10. Statistical Analysis - Central Insecticides Board and Registration

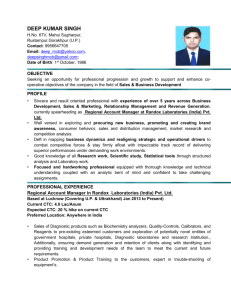

advertisement