Relations between phase diagram, kinetics of thermal annealing

advertisement

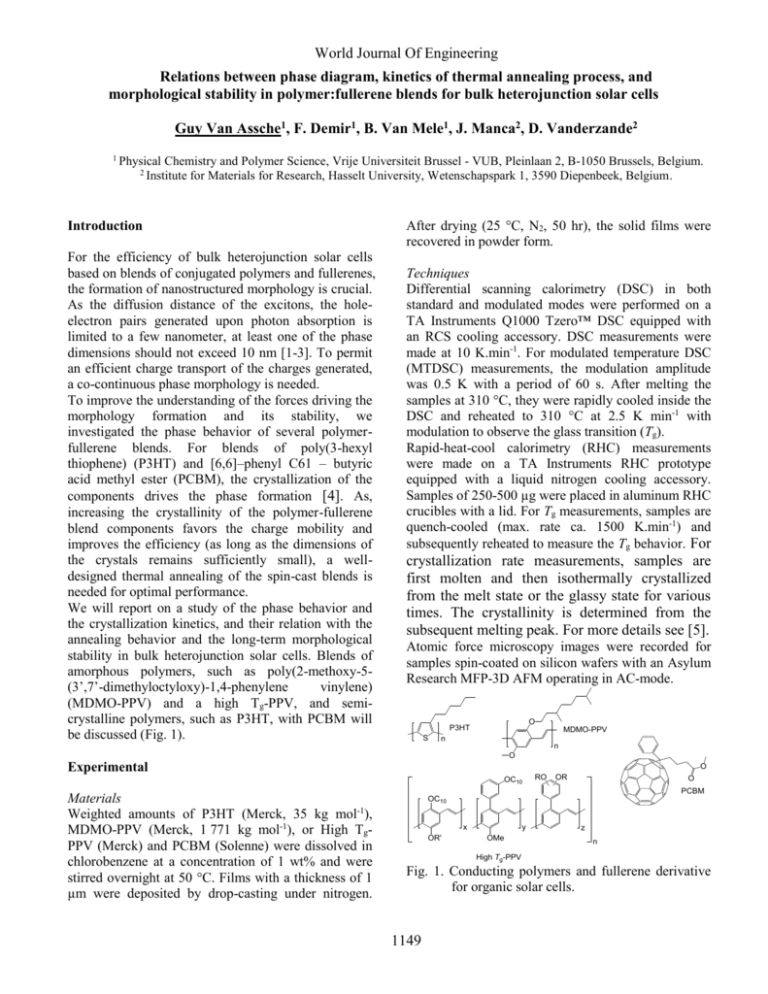

World Journal Of Engineering Relations between phase diagram, kinetics of thermal annealing process, and morphological stability in polymer:fullerene blends for bulk heterojunction solar cells Guy Van Assche1, F. Demir1, B. Van Mele1, J. Manca2, D. Vanderzande2 1 Physical Chemistry and Polymer Science, Vrije Universiteit Brussel - VUB, Pleinlaan 2, B-1050 Brussels, Belgium. 2 Institute for Materials for Research, Hasselt University, Wetenschapspark 1, 3590 Diepenbeek, Belgium. Introduction For the efficiency of bulk heterojunction solar cells based on blends of conjugated polymers and fullerenes, the formation of nanostructured morphology is crucial. As the diffusion distance of the excitons, the holeelectron pairs generated upon photon absorption is limited to a few nanometer, at least one of the phase dimensions should not exceed 10 nm [1-3]. To permit an efficient charge transport of the charges generated, a co-continuous phase morphology is needed. To improve the understanding of the forces driving the morphology formation and its stability, we investigated the phase behavior of several polymerfullerene blends. For blends of poly(3-hexyl thiophene) (P3HT) and [6,6]–phenyl C61 – butyric acid methyl ester (PCBM), the crystallization of the components drives the phase formation [4]. As, increasing the crystallinity of the polymer-fullerene blend components favors the charge mobility and improves the efficiency (as long as the dimensions of the crystals remains sufficiently small), a welldesigned thermal annealing of the spin-cast blends is needed for optimal performance. We will report on a study of the phase behavior and the crystallization kinetics, and their relation with the annealing behavior and the long-term morphological stability in bulk heterojunction solar cells. Blends of amorphous polymers, such as poly(2-methoxy-5(3’,7’-dimethyloctyloxy)-1,4-phenylene vinylene) (MDMO-PPV) and a high Tg-PPV, and semicrystalline polymers, such as P3HT, with PCBM will be discussed (Fig. 1). After drying (25 °C, N2, 50 hr), the solid films were recovered in powder form. Techniques Differential scanning calorimetry (DSC) in both standard and modulated modes were performed on a TA Instruments Q1000 Tzero™ DSC equipped with an RCS cooling accessory. DSC measurements were made at 10 K.min-1. For modulated temperature DSC (MTDSC) measurements, the modulation amplitude was 0.5 K with a period of 60 s. After melting the samples at 310 °C, they were rapidly cooled inside the DSC and reheated to 310 °C at 2.5 K min-1 with modulation to observe the glass transition (Tg). Rapid-heat-cool calorimetry (RHC) measurements were made on a TA Instruments RHC prototype equipped with a liquid nitrogen cooling accessory. Samples of 250-500 µg were placed in aluminum RHC crucibles with a lid. For Tg measurements, samples are quench-cooled (max. rate ca. 1500 K.min-1) and subsequently reheated to measure the Tg behavior. For crystallization rate measurements, samples are first molten and then isothermally crystallized from the melt state or the glassy state for various times. The crystallinity is determined from the subsequent melting peak. For more details see [5]. Atomic force microscopy images were recorded for samples spin-coated on silicon wafers with an Asylum Research MFP-3D AFM operating in AC-mode. O P3HT S MDMO-PPV n n O Experimental O OC10 Materials Weighted amounts of P3HT (Merck, 35 kg mol-1), MDMO-PPV (Merck, 1 771 kg mol-1), or High TgPPV (Merck) and PCBM (Solenne) were dissolved in chlorobenzene at a concentration of 1 wt% and were stirred overnight at 50 °C. Films with a thickness of 1 µm were deposited by drop-casting under nitrogen. RO OR O PCBM OC10 x OR' y OMe z n High Tg-PPV Fig. 1. Conducting polymers and fullerene derivative for organic solar cells. 