspiratory gas stream inhaled by the patient. The correct technique for use of a nebulizer is important ( show table 2) [8,9]. A number of factors determine the efficiency of a nebulizer system, including the respirable dose, nebulization time, dead volume of the device, and the gas used to drive the nebulizer. Respirable dose — The most important characteristic of nebulizer performance is the respirable dose delivered to the patient. The respirable dose is a function of the mass output of the nebulizer and the size of the particles produced. Droplet size should be 2 to 5 µm for airway deposition and 1 to 2 µm or smaller for parenchymal deposition. Droplet size is usually reported as mass median aerodynamic diameter (MMAD), which is the median diameter around which the mass of the aerosol is equally divided. Nebulization time — Nebulization time, the time required to deliver a dose of medication, is an important determinant of patient compliance in the outpatient setting. In addition, a reduction in nebulization time may decrease the need for clinical supervision in hospitalized or emergentlytreated patients. In general, the greater the volume of drug to be delivered and the lower the flow rate of the driving gas, the longer the nebulization time. Treatment is complete when the nebulizer begins sputtering. Although usually given on a scheduled basis, continuous aerosolized bronchodilators can be administered in the treatment of acute asthma. The available evidence suggests that this therapy is safe, at least as effective as intermittent nebulization, and may be superior to intermittent nebulization in patients with the most severe pulmonary dysfunction [ 4,10]. (See "Pathogenesis and management of status asthmaticus in adults"). Several configurations have been described for continuous nebulization, including frequent refilling of the nebulizer, use of a nebulizer and infusion pump, and use of a large volume nebulizer [ 4]. Dead volume — The volume of medication trapped inside the nebulizer, and therefore not available for inhalation, is referred to as the dead volume of the device. The dead volume is typically in the range of 1 to 3 mL. Increasing the amount of solution within the nebulizer (the fill volume) reduces the proportion of the dose lost as dead volume. Although nebulizer output increases with a greater fill volume, this also results in an increase in nebulization time. Considering both factors, a nebulizer fill volume of 4 to 6 mL is recommended [7]. During nebulization, the solution within the nebulizer becomes increasingly concentrated as water evaporates from the solution. Thus, on a per breath basis, more medication is delivered late in the course of a treatment. Evaporative effects also result in cooling of the nebulizer solution over time. Treatment is complete when the nebulizer begins sputtering. Driving gas — Increasing the flow rate of the driving gas results in an increase in nebulized output and a reduction in particle size. A flow of 8 L/min is recommended to optimize drug delivery [7]. This may be problematic when a compressor is used to power the nebulizer, as the flow from these is often <8 L/min, resulting in sub-optimal drug aerosolization and delivery [11-13]. Gas density — The density of the gas powering the nebulizer affects nebulizer performance. For example, the inhaled mass of albuterol is significantly reduced when a nebulizer is powered with a mixture of helium and oxygen (heliox). Accordingly, the flow to the nebulizer should be increased by 50 percent if it is powered with heliox [14]. Heliox may improve aerosol delivery to the lower respiratory tract, because the decrease in density results in the creation of smaller particles; however, the clinical benefit of this approach is unclear [15-20]. (See "Physiology and clinical use of heliox"). Mouthpieces and facemasks — Inhaled aerosols can be administered using a mouthpiece or a facemask. Bronchodilator response appears similar with either interface, and some have argued that the selection of patient interface should be based upon patient preference. Significant facial and eye deposition of aerosol can occur when a face mask is used, especially in young children [ 21]. Eye deposition is of particular concern when aerosolized anticholinergic agents are administered, as this can result in blurring of vision, pupil dilation, and worsening of narrow angle glaucoma. When a facemask is used, it is important to instruct the patient to inhale through the mouth to minimize nasopharyngeal deposition of medication. We generally favor use of a mouthpiece, rather than a face mask, for aerosol administration. Breathing pattern — The breathing pattern of the patient affects the amount of aerosol deposited in the lower respiratory tract. Airflow obstruction increases the need for inhaled bronchodilator therapy, but can decrease the effectiveness of that treatment. To improve aerosol penetration and deposition in the lungs, the patient should be encouraged to use a slow breathing pattern with an occasional deep breath. Drug formulation — Drug formulation can affect nebulizer performance [ 22-24]. Metered dose inhalers and dry powder inhalers have always been tested and approved as a drug-delivery system combination. Some drug solutions are only approved for delivery with specific nebulizers [ 25]. Examples of medications that should be delivered only by approved nebulizer include pentamidine, ribavirin, rhDNAase, and tobramycin. Nebulizers for specific medications — Specially constructed small-volume nebulizers, such as the Respirgard II for aerosolized pentamidine, should be used when contamination of the ambient environment with the aerosolized drug needs to be avoided [ 4]. The Respirgard II is fitted with one- way valves and filters to minimize gross contamination of the environment. A separate device was developed to allow the safe delivery of aerosolized ribavirin, which is potentially teratogenic. The Small-Particle Aerosol Generator (SPAG) was designed specifically to aerosolize ribavirin. It consists of a nebulizer and drying chamber that reduce the MMAD to about 1.3 µm, which optimizes drug delivery to distal airspaces. The SPAG is used with a scavenging system to minimize contamination of the ambient environment. New nebulizer designs — With the traditional nebulizer design, an aerosol is generated throughout the patient's respiratory cycle. This results in considerable waste of aerosol during exhalation. Newer designs reduce aerosol waste during the exhalation phase . Breath-enhanced nebulizers, such as the Pari LC, are designed to allow release of more aerosol during inhalation. With this design, exhaled gas is routed out the expiratory valve in the mouthpiece and aerosol is contained in the nebulizer chamber during the expiratory phase. The Circulaire nebulizer reduces waste from a constant-output nebulizer by attachment of a storage bag with a one-way valve in the mouthpiece connector. During the expiratory phase, aerosol is collected in the bag and delivered to the patient on the subsequent