doc

advertisement

ECE 477 Final Report Spring 2008

Team 10 Global Pigeon

Team Members:

#1: David Collins_________________

Signature: ____________________ Date: _________

#2: Matt Ligocki_________________

Signature: ____________________ Date: _________

#3: Daniel Bixby_________________

Signature: ____________________ Date: _________

#4: Paul Ng _____________________

Signature: ____________________ Date: _________

CRITERION

Technical content

Design documentation

Technical writing style

Contributions

Editing

Comments:

0

0

0

0

0

1

1

1

1

1

2

2

2

2

2

3

3

3

3

3

SCORE

4 5 6 7

4 5 6 7

4 5 6 7

4 5 6 7

4 5 6 7

8

8

8

8

8

9

9

9

9

9

10

10

10

10

10

MPY

3

3

2

1

1

TOTAL

PTS

ECE 477 Final Report

Spring 2008

TABLE OF CONTENTS

Abstract

1

1.0 Project Overview and Block Diagram

2

2.0 Team Success Criteria and Fulfillment

5

3.0 Constraint Analysis and Component Selection

6

4.0 Patent Liability Analysis

11

5.0 Reliability and Safety Analysis

16

6.0 Ethical and Environmental Impact Analysis

21

7.0 Packaging Design Considerations

26

8.0 Schematic Design Considerations

31

9.0 PCB Layout Design Considerations

36

10.0 Software Design Considerations

40

11.0 Version 2 Changes

47

12.0 Summary and Conclusions

48

13.0 References

49

Appendix A: Individual Contributions

A-1

Appendix B: Packaging

B-1

Appendix C: Schematic

C-1

Appendix D: PCB Layout Top and Bottom Copper

D-1

Appendix E: Parts List Spreadsheet

E-1

Appendix F: Software Listing

F-1

Appendix G: FMECA Worksheet

G-1

-ii-

ECE 477 Final Report

Spring 2008

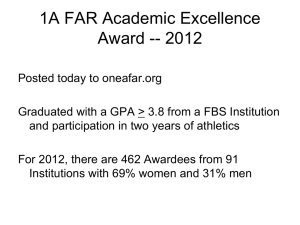

Abstract

The objective of Team Global Pigeon is to build a semi-autonomous RC plane capable of

flying to GPS waypoints and taking photographs. The airframe chosen was a Multiplex Easy

Glider Electric. It is effectively a foam glider with an electric motor for thrust. The design will be

semi-autonomous as the plane will require human controlled take off and landing using a

standard RC radio controller. Once at cruising altitude, the radio controller will send a signal to

switch to autopilot mode. The plane will then fly to each of a series of GPS waypoints. Upon

getting sufficiently close to each objective, the plane will begin triggering the attached digital

camera to take photos.

-1-

ECE 477 Final Report

Spring 2008

1.0 Project Overview and Block Diagram

The design is built around the Multiplex Easy Glider Electric RC plane, which is

effectively a foam glider using an electric motor for thrust. The plane was selected for its

durability and crash resistance. A retail point-and-shoot camera is mounted on the plane. The

shutter is wired to a microcontroller for automated photography. The takeoff and landing of the

plane is controlled manually using a standard radio controller. As described in the abstract, it will

be switched to autopilot mode once it has reached the desired altitude. From this point the

microcontroller reads GPS waypoints which have been prewritten onto an SD card. These values

are used as a reference for controlling the plane's flight. In addition the plane periodically writes

its position to the SD card for later use, such as allowing the flight path to be read and mapped

by a computer. Upon reaching the specified coordinates, the microcontroller triggers the camera

to take a series of photographs before proceeding to the next waypoint. The photographs are

stored in the cameras built in SD card.

The design has the potential for improvements in the aerial photography field. It would

greatly improve the cost and efficiency of aerial photography, as it eliminates the necessity of a

human flying in a significantly larger plane. It could also improve the accuracy and precision

with which photos are taken from the plane. The plane can also be used for small scale

geographical surveying. Multiple planes could also be used in search and rescue missions to

scour a large area.

-2-

ECE 477 Final Report

Spring 2008

Figure 1.1: Global Pigeon Block Diagram

-3-

ECE 477 Final Report

Spring 2008

Figure 2.2: Global Pigeon Final Assembly

-4-

ECE 477 Final Report

Spring 2008

2.0 Team Success Criteria and Fulfillment

1. An ability to fly an R/C plane autonomously once airborne, based on pre-programmed

waypoints.

2. An ability to decode and display GPS coordinates.

3. An ability to control motor speed and control surface position.

4. An ability to capture still images.

5. An ability to read waypoints from a MicroSD removable storage device.

As of the writing of this report, PSSC’s two through five have been successfully

completed and demonstrated. The first PSSC is currently partially completed. The plane is

capable of becoming airborne with the additional weight load and flies stable.

The

microcontroller is currently not capable of controlling the plane during a real flight scenario due

to RF interference emitted by the plane’s circuit board. Possible solutions to this problem are

currently being developed.

The remaining PSSC’s are demonstrated while the plane is on the ground. Criteria two is

demonstrated by hooking up an external LCD screen to the plane and walking around outside.

As the plane moves around, up to date latitude and longitude coordinates are displayed to the

LCD. Criteria three and four are demonstrated by having a laptop send commands to the plane’s

microcontroller which then controls the plane’s control systems and camera. Criteria five is

demonstrated by first programming GPS coordinates to a microSD card using a laptop. The card

is then inserted into the plane and the coordinates are read from the plane via the laptop’s serial

connection.

-5-

ECE 477 Final Report

Spring 2008

3.0 Constraint Analysis and Component Selection

The objective of this project is to build a semi-autonomous RC plane capable of flying to

GPS way points and taking photographs. This will be accomplished by modifying an existing

RC plane. These modifications will include replacing components that are already part of the

plane such as motor and battery pack as well as adding additional hardware to facilitate the

plane’s ability to track its own location and heading. This additional hardware must not weigh

the plane down to the point where it is no longer capable of attaining flight and must be evenly

distributed within the limited space of the plane’s fuselage as to not affect the plane’s center of

gravity. This section will explain the component selection rationale for the project in terms of its

major design constraints.

3.1

Design Constraint Analysis

The primary design constraint of this project is the weight of the additional hardware

added to the plane. If the plane becomes too heavy, there exists the possibility that it will not be

able to get off of the ground. With the additional weight comes the issue of how it is distributed

within the plane’s fuselage. If the hardware’s weight is not evenly distributed, the plane will not

fly level. A final consideration in hardware selection is size. The majority of the additional

hardware must fit within the fuselage of the plane.

This space is limited and excessive

modification to the fuselage can weaken the plane’s structure.

3.2

Computation Requirements

The plane’s microcontroller will be responsible for navigating between way points and

making course adjustments as necessary. Course computations are made based off of data from

the plane’s GPS module. The rate of these computations is limited by the GPS module which

can only provide updated position information at a rate of five hertz [1].

The basic control algorithm will consist of checking the plane’s current position and

heading, comparing this to where the plane needs to go, and then making any control

adjustments as necessary. A possible advancement to this algorithm is to have the plane adapt

for flight conditions. If the microcontroller notices that the plane is consistently drifting of

course in a particular direction, it can have the plane compensate for this drift throughout the

-6-

ECE 477 Final Report

Spring 2008

planned flight. This type of control algorithm would also be relatively simple to implement and

would not require any severe computational power.

3.3

Interface Requirements

The microcontroller will be required to interface with a variety of on board sensors and

flight control components. The GPS module will interface to the microcontroller via RS-232

SCI [1]. The microcontroller will receive its GPS waypoints from a microSD card. This device

will interface via a SPI bus [2].