1149 World Journal Of Engineering Results and Discussion long-term stability at application temperature from MTDSC: 2 (heating after quench), Figure 17a K minelevated , +/- 0.5 K temperatures. per 60 s accelerated ageing tests at2.5 more nd Conclusion A thorough study of the thermal transitions and isothermal annealing of polymer:fullerene blends revealed several key aspects for the usage of these materials for solar cell applications. The glass transition of the polymer:fullerene blends is crucial for the long-term stability of the required nanostructured morphology needed for optimal performance. The temperature dependence of the crystallization rate can be used to control the thermal annealing on the one hand, but might also prove useful for predicting the o 150 P3HT/PCBM: MDMO-PPV/PCBM: HTg-PPV/PCBM: single lower, lower, upper upper 100 50 0 0 20 40 60 80 100 Weight fraction of PCBM, fw (wt %) Fig. 2. Tg versus weight fraction PCBM for blends of P3HT, MDMO-PPV, and high-Tg PPV with PCBM (RHC). 1E-1 Crystallization rate (1/s) For all polymers, the thermal transitions for blends with PCBM contents ranging from 0 to 100 wt% were studied by DSC, MTDSC, and RHC. At sufficiently high PCBM contents, the crystallization of PCBM is detected when cooling at 10 K.min-1, however, the crystallization temperature decreases as the PCBM content is lowered. For blends with the semicrystalline P3HT, the crystallization of P3HT is observed up to 50 wt% PCBM, and the crystallization and melting temperature gradually decrease with increasing PCBM content. For the amorphous polymers, a single Tg, indicating a homogeneous blend, is observed in most cases. For MDMO-PPV, a double Tg, indicating phase separation in the amorphous phase, is observed at 70-90 wt% PCBM. This is especially clear for samples rapidly cooled by RHC, as in this case crystallization could be avoided, even for pure PCBM, permitting the analysis of the materials in their amorphous state (Error! Reference source not found.). For the reorganization of the material during annealing or during application, the Tg is crucial: if the Tg of the amorphous phase is sufficiently high, all cooperative mobility is frozen and the phase morphology should be stable. As the Tg’s of P3HT (~20°C) and MDMO-PPV (~60°C) are quite low, the Tg’s of their blends with PCBM at relevant PCBM contents (50-80 wt%) do not exceed 80°C, indicating that a long-term stability of the nanomorphology can not be expected during application. For high-Tg PPV, the Tg is sufficiently high to expect an improved long-term stability. The rate of crystallization during the annealing of P3HT:PCBM blends at temperatures ranging from 60°C to 160°C goes through a maximum around 125°C, and is generally faster for samples crystallized after quenching to the glassy state (Fig. 3). Glass transition temperature, Tg ( C) -1 1E-2 1E-3 from the Melt from the Glass 1E-4 50 90 130 170 Temperature (°C) Fig. 3. Crystallization rate versus temperature for a P3HT:PCBM 50:50 blend (RHC). References 1. Yang, X. N., Loos, J., Veenstra, S. C., Verhees, W. J. H., Wienk, M. M., Kroon, J. M., Michels, M. A. J., and Janssen, R. A. J. Nanoscale morphology of high-performance polymer solar cells. Nano Letters, 5(4) (2005) 579-583. 2. Ma, W. L., Yang, C. Y., and Heeger, A. J. Spatial Fouriertransform analysis of the morphology of bulk heterojunction materials used in "plastic" solar cells. Adv. Mater., 19(10) (2007) 1387-+. 3. Thompson, B. C. and Frechet, J. M. J. Polymer-fullerene composite solar cells. Angew. Chemie-Int. Ed., 47(1) (2008) 58-77. 4. Zhao, J., Swinnen, A., Van Assche, G., Manca, J., Vanderzande, D., and Van Mele, B. Phase Diagram of P3HT/PCBM Blends and Its Implication for the Stability of Morphology. J. Phys. Chem. B, 113(6) (2009) 1587-1591. 5. Demir, F., Van den Brande, N., Van Mele, B., Berth, S., Vanderzande, D., Manca, J., Van Assche, G. Isothermal 1150 World Journal Of Engineering crystallization of P3HT:PCBM blends studied by RHC. J. Therm. Anal. Calorim., published oinline (2011).. 1151