EE 477 Final Report

advertisement

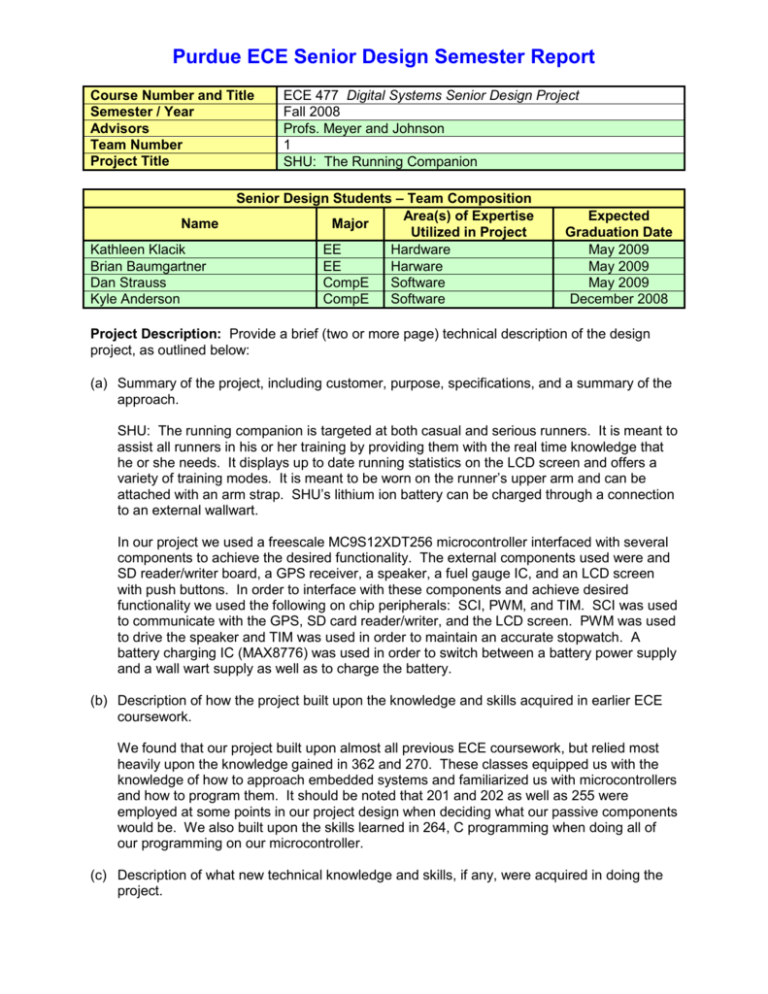

Purdue ECE Senior Design Semester Report Course Number and Title Semester / Year Advisors Team Number Project Title Name Kathleen Klacik Brian Baumgartner Dan Strauss Kyle Anderson ECE 477 Digital Systems Senior Design Project Fall 2008 Profs. Meyer and Johnson 1 SHU: The Running Companion Senior Design Students – Team Composition Area(s) of Expertise Major Utilized in Project EE Hardware EE Harware CompE Software CompE Software Expected Graduation Date May 2009 May 2009 May 2009 December 2008 Project Description: Provide a brief (two or more page) technical description of the design project, as outlined below: (a) Summary of the project, including customer, purpose, specifications, and a summary of the approach. SHU: The running companion is targeted at both casual and serious runners. It is meant to assist all runners in his or her training by providing them with the real time knowledge that he or she needs. It displays up to date running statistics on the LCD screen and offers a variety of training modes. It is meant to be worn on the runner’s upper arm and can be attached with an arm strap. SHU’s lithium ion battery can be charged through a connection to an external wallwart. In our project we used a freescale MC9S12XDT256 microcontroller interfaced with several components to achieve the desired functionality. The external components used were and SD reader/writer board, a GPS receiver, a speaker, a fuel gauge IC, and an LCD screen with push buttons. In order to interface with these components and achieve desired functionality we used the following on chip peripherals: SCI, PWM, and TIM. SCI was used to communicate with the GPS, SD card reader/writer, and the LCD screen. PWM was used to drive the speaker and TIM was used in order to maintain an accurate stopwatch. A battery charging IC (MAX8776) was used in order to switch between a battery power supply and a wall wart supply as well as to charge the battery. (b) Description of how the project built upon the knowledge and skills acquired in earlier ECE coursework. We found that our project built upon almost all previous ECE coursework, but relied most heavily upon the knowledge gained in 362 and 270. These classes equipped us with the knowledge of how to approach embedded systems and familiarized us with microcontrollers and how to program them. It should be noted that 201 and 202 as well as 255 were employed at some points in our project design when deciding what our passive components would be. We also built upon the skills learned in 264, C programming when doing all of our programming on our microcontroller. (c) Description of what new technical knowledge and skills, if any, were acquired in doing the project. Firstly, this was the first time anyone had done a PCB layout. The software used to create the layout and the conventions used in placing parts and routing traces required much learning—often times through trial and error. Also, this was the first time anyone on the team had worked on a project of this scale. The planning involved with determining what parts were needed and actually ordering those parts proved more difficult than expected. By the time the last parts were ordered, the methods and organization used to do so had become much smoother and more honed. Thirdly, the software development process was something that was also relatively new. In previous projects, the process of programming the microcontroller and flashing the controller’s memory was something that those working on it were mostly walked through. This time around, the development environment, the low-level specifics of programming, the method of flashing and debugging the controller, and the process of debugging the program for each individual external component were all more complicated and less laid our for the developers than previously had been. (d) Description of how the engineering design process was incorporated into the project. Reference must be made to the following fundamental steps of the design process: establishment of objectives and criteria, analysis, synthesis, construction, testing, and evaluation. In our design project, the first step is to decide upon project specific success criteria. These are the objectives that we would like our project to accomplish. After deciding on success criteria, the next step is to pick out the parts that our project will need in order to accomplish our set goals. To do this we needed to analyze the things that we want our project to do and then decide on the specific IC or hardware configuration to do this. It is important