The plane itself includes four servos for controlling the rudder, elevators and ailerons, a

motor, and a RF radio receiver. All of the radio channels will interface to the microcontroller’s

timer module for data recording. One unused radio signal will be used to determine if the plane

is in automated or manual flight mode. During automated flight the microcontroller will be

responsible for controlling the plane’s rudder and elevators. This will be accomplished by using

PWM outputs. A digital output signal will be used as a select line to an external multiplexer to

choose between the microcontroller and RF receiver control signals. The digital camera used to

accomplish aerial photography will interface to the microcontroller using several digital outputs

to control its power, shutter, and auto-focus. There will also be another digital input connected

to the camera to detect if it has power.

A detachable LCD screen will be used for preflight analysis and debugging. This screen

will interface via RS-232 SCI and will also include a digital input pin used for detecting when

the display is attached. Other miscellaneous interfaces include digital outputs for indicator LEDs

and digital inputs for input switches. All of the electronic components selected utilize either

3.3V or 5V input voltage. Converting between these will be handled using level translation

buffers.

-7-

ECE 477 Final Report

Spring 2008

Peripheral

Etek 5Hz GPS EB-85A

microSD

Servo and Drive output

LCD Screen

Auto/Manual Select output

Camera control

Camera power detection

Auto/Manual PWM input

Display connection detection

Indicator LEDs

Miscellanous I/O

I/O Interface

SCI

SPI

PWM

SCI

GPIO

GPIO

GPIO

Timer Counter

GPIO

GPIO

GPIO

Number of Pins

2

4

4

2

1

3

1

5

1

3

1

Table 3.1: I/O Requirements

3.4

On-Chip Peripheral Requirements

On-chip peripheral requirements are based off of the requirements of external components.

The microcontroller selected will require at a minimum two RS-232 SCI, one SPI, four PWM

channels, five timer channels, and ten general purpose I/O pins. This comes to a total pin

requirement of twenty-seven pins.

3.5

Off-Chip Peripheral Requirements

Several off-chip peripherals are required for the successful operation of the plane. The

first set of peripherals is the plane’s control systems. This includes the control surface servos,

motor, and radio receiver. These parts come with the plane but the motor will be upgraded to

give the plane more power and the radio receiver will be upgraded to allow the extra control

signal required to switch from manual to automated flight. A multiplexor will also be required to

switch between the radio receiver control signals and those generated by the microcontroller.

The second set of off-chip peripherals is the navigation equipment. This includes the GPS

module and microSD card. The GPS module will be required to have decent accuracy in terms

of both position and altitude measurement. The final off-chip peripheral is the digital camera.

The camera is required to be light weight and small to allow it to be easily mounted to the plane.

-8-

ECE 477 Final Report

3.6

Spring 2008

Power Constraints

The plane is powered by an onboard battery pack. The plane’s motor will be the largest

power draw on the battery. The hardware added to the plane will add weight to the plane

increasing the required strain on the motor and therefore decreasing the plane’s battery life. This

additional hardware will also draw power from the plane’s battery but is considered insignificant

compared to the draw from the motor.

Compensating for these extra power requirements will involve replacing the plane’s

standard battery pack. The new battery pack must be able to fit in the plane in the same location

as the existing battery and must not add any more weight to the plane as to negate its benefits.

3.7

Packaging Constraints

The packaging of the project is the plane. Since no one on the team is an experienced RC

plane pilot, the plane chosen for the project is the Multiplex Easy Glider.

This plane is

recommended by RC plane enthusiasts as the perfect plane for beginners due to its stability in

flight and ability to self correct. The plane is also designed to survive crashes with little to no

damage. There are built-in compartments within the fuselage to hold the necessary electronic

components. The plane is also made of foam allowing easy modification to the body.

3.8

Cost Constraints

We currently know of no commercial aerial reconnaissance drones available to the general

public. There are known modifications to RC planes performed by other enthusiasts to perform

aerial reconnaissance. Since these are not commercial products we cannot perform a cost

comparison. The only known aerial reconnaissance drones that we know of existing are the MQ1 Predator and the RQ-4 Global Hawk currently deployed by the US military. These planes cost

$4 million and $123.2 million each respectively [3] [4]. The operational range and altitudes of

these planes far exceed the capabilities of our own design. These planes also have the capability

to be armed with missiles. Due to federal regulations we will not be able to turn our plane into

an aerial weapons platform.

-9-

ECE 477 Final Report

3.9

Spring 2008

Component Selection Rationale

It was initially decided that our microcontroller would be one of the variants of the

Freescale HCS12 family.

Due to our peripheral interfacing requirements this limited our

possible selections either a HCS12E or HCS12A. Both provide all of the required interfaces

with the “E” variant providing one extra SCI interface [5] [6]. The downfall of the “E” variant is

the fact that its PWM only has 8-bit accuracy while the “A” has 16-bit accuracy [5] [6]. This

would severely limit to number of positions we could set our plane’s servos to. After deciding

on the HCS12A we then decided on the exact part. The microcontroller comes in 80 and 112 pin

packages. Due to our component size limitations it was decided to use an 80 pin variant. Our

final selection ended up being the MC9S12A64CFUE due to it providing the largest amount of

flash memory in for the package size.

Our inspiration for the selection of our GPS module and digital compass comes from a

senior design project from a previous semester [7]. Since this team had already found relatively

cheap and accurate devices, we used their component selections to decrease our research time.

Our project constraints required that are GPS module be mounted within the fuselage of the

plane and preferably be a bare unpackaged product. This limited us to the GPS 15 and Etek EB85A [1] [8]. The GPS 15 provides decent accuracy (<15m positional error) and is cheap [8].

The EB-85A provides greater accuracy (<3m positional error) but with an increased cost [1]. It

was decided that the improvements in accuracy of the 15L outweighed the cost increase and was

therefore chosen.

3.10 Summary

The most important consideration we must keep in mind when developing this project is

the plane must maintain the ability to fly when we are complete modifying it. We have chosen

parts that are overall small in size and use simple interfaces to minimize the overall amount of

circuitry required while still maintaining necessary levels of accuracy. Overall, the project has

no one overall complex element but instead consists of many relatively simple components. In

the end these components must work in harmony with each other in order for the project to be

successful.

-10-

ECE 477 Final Report

Spring 2008

4.0 Patent Liability Analysis

The goal of Project Global Pigeon has been to modify an existing radio-controlled plane

and to make it into an unmanned aerial vehicle. This section seeks to analyze patents whose

functions are similar to ours, and to determine the possibility of infringement upon each of them.

4.1

Results of Patent and Product Search

4.1.1 System and method for automatically collecting images of objects at geographic

locations and displaying same in online directories [10]

Filing Date: Mar. 24, 2004

Condensed Abstract: A camera and a GPS receiver are both mounted on a vehicle and receive

time information from a synchronized clock. The camera captures images while the GPS receiver

determines the geographic location. Both events are time-stamped, and as a result each image

can afterward be correlated with a street address based on the corresponding GPS data.

