tactile sensing system using artificial neural networks

advertisement

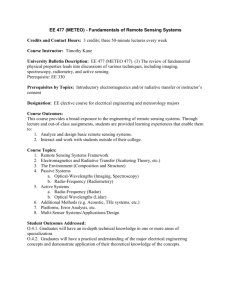

T TA AC CT TIIL LE E SSE EN NSSIIN NG G SSY YSST TE EM MU USSIIN NG GA AR RT TIIFFIIC CIIA AL L N NE EU UR RA AL LN NE ET TW WO OR RK KSS ABSTRACT Object Identification plays an important role in various applications ranging from robotics to computer vision. Artificial neural network (ANN) is being used for in various pattern recognition applications due to the advantages of ability as well as adaptability to learn. This paper presents identification of object independent to size, position and orientation using the concept of ANN and moments. The image of the object is taken with the help of the tactile sensing system. This paper describes the complete hardware and software concepts of the system for the object identification with the help of ANN. Keywords: Tactile sensing, Object orientation, force sensing sites. INTRODUCTION Of the many sensing operations performed by the human beings, the one that is probably the most likely to be taken for granted is that of touch. Touch is not only complementary to vision, but it offers many powerful sensing capabilities. Tactile sensing is another name of touch sensing, which deals with the acquisition of information about the object simply by touching that object .Touch sensing gives the information about the object like shape , hardness , surface details and height of the object etc. Tactile sensing is required when an intelligent robot wants to perform delicate assembly operations. During this assembly operation an industrial robot must be capable of recognizing parts, determining their position, orientation and sensing any problem encountered during the assembly from the interface of the parts. Keeping all these things in mind a tactile sensing system is developed which uses image processing techniques for preprocessing and analysis along with ANN’s for object identification. Classification of the object independent of translation, scale, rotation is a difficult task. The concept of artificial neural network is used in this system for the proper identification of the object irrespective to their size, position and the orientation. CONFIGURATION OF TACTILE SENSING SYSTEM This system uses conductive plasterer as a sensor, which has property that its conductivity changes as the function of the pressure. Fig 1 shows the configuration of the system. The conductive elastomer is mounted on 8*8 force sensing sites for the measurement of pressure distribution on the object. These force sensing sites are connected through PC add on data acquisition card. Stepper motor is used to apply specific amount of pressure for proper identification of the objects. Hardware for scanning the matrix and related signal conditioning is designed along with the stepper motor interface circuitry. Once the image of the object is acquired through the tactile sensing system then it is further processed using image processing concepts for the proper identification and inferring other properties of the objects. Tactile data for the object identification is acquired using row-scanning technique. After the removal of noise from this tactile data it passes to the different modules of the system for further processing. DATA ACQUISITOIN CARD TACTILE IMAGER MOUNTED ON STEPPER MOTOR DATA INPUT OUTPUT CARD COMPUTER FOR TACTILE DATA PROCEESSING Figure1. Configuration of the system TACTILE DATA PROCESSING Main modules of this system are preprocessing, data acquisition, matrix representation graphical representation, edge detection and moments calculations for generating a feature vector. Tactile image acquisition involves conversion of the pressure image into an array of numbers that can be manipulated by the computer. In this system tactile sensor is used to obtain the pressure data of the object and this data is further acquired with the help of data acquisition and data input output card, which are interfaced with the computer. The preprocessing module involves in the removal of the noise, which is essential for acquiring the image of the object under consideration. The image is analyzed by a set of numerical features to remove redundancy from data and reduce its dimensions. Invariant moments are calculated in this module which is required by the next module to the artificial neural for the identification of the object independent to scale, rotation and position. SYSTEM MODULES Main module of this system includes the description of the system and gives many options to the user for processing the tactile data in different forms like automatic or manual processing of the data. Feature extraction module is used for the calculation of the moments from the acquired tactile data. The application of moments provides a method of describing the object in terms of its area, position and the orientation. These invariant moments are used by the ANN as the input neurodes which is the important data for the classification and identification of the object. Flow chart for taking the image identification is shown in Fig.3. START N Is System Ready Y Acquire the Image Pre processing of the image No Card Detected STOP User Option for Image Identification STOP Figure 3. Flowchart of image identification ARTIFICIAL NEURAL NETWORK Artificial neural network ,which is inspired from the studies of biological nervous system ,has been used for various applications like supervised classifier. Object identification is decision making process that requires the neural network to identify the class and category, which best represent the input pattern. TACTILE IMAGE ACQUISITION PRE PROCESSING OBJECT IDENTIFICAITON BY ANN Figure 2. Tactile Data processing To overcome the difficulty of identifying the object using the moment alone use of artificial neural networks for the same purpose was investigated. The back propagation algorithm was implemented in the software to generate three-layered network. The feature vector was given as the input layer to the network. The number of input neurodes was equal to the number of feature vectors (invariant moments). The number of