inhalation. The AeroEclipse nebulizer has a breath-actuated valve that triggers aerosol generation only during inhalation, eliminating the need for a storage bag or reservoir [ 26]. Ultrasonic nebulizers — Ultrasonic nebulizers consist of a power unit and transducer, with or without an electric fan [4]. The power unit converts electrical energy to high-frequency ultrasonic waves with a frequency of 1.63 megahertz. A piezoelectric element in the transducer vibrates at the same frequency as the applied wave. Ultrasonic waves are transmitted to the surface of the solution to create an aerosol. A fan is used to deliver the aerosol to the patient, or the aerosol is evacuated from the nebulization chamber by the inspiratory flow of the patient. Small volume ultrasonic nebulizers are commercially available for delivery of inhaled bronchodilators; large volume ultrasonic nebulizers are used for sputum induction. A potential issue with the use of ultrasonic nebulizers is drug inactivation by ultrasonic waves; however, to date this has not been shown to occur with medications commonly delivered using this system. Vibrating mesh nebulizers — Several manufacturers have developed aerosol devices that use a vibrating mesh or plate with multiple apertures to produce a liquid aerosol ( show figure 3) [27]. A common feature of these devices is their ability to generate aerosols with a high fine-particle fraction, which results in more efficient drug delivery compared to conventional nebulizers. The aerosol is generated as a fine mist, and no internal baffling system is required. These nebulizers are portable, battery-operated, and they have minimal residual medication volume; some are breathactuated [27]. They are being developed in cooperation with pharmaceutical companies to deliver expensive formulations with which precise dosing is needed. The iNeb nebulizer uses vibrating mesh technology with adaptive aerosol delivery (ADD). ADD monitors the patient's breathing pattern and injects the aerosol at the beginning of inhalation. This improves the likelihood of the aerosol penetrating deep into the respiratory tract. This nebulizer is used specifically for the administration of Ventavis® (iloprost) Inhalation Solution (CoTherix, Inc) for the treatment of pulmonary arterial hypertension (show figure 4). METERED DOSE INHALERS — A metered dose inhaler (MDI) consists of a pressurized canister, a metering valve and stem, and a mouthpiece actuator (show figure 5) [28]. The canister contains the drug suspended in a mixture of propellants, surfactants, preservatives, flavoring agents, and dispersal agents. The propellant has traditionally been a chlorofluorocarbon (CFC). Following adoption of the Montreal protocol, an international agreement to ban CFCs, CFC-free propellants such as hydrofluoroalkane (HFA) 133a have become available [29-43]. Patients should be informed that the plume emitted from an HFA-MDI is warmer and softer than the CFC plume. Without this information, the patient may interpret the difference in sensation as the aerosol passes through the upper respiratory tract as an ineffectively delivered dose. The mixture is released from the MDI canister through a metering valve and stem into an actuator boot. After volatilization of the propellant, the final volume emitted from the MDI is 15 to 20 mL per dose [44]. The MDI can be actuated as frequently as every 15 seconds [45]. Lung deposition ranges between 10 percent and 25 percent of the nominal dose in adults. The correct technique for using a MDI is shown in the table (show table 3) [8,9]. The Autohaler (3M Corporation), designed for patients with poor hand-breath coordination, is an example of a flow-triggered MDI that actuates in response to the patient's inspiratory effort [46-50]. Patient teaching — Important patient teaching issues related to the use of an MDI include priming, creaming (separation of drug from other ingredients in the canister), and determining when the canister is empty. When an MDI is new, or if it has not been used for several days (eg, a patient using inhaled beta-agonists on an as-needed basis), the first several actuations deliver an inconsistent dose until the metering chamber is primed [51-53]. The clinical effects of this can be avoided by wasting several actuations from the MDI. Creaming is reversed by shaking the canister before use [54,55]. Determining when an MDI is empty — It is important for the patient to have a means to determine when the canister is empty. A few MDIs are now being manufactured with integrated dose counters, including Ventolin-HFA®, available in the United States as of June 2006 (show figure 6) [56]. Another method is to have the patient maintain a log of the number of actuations, and to dispose of the device when the designated number of actuations has been reached. The technique of dropping the canister into a pan of water and observing how it floats has been shown to be unreliable and is no longer recommended [57,58]. (See "Metered dose inhaler techniques in adults" and see "Patient information: Metered dose inhaler techniques"). Spacers and holding chambers — Spacers and valved holding chambers are accessory devices that reduce oropharyngeal deposition of drug, improve distal delivery, and minimize the importance of hand-breath coordination. A spacer device is an open-ended tube or bag that allows the MDI plume to expand and the propellant to evaporate. A valved holding chamber incorporates a one-way valve that permits aerosol delivery from the chamber only during the inspiratory phase. Accessory devices either use the boot that comes with the MDI or incorporate a universal canister adapter to actuate the MDI (show figure 7). A valved holding chamber can incorporate a mask for patients who are unable to use a mouthpiece due to age, poor coordination, or impaired mental status. The technique for use of a spacer or valved holding chamber is provided ( show table 4) [8,9]. Drug particles deposit on the inner surface of the device due to static charge on the plastic material of the chamber [59-61]. For this reason, the chamber may be less effective when it is new compared to after it has been in use. Washing the device with dishwashing detergent and then allowing it to air-dry eliminates this static charge [62,63]. Anti-static devices are commercially available from several manufacturers. It is important to instruct patients to only actuate one dose into the holding chamber at a time, rather than multiple doses, and to inhale the drug from the chamber immediately after the MDI has been actuated [64-66]. DRY POWDER INHALERS — Dry powder inhalers (DPIs) create aerosols by drawing air through a dose of powdered medication (show figure 8 and show figure 9) [67-69]. The release of respirable particles of the drug requires inspiration at relatively high inspiratory flow rates [ 70,71], which results in pharyngeal impaction of the larger carrier particles that comprise the bulk of the aerosol. The oropharyngeal impaction of carrier particles gives the patient the sensation of having inhaled a dose. DPIs