Claims with Potential for Infringement:

Claim 1: “A method of preparing images of objects at geographic locations for use in an online

directory, comprising: (a) receiving images of objects, wherein each image is associated with a

geographic location; (b) automatically correlating each image with a street address based on each

image's associated geographic location, wherein one or more images are correlated with each

street address; and (c) providing an image for display with a listing in an online directory based

on a street address in the listing.” [10] Claim 4: “The method of claim 1, wherein receiving

images of objects further comprises: (i) receiving time-stamped images captured by a camera;

(ii) receiving time-stamped geographic locations as determined by a GPS receiver that is located

with the camera; and (iii) automatically associating each image with a geographic location based

on corresponding respective time-stamps.” [10] Claim 7: “The method of claim 4, wherein the

time-stamped images are captured using a digital still camera.” [10] Description of preferred

embodiment: “The vehicle 9 may be an automobile, as illustrated, but may be of any other type

apparent to one skilled in the art, such as a bicycle, bus, or airborne vehicle such as a manned or

unmanned airplane.” [10]

-11-

ECE 477 Final Report

Spring 2008

4.1.2 Precision Approach and Control [11]

Filing Date: Sept. 19, 2006

Condensed Abstract: A camera is mounted on an aircraft, along with a navigation system and a

computer/controller for determining and executing the movement of the aircraft. The camera and

navigation system work in tandem to determine the angle and distance to a fixed point on the

ground. This data is fed to the controller which then moves the plane accordingly in order to

achieve a perpendicular distance to the ground point.

Claims with Potential for Infringement:

Claim 1: “An aircraft command and control system, comprising: a camera, including a

rangefinder, disposed aboard the aircraft for measuring an azimuth angle, an elevation angle and

a slant range from a fixed point on the aircraft relative to a selected target point on a surface

located below the aircraft; a navigation system disposed aboard the aircraft for measuring a

latitude and a longitude of a point on the surface that is disposed perpendicularly below the fixed

point on the aircraft; a computer for computing the position of the fixed point on the aircraft

relative to the target point on the surface from the respective measurements of the camera and the

navigation system; and, a controller for controlling the movement of the aircraft such that the

fixed point on the aircraft is positioned at a selected azimuth angle, elevation angle and slant

range above the selected target point on the surface.” [11] Claim 4: “The system of claim 1,

wherein the navigation system comprises a Global Positioning Satellite (GPS) system, an Inertial

Navigation System (INS), or both a GPS and an INS.” [11] Claim 5: “The system of claim 1,

wherein the aircraft comprises a helicopter or an aerial vehicle.” [11] Claim 6: “The system of

claim 1, wherein the aircraft is unmanned.” [11]

4.1.3 Unmanned airborne reconnaissance system [12]

Filing Date: July 12, 2002

Condensed Abstract: The system includes a lightweight, portable aircraft which fits in a box

alongside a foldable launch rail. The rail and one of two launching methods are used to get the

plane in the air. Once airborne, the craft is guided by remote control and/or by a programmed onboard computer. The craft contains a camera for recording and transmitting ground images.

-12-

ECE 477 Final Report

Spring 2008

Claims with Potential for Infringement:

Claim 1: “An airborne reconnaissance system comprising: an unmanned aircraft system adapted

to be disassembled; a launch system for said unmanned aircraft system, said launch system

adapted to be disassembled; a remote control system for remote control of said unmanned

aircraft system; said remote control system being detachable from said unmanned aircraft system

and said launch system; a container for receiving said unmanned aircraft system and said launch

system in their disassembled states; said container containing said unmanned aircraft system and

said launch adapted to be carried as a backpack; and means for assembly and disassembly of said

unmanned aircraft and said launch; wherein said reconnaissance system is transportable, fielddeployable, and operational by one person.” [12] Claim 6: “The reconnaissance system of claim

1 wherein the remote control system is controllable in real time.” [12] Claim 7: “The

reconnaissance system of claim 1 wherein the remote control system is programmable.” [12]

4.2

4.2.1

Analysis of Patent Liability

Analysis of Liability involving invention of [10], System and method for

automatically collecting images of objects at geographic locations and displaying same in

online directories

The inventors of [10] have developed a method of collecting images in a way that enables

the eventual automatic association of a given address with said images. With the existing lookup

tables that correlate addresses with GPS locations, this allows each image, which through timestamping is already associated with the corresponding time-stamped GPS location, to be

assigned to the address corresponding to that location and entered into an online directory like

yellowpages.com. Project Global Pigeon’s goals and features do not include any form of

“displaying [images of objects at geographic locations] in online directories”; therefore we are

not literally infringing upon [10]. As to the doctrine of equivalents question, our project is

similar to [10] in that it utilizes both an on-board digital still camera and a GPS receiver in the

image collection process. However, in our project the images are captured only upon reaching

specific GPS locations and are not time-stamped. The images we collect are associated with the

-13-

ECE 477 Final Report

Spring 2008

GPS data through human methods, i.e. noting the number of pictures to be taken at each pre-set

location and afterwards ordering them in accordance.

4.2.2 Analysis of Liability involving invention of [11], Precision Approach and Control

Project Global Pigeon does not literally infringe on [11], as the selected camera does not

include a rangefinder and is not involved in the approach to a specific GPS waypoint. Like [11],

our plane's flight is based upon a target point, in our case GPS. The microcontroller on board our

plane constitutes both the “computer” and “controller” described in Claim 1. Similar to [11], we

use the present and target GPS locations as inputs to the micro, which then directs the movement

of the plane accordingly to approach the target point. Were we to select an upgraded camera that

included a rangefinder and use it to measure the distance and angle to the target points –

improving the precision of the approach - it could combine with the previous similarities to

constitute infringement under the doctrine of equivalence. However, our camera is only used in

the eventual image capture, not as an assistant in the navigation of the plane. The inventors of

[11] have not claimed an approach method that uses only GPS data, nor have they made the

camera's rangefinder feature optional which would allow for the use of our regular still camera.

4.2.3 Analysis of Liability involving invention of [12], Unmanned airborne reconnaissance

system

This patent simultaneously displays the broadest and most vague language of the three

selected. We make no use of mechanics in our launch system; thus our project does not literally

infringe on [12]. Our plane is simply launched with one person throwing it into the air while

another holds the radio transmitter. By using the JR XP652 Radio Set, Project Global Pigeon

displays the features of claims 6 and 7 regarding the remote control system. Both of these are

derived from the system of claim 1 which has similarities and differences to our project. Our

plane, the Multiplex Easy Glider, can run unmanned and be disassembled to an extent; however

the latter includes only the wings and cockpit plug once construction is complete. Finally, the

inventors have not included a still camera like ours in any of their claims, with each reference

being made to a video camera specifically.

-14-

ECE 477 Final Report

4.3

Spring 2008

Action Recommended

Project Global Pigeon is not literally infringing upon [10], [11], or [12]. By refraining

from any sort of time-stamped image capture and/or the association of images and GPS data for

storage, we have avoided infringing upon [10] by the doctrine of equivalents. By not attempting

to improve the precision of our waypoint approach by using a rangefinder we avoid infringing

similarly upon [11]. Finally, we have avoided doctrine-of-equivalence infringement on [12] by

refraining from the development of either a mechanical launch system or the upgrade to a

continuous capture camera.

4.4

Summary

This report presented three patents/products whose functions were similar to those of

Project Global Pigeon. It analyzed the potential of each for both literal infringement and

infringement according to the doctrine of equivalence, and prescribed a course of action in each

case. For all of them, there were similarities and differences, but we have been able to avoid - or

design around - the features that could constitute infringement.

-15-

ECE 477 Final Report

Spring 2008

5.0 Reliability and Safety Analysis

The safety of the operator and any bystanders is the primary concern in the failure

analysis. The aircraft has three major sources of danger beyond the typical heat issues from

shorts on the circuit board. The first is simply the fact that it is a large flying object that could

crash into a person. The next source of danger is the plane’s power source. A lithium-polymer

battery was chosen thanks to its extremely high energy density; unfortunately, they are also

prone to catching on fire. The final source of danger is the propeller on the front of the aircraft.

