15141 Demonstrate knowledge of pastry technology and

advertisement

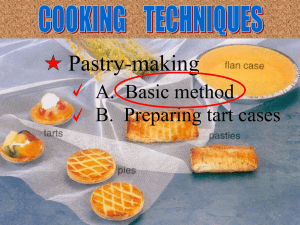

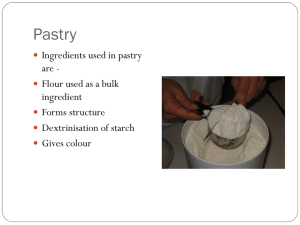

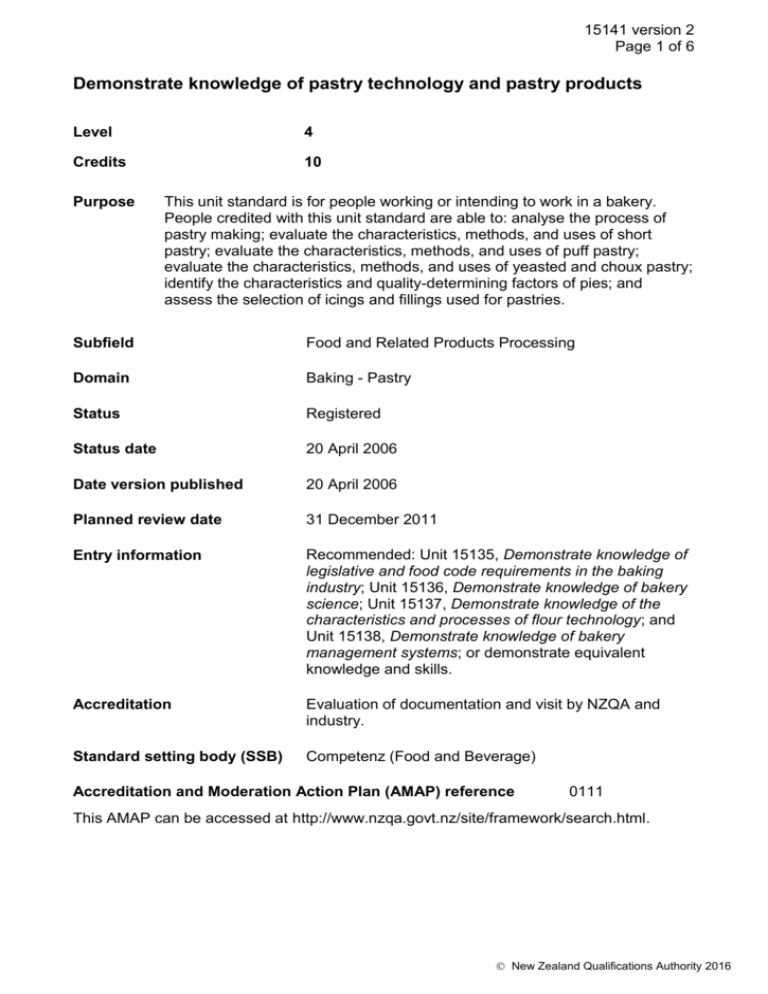

15141 version 2 Page 1 of 6 Demonstrate knowledge of pastry technology and pastry products Level 4 Credits 10 Purpose This unit standard is for people working or intending to work in a bakery. People credited with this unit standard are able to: analyse the process of pastry making; evaluate the characteristics, methods, and uses of short pastry; evaluate the characteristics, methods, and uses of puff pastry; evaluate the characteristics, methods, and uses of yeasted and choux pastry; identify the characteristics and quality-determining factors of pies; and assess the selection of icings and fillings used for pastries. Subfield Food and Related Products Processing Domain Baking - Pastry Status Registered Status date 20 April 2006 Date version published 20 April 2006 Planned review date 31 December 2011 Entry information Recommended: Unit 15135, Demonstrate knowledge of legislative and food code requirements in the baking industry; Unit 15136, Demonstrate knowledge of bakery science; Unit 15137, Demonstrate knowledge of the characteristics and processes of flour technology; and Unit 15138, Demonstrate knowledge of bakery management systems; or demonstrate equivalent knowledge and skills. Accreditation Evaluation of documentation and visit by NZQA and industry. Standard setting body (SSB) Competenz (Food and Beverage) Accreditation and Moderation Action Plan (AMAP) reference 0111 This AMAP can be accessed at http://www.nzqa.govt.nz/site/framework/search.html. New Zealand Qualifications Authority 2016 15141 version 2 Page 2 of 6 Special notes 1 Enactments and codes relevant to this unit standard include but are not limited to the: Food Act 1981; Health and Safety in Employment Act 1992; Resource Management Act 1991; Food (Safety) Regulations 2002; Food Hygiene Regulations 1974; Australia New Zealand Food Standards Code, available at http://www.foodstandards.govt.nz/. 2 Definition Organisational procedures refers to documents that include: worksite rules, codes, and practices; equipment operating instructions; production specifications; documented quality management systems; and health and safety requirements. 3 Performance must be consistent with documented organisational policies and procedures. Elements and performance criteria Element 1 Analyse the process of pastry making. Performance criteria 1.1 The history of pastry making is outlined in terms of its origin and evolution from the ancient Egyptian period through to modern day. 1.2 Distinction between puff pastry and short pastry is determined by assessing specific pastry characteristics. Range 1.3 shortness, lamination, lift, flakiness. Pastry ingredients are identified and evaluated in terms of their form, function, and use. Element 2 Evaluate the characteristics, methods, and uses of short pastry. Performance criteria 2.1 The meaning of ‘short’ is explained in terms of how it relates to pastry and pastry products. 2.2 Short pastries are classified according to recipe balance and uses. Range 2.3 short, sweet, wholemeal. Short pastry ingredients are assessed against requirements for quality and use in short pastry processes. New Zealand Qualifications Authority 2016 15141 version 2 Page 3 of 6 2.4 Short pastry methods are compared in terms of sequence and pace of ingredient addition, and mixing speeds. Range 2.5 small batch method, shortening method, sweet pastry method, wholemeal pastry method. Factors which determine the quality of short pastry are identified from quality assessment sheets. Range texture, volume, shape, degree of shortness, mouthfeel. 2.6 Causes of poor short pastry quality are established and corrective measures outlined from an analysis of ingredient quality, recipe balance, and processing methods. 2.7 A list of five short pastry products is compiled from a literature review and survey of local bakeries and patisseries. 2.8 Each listed product is supported by a description and illustrated to show detail. Element 3 Evaluate the characteristics, methods, and uses of puff pastry. Performance criteria 3.1 Puff pastry ingredients are assessed against requirements for quality and use in puff pastry processes. 3.2 Puff pastry methods are compared in terms of fat incorporation and placement, sheeting, and intended usage. Range Scotch, French, English. 3.3 Lamination is defined by process and function. 