SWP-4a dispensing LN..

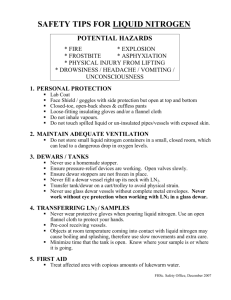

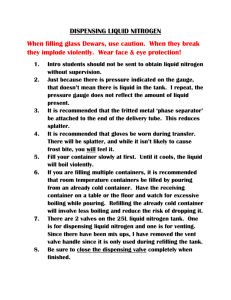

advertisement

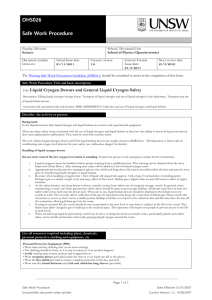

OHS026 Safe work procedure 1. Completed by: Lance Islip, 2. Suddha Moorkooth 3. minor changes by GT Keenan 2911-2012 The Writing Safe Work Procedures Guideline (OHS027) should be consulted to assist in the completion of this form Faculty/Division: SCIENCE Document number Protein SWP -4a School/Unit: Physics Protein laboratory Liquid Nitrogen bulk storage- Newton Building Initial Issue date 10/052011 Current version 1.0 Current Version Issue date 29-11-2012 Next review date 10/05/2016 2.Safe work procedure title and basic description of activity Title: DISPENSING LIQUID NITROGEN FROM STORAGE TANKS Description of activity:- DISPENSING LIQUID NITROGEN FROM STORAGE TANKS 3.List Hazards and risk controls as per risk assessment Associated risk assessment number and location: Hazards Weight of Dewar and liquid nitrogen Controls Exposure to an asphyxiant and suffocation Decant in an open area (ensure roller shutter is open) Cold burns and frost bite PPE so no skin is exposed to splashes or spill, SWP and training, very slowly add nitrogen to empty containers until they cool sufficiently to prevent splashing Fire due to presence of liquid oxygen Removal of ignition sources, SWP and training. Check liquid in container for a blue tinge – Oxygen present if blueish. Explosive rupture of containers Do not decant into containers with screw on lids or sealable lids. Containers must be designed for cryogenic use. Check containers for presence of water prior to first filling. Do Manual Handling Training, use trolleys for dewars, have help to carry or push dewars. 4.List resources required including personal protective clothing, chemicals and equipment needed Leather Gauntlets/Gloves Laboratory gowns with sleeves pulled over cuffs of Cryogenic Gloves Liquid proof Shoes Laboratory Face Shield Cryogenic apron which goes down to cover the shoes to prevent splash entry. Long trousers without cuffs which sit over the tops of shoes _______________________________________________________________________________________________________________ Page 1 of 4 OHS026 safe work procedure Current Version: 3.0 04/03/2011 5.List step by step instructions or order for undertaking the task DISPENSING LIQUID NITROGEN FROM STORAGE TANKS A) Inspect the dewar to be filled. Dispense only into Dewars that are rated for liquid nitrogen. o Never use a Dewar that does not have a pressure relief valve or pressure venting lid/stopper. o Never use Dewars with makeshift or homemade lids/stoppers. o Use pressure venting lids/stoppers supplied by the Dewar manufacturer Dispense only into Dewars that are: o Dry and clean o Equipped with carrying handles or wheels o Stable/not in danger of tipping over easily B) Check condition of Required Personal Protective Equipment and then put it on o Leather Gauntlets/Gloves o Lab Coat with sleeves pulled over cuffs of Cryogenic Gloves o Liquid proof Shoes o Laboratory Face Shield o Cryogenic apron o Long trousers C) Ensure there are no ignition sources present. Any liquid forming off the piping carrying the liquid nitrogen will be liquid oxygen. If liquid oxygen forms stop dispensing, allow the piping temperature to increase, and then recommence dispensing. Persons filling Dewar(s) will be in constant attendance during filling 1. Appropriate personal protective equipment is provided within the facility and must be worn prior to opening liquid nitrogen tap. Earplugs are optional due to the noise generated from the liquid nitrogen pipe cooling down. 2. Place hose in the dewar to the bottom of the vessel if possible. 3. DO NOT place face or head over the opening of the dewar during the early stages of filling 4. Turn on tap full, then turn back one full turn. Within 3-5 seconds a cold steam will come out of the hose and liquid nitrogen soon afterwards. 