It could cut the user if it started unexpectedly on the ground. The following analyses elaborate

on failure modes and the reliability of specific components which would contribute to the

failures.

5.1

Reliability Analysis

Reliability analysis was performed on three particular components on the circuit board of

the Global Pigeon project. The microcontroller used on the board, an MC9S12A64CFUE [13],

was chosen for reliability analysis because it is by far the most complex component. It also has

the highest pin count, which increases the failure rate. The Military Reliability Prediction of

Electronic Equipment Handbook [14] was referenced to determine a failure model of the

microcontroller as well as the other components. The most fitting model for the microcontroller

is that of a microcircuit as described in Section 5.1 of the handbook [14]. The model defines the

failure rate to be: P (C1 T C 2 E ) Q L failures per million hours of operation.

Each term in the equation corresponds to a contributing factor in failure. C1 is the die

complexity failure rate. In the case of the 9S12A64, C1 = 0.28 because it is a MOS device that

can operate with 16 bit integers. The term T is the temperature factor. It can be approximated

based on TJ, the junction temperature, and the logic family using the table in section 5.8 of the

handbook [14]. It was assumed that the maximum power draw is 250mW in accordance with the

datasheet [13] along with JA =51°C/W. JA is the thermal resistance between the junction and

ambient.

The maximum junction temperature was calculated according to the following

equation at room temperature: TJ JA P TA . This lead to a value of TJ = 35°C which in turn

corresponds to T = 0.16 for a MOS device [14].

-16-

ECE 477 Final Report

Spring 2008

The next term in the failure rate equation is C2, it represents the package failure rate.

Assuming that the package is non-hermetic, the 80 pin package corresponds to C2 = 0.041 [14].

The environment factor, E , was assumed to have a value of 5.0. This corresponds to the

environment of an unmanned cargo aircraft. This environment was chosen because the Global

Pigeon will fly and could have to deal with shock from rough landings. The quality factor, Q ,

was chosen to have a value of 10 because the IC is a commercial, not military product. The

learning factor, L , was assumed to be 1 because this component has been in production for

more than two years. Inserting all of these values into the failure rate equation yields: P = 2.50

failures / Mhr. This corresponds to a mean time to failure, MTTF, of 45.7 yrs.

The next component, a 5 V switching regulator, part number LM2679SD-5.0 [15], was

initially modeled as a linear MOS device, using the same equation and assumptions as above.

This resulted in P = 0.85 and MTTF = 135 yrs. However, given the high power nature of this

device, the failure rate seemed low. The calculations were repeated by modeling it as a low

frequency Si FET. This model is valid because the datasheet [15] claims that the output of the

regulator is switched by a DMOS FET at 260 kHz. Therefore, the failure rate is defined as:

P b T A Q E [14]. The later four terms have the same meaning as in the preceding set of

calculations. The term b is the base failure rate. In the case of this device, b = 0.012 because

it is a MOSFET. Assuming a 5 V supply voltage and 2 A max current draw along with 89%

efficiency, the regulator should dissipate at most 1.1W of heat. Based on the small onboard heat

sink, the thermal resistance of the chip is JA = 56°C/W [15]. This leads to a maximum junction

temperature of 85°C which results in T = 3 according to the table in section 6.4 of the military

handbook [14]. The term A is assumed to have a value of 4 because this component is rated to

a maximum supply of 5 A at 5 V or 25W. The quality term Q = 8.0 because the casing is

plastic and does not meet military specifications. The final environment term, E , was chosen to

have a value of 20 due to the operation conditions described for the microcontroller. Multiplying

all of these terms together results in an expected failure rate of P = 23.04 failures per million

hours of operation. This in turn leads to an MTTF of 4.95 yrs. This is a clearly much more

conservative lifetime estimate than when modeled as a microcircuit.

-17-

ECE 477 Final Report

Spring 2008

The final component chosen for analysis was the servo signal multiplexer. It has a part

number: SN74CBT3257 [16]. This component was chosen for analysis because if it were to fail,

the plane would immediately crash as it directly feeds the control signals to the servo motors.

The analysis began by assuming that the multiplexer is a digital MOS microcircuit with less than

100 gates. This leads to a C1 die failure rate of 0.010. The overall failure model is the same as

that used in the microcontroller: P (C1 T C 2 E ) Q L . The part datasheet [16] provides a

thermal resistance value JA = 90°C/W for the SOIC package. Assuming a maximum current

draw of 15 mA at 5 V, the junction temperature should be about 30°C. This corresponds to T =

0.13 for a digital MOS device [14]. C2 is given a value of 0.0072 because the package has 16

pins and is a non-hermetic SMT. The final three parameters have the same set of assumptions

and values as those stated for the microcontroller namely: E = 5.0, Q = 10, and L = 1.

Combining all of the terms together results in an expected failure rate: P = 0.373 failures / Mhr.

The mean time to failure is 306 yrs.

Component

MC9S12A64CFUE

LM2679SD-5.0

SN74CBT3257

Table 5.1 – Component Failure Rates

λp (Failures / Mhr)

2.50

23.04

0.37

MTTF (yr)

45.7

4.95

306

Given the possible manners in which a failure of the Global Pigeon would lead to bodily

harm, the failure rate of the first two components is much too high. These results show without a

doubt that more safety features are needed in the system. A failure of any of these components

would lead to the plane crashing, and possibly hitting a person in the process. The circuit design

could be improved if there was redundancy and self testing built in at all stages. Adding

redundant and more varied sensors would be an important step as the microcontroller has no

choice but to trust the reading coming in.

A first improvement would be to add a gyro,

accelerometer, and barometric altimeter. The values from these sensors could then be contrasted

with the readings coming in from the thermopiles and GPS receiver to get a more accurate view

of the plane’s position and orientation.

Another good step would be to have redundant

processing in the form of a second microcontroller. Each would read from the inputs and share

-18-

ECE 477 Final Report

the outputs.

Spring 2008

The output servo multiplexer had a relatively low failure rate, but adding a

watchdog of some sort would be good to reduce the likelihood of its failure crashing the plane.

5.2

Failure Mode, Effects, and Criticality Analysis (FMECA)

For the purposes of failure mode analysis, the circuit diagram of this project was divided

into six blocks, A through F. Higher criticality blocks are addressed first. Block A contains the

microcontroller. Block B consists of the voltage regulators and battery sensing circuit. Block C

holds the radio input circuitry and the servo output multiplexer. Block D is just the thermopile

amplifiers. Block E contains both the GPS and MicroSD interface circuits. The final block,

Block F holds the camera and LCD interface circuits.

Three levels of criticality were used in the analysis: high, medium, and low.

High

criticality failures are those which could result in personal injury. The Global Pigeon, by its

nature has many high criticality failure modes. Some of these modes include: the lithiumpolymer battery catching on fire, the plane crashing into a person, and an unanticipated start of

the propeller. Medium criticality failures are those which are unlikely to cause injury, but which

inhibit the ability to fly autonomously. An inability to communicate with the MicroSD card, or

GPS module would constitute a medium criticality failure as the system would not allow the user

to switch into autonomous mode. Low criticality failures do not cause injury nor do they inhibit

the ability to fly autonomously. A loss of camera or LCD control would fall into this category.

Individual failure modes are listed in the tables of Appendix G.

Ideally, the failure rate for high criticality failures would be less than 10-9. Medium

criticality failures would have a rate between 10-6 and 10-9. Low criticality failures would then

have a rate between 10-4 and 10-6. Based on the results of component reliability analysis, these

goals have not been met with the current circuit design. Many safety features would need to be

added to reduce the failure rates before this product could be considered for production.