produce aerosols in which most of the drug particles are in the respirable range; however, the distribution of particle sizes differs significantly among various DPIs. Because DPIs are breath-actuated, they reduce the problem of coordinating inspiration with actuation. Breath coordination is still important because exhalation into a DPI blows the powder from the device. Patients must be instructed to exhale while turned away from the device, then put their mouth quickly to the mouthpiece and inhale. In addition, since the magnitude and duration of the patient's inspiratory effort influence aerosol generation from a DPI, these devices should be used cautiously in the elderly and those with altered mental status or neuromuscular weakness. Finally, the manipulation required to operate some devices may make use difficult for patients with limited dexterity. The technique of using DPIs differs among devices ( show table 5A-5B) [8,9]. DPIs can be single- or multi-dose devices. The multi-dose devices contain a month's worth of medication or more. With single-dose devices, the patient places a capsule into the device immediately before each treatment. Because these capsules are similar in appearance to oral medications, it is important to instruct patients not to ingest the capsules. High ambient humidity produces clumping of the dry powder, creating larger particles that are not as effectively aerosolized. Multi-dose DPI devices contain individual doses protected from humidity, which limit this effect. The effect of humidity makes all DPIs ineffective when delivered to patients receiving mechanical ventilation. SPONTANEOUSLY BREATHING PATIENTS — For spontaneously breathing patients, there are advantages and disadvantages to each aerosol delivery device ( show table 6). However, the available evidence from systematic reviews and meta-analyses suggests equivalence among nebulizers, metered dose inhalers, and dry powder inhalers with respect to drug delivery when used correctly [72-78]. Accordingly, the selection of an aerosol delivery device is not based on a clear superiority of one device over another [3]. The selection of an aerosol delivery device is usually based upon the preference and convenience of the clinician and patient, the ability of the patient to use the device correctly, and the cost of therapy. The selection of device is also limited by drug formulation, as some formulations are only available for one delivery device. The nebulizer is often considered the most expensive aerosol delivery device. The prescription of multiple delivery devices can be confusing, and may impair compliance with therapy, particularly in patients with complicated regimens [ 79]. Regardless of the delivery technique, patient instruction in the proper use of the device is crucial. All health care professionals interacting with the patient share responsibility for this teaching; this includes physicians, respiratory therapists, nurses, and pharmacists. Thus, all involved clinicians also must take responsibility to understand the correct use of aerosol delivery devices. Patients with tracheostomies — Techniques have also been described for the delivery of aerosols by nebulizer or MDI in a spontaneously breathing patient with a tracheostomy tube ( show figure 10) [80]. MECHANICALLY VENTILATED PATIENTS — Nebulized medications can be delivered to patients receiving mechanical ventilation using either an MDI or a nebulizer. A DPI cannot be used to deliver dry powder during mechanical ventilation because ventilator circuit humidification impairs aerosol formation. A number of factors affect aerosol delivery during mechanical ventilation ( show table 7) [81-87]. One major factor is that humidification of inhaled gas decreases aerosol deposition by approximately 40 percent due to increased particle drug deposition in the ventilator circuit. For this reason, increased dosage of medication is often required to achieve a therapeutic effect in mechanically ventilated patients. Metered dose inhaler — A special actuator is needed to adapt the MDI into the ventilator circuit (show figure 11). The size, shape, and design of these actuators have a major impact on drug delivery to the patient. An MDI with a chamber results in a four- to six-fold greater delivery of aerosol than MDI actuation into a connector attached directly to the endotracheal tube, or into an in-line device that lacks a chamber. When using an MDI during mechanical ventilation, it is important to synchronize actuation with inspiratory airflow to optimize drug delivery. Helium-oxygen mixtures also affect aerosol deposition, and in vitro modeling has reported a 50 percent increase in deposition of albuterol from an MDI during mechanical ventilation when heliox was used as the driving gas [88]. However, heliox can dramatically interfere with the functioning of flow sensors and oxygen levels when delivered through a mechanical ventilator, and care must be taken if this approach is employed [89-91]. (See "Physiology and clinical use of heliox", section on Instrument sensitivity). Nebulizer — Delivery of a large tidal volume, use of an end-inspiratory pause, and use of a slow inspiratory flow affect aerosol delivery by nebulizer but not by MDI [81]. Nebulizer performance can be optimized by placing the nebulizer 30 cm from the endotracheal tube, rather than at the Y-piece, because the inspiratory ventilator tubing acts as a spacer. Operating the nebulizer only during inspiration is more efficient for aerosol delivery compared with continuous aerosol generation. When a breath-actuated nebulizer is used, the delivered dose increases by more than five-fold. In addition, when the humidifier is bypassed the delivered dose increases by a factor of nearly four [ 82]. Disadvantages of nebulizer use during mechanical ventilation include circuit contamination, decreased ability of the patient to trigger the ventilator, and the associated increases in tidal volume and airway pressure due to nebulizer flow. (See "Ventilator circuit change and ventilator-associated pneumonia"). Choice of device — Although the nebulizer is less efficient than the metered dose inhaler during mechanical ventilation, the nebulizer can deliver a greater cumulative dose to the lower respiratory tract [92]. Thus, nebulizers and MDIs produce similar therapeutic effects in mechanically ventilated patients [93]. The use of an MDI for routine bronchodilator therapy in ventilator-supported patients is preferred because of the problems associated with the use of nebulizers, including contamination and triggering difficulty, as well as increased pressure and volume delivery. Aerosol delivery by MDI is easy to administer, involves less personnel time, provides a reliable dose of the drug, and is free from the risk of bacterial contamination. When an MDI is used with an in-line spacer, the ventilator circuit does not need to be disconnected with each treatment; this may reduce the risk of ventilator-associated pneumonia. This also prevents the loss of positive end-expiratory pressure (PEEP) in patients