that we paid attention to the specific things that we wished for our hardware to do and also that we paid attention to the ratings of every IC and discrete components that was chosen. If we had neglected to pay attention to the ratings of the ICs and discrete components, there is a good chance or project would not have worked, because of this the step of analyzing was very important to our project. Checking to make sure all of our parts would work together by paying attention to their ratings is also part of the synthesis step in the design process. Without doing this, there would be no guarantee that our chosen parts would work together to form our final project. In addition, it is important to have a solid schematic going into the PCB design, where we really began to visualize what our project will look like when it is all finished. During the construction phase, we ran into a couple problems with our PCB. Our main problem was that we neglected to make a connection for a ground plate on one of our ICs. After we came up with a solution to this problem, we managed to assemble the rest of our PCB with minimal incidents. (e) Summary of how realistic design constraints were incorporated into the project (consideration of most of the following is required: economic, environmental, ethical, health & safety, social, political, sustainability, and manufacturability constraints). Economic: Economically, our design was constrained in the sense that we limited the amount of unnecessary features our device would have. In the beginning we were looking at making our device a touch screen device but decided against it because of both cost and complexity purposes. Environmental: Our product does not have much of an impact on the environment other than in the LCD manufacturing phase and in the recycling phase. In order to combat these problems, we could use green LCDs and offer a monetary reward system so that the user would send their product back to us and we could recycle the parts when the original product’s life cycle is over. -2- Ethical: Our project’s main ethical concern is whether we will test our project well enough to go to market and also whether our battery could potentially short and cause a fire or extreme heat and burn the user’s arm. In order to combat these issues, we will put our project through thorough tests such as lots of shaking, some extreme motion jolts, and moisture testing. In the case of the battery, we could just put a fuse in line with it to prevent a short circuit between ground and power. Health & Safety: Certain failure modes posed a safety risk to the user. If any voltages went too high, there was the potential for high temperatures which could cause burns to the user. The battery, especially, could become dangerous if anything went seriously wrong. Safety checks, both in software and hardware needed to be added. In the initial design process, portability took precedence over safety. Nonetheless, fuses and emergency shutdown modes were added. Sustainability: It was necessary that our device be able to sustain a lifetime of wear and tear on the user’s arm. Due to this it was necessary that our product be thoroughly tested to ensure that it would not fail prematurely during routine usage. We needed to make sure that we used very durable materials and employed durable foam to keep parts from moving around inside the enclosure. Manufacturability: When picking out parts, we used parts that were mostly easy to integrate. It was necessary that our product was designed in such a way that it would be easily manufactured and would also be profitable. (f) Description of the multidisciplinary nature of the project. Many different disciplines of skills needed to be used for this project. There was the obvious division between electrical and computer engineering. Schematic design was more electrical engineering, while programming the processor was more computer engineering. The two came together for the PCB layout design and circuit board population. There was also the more managerial work such as putting together presentations, ordering parts, and writing the final report. Some reports touched on patent law, safety and ethics, and marketing. (g) Description of project deliverables and their final status. SHU currently meets three out of five project specific success criteria. The user is able to successfully navigate the menu system using pushbuttons and the LCD. The battery is able to be charged through a connection to an AC wallwart, and the fuel gauge displays the amount of battery left on the screen. We hope to get the SD card storage and GPS tracking ability working soon. -3-