Additionally, it was assumed that failures would only occur on the custom PCB of the system.

Given the complexity of the system overall, it would be important to determine the reliability of

the devices connected to the PCB during the safety redesign process.

-19-

ECE 477 Final Report

5.3

Spring 2008

Summary

The failure rate analysis has shown the steps involved in determining reasonable reliability

predictions for the most critical components on the circuit board of the Global Pigeon. These

components consist of the microcontroller, voltage regulators, and radio multiplexer. The results

of the reliability analysis indicate that further refinements are needed to add redundancy and

failure detection into the system. This need is reinforced by the findings of the failure mode

analysis. Many of the components are single points of failure. This setup is unacceptable from a

safety point of view. Further design revision would be needed before production of this system

could begin.

-20-

ECE 477 Final Report

Spring 2008

6.0 Ethical and Environmental Impact Analysis

Global Pigeon is an Unmanned Aerial Vehicle that has the ability to fly to preprogrammed

GPS points and take pictures at those locations. The product utilizes a GPS module, a radio

receiver, a RC model motor, Lithium Polymer battery and several servos to control the direction

of the plane. These all plug into the PCB which hosts the microcontroller. With each part of the

product, comes its own set of environmental and ethical problems. For the ethical aspect of the

project, the reliability of construction, operation use and misuse are taken into consideration. For

the environmental aspect, pollution and wastes during three phases of the product life,

manufacturing, normal use and disposal/recycling, are taken into consideration. Furthermore, the

electrical consumption of the product will also be taken into consideration.

6.1

Ethical Impact Analysis

The ethical challenges faced by the team to bring the project to the market would be

mostly how to deal with misuse. The goal of Global Pigeon is to offer a reliable UAV that has

the ability to take pictures remotely. This aspect of the plane can be put to relatively good use

such as crop monitoring or land surveying.

Two markets have to be considered when discussing the ethical issues in correlation to the

product. The first market is the general public. This market is currently the intended market for

the product. Since this is the general public we are talking about, there are very few restrictions

that can be put on the sale of the plane. As a result, unexpected use of the plane for such as usage

of the plane by stalkers cannot be predetermined. Little or nothing can be done against such

offenders of the law. As such, a disclaimer should be placed in the user manual to say that the

developers or manufacturers should not be responsible for the actions of the private end user

party.

A relatively big problem that can arise from end user error is that the user flies the plane

into restricted airspace such as an airport. The plane can interfere with air traffic in restricted

airspace. Furthermore the radio receiver, although unlikely, might cause interference with the

traffic control tower. This is a problem faced not only by our product but by any standard RC

plane. However the possibility of a GPS malfunction and the product flying into restricted

airspace still exists. To resolve the problem of a malfunction or even eliminate the possibility of

such an occurrence, we can hardcode the GPS locations of such locations onto the software used

-21-

ECE 477 Final Report

Spring 2008

to upload the GPS coordinates to the module to prevent the user from programming such

locations in. The software would have to include an update feature to check keep the location list

current. These measures will be applied if the prototype goes into full scale production.

Another problem is the susceptibility to explosion of the lithium polymer battery utilized

in the product. Lithium based batteries have the potential to explode if damaged or overcharged.

This has the ability to cause harm to the user. However if used properly the batteries should not

pose a significant problem unless it contains a manufacturing defect. This problem can be solved

by instructing the end user with the correct method of operation and document procedures inside

the user manual. Furthermore, stickers should be placed on the battery itself indicating danger

and the asking the user to refer to the manual.

The other market to take into consideration would be for military or private company

usage. In this event the product can be limited to selected personnel whom are specifically

trained to use the equipment therefore limiting the amount of misuse by the end user. However

this scenario would be unlikely since the product was not design with this market in mind nor is

it built to military required specifications. The product would have to undergo extensive

modification in order to meet the required specifications.

Another factor to take into consideration would be the durability of the construction of the

plane. As this is a novel RC plane product, many crashes can be expected and some level of

durability should be expected by the end user. Since the body of the plane is not manufactured by

us, we have chosen a model of plane that has received relatively high reviews of durability and

susceptibility to damage. Since any damage to the body can easily result in the internal battery

module being damaged and exploding, it is required by the IEEE code of ethics [17] that we

provide a decision that is consistent with the safety, health and welfare of the public.

Consequently we selected a durable body for the product.

6.2

Environmental Impact Analysis

Multiple items have to be considered for an environmental impact analysis. The most

critical items are the PCB, the foam body of the plane, the lithium polymer battery, the electric

motor used, the external LCD display and the radio controller. Incentives for the user to recycle

will be discussed later in the section.

-22-

ECE 477 Final Report

Spring 2008

6.2.1 Manufacturing Phase

In the manufacturing phase of the life cycle, the PCB requires multiple toxic chemicals to

be used. The process produces multiple air emissions including various acids, chlorine,

ammonia and solvent vapors. It also produces effluents such as organic solvents, vinyl polymer,

stannic oxide and solid wastes such as metal plating and hydroxide sludge [18]. If the product is

placed in full scale manufacturing, air scrubbers and waste reclaiming will be needed in order to

reduce the pollution output. Items such as the fibers used for the board layer can be recycled,

whereas chemicals used can be reclaimed through chemical techniques. Manufacturers such as

Advanced Circuits [19] offer RoHS compliant PCB Manufacturing with appropriate waste

disposal facilities.

The foam body of the plane although not manufactured by us also produces pollution and

therefore should be accounted for. The manufacturing process requires chemicals such as

hydrogen fluoride which is highly toxic and corrosive. The hydrogen fluoride will have to be

treated before being released into water sources.

With regards to the electric motor, dioxin fumes are produced during the manufacturing

phase especially during the smelting phase of to produce metal to fabricate the motors with.

The LCD display used is a simple 20X4 text display. During the production stage of the

LCD, sulfur hexafluoride, a greenhouse gas is produced [21]. The process also utilizes chemicals

that need to be treated before being released.

Finally the radio controller contains its own PCB, LCD and plastic casing. The production

of the radio controller will contribute to all the pollution factors as stated above since it a device

in itself.

6.2.2 Normal Use

During the normal operation phase, the PCB the will not be producing any pollutants since

the board will be completely RoHS compliant. None of the onboard components used emit high

levels of EM radiation since no RF circuitry is used. The foam body of the plane will not

contribute to pollution during normal use.

The lithium polymer battery can pose a potential environmental hazard due to the

dangerous chemicals used in it. The main chemical in the battery lithium is deadly if consumed.

-23-

ECE 477 Final Report

Spring 2008

The battery itself poses the potential to be a fire hazard if punctured or incorrectly used. This

means that should the plane crash in a forested area, it has the potential to start a forest fire.

During normal operation, the motor poses no extra pollution since it does not consume any

fossil fuels directly. The LCD screen does not contribute to pollution during normal usage either.

During its operation, the controller will contribute to EM pollution, Since it utilizes radio

waves. It is unlikely that the EM pollution would have any adverse effects on humans.

6.2.3 End of Life Cycle

The PCB is one of the products that contribute highest to e-waste. Especially deadly is the

lead used in the manufacturing of the board which if not properly dealt with can pollute ground

water. Lead poisoning is known to cause blindness, impotency and neurological damage [20].

Fortunately, companies such as TCI Inc. [22] offer recycling for PCBs. In the event of disposal,

the user should be notified of the proper disposal methods in order to send the board for

recycling. To facilitate this, the sales package should include a PCB recycling package to

promote recycling.