with acute respiratory distress syndrome (ARDS). ( See "Ventilator circuit change and ventilator-associated pneumonia", and see "Mechanical ventilation in acute respiratory distress syndrome"). Aerosol therapy can also be administered during noninvasive positive pressure ventilation (NPPV) (show figure 12) [94,95]. In patients with acute asthma randomized to albuterol delivery by NPPV versus conventional nebulizer, a greater improvement in peak expiratory flow occurs in patients randomized to receive NPPV [96]. Benefit for the delivery of albuterol by MDI with spacer during NPPV has also been reported [97]. (See "Treatment of acute exacerbations of asthma in adults" and see "Noninvasive positive pressure ventilation in acute respiratory failure"). INFORMATION FOR PATIENTS — Educational materials on this topic are available for patients. ( See "Patient information: Overview of managing asthma", see "Patient information: Trigger avoidance in asthma", see "Patient information: Metered dose inhaler techniques", and see "Patient information: How to use a peak flow meter"). We encourage you to print or e-mail these topics, or to refer patients to our public web site www.patients.uptodate.com, which includes these and other topics. SUMMARY — Effective delivery of inhaled medications requires selection of the appropriate drug, proper use of the delivery device, education of the patient in the correct use of the device, and patient compliance. Frequent review of the proper use of the device is crucial. All health care professionals interacting with the patient share responsibility for this teaching and should personally understand the correct use of the various devices. Available devices Three principal types of devices are used to deliver inhaled medications: nebulizers, metered dose inhalers (MDIs), and dry powder inhalers (DPIs). The nebulizer is often considered the most expensive aerosol delivery device. (See "Overview" above) The most commonly-used type of nebulizer is the pneumatic (or jet) nebulizers ( show figure 1). Nebulizer performance is affected by both technical factors, such as mechanism of aerosol generation and drug formulation (not all medications can be used with all nebulizers), as well as patient-related factors (show table 1). (See "Nebulizers" above). With all of the standard nebulizers, patients should be encouraged to use a slow breathing pattern with an occasional deep breath. We generally favor the use of mouthpieces over face masks, as the latter are associated with some facial and eye deposition of aerosol. ( See "Mouthpieces and facemasks" above). Newer nebulizer designs include breath-actuated devices that deliver the majority of the medication during inhalation, and vibrating mesh nebulizers that produce a very fine mist of aerosolized medication and deliver more of the dose to the patient. (See "New nebulizer designs" above). A MDI consists of a pressurized canister, a metering valve and stem, and a mouthpiece actuator (show figure 5) [28]. CFC propellants are gradually being replaced with non-CFC agents, such as hydrofluoroalkane (HFA). Lung deposition ranges between 10 and 25 percent of the nominal dose in adults. (See "Metered dose inhalers" above). The correct technique for using a MDI is shown in the table (show table 3). The Autohaler is an example of a flow-triggered MDI that actuates in response to the patient's inspiratory effort and can be useful to patients who have trouble coordinating breathing and actuation. Patients should also be taught about the importance of priming and shaking the canister before use, and how to determine when the canister is empty. (See "Metered dose inhalers" above). MDIs can be used with spacers and valved holding chambers, accessory devices that reduce oropharyngeal deposition of drug, improve distal delivery, and minimize the importance of handbreath coordination. (See "Spacers and holding chambers" above). DPIs create aerosols by drawing air through a dose of powdered medication ( show figure 8 and show figure 9). The technique of using DPIs differs among devices ( show table 5A-5B). (See "Dry powder inhalers" above). Options for different patient situations For spontaneously breathing patients, there are advantages and disadvantages to each aerosol delivery device (show table 6). However, nebulizers, MDIs, or DPIs are all effective when used correctly. Thus, we recommend selecting a delivery device based upon convenience, cost, and the patient's preferences and ability to use the device correctly ( Grade 1B). (See "Spontaneously breathing patients" above). Techniques have also been described for the delivery of aerosols by nebulizer or MDI in a spontaneously breathing patient with a tracheostomy tube ( show figure 10). (See "Patients with tracheostomies" above). In mechanically-ventilated patients, both MDIs and nebulizers are equivalently effective. We suggest the use of MDIs, because this method is technically easier, involves less personnel time, provides a reliable dose of the drug, and is free from the risk of bacterial contamination that can occur with a nebulizer (Grade 2B). Patients can also receive inhaled therapies during NPPV. ( See "Mechanically ventilated patients" above). Use of UpToDate is subject to the Subscription and License Agreement. 1. 2. 3. 4. 5. REFERENCES Olschewski, H, Simonneau, G, Galie, N, et al. Inhaled iloprost for severe pulmonary hypertension. N Engl J Med 2002; 347:322. Henry, RR, Mudaliar, SR, Howland III, WC, et al. Inhaled insulin using the AERx insulin diabetes management system in healthy and asthmatic subjects. Diabetes Care 2003; 26:764. Dolovich, MB, Ahrens, RC, Hess, DR, et al. Device selection and outcomes of aerosol therapy: evidence-based guidelines: American College of Chest Physicians/American College of Asthma, Allergy, and Immunology. Chest 2005; 127:335. Hess, DR. Nebulizers: principles and performance. Respir Care 2000; 45:609. Rau, JL. Design principles of liquid nebulization devices currently in use. Respir Care 2002; 47:1257. Leung, K, Louca, E, Coates, AL. Comparison of breath-enhanced to breath-actuated nebulizers for rate, consistency, and efficiency. Chest 2004; 126:1619. 7. Hess, D, Fisher, D, Williams, P, et al. Medication nebulizer performance. Effects of diluent volume, nebulizer flow, and nebulizer brand. Chest 1996; 110:498. 8. Fink, JB. Aerosol device selection: Evidence to practice. Respir Care 2000; 45:874. 9. Kacmarek, RM, Hess, D. The interface between patient and aerosol generator. Respir Care 1991; 36:952. 10. Rodrigo, GJ, Rodrigo, C. Continuous vs intermittent beta-agonists in the treatment of acute adult asthma: a systematic review with meta-analysis. Chest 2002; 122:160. 11. Reisner, C, Katial, RK, Bartelson, BB, et al. Characterization of aerosol output from various nebulizer/compressor combinations. Ann Allergy Asthma Immunol 2001; 86:566. 12. Standaert, TA, Bohn, SE, Aitken, ML, Ramsey, B. The equivalence of compressor pressure-flow relationships with respect to jet nebulizer aerosolization characteristics. J Aerosol Med 2001; 14:31. 