5. Keep a very close watch on the filling process. One hand should remain on the tap in case an emergency stop is required. 6. Fill to three quarters full (filling full would cause spillage). Check the depth using the depth guage provided, and then wait for the liquid N2 to settle before you put the lid on. 7. Turn off tap completely 8. Slowly and carefully remove hose from the dewar taking care not to drip or splash liquid onto yourself or others and place hose on hook provided. 9. Fit lid to the dewar, leaving a gap for gas to escape. Ensure lid is NOT tight fitting or sealing. 10. Remove PPE. 11. Lock the cage. 6.List emergency shutdown procedures Turn off the tap if it is safe to do so. 7.List Emergency procedures for how to deal with fires, spills or exposure to hazardous substances If unable to turn off the tap, leave the area and instruct others to leave the area. Contact the floor warden or building SECO (x58031) to initiate a floor evacuation (whole building NOT required to be evacuated). If you cannot arrange for the floor to be evacuated then press the break glass alarm for a building evacuation. Contact the OHS unit 9385 1565 or Lance Islip on 0408557965 and ask for an oxygen monitor to be brought over to gauge when it is safe to return. If uncontactable then allow 30 minutes before re-entering the building after the spill has stopped. _______________________________________________________________________________________________________________ Page 2 of 4 OHS026 safe work procedure Current Version: 3.0 04/03/2011 First aid for cryogenic burns The following procedure should be carried out: (a) Remove the victim from the possibility of further contact with the liquid or vessel. (b) Move the victim to a warm place (about 22°C) but do not apply direct heat. (c) If qualified medical attention is not immediately available, arrange for the victim to be transported to a hospital without delay. (d) If immediate hospitalization is not possible, proceed with steps (e) to (i). (e) Gently, flush the affected areas of the skin with large quantities of unheated tap water. Do not use hot water or any other form of direct heat. (f) Loosen any clothing that might restrict the circulation to the affected area but take care not to remove any clothing frozen to flesh. (g) Protect the affected areas with dry, sterile, non-adhering dressings. Do not apply too tightly so as to restrict blood circulation. Keep the affected part at rest. (h) Treat the patient generally for shock. (i) Do not give the patient alcohol to drink or tobacco to smoke. Both of these will restrict blood flow. 8.List Clean up and waste disposal requirements In case of spill, simply allow it to evaporate harmlessly. Check that no liquid has become trapped in your clothing, shoes etc. 9.List legislation used in the development of this SWP NSW OHS Act 2000 NSW OHS Regulation 2001 Australia Dangerous Goods Code AS 1894:1997 The storage and handling of non-flammable cryogenic and refrigerated liquids 10.List competency required – qualifications, certificates, licensing, training - e.g. course or instruction: The ability to accurately follow this procedure. Understanding of the hazards associated with cryogens Knowledge of nearest running water source for first aid 11.Supervisory approval, And review Supervisor: Shauna Simon Responsibility for SWP review: Shauna Signature: Simon Date of review: 10/05/2014 _______________________________________________________________________________________________________________ Page 3 of 4 OHS026 safe work procedure Current Version: 3.0 04/03/2011 12.SWP Sign off sheet SWP name and version: In signing this section the assessor/ authorisor agrees that the following persons are competent in following this SWP Name Signature Date Competent Name of Assessor/Authoriser Assessor/Authoriser signature _______________________________________________________________________________________________________________ Page 4 of 4 OHS026 safe work procedure Current Version: 3.0 04/03/2011