3.4 Laminating methods are compared in terms of the number of folds and turns. Range 3.5 half-turn, book fold. Factors which determine the quality of puff pastry are identified from quality assessment sheets. Range texture, volume, shape, degree of layers, flakiness, lift, mouthfeel. 3.6 Causes of poor puff pastry quality are established and corrective measures outlined from an analysis of ingredient quality, recipe balance, and processing methods. 3.7 A list of five puff pastry products is compiled from a literature review and survey of local bakeries and patisseries. New Zealand Qualifications Authority 2016 15141 version 2 Page 4 of 6 3.8 Each listed product is supported by a description and illustrated to show detail. Element 4 Evaluate the characteristics, methods, and uses of yeasted and choux pastry. Performance criteria 4.1 Yeasted and choux pastries are classified in terms of recipe balance, internal structure and texture, and uses. 4.2 Ingredients for yeasted and choux pastries are assessed against requirements for quality and use in these pastry processes. 4.3 Yeasted and choux pastry methods are compared by an analysis of the processing steps involved. Range 4.4 sequence and pace of ingredient addition, fermentation times, resting times and temperature, cutting and shaping, cooking, baking. Factors which determine the quality of yeasted and choux pastry are identified from quality assessment sheets. Range texture, volume, shape, degree of layers, flakiness, lift, mouthfeel. 4.5 Causes of poor yeasted and choux pastry quality are established and corrective measures outlined from an analysis of ingredient quality, recipe balance, and processing methods. 4.6 A list of four yeasted or choux pastry products is compiled from a literature review and survey of local bakeries and patisseries. 4.7 Each listed product is supported by a description and illustrated to show detail. Element 5 Identify the characteristics and quality-determining factors of pies. Performance criteria 5.1 Pies are classified according to pastry type and filling. Range 5.2 closed-top pies, open-top pies, quiches, pasties, flans, tarts. Requirements for meat pies are stated in terms of the Food (Safety) Regulations 2002. New Zealand Qualifications Authority 2016 15141 version 2 Page 5 of 6 5.3 Ingredients used in pies are identified and assessed in terms of use and requirements for quality. Range 5.4 Factors which determine the quality of pies are identified from quality assessment sheets. Range 5.5 sweet, savoury, thickeners, salt, flavouring ingredients, water, caramel. height, evenness of lift, evenness of baking, shape, colour, surface appearance, tops and bases, fillings, mouthfeel, flavour. Causes of poor pie quality are established and corrective measures outlined from an analysis of ingredient quality and quantity, recipe balance, and processing methods. Element 6 Assess the selection of icings and fillings used for pastries. Performance criteria 6.1 Commonly used icings are classified in terms of recipe balance, characteristics, and use. Range 6.2 Commonly used fillings are classified in terms of recipe balance, characteristics, and use. Range 6.3 flat icings, fondant, creamed icings, almond paste, glazes, meringue, marshmallow, streusel. whipped cream, ganache, custard, caramel, streusel, fruit, jam. Methods for filling and icing pastries are compared against specifications for finished product and application techniques. Range hand, machine. Please note Providers must be accredited by the Qualifications Authority, or an inter-institutional body with delegated authority for quality assurance, before they can report credits from assessment against unit standards or deliver courses of study leading to that assessment. Industry Training Organisations must be accredited by the Qualifications Authority before they can register credits from assessment against unit standards. Accredited providers and Industry Training Organisations assessing against unit standards must engage with the moderation system that applies to those standards. New Zealand Qualifications Authority 2016 15141 version 2 Page 6 of 6 Accreditation requirements and an outline of the moderation system that applies to this standard are outlined in the Accreditation and Moderation Action Plan (AMAP). The AMAP also includes useful information about special requirements for organisations wishing to develop education and training programmes, such as minimum qualifications for tutors and assessors, and special resource requirements. Comments on this unit standard Please contact the Competenz qualifications@competenz.org.nz if you wish to suggest changes to the content of this unit standard. New Zealand Qualifications Authority 2016