13. Standaert, TA, Vandevanter, D, Ramsey, BW, et al. The choice of compressor effects the aerosol parameters and the delivery of tobramycin from a single model nebulizer. J Aerosol Med 2000; 13:147. 14. Hess, DR, Acosta, FL, Ritz, RH, et al. The effect of heliox on nebulizer function using a beta-agonist bronchodilator. Chest 1999; 115:184. 15. Kress, JP, North, I, Gelbach, BK, et al. The utility of albuterol nebulized with heliox during acute asthma exacerbations. Am J Respir Crit Care Med 2002; 165:1317. 16. Henderson, SO, Acharya, P, Kilaghbian, T, et al. Use of heliox-driven nebulizer therapy in the treatment of acute asthma. Ann Emerg Med 1999; 33:141. 17. Anderson, M, Svartengren, M, Philipson, K, et al. Deposition in man of particles suspended in air or in helium-oxygen mixture at different flow rates. J Aerosol Med 1990; 3:209. 18. Anderson, M, Svartengren, M, Bylin, G, et al. Deposition in asthmatics of particles inahled in air or in helium-oxygen. Am Rev Respir Dis 1993; 147:524. 19. Habib, DM, Garner, SS, Brandeburg, S. Effect of helium-oxygen on delivery of albuterol in a pediatric, volume- cycled, ventilated lung model. Pharmacotherapy 1999; 19:143. 20. Svartengren, M, Anderson, M, Philison, K, et al. Human lung deposition of particles suspended in air or in helium-oxygen mixture. Exp Lung Res 1989; 15:575. 21. Sangwan, S, Gurses, BK, Smaldone, GC. Facemasks and facial deposition of aerosols. Pediatr Pulmonol 2004; 37:447. 22. Coates, AL, MacNeish, CF, Meisner, D, et al. The choice of jet nebulizer, nebulizing flow, and addition of albuterol affects the output of tobramycin aerosols. Chest 1997; 111:1206. 23. MacNeish, CF, Meisner, D, Thibert, R, et al. A comparison of pulmonary availability between Ventolin (albuterol) nebules and Ventolin (albuterol) respirator solution. Chest 1997; 111:204. 24. Flament, MP, Leterme, P, Burnouf, T, Gayot, A. Influence of formulation on jet nebulisation quality of alpha 1 protease inhibitor. Int J Pharm 1999; 178:101. 25. Hess, DR. Liquid nebulization: emerging technologies conference summary. Respir Care 2002; 47:1471. 26. Rau, JL, Ari, A, Restrepo, RD. Performance comparison of nebulizer designs: constant-output, breath-enhanced, and dosimetric. Respir Care 2004; 49:174. 27. Dhand, R. New frontiers in aerosol delivery during mechanical ventilation. Respir Care 2004; 49:666. 28. Newman, SP. Principles of metered-dose inhaler design. Respir Care 2005; 50:1177. 29. Hawksworth, RJ, Sykes, AP, Faris, M, et al. Albuterol HFA is as effective as albuterol CFC in preventing exercise-induced bronchoconstriction. Ann Allergy Asthma Immunol 2002; 88:473. 30. Langley, SJ, Sykes, AP, Batty, EP, et al. A comparison of the efficacy and tolerability of single doses of HFA 134a albuterol and CFC albuterol in mild-to-moderate asthmatic patients. Ann Allergy Asthma Immunol 2002; 88:488. 31. Cheng, YS, Fu, CS, Yazzie, D, Zhou, Y. Respiratory deposition patterns of salbutamol pMDI with CFC and HFA-134a formulations in a human airway replica. J Aerosol Med 2001; 14:255. 32. Richards, J, Hirst, P, Pitcairn, G, et al. Deposition and pharmacokinetics of flunisolide delivered from pressurized inhalers containing non-CFC and CFC propellants. J Aerosol Med 2001; 14:197. 33. Boccuzzi, SJ, Wogen, J, Roehm, JB. Use of hydrofluoroalkane propellant delivery system for inhaled albuterol in patients receiving asthma medications. Clin Ther 2000; 22:237. 34. Huchon, G, Hofbauer, P, Cannizzaro, G, et al. Comparison of the safety of drug delivery via HFA- and 6. CFC-metered dose inhalers in CAO. Eur Respir J 2000; 15:663. Magnussen, H. Equivalent asthma control after dose reduction with HFA-134a beclomethasone solution aerosol. Comparative Inhaled Steroid Investigation Group (CISIG). Respir Med 2000; 94:549. 36. Shapiro, G, Bronsky, E, Murray, A, et al. Clinical comparability of ventolin formulated with hydrofluoroalkane or conventional chlorofluorocarbon propellants in children with asthma. Arch Pediatr Adolesc Med 2000; 154:1219. 37. Atkins, P. Chlorofluorocarbon to hydrofluoroalkane formulations: An industry perspective. J Allergy Clin Immunol 1999; 104:S268. 38. Brindley, A. The chlorofluorocarbon to hydrofluoroalkane transition: The effect on pressurized metered dose inhaler suspension stability. J Allergy Clin Immunol 1999; 104:S221. 39. Bronsky, E, Ekholm, BP, Klinger, NM, Colice, GL. Switching patients with asthma from chlorofluorocarbon (CFC) albuterol to hydrofluoroalkane-134a (HFA) albuterol. J Asthma 1999; 36:107. 40. Ramsdell, JW, Klinger, NM, Ekholm, BP, Colice, GL. Safety of long-term treatment with HFA albuterol. Chest 1999; 115:945. 41. Bleecker, ER, Tinkelman, DG, Ramsdell, J, et al. Proventil HFA provides bronchodilation comparable to ventolin over 12 weeks of regular use in asthmatics. Chest 1998; 113:283. 42. Tinkelman, DG, Bleecker, ER, Ramsdell, J, et al. Proventil HFA and ventolin have similar safety profiles during regular use. Chest 1998; 113:290. 43. Leach, CL. The CFC to HFA transition and its impact on pulmonary drug development. Respir Care 2005; 50:1201. 44. Hess, D, Daugherty, A, Simmons, M. The volume of gas emitted from five metered dose inhalers at three levels of fullness. Respir Care 1992; 37:444. 45. Fink, JB, Dhand, R, Grychowski, J, et al. Reconciling in vitro and in vivo measurements of aerosol delivery from a metered-dose inhaler during mechanical ventilation and defining efficiency-enhancing factors. Am J Respir Crit Care Med 1999; 159:63. 46. Newman, SP, Weisz, AW, Talaee, N, Clarke, SW. Improvement of drug delivery with a breath actuated pressurised aerosol for patients with poor inhaler technique. Thorax 1991; 46:712. 47. Marshik, PL, Larsen, JS, Leach, CL, et al. A novel breath actuated device (Autohaler) consistently actuates during the early phase of inspiration. J Aerosol Med 1995; 8:187. 48. Smith, KJ, Chan, HK, Brown, KF. Influence of flow rate on aerosol particle size distributions from pressurized and breath-actuated inhalers. J Aerosol Med 1998; 11:231. 49. Niggemann, B. Breath-actuated metered-dose inhaler. J Allergy Clin Immunol 1995; 95:921. 50. Chapman, KR, Love, L, Brubaker, H. A comparison of breath-actuated and conventional metereddose inhaler inhalation techniques in elderly subjects. Chest 1993; 104:1332. 51. Blake, KV, Harman, E, Hendeles, L. Evaluation of a generic albuterol metered-dose inhaler: importance of priming the MDI. Ann Allergy 1992; 68:169. 52. Ross, RN. Loss of bronchodilator medication in priming a conventional metered dose inhaler: A cost of treating asthma. Med Interface 1997; 10:141. 53. Cyr, TD, Graham, SJ, Li, KY, Lovering, EG. Low first-spray drug content in albuterol metered-dose inhalers. Pharm Res 1991; 8:658. 54. Everard, ML, Devadason, SG, Summers, QA, Le Souef, PN. Factors affecting total and "respirable" dose delivered by a salbutamol metered dose inhaler. Thorax 1995; 50:746. 55. Berg, E. In vitro properties of pressurized metered dose inhalers with and without spacer devices. J Aerosol Med 1995; 8 Suppl 3:S3. 56. Rickard, KA. Not running on empty. Ann Allergy Asthma Immunol 2006; 97:558. 