output neurodes was kept equal to the number of the objects to be identified. Here it was considered only five objects like square, triangular, rectangular, bar, circle. Several experiments were carried out and it was observed that for input neurodes equal to the seven, hidden neurodes required were three .Increase in hidden neurodes increase the complexity of the network and also increases the computational time of the system .Also less number of hidden neurodes takes longer time to be trained .Hence the optimum value of hidden value to be decided for the use of artificial neural network. EXPERIMENTATION Stepper motor is used for exerting specific amount of pressure on the object ,which is required for the handling of delicate objects, getting proper image of the object and calculating the height of object .First of all stepper motor is arranged in such a way that its angular motion is converted into the linear motion and it was designed in such a way that it travels linear distance of 0.03 mm per step. This part of calibration is also used for calculating the height of the object .To begin with ,motion of the stepper motor was calibrated in terms of pressure applied and the linear displacement . Pressure calibration of stepper motor is done with the help of capacitor pressure sensor in which foam is used as dielectric between two parallel plates of the capacitor .First graph was plotted pressure verses the change in the value of the capacitance .Response of the same is shown in Graph1. Then the same capacitive tactile was used to find the number of steps verses change in capacitance response as shown in Graph 2.Then with the help of the two graphs the third graph was plotted pressure verses number of steps of the stepper ,Which is given in Graph 3.This process was repeated for the many capacitive tactels. And the pressure calibration was completed in this way. Finally It was found that stepper motor could exert pressure 19N/M2 per step. After the calibration of the stepper motor the sensor (elastometer) was calibrated in terms of the pressure and time response. Thus the system with stepper motor used for applying specific amount of pressure along with the data acquisition and data input Output card could be used for acquiring a tactile data. Programs were developed to scan and digitize individual tactels and store the tactile information in the form of a two dimensional array. The response of change in the ADC out put voltage with the number of steps of the stepper motor is shown in Graph 4. EXPERIMENTS ON OBJECT IDENTIFICATION WITH THE HELP OF ANN After the calibration of the sensor and the system the experiments were performed on the objects like square, triangular, circular, rectangular. The network was trained by generating the learn data file having moments with change in the position ,size and orientation of the objects. The trained network was linked with the moments module and derived moments were input to the neural network. Target pattern was set at less than 0.5 for output not belonging to the class and greater than 0.5 for correct class. GRAPH 1 GRAPH 3 GRAPH 2 GRAPH 4 (A) Change in position For this experiment the position of the object is varied over the array of the sensor. And the moments were calculated for the same object. Then the network was trained with the help of three sets of data by varying its position . Then is was observed that network was successful to identify the object which was not included in the training set of the object. (B) Change in size Size of square was varied as 2X2,4X4 ,6X6.Invariant moments calculated from these objects and network was trained then network was given set of the data which was not included in the training and it was observed that the network was successful to give proper identification of the object. (C) Change in orientation The network was trained with set of data by changing its orientation and this network was tested for the data, which was not included in the training set. Finally it was observed that network can identify the objects independent of the size, orientation and position of the object. These experiments have been carried out for the identification of the square, triangular, circular , rectangular ,bar type of the object once the training. Of the artificial neural network has been completed with the help of moment data file. In this way different types of objects were tested and it was concluded that system is intelligent enough to give best results for the identification of different types of objects and describing the object under consideration in many ways. For further analysis of the object the tactile data automatically passed to the different modules of the system. CONCLUSION This system is well suited for the classification of the object with the help of ANN and moments. Classification and identification of the object is independent to size, position and orientation of the object under consideration .This system has capability of describing the object under test in different forms like identification , height ,edge, contact area, pressure distribution ,on the object,3-D representation, orientation, position etc of the object. The system has well support of software for processing the tactile data in different forms and taking any decision after the identification of the object. Finally it is observed that this system is intelligent enough for the identification of different types of the object like square, rectangle ,circle, bar, triangle independent to their position ,orientation and scale and giving its many physical properties .This system has various applications in robotics, medical and tele-operations and in computer vision. REFERENCES: [1].Prasant Kumar Patra, Neural network for invariant image Classification, Journal of the IETE, vol 42, nos4-5, pp 282-290, July-October 1994. [2].R.P.L. Rectier, Tactile Imaging, Security and Actuators, A (1992) pp 83-89. [3].G.J. Awcock & R.Thomas , Applied image processing, McGraw Hill , pp162-166 [4]. Elepart &Bobbins (Eds), Neural Network PC Tools A practical guide [5]. Philip D.Wasserman ANZA Reasearch, Inc Neural Computing