MS Word - CORDIS

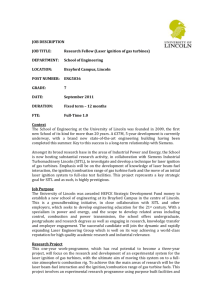

advertisement

GROWTH – DEDICATED CALL – 1/00 TOPIC III.1 Mechanical Ignition Hazards in Potentially Explosive Gas and Dust Atmospheres 1. CONFORMITY WITH THE WORK PROGRAMME This topic falls under the Competitive and Sustainable Growth Programme, generic activity Measurement and Testing. Specifically, it is related to Objective GROW-20006.2.1 Methodologies to support standardisation and Community policies for which expressions of interest have been called. Research on mechanical ignition hazards is required by Working Group 2 (Equipment for use in potentially explosive atmospheres) of CEN TC305 (Potentially explosive atmospheres-Explosion prevention and protection) working on standards for nonelectrical equipment intended for use in potentially explosive atmospheres. The working group is preparing a set of harmonised standards to support the essential safety requirements of the ATEX Directive 94/9/EC Its aim is the development and validation of a testing method for inclusion in a European harmonised standard, and the specification of safety criteria needed to assess the safety of equipment. 2. KEYWORDS Explosive atmospheres, ignition risk, hazards, ATEX. 3. SUMMARY OF OBJECTIVES AND JUSTIFICATION Research is needed to provide data that can be used to estimate the probability of frictional and mechanical ignitions in industrial plant. The guidance currently available is inadequate . The aims are to: (a) rank combustible materials in the order of their ignitability by frictional means, by reference to standard ignitability characters, (b) measure the energy or power necessary to ignite explosive atmospheres or dust deposits, measure the power and energy available to cause ignition in plant where frictional effects are likely, and produce methods for estimating the danger of an ignition and for preventing the onset of ignitions. DC 1/00/Topic III.1/ Pg 2 4. BACKGROUND Analysis of industrial dust explosion incidents reveals that friction and mechanical failure and flaming material are, in a substantial percentage of these incidents, the known source of ignition. The evidence shows that a high fraction of recorded incidents results from ignitions due to mechanical friction. The basic European standard on explosion protection and prevention, EN1127-1 ‘Explosion prevention and protection - Part 1: Basic concepts and methodology’ lists ignition sources that manufacturers of equipment must consider. Mechanical ignition sources are listed in this standard. Although there is high potential for ignition by mechanical sources, there is no generally accepted systematic method for estimating the ignition probability of mechanical sources in specific operations or equipment, or how this probability varies with different types of explosive environment. There is no over-arching guidance that can generally be applied throughout industry, or enough data and information available to allow risk assessments to be applied to industrial plant where frictional effects are a possibility. Mechanically generated sparks take three forms: Grinding sparks Friction sparks Impact sparks - a quick contact (20-50 milliseconds) of two surfaces in relative motion, rubbing together over an extended time, (0.5 – 20.0 seconds) of two surfaces in relative motion single contact of two surfaces in relative motion. Tests have demonstrated that mechanically generated sparks are capable of igniting explosive atmospheres. The likelihood of ignition depends on the atmospheres, the materials in contact and the relative velocity of the two surfaces. The important parameters that determine the likelihood of ignition by a hot surface are the temperature of the surface and its area. The most important hazard as regards hot surfaces is the ignition of a dust layer. The practical dangers are that a smouldering or burning layer can act either directly as an ignition source for a dust cloud or produce burning material that can break away and ignite a dust cloud in another part of the plant. Dust clouds can be ignited by various burning or smouldering ignition sources. Currently, there is insufficient data to allow the development of acceptable harmonised standards for CEN TC 305. The probability of ignition cannot be estimated for the majority of explosive atmospheres, and this is especially true of dusty environments, where the number of variables and likely ignition scenarios increase. Without this fundamental information the ignition hazard of equipment can not be assessed. A properly researched methodology for specifying accurately the safety requirements of equipment where frictional effects may occur is an important need for the standards making process. DC 1/00/Topic III.1/ Pg 3 5. ECONOMIC AND SOCIAL BENEFITS Potentially explosive atmospheres occur throughout industry, and explosions can affect the health and safety of employees, and others beyond the workplace boundary. Apart from flame and blast effects, explosions produce combustion products which can be harmful to people and the environment if they are released into the atmosphere. The essential safety requirements in the ATEX 100a Directive 94/9/EC indicate strongly that avoidance of ignition sources is a fundamental aspect of establishing a basis of safety when potentially explosive atmospheres are present. In the absence of a satisfactory procedure and comprehensive data for estimating the frictional ignition risk, safety has to be based on explosion protection that precise data on mechanical ignitions would show to be unnecessary. It is more effective to prevent explosions than to rely on explosion protection. The proposed research will produce methods for evaluating the ignition potential of frictional sources. The economic benefit is that manufacturers will be able to design equipment that is reliably protected against the ignition hazard without placing undue reliance on unnecessary protection techniques. The research should be carried out at a European level because the content of the proposal covers a number of technical areas, and a range of expertise is required. The endeavours of several countries will ensure that the resulting guidance and test specifications would have a wide acceptance for inclusion in standards. 6. SCIENTIFIC AND TECHNOLOGICAL OBJECTIVES The aim of the work is to develop criteria and test methods for assessment of ignition hazards from mechanical ignition sources: 1. To establish the duration, extent and temperature of hot surfaces produced at a point of contact by impact and rubbing friction, and to relate these to the friction conditions (eg. surface materials, energy transfer, power loss, velocity at contact and energy of impact). 2. To establish a test to characterise powder deposit sensitivity to heated surfaces of the type found in 1. The dusts should be characterised by variation of the ignitability characteristics, with a view to formulating families of dusts to which specific sensitivities can apply. 3. To establish a test to characterise the sensitivity of explosive atmospheres to a) localised transient heated areas, with the characteristics of those produced in 1, and the ignition of dust deposits as described in 2. b) heated metal particles, with the characteristics of those produced in 1. Explosive gas or vapour atmospheres should be characterised by the existing classification scheme (EN 50 014: Electrical apparatus for potentially explosive atmospheres – General Requirements). Dust atmospheres should be characterised by variation of the ignitability parameters of the dust, with a view to formulating families of dusts to which certain sensitivities can apply, 4. To establish the conditions in dust handling plant that would ensure avoidance of ignition by frictional means. DC 1/00/Topic III.1/ Pg 4 7. TIME SCALE This research can be completed in four years. The results will then be exploited by amendments to standards, and inclusion in the update of EN 1127-1. Result Format The results will be presented in the form of test methods and assessment methodologies for inclusion in CEN European Standards. 8. IMPORTANT ADDITIONAL INFORMATION Regular consultation with Working Group 2 of CEN TC 305 will be necessary throughout this project, as will contact with manufacturers and users, and notified bodies. It is recommended that such consultation be specified as part of the work programme, to ensure that the outcomes are satisfactory to the standards-making bodies.