At the end of its life, the foam body has the potential to be the largest object to contribute

to landfill pollution since it is non biodegradable. To rectify this, the foam body should be

recycled. Companies such as Foam Recycle Center offer foam recycling services for certain

states. A directory of local foam recycling companies will be provided in the user manual.

If incorrectly disposed of, excessive lithium chemicals from the battery can leak into

ground and contaminate groundwater. In this event, harm can be caused to the individuals that

consume the groundwater. Companies like Toxco Inc [23] offer lithium battery recycling

services through chemical processes. Proper disposal methods will be included inside the user

manual in addition to a sticker on the battery to advise the end user on the proper disposal

techniques of the battery. Due to the rising awareness of the general public of the problems with

not recycling batteries, there are many local places provide this service. A list of such places can

be found on the Rechargeable Battery Recycling Corporation’s website.

At the end of its life, the motor can be scrapped and sent to be recycled. Most garbage

processing facilities already do this therefore there should be no additional concern on the user’s

end.

-24-

ECE 477 Final Report

Spring 2008

At the end of its functional lifespan, the LCD should be recycled to reduce e-waste.

Furthermore, the lead used in the PCB of the LCD display can cause similar problems such as

those stated above. The liquid crystals can be extracted and reused however it is more likely that

the product will end up at a land fill. In order to rectify the situation, guidelines to recycle the

LCD will be given in the user manual and a sticker will be placed to inform the user of proper

recycling techniques.

In all likelihood, the user would probably dispose of the radio controller without separating

its components at the end of its use. As a result, we would have to provide a service specific to

the device if we want to do any recycling for this specific item. However providing such a

service would be costly and a solution to this would be to inbuilt the cost of the recycling into the

sale cost.

Unfortunately, even given the proper guidelines, it is more than likely that the end user

would dispose of the product in an inappropriate manner however non-environmentally friendly

it is. To properly dispose of all the components, the manufacturer can include a recycling

package with the sale package with mailing cost provided. This would encourage end users to

recycle their products.

The product will utilize a lithium polymer battery that provides 11.1 volts. Depending on

the usage of the product, the user might be required to recharge the battery several times a day.

However in reality, the user will probably be not utilizing the product on a daily basis. Therefore

the electrical footprint of the product is minute and does not contribute much to electrical

pollution by power plants.

6.3

Summary

As a household product, Global Pigeon will face multiple environmental and ethical

problems that will have to be resolved. In order to resolve these issues, adequate user intelligence

must be established. Therefore the product should be sold to users of a certain age criteria. By

establishing user intelligence, the product, in all hopes, will be used in a public approved

manner. By providing the necessary facilities and services to dispose of the product, the carbon

footprint of the product can be reduced. These include using RoHS compliant devices and

alternative manufacturing techniques produce fewer pollutants. If all the above criteria are met,

they will minimize both ethical and environmental impact that the product will have on society.

-25-

ECE 477 Final Report

Spring 2008

7.0 Packaging Design Considerations

The goal of our design project is to modify an existing radio-controlled plane in such a

way that it can fly to pre-programmed GPS waypoints and take photographs with a digital

camera mounted beneath the plane. During the first stage of the flight, the plane will be

controlled manually. Upon reaching the desired altitude, the plane will be switched to auto-pilot.

Starting from this point and running until the user is ready to land the plane, it will be controlled

by the PCB. This board will be installed in the fuselage of the plane. This report will present the

packaging considerations and specifications for our project, along with a look at some

commercial unmanned aerial vehicles and how their packaging influences or compares to our

planned implementations.

7.1

Commercial Product Packaging

Initially, we had trouble locating commercial unmanned aerial vehicles with which to

compare packaging methods. The U.S. Air Force uses the MQ-1 Predator and RQ-4 Global

Hawk, which are multi-million dollar reconnaissance drones and not available to the public.

There are many online examples of RC enthusiasts modifying their planes to accommodate onboard cameras (both wireless and hard-wired to the microcontroller). In the past week we located

an online social networking platform, named DIY Drones, which is devoted to amateur UAV’s

and includes a forum for the hobbyists to interact. The next two sections present two of the

projects whose objectives were similar to our own.

-26-

ECE 477 Final Report

Spring 2008

7.1.1 GeoCrawler 5

Figure 1: GeoCrawler 5 with GPS-guided autopilot

The GeoCrawler 5 uses the Predator airframe along with the Picopilot autopilot. The

finished project includes 20 pre-set GPS waypoints and a camera (not shown) with a

programmable time-lapse function [24]. During flight, a gyroscope stabilizes the camera,

keeping it pointed straight down. The maker attached a pair of spruce rails to the planes

underside, where he judged the center of gravity to be. He then put four screws into the rails to

form the payload attachment point. From there he used the wonders of rubber bands to mount his

camera. A video of the stabilized camera has been posted on his blog [25].

The maker was pleased with the amount of room inside his fuselage, where he stored all of

his electronics. Like him, we plan to keep our own components inside. Our Multiplex Easy

Glider plane, however, does not include landing gear. Attaching the digital camera directly

underneath, as was done here, could potentially cause damage to the camera upon landing. We

did choose the underneath method and constructed a foam case to protect the camera.

-27-

ECE 477 Final Report

Spring 2008

7.1.2 Multiplex Easy Star aerial photography platform

Figure 2: Digital camera shown mounted on top (left) and bottom (right) of Multiplex Easy Star. The second

photo shows the lens poking through the pre-cut hole in the fuselage.

The website also included a project which used the Multiplex Easy Star [26], a foam plane

used frequently by beginning RC hobbyists. The maker of this project displayed two methods of

mounting the camera, both of which have the electronics mounted inside the fuselage (Figure 2).

Mounting the camera on top after removing the canopy leaves a greater amount of room for the

electronics; however it is completely unprotected against crashes into trees, hills, etc [27]. Seeing

as we have supplied our own digital camera, we would like to keep it as protected as possible.

The second method is closer to our original liking. Presumably the room in the fuselage is

significantly reduced. Still, the project maker made no complaints of struggling to fit his

electronics alongside the camera. In addition, our camera has been stripped of all unnecessary

features and would take up less space than the fully-intact one shown. But as a final blow, the

fuselage on the Easy Glider is significantly narrower than that of the Easy Star. Due to this and

the components already occupying the fuselage, we elected to mount the camera outside as

described in section 7.2.

7.2

Project Packaging Specifications

The packaging for our project is the RC plane itself. Due to the narrowness of the Easy

Glider’s fuselage, our PCB is mounted upon the edges of the cockpit area above the rudder and

elevator servos. This required some hollowing out of the cockpit plug due to the height of the

component headers. The two servos controlling the plane’s ailerons are fitted into the wings

-28-

ECE 477 Final Report

Spring 2008

themselves. There is a pre-cut slot for the battery in the fuselage between the wings, which

needed to be widened to make room for the 3-cell selection.

A pre-cut slot in the nose of the plane is meant to house the drive motor. In the default setup, the motor shaft sticks out from a small hole in the the nose and attaches to the propeller. With

the added weight due to the PCB, digital camera, and the major components listed in the design

constraints report, we chose to upgrade the existing SPEED 400 motor to a Mega 16/15/4

brushless motor. When compared to the SPEED 400, it is 1.7 millimeters shorter in length and

just 0.7 millimeters greater in diameter while weighing close to 0.3 ounces more [28][29]. This

would fit nicely into the existing slot; however a gearbox was required to keep the rotational

speed of the prop beneath its maximum, which required a certain amount of modifications to the

inside of the plane nose. Appendix A includes some scale drawings showing how the

components compare to the overall plane size.