57. Cain, WT, Oppenheimer, JJ. The misconception of using floating patterns as an accurate means of measuring the contents of metered-dose inhaler devices. Ann Allergy Asthma Immunol 2001; 87:417. 58. Ogren, RA, Baldwin, JL, Simon, RA. How patients determine when to replace their metered-dose inhalers. Ann Allergy Asthma Immunol 1995; 75:485. 59. Dompeling, E, Oudesluys-Murphy, AM, Janssens, HM, et al. Randomised controlled study of clinical efficacy of spacer therapy in asthma with regard to electrostatic charge. Arch Dis Child 2001; 84:178. 60. Anhoj, J, Bisgaard, H, Lipworth. Effect of electrostatic charge in plastic spacers on the lung delivery 35. 61. 62. 63. 64. 65. 66. 67. 68. 69. 70. 71. 72. 73. 74. 75. 76. 77. 78. 79. 80. 81. 82. 83. 84. 85. 86. 87. 88. of HFA-salbutamol in children. Br J Clin Pharmacol 1999; 47:333. van der, Veen MJ, van der, Zee JS. Aerosol recovery from large-volume reservoir delivery systems is highly dependent on the static properties of the reservoir. Eur Respir J 1999; 13:668. Wildhaber, JH, Janssens, HM, Pierart, F, et al. High-percentage lung delivery in children from detergent-treated spacers. Pediatr Pulmonol 2000; 29:389. Pierart, F, Wildhaber, JH, Vrancken, I, et al. Washing plastic spacers in household detergent reduces electrostatic charge and greatly improves delivery. Eur Respir J 1999; 13:673. Rau, JL, Restrepo, RD, Deshpande, V. Inhalation of single vs multiple metered-dose bronchodilator actuations from reservoir devices. Chest 1996; 109:969. Barry, PW, O'Callaghan, C. The effect of delay, multiple actuations and spacer static charge on the in vitro delivery of budesonide from the Nebuhaler. Br J Clin Pharmacol 1995; 40:76. Wildhaber, JH, Devadason, SG, Eber, E, et al. Effect of electrostatic charge, flow, delay and multiple actuations on the in vitro delivery of salbutamol from different small volume spacers for infants. Thorax 1996; 51:985. Fink, JB. Metered-dose inhalers, dry powder inhalers, and transitions. Respir Care 2000; 45:623. Newman, SP, Busse, WW. Evolution of dry powder inhaler design, formulation, and performance. Respir Med 2002; 96:293. Atkins, PJ. Dry powder inhalers: an overview. Respir Care 2005; 50:1304. Broeders, ME, Molema, J, Vermue, NA, Folgering, HT. Peak inspiratory flow rate and slope of the inhalation profiles in dry powder inhalers. Eur Respir J 2001; 18:780. Chavan, V, Dalby, R. Effect of rise in simulated inspiratory flow rate and carrier particle size on powder emptying from dry powder inhalers. AAPS PharmSci 2000; 2:E10. Brocklebank, D, Wright, J, Cates, C. Systematic review of clinical effectiveness of pressurised metered dose inhalers versus other hand held inhaler devices for delivering corticosteroids in asthma. BMJ 2001; 323:896. Brocklebank, D, Ram, F, Wright, J, et al. Comparison of the effectiveness of inhaler devices in asthma and chronic obstructive airways disease. Health Technol Assess 2001; 5:1. Turner, MO, Patel, A, Ginsburg, S, et al. Bronchodilator delivery in acute airflow obstruction. A metaanalysis. Arch Intern Med 1997; 157:1736. Cates, CC, Bara, A, Crilly, JA, Rowe, BH. Holding chambers versus nebulisers for beta-agonist treatment of acute asthma. Cochrane Database Syst Rev 2006; :CD000052. Frei, SP. Cost comparison of bronchodilator delivery methods in Emergency Department treatment of asthma. J Emerg Med 2000; 19:323. Turner, MO, Gafni, A, Swan, D, et al. A review and economic evaluation of bronchodilator delivery methods in hospitalized patients. Arch Intern Med 1996; 156:2113. Ram, FS, Wright, J, Brocklebank, D, White, JE. Systematic review of clinical effectiveness of pressurised metered dose inhalers versus other hand held inhaler devices for delivering beta (2 )agonists bronchodilators in asthma. BMJ 2001; 323:901. van der, Palen J, Klein, JJ, van Herwaarden, CL, et al. Multiple inhalers confuse asthma patients. Eur Respir J 1999; 14:1034. Piccuito, CM, Hess, DR. Albuterol delivery via tracheostomy tube. Respir Care 2005; 50:1071. Hess, D. Aerosol delivery during mechanical ventilation. Minerva Anestesiol 2002; 68:321. Miller, DD, Amin, MM, Palmer, LB, et al. Aerosol delivery and modern mechanical ventilation: in vitro/in vivo evaluation. Am J Respir Crit Care Med 2003; 168:1205. Georgopoulos, D, Mouloudi, E, Kondili, E, Klimathianaki, M. Bronchodilator delivery with metereddose inhaler during mechanical ventilation. Crit Care 2000; 4:227. Dhand, R, Jubran, A, Tobin, MJ. Bronchodilator delivery by metered-dose inhaler in ventilatorsupported patients. Am J Respir Crit Care Med 1995; 151:1827. Dhand, R, Tobin, MJ. Bronchodilator delivery with metered-dose inhalers in mechancically ventilated patients. Eur Respir J 1996; 9:585. Dhand, R, Tobin, MJ. Inhaled bronchodilator therapy in mechanically ventilated patients. Am J Respir Crit Care Med 1997; 156:3. Duarte, AG, Fink, JB, Dhand, R. Inhalation therapy during mechanical ventilation. Respir Care Clin N Am 2001; 7:233. Goode, ML, Fink, JB, Dhand, R, et al. Improvement in aerosol delivery with helium-oxygen mixtures during mechanical ventilation. Am J Respir Crit Care Med 2001; 163:109. 89. 90. 91. 92. 93. 94. 95. 96. 97. Tassaux, D, Jolliet, P, Thouret, JM, et al. Calibration of seven ICU ventilators for mechanical ventilation with helium-oxygen mixtures. Am J Respir Crit Care Med 1999; 160:22. Devabhaktuni VG, Torres A Jr, Wilson S, Yeh MP. Effect of nitric oxide, perfluorocarbon, and heliox on minute volume measurement and ventilator volumes delivered. Crit Care Med 1999; 27:1603. Oppenheim-Eden A, Cohen Y, Weissman C, Pizov R. The effect of helium on ventilator performance: study of five ventilators and a bedside Pitot tube spirometer. Chest 2001; 120:582. Marik, P, Hogan, J, Krikorian, J. A comparison of bronchodilator therapy delivered by nebulization and metered-dose inhaler in mechanically ventilated patients. Chest 1999; 115:1653. Duarte, AG, Momii, K, Bidani, A. Bronchodilator therapy with metered-dose inhaler and spacer versus nebulizer in mechanically ventilated patients: Comparison of magnitude and duration of response. Respir Care 2000; 45:817. Chatmongkolchart, S, Schettino, GP, Dillman, C, et al. In vitro evaluation of aerosol bronchodilator delivery during noninvasive positive pressure ventilation: effect of ventilator settings and nebulizer position. Crit Care Med 2002; 30:2515. Branconnier, MP, Hess, DR. Albuterol delivery during noninvasive ventilation. Respir Care 2005; 50:1649. Pollack, CV Jr, Fleisch, KB, Dowsey, K. Treatment of acute bronchospasm with beta-adrenergic agonist aerosols delivered by a nasal bilevel positive airway pressure circuit. Ann Emerg Med 1995; 26:552. Nava, S, Karakurt, S, Rampulla, C, et al. Salbutamol delivery during non-invasive mechanical ventilation in patients with chronic obstructive pulmonary disease: A randomized, controlled study. Intensive Care Med 2001; 27:1627. GRAPHICS Pneumatic nebulizer Pneumatic nebulizer A jet flow of driving gas creates an area of low pressure above the medication reservoir, generating an aerosol. The baffle helps insure the formation of