Due to the absence of landing gear it would have been convenient to fit the camera in the

fuselage, as was done for the Easy Star in Figure 2. The fuselage was too narrow, however, and

we ended up constructing a hideous foam case to house and protect the camera on the underside

of the plane. Despite its size and un-aerodynamic structure, the plane still flew successfully with

the case hanging off of the bottom.

Smaller foam boxes were used to mount the thermopiles and GPS module onto the top and

tail of the plane, respectively. These also protected the components well during flight.

7.3

PCB Footprint Layout

Nearly all of the major components listed in the Design Constraints homework are

connected to the PCB through connector headers as shown in Appendix C. The footprint selected

for the microcontroller is simply the one in the OrCAD parts library matching our 9S12A64

(80QFP version) [6]. As for the IC’s, smaller was better when it came to footprints, enabling us

to keep the board size minimized. That size came to be 2.5 inches by 3.5 inches.

7.4

Summary

As far as packaging goes, our main consideration was that we were modifying an existing

RC plane through the addition and upgrade of components. We wanted to include the electronics

and camera without having to make excessive modifications to the structure of the plane, or to

-29-

ECE 477 Final Report

Spring 2008

expose them to unnecessary in-flight risks. By all accounts this was accomplished, although the

modifications were far from works of art. It was essential that we knew our modifications will fit

the selected plane package before we proceeded to the advanced stages of our design.

-30-

ECE 477 Final Report

Spring 2008

8.0 Schematic Design Considerations

The project is to construct an Unmanned Aerial Vehicle using a standard RC Plane. The

RC plane will be bought from a commercial outlet and then modified to suit our purposes. The

plane will fly autonomously using GPS coordinates and at predefined waypoints will initiate a

picture taking process. The coordinates will be stored on an onboard microSD card. The onboard

microcontroller will control all the servos and motor speed in order to steer the plane in the right

direction. The plane will use a GPS receiver to acquire GPS coordinates, altitude and velocity.

The plane will not take off autonomously and will need a manual controller. A six channel radio

transmitter and receiver will be used to send manual servos and motor control data as well as a

signal that initiates the switch to automatic mode. A tilt sensor using thermopiles enable the

plane to balance itself while in midair. The circuitry onboard the plane is limited to a small

amount due to the fuselage of the plane and the limited lift achieved using a small RC plane. The

intended use for the project is for aerial photography. This can be especially useful to land

surveyors and enthusiasts in the field. All they would have to do is supply the GPS coordinates

and launch the plane nearby and wait for it to return.

8.1

Theory of Operation

8.1.1 Microcontroller

The microcontroller selected for this project was the Freescale 9S12SA64CFUE [13]. This

specific MCU was selected because the team was familiar with the S12 series of microcontrollers

from previous classes. The microcontroller will be operating at a frequency of 8MHz. This speed

is suitable since the MCU will be powered by Li-Po batteries and conserving power is important.

Also the speed is fast enough to accommodate all our needs. The microcontroller is the heart of

the project and will be responsible for acquiring data from the sensors and receivers and

directing the plane via the servos and motors.

8.1.2 Power Supply

The plane will be powered by a 3-Cell Lithium Polymer battery. The battery provides a

nominal 11.1V source since it is required by the Electronic Speed Controller to power the motor.

To achieve the 5V rail and 3.3V rail, the LM2679-5.0[15] and LM2679-3.3[15] non synchronous

-31-

ECE 477 Final Report

Spring 2008

buck converters will be used to regulate the voltage. The regulators provide up to 5A of current

and an efficiency of up to 92%. High efficiency regulators are needed due to the limited amount

of power we are working with. The high amount of current they provide are suitable for our

needs since we will be powering 4 servos, a camera and a radio receiver which can draw a

substantial amount of current.

8.1.3 JR R600 Radio Receiver

The radio receiver was donated to the team by a member of the local Cloud Jockey RC

club. The receiver is manufactured by JR radios and features 6 channels for us. We will be using

one channel exclusively for the autopilot toggle. We require another 4 channels for servo

controls. The remaining one channel can be used for manual camera trigger. The receiver uses

5V and draws a current of 12mA.

8.1.4 GPS Receiver

The GPS receiver selected by the team is the Etek EB-85A [1]. The module initially found

was the Garmin 15L. The Etek features an onboard antenna thus effectively saving us the need

for another external component. Weighing in at 15 grams, the weight of the module is also

substantially less than the Garmin 15L.The Etek updates at 5 Hz and features a sensitivity of 158dbm. It uses a UART to communicate with the MCU serially. Upon intialization it constantly

updates itself and transmits data to the MCU. It requires a 3.3-5V power supply and consumes an

initial acquisition current of 59mA and 33mA after 20 minutes of tracking. The default baud rate

of the module is 4800 bps. The module will interface with the MCU using the 64AFCUE’s

onboard SCI Module.

8.1.5 microSD Card

The microSD card interfaces with the MCU via the SPI interface. The card uses a logic

level of 3.3V. To compensate a voltage level translator will be used to interface the microSD

card to the MCU. The GPS coordinates and flight data are all stored on the microSD card.

Information on how to access the microSD card and write to it was found at the several websites

[30].

-32-

ECE 477 Final Report

Spring 2008

8.1.6 Melexis Thermopile Tilt Sensor

The tilt sensor is a setup that requires two thermopiles pointed 180 degrees from each

other. The logic behind this is that the black body radiation coming from the ground is higher

than that of the sky [31]. Therefore using thermopiles, the system is then able to detect the angle

of tilt. Since the thermopiles only provide a 47 microvolts/degree resolution, the signal will be

amplified and passed to the microcontroller using the ATD converter. The thermopiles selected

are the Melexis MLX90247 [32].

8.1.7 Servos

The system will require the use of four servos in total. The plane will require 2 servos for

ailerons, one for the rudder and one for the elevator. Each servo requires 5V to power and a pulse

width modulated signal to determine the angle of rotation. The PWM signal will be provided by

the MCU upon triggering the autopilot mode. If not in autopilot mode, a mux automatically

selects the manual mode of the plane and the signals from the R600 Radio Receiver are directly

transmitted to the servos.

8.1.8 HP Photosmart R707

The UAV will use a commercially available HP Photosmart R707 that has been stripped of

its case and battery to take pictures at the designated waypoints. The camera is activated by

pulling the required switch low. This is achieved by using a ULN2003A High-Voltage HighCurrent Darlington Transistor Array [33]. By connecting the collector to the contact of the pin

and the base of the transistor to the MCU, functions such as turning on the camera, auto-focus

and image capture can be done. Upon require the specific function, the MCU turns on the

transistor thus sinking the pin and activating the camera. Pictures taken will be stored on an SD

card on board the camera.

8.1.9 External LCD Interface

A 20X4 LCD [35] using the Hitachi HD44780 [34] interface will be placed externally for

diagnostics and data representation purposes. The LCD interface will use a serial RS-232

backpack to accept data. The LCD will be powered via the plane’s power supply. The LCD will

-33-

ECE 477 Final Report

Spring 2008

be connected using the UART module available on the MCU. The default baud rate of

transmission is 9600bps.

8.1.10 Brushless DC Motor

A brushless DC motor will be used to replace the standard brushed DC motor on the plane

due to higher voltage efficiency and lighter weight. Much similar to the servos, the DC motor is

controlled by a PWM signal which will be provided by the MCU. The motor will also feature a

manual override feature which will allow the user to take control of the plane during takeoff or

landing.

8.2

Hardware Design Narrative

The microcontroller serves as the control for directing the plane and controlling the motor

speed. It will also balance the plane while the plane is in midair. The microcontroller will

interface with the LCD, GPS receiver and microSD card via SCI (I2C and UART) and SPI. It

will output to the servos and motor control via PWM signals and use general I/O pins for the

camera. The ATD converter module is used to sample the thermopiles for tilt sensor data.

8.2.1 SCI

The UART module will be used to receive data from both the GPS module and to transmit

data to the external LCD. A baud rate of 9600 bps will be used for the LCD and 4800 bps for the

GPS module. They use port pins PS0/RXD0, PS1/TXD0 and PS2/RXD1.

8.2.2 SPI

The microSD card will utilize the SPI interface on the MCU. It uses PM5/SCK0,

PM4/MOSI0, PM3/SS0, PM2/MISO0 and PM1.

8.2.3 PWM

The PWM module will be used to control four servos; these will be assigned to port pins

PP0, PP1, PP2 and PP3. The PWM module will also be used for motor speed control which is

assigned to PP4.

-34-

ECE 477 Final Report

Spring 2008

8.2.4 ATD

The onboard ATD module will be used to sample data from the thermopiles to determine

tilt angle and to check the voltage level of the system. The tilt sensing system requires 4 ATD

ports which are assigned to PAD00/AN00, PAD01/AN01, PAD02/AN02 and PAD03/AN03.

The voltage checking system requires one port and is assigned PAD04/AN04.

8.2.5 TIM

The timing module on the system will be used to accurately keep flight time for data

logging purposes.

8.2.6 General I/O

General I/O pins will be used to control the camera and for diagnostic purposes. IOC pins

will be used as inputs for the radio receiver. The IOC pins assigned to the radio receiver are PT0

through PT5. The pins used for the camera are PB0 through PB4. Pins PB5 and PB6 are used for

diagnostic LEDs.

8.3

Summary

Our most important design consideration in designing was the weight and the efficiency of

our circuitry. Weight is a very big problem due to the limited lift we can achieve from the RC

plane and efficiency limited our flight time. We also considered circuit size due to the limited

space available on board the plane. As of such we had relatively tight constraints to work within

but the team managed to come up with a reasonable design. As a result multiple iterations of

designing were done to come up with an optimized design. If the design constraints are met and

all flight conditions are optimal, the RC plane should achieve a reasonable amount of flight time.

-35-

ECE 477 Final Report

Spring 2008

9.0 PCB Layout Design Considerations

The purpose of Global Pigeon is to build a semi-autonomous RC plane capable of flying to

GPS way points and taking photographs. To accomplish this goal, all of the planes control

systems and a variety of sensors will be interfaced to a microcontroller. The microcontroller will

be mounted to a PCB along with the power regulation system, SD card interface, and the IC’s

required to communicate with the other components. All components except those previously

mentioned are not attached to the PCB and will be mounted throughout the plane.

There are two primary constraints to the design of the PCB. The first constraint is board

size. Since the board must be contained within the fuselage of the plane, the board is limited to a

size of 3.5”x2.5”. The second constraint is power. Every component within the plane except for

the motor will be powered from the PCB. This will cause peak current draws of 3A from each

power rail. This report will explain how the PCB will be designed with these constraints while

still maintaining proper signal integrity and manufacturability.

9.1

PCB Layout Design Considerations – Overall

The PCB layout is divided into the following major areas: digital control, digital data,

analog, power, and clocking. These major areas surround the microcontroller. The primary

purpose of this organization is to isolate various signals from each other in order to minimize

noise [36]. All of the major IC’s and signal routing will be done on the top layer of the board.

Signal routing will only be done on the bottom layer when absolutely necessary. The bottom

layer will be reserved for placing passive components and power routing. All signal traces on the

board will be routed with 12mil width with 12mil inter trace spacing. Due to the board’s size

constraints, making the traces any wider or further apart could make it impossible to route all of

the signals.

Making the traces any narrower or closer together can introduce the risk of

manufacturing defects. Changes to the default trace width and spacing will only be made when

absolutely necessary for noise reduction purposes.

The digital control area consists of the camera, radio receiver, and servo/throttle interfaces.

These signals consist of general purpose I/O signals and PWM generated signals. These signals

are not particularly sensitive and should be able to tolerate a minimal level of interference

without any major repercussions to the system. None of these interfaces have any special

component placement or routing considerations.

-36-

ECE 477 Final Report

Spring 2008

The digital data area consists of the SPI interface to the SD card slot, and two SCI

interfaces, one going to the GPS and the other to an external LCD screen used for debugging

purposes. The traces used for these signals are routed as directly as possible to their respective

headers. Extra consideration is taken in ensuring that no other possibly noisy traces come in

proximity to these signals. Any traces which pass under these signals on another layer are routed

to cross so they are perpendicular to each other. The SPI bus utilizes a clock signal which must

be isolated from other signals on the board and be as short as possible.

The analog area consists of the thermopile sensor interface and a voltage sensing circuit

for measuring battery life. The thermopile sensors provide temperature readings by comparing

the sensor’s temperature with the ambient temperature. The sensor transmits this reading by

outputting an analog electrical signal which is offset from a central bias by 46 micro volts per

degree Celsius [32]. These signals are fed into differential amplifiers and then sent to the

microcontroller’s analog to digital convertor for reading. Due to the small voltage offset per

degree temperature, the smallest amount of noise introduced to these traces can greatly throw off

the reading. The operational amplifiers used in this circuit will be placed as close as possible to

board headers to minimize the total distance the unamplified signal has to travel. The traces used

will be wider and have increased spacing to further decrease noise. A copper pour attached to

ground will also be utilized to help noise immunity [36]. Copper pours will also be utilized in

the other areas of the board but will be isolated from the pour in the analog section.

Component size is also a major consideration for this board. Most of the IC’s on the board

come in a variety of packages. The smallest package type for each IC was chosen as long as the

pin pitch was at least .5mm. A smaller pin pitch could lead to issues during board assembly with

pins being shorted.

The placement of the components relative to each other is another

consideration. The limited area of the board forces components to be placed at close distances

relative to each other. While this is good from a routing perspective, it can make it difficult to

solder components to the board. All components are placed on the board in a method to ensure

that one component won’t prevent the soldering of another component. There are also several

surface mount resistors and capacitors that will be soldered to the bottom layer of the board.

Most of these components will be 1206 size but any component which there is a large number of

(such as 1k pull-up resistors) will be ordered as 0805 size to minimize area.

-37-

ECE 477 Final Report

9.2

Spring 2008

PCB Layout Design Considerations – Microcontroller

The microcontroller utilizes six bypass capacitors in the range of 100nF to 220nF [13].

These capacitors are located directly beneath the microcontroller and have trace lengths to their

respective power and ground pins of a few millimeters.

The grounding system for the

microcontroller must be centered on the VSSR pin and the VSSPLL pin must be directly

connected to VSSR [13].

All of the ground connections must consist of low ohmic low

inductance connections [13]. All of these grounding requirements will be accomplished through

the use of a ground copper pour under the microcontroller.

The oscillator and PLL circuits have a dedicated location on the board located directly

below the microcontroller. The components used in these circuits are placed to allow direct trace

connections with the minimum distance possible. No other signals can be routed through this

area [13]. The crystal oscillator casing will also be connected to ground to further reduce noise

in the circuit [36].

9.3

PCB Layout Design Considerations - Power Supply

The board has two primary supply voltages: 3.3V and 5V. These supplies are managed by

two switching regulators. Each of these regulators has specific layout considerations. The catch

diode and input capacitor must be placed close to the regulator [37]. A ground plane will be

used and connected to the tab on each regulator [37]. The last specific requirement is the