respirable particles, and prevents inhalation of oversized droplets of medication. Most nebulizers require a flow rate of 8 liters per minute for optimum performance. Nebulizer performance Factors affecting aerosol delivery by nebulizer Technical Factors Mechanism and manufacturer Patient Factors Flow rate Breathing pattern Fill volume Nose vs mouth breathing Solution characteristics Artificial airway Characteristics of driving gas Airway obstruction Designs to enhance output Positive pressure level Continuous vs. intermittent delivery Nebulizer technique Technique for use of medication nebulizer Assemble apparatus Add medication to nebulizer Use a fill volume of 4 to 6 mL Attach a gas source with a flow of 8 L/min Place patient in a comfortable position Instruct patient to breathe through the mouth Periodically tap nebulizer to return impacted particles to reservoir. Encourage patient to breathe with a slow inspiratory flow and an occasional deep breath Assess patient for comfort, adverse effects, and response throughout treatment Terminate treatment when nebulizer begins to sputter Nebulizers vibrating mesh Vibrating mesh nebulizers Vibrating mesh nebulizers generate fine mists with more efficient dry delivery and minimal residual medication volume compared to conventional nebulizers. Nebulizer iNeb iNeb nebulizer showing device and principle of operation The iNeb nebulizer monitors the patient's breathing pattern and injects the aerosolized medication at the start of each inhalation. It is used for the administration of iloprost. Metered dose inhaler Metered dose inhaler Medication is stored under pressure in the canister and released in fixed volumes from the dosing chamber following actuation. Metered dose inhaler technique Technique for use of a MDI Warm the MDI canister to body temperature Shake vigorously Uncap mouthpiece and check for loose objects in the device Open mouth and keep tongue from obstructing the mouthpiece Hold the MDI in a vertical position, with the outlet aimed at the mouth Place canister outlet between lips or position it about 4 cm from the mouth Breathe out normally Breathe in slowly; actuate the MDI at beginning of inspiration Continue to inhale to total lung capacity Hold breath for 4 to 10 seconds Wait at least 15 seconds between actuations Recap mouthpiece MDI with counter MDI with counter Some MDIs are now manufactured with built-in dose counters. MDI spacers Accessory devices used with metered dose inhalers (A) AeroChamber, (B) AeroChamber with mask, and (C) InspirEase. These devices can facilitate the use of metered dose inhalers and decrease the amount of drug deposited on the upper airway. MDI with spacer technique Technique for use of MDI with spacer or valved holding chamber Warm MDI canister to body temperature Assemble apparatus and check for loose objects in the device Shake canister vigorously Hold canister in vertical position Breathe out normally Place holding chamber in mouth, or place mask completely over nose and mouth Encourage patient to breathe through mouth Breathe in slowly and actuate MDI once at the beginning of inspiration Allow 15 seconds between actuations Dry powder inhalers Examples of various dry powder inhalers With these devices, the patient inhales the medication in the form of a fine powder rather than an aerosol. (A) Aerolizer, (B) Turbuhaler, (C) Diskus, (D) Diskhaler, (E) HandiHaler. Courtesy of Dean Hess, RRT, PhD. DPI twisthaler The twisthaler device Dry powder inhaler technique I Technique for use of various dry powder inhalers - I Aerolizer Remove cover and hold the base of inhaler. Twist mouthpiece in counter-clockwise direction. Remove capsule from foil blister immediately before use and place capsule in the base of the inhaler. Hold the base of the inhaler and turn clockwise to close. Simultaneously press both buttons once to pierce the capsule. Exhale normally - do not exhale into the mouthpiece. Tilt head back slightly, hold device horizontal with the buttons on the left and right, place mouthpiece into the mouth, and close lips around mouthpiece. Breathe in rapidly and steadily, as deeply as possible; hold breath. Remove device from mouth and exhale outside device. Open chamber and examine capsule; if powder remains, repeat inhalation process. After use, remove and discard capsule, and cover mouthpiece; store device in cool, dry place. Diskhaler Remove mouthpiece cover and pull tray out from device. Place disk on wheel with numbers facing up. Rotate disk by sliding tray out and in. Lift back of lid until fully upright so that needle pierces both sides of blister. Keep device level while inhaling dose with a rapid and steady flow. Breathe in rapidly and steadily, as deeply as possible; hold breath. Remove device from mouth and exhale outside device. Brush off any powder remaining within device once every week; store device in cool, dry place. Diskus Open the device and slide the lever until it clicks. Keep device level while inhaling dose. Breathe in rapidly and steadily, as deeply as possible; hold breath. Remove device from mouth and exhale outside device; store device in cool, dry place. Dry powder inhaler technique II Technique for use of various dry powder inhalers - II HandiHaler Capsules should be stored in sealed blisters and only removed immediately before use. Peel back the foil using the tab until one capsule is fully visible. Open the dust cap by pulling it upwards, then open the mouthpiece. Place the capsule in the center chamber (it does not matter which end of the capsule is placed in the chamber). Close the mouthpiece firmly until you hear a click, leaving the dust cap open. Hold the HandiHaler with the mouthpiece upwards and press the piercing button completely in once and release. Breathe out completely. Do not breathe into the mouthpiece at any time. Close your lips tightly around the mouthpiece. Breathe in rapidly and steadily, as deeply as possible; hold breath. To ensure you get the full dose, repeat the inhalation from the HandiHaler as described. After the dose, open the mouthpiece, tip out the used capsule, and dispose. Do not handle used capsules. Close the mouthpiece and dust cap for storage; store device in cool, dry place. Turbuhaler Twist and remove cover. Hold inhaler upright with mouthpiece facing up. Turn grip right then left until it clicks. Inhaler may be held upright or horizontal. Breathe in rapidly and steadily, as deeply as possible; hold breath. Remove device from mouth and exhale outside device. Replace cover and twist to close; store device in cool, dry place. Twisthaler Hold the inhaler straight up with the pink portion (the base) on the bottom. Remove the cap while it is in the upright position to make sure you get the right amount of medicine with each dose. Hold the pink base and twist the cap in a counter-clockwise direction to remove it. As you lift off the cap, the dose counter on the base will count down by 1. This action loads the medicine that you are now ready to inhale. Make sure the indented arrow located on the white portion (directly above the pink base) is pointing to the dose counter. Breathe out normally - do not exhale into the device. Place the mouthpiece into your mouth, with the mouthpiece facing towards you, and close your lips tightly around it. Inhale dose with a rapid and steady flow while holding the Twisthaler horizontal. Remove the mouthpiece from your mouth and hold your breath for 5 to 10 seconds (or as long as you comfortably can). When you exhale, be sure that you are not exhaling into the device Immediately replace the cap and turn in a clockwise direction as you gently press down until you hear a click. Firmly close the Twisthaler to assure that your next dose is properly loaded. Be sure that the arrow is in line with the dose-counter window. Store device in cool dry place. The dose counter displays the number of doses remaining. When the unit reads 01, this indicates the last remaining dose. When the counter reads 00, the unit must then be discarded. Aerosol device comparison Advantages and disadvantages of various aerosol devices Type Jet nebulizer Advantages Patient coordination not required Disadvantages Expensive High doses possible Not portable - pressurized gas source required No CFC release More time required Contamination possible Device preparation required before treatment Not all medications available Less efficient than other devices (dead volume loss) Ultrasonic nebulizer Patient coordination not required Expensive Contamination possible High doses possible Prone to malfunction No CFC release Not all medication available Small dead volume Quiet Device preparation required before treatment No drug loss during exhalation Faster delivery than jet nebulizer Metered-dose inhaler Convenient Patient coordination essential Less expensive than nebulizer Patient actuation required Large pharyngeal deposition Portable Difficult to deliver high doses More efficient than nebulizer No drug preparation required Many use CFC propellants Not all medications available Difficult to contaminate Metered-dose inhaler with holding chamber Less patient coordination required More complex for some patients More expensive than MDI alone Less pharyngeal deposition Less portable than MDI alone Dry powder inhaler Less patient coordination required Requires moderate to high inspiratory flow Convenient Some units are single dose Breath-hold not required Can result in high pharyngeal deposition Propellant not required Not all medications available Portable Difficult to deliver high doses Breath-actuated CFC: chlorofluorocarbon; MDI: metered-dose inhaler. From Consensus Statement: Aerosols and Delivery Devices. Respir Care 2000; 45:589. MDI use with trach Equipment for aerosol delivery to tracheostomy in spontaneously breathing patients Aerosol delivery ventilator Factors affecting aerosol delivery during mechanical ventilation Nebulizer Position of nebulizer placement in the circuit Type of nebulizer and fill volume Treatment time Duty cycle (I:E ratio) Ventilator brand MDI Type of actuator Timing of actuation Nebulizer and MDI Endotracheal tube size Humidification of the inspired gas MDI in-line spacer Inline metered dose inhaler spacing device Using a chamber results in a four- to six-fold greater delivery of aerosol than actuation into a connector attached directly to the endotracheal tube, or into an inline device that lacks a chamber. Neb or MDI use with NPPV Aerosolized medications, either by nebulizer or MDI, can be administered during NPPV Grade 1B Grade 1B recommendation A Grade 1B recommendation is a strong recommendation, and applies to most patients. Clinicians should follow a strong recommendation unless a clear and compelling rationale for an alternative approach is present. Explanation: A Grade 1 recommendation is a strong recommendation. It means that we believe that if you follow the recommendation, you will be doing more good than harm for most, if not all of your patients. Grade B means that the best estimates of the critical benefits and risks come from randomized, controlled trials with important limitations (eg, inconsistent results, methodologic flaws, imprecise results, extrapolation from a different population or setting) or very strong evidence of some other form. Further research (if performed) is likely to have an impact on our confidence in the estimates of benefit and risk, and may change the estimates. Recommendation grades 1. Strong recommendation: Benefits clearly outweigh the risks and burdens (or vice versa) for most, if not all, patients 2. Weak recommendation: Benefits and risks closely balanced and/or uncertain Evidence grades A. High-quality evidence: Consistent evidence from randomized trials, or overwhelming evidence of some other form B. Moderate-quality evidence: Evidence from randomized trials with important limitations, or very strong evidence of some other form C. Low-quality evidence: Evidence from observational studies, unsystematic clinical observations, or from randomized trials with serious flaws For a complete description of our grading system, please see the UpToDate editorial policy that can be found by clicking on Help, and then About UpToDate Grade 2B Grade 2B recommendation A Grade 2B recommendation is a weak recommendation; alternative approaches may be better for some patients under some circumstances. Explanation: A Grade 2 recommendation is a weak recommendation. It means "this is our suggestion, but you may want to think about it." It is unlikely that you should follow the suggested approach in all your patients, and you might reasonably choose an alternative approach. For Grade 2 recommendations, benefits and risks may be finely balanced, or the benefits and risks may be uncertain. In deciding whether to follow a Grade 2 recommendation in an individual patient, you may want to think about your patient's values and preferences or about your patient's risk aversion. Grade B means that the best estimates of the critical benefits and risks come from randomized, controlled trials with important limitations (eg, inconsistent results, methodologic flaws, imprecise results, extrapolation from a different population or setting) or very strong evidence of some other form. Further research (if performed) is likely to have an impact on our confidence in the estimates of benefit and risk, and may change the estimates. Recommendation grades 1. Strong recommendation: Benefits clearly outweigh the risks and burdens (or vice versa) for most, if not all, patients 2. Weak recommendation: Benefits and risks closely balanced and/or uncertain Evidence grades A. High-quality evidence: Consistent evidence from randomized trials, or overwhelming evidence of some other form B. Moderate-quality evidence: Evidence from randomized trials with important limitations, or very strong evidence of some other form C. Low-quality evidence: Evidence from observational studies, unsystematic clinical observations, or from randomized trials with serious flaws For a complete description of our grading system, please see the UpToDate editorial policy that can be found by clicking on Help, and then About UpToDate.