How Optical Fibers Work

advertisement

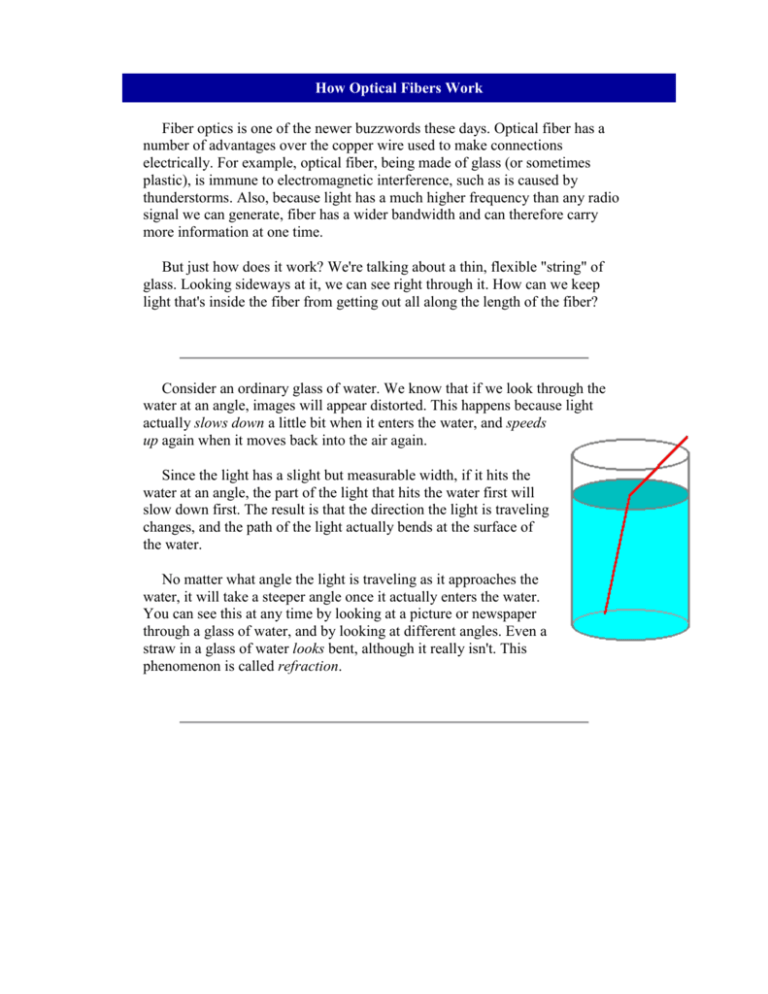

How Optical Fibers Work Fiber optics is one of the newer buzzwords these days. Optical fiber has a number of advantages over the copper wire used to make connections electrically. For example, optical fiber, being made of glass (or sometimes plastic), is immune to electromagnetic interference, such as is caused by thunderstorms. Also, because light has a much higher frequency than any radio signal we can generate, fiber has a wider bandwidth and can therefore carry more information at one time. But just how does it work? We're talking about a thin, flexible "string" of glass. Looking sideways at it, we can see right through it. How can we keep light that's inside the fiber from getting out all along the length of the fiber? Consider an ordinary glass of water. We know that if we look through the water at an angle, images will appear distorted. This happens because light actually slows down a little bit when it enters the water, and speeds up again when it moves back into the air again. Since the light has a slight but measurable width, if it hits the water at an angle, the part of the light that hits the water first will slow down first. The result is that the direction the light is traveling changes, and the path of the light actually bends at the surface of the water. No matter what angle the light is traveling as it approaches the water, it will take a steeper angle once it actually enters the water. You can see this at any time by looking at a picture or newspaper through a glass of water, and by looking at different angles. Even a straw in a glass of water looks bent, although it really isn't. This phenomenon is called refraction. The same phenomenon happens with glass, although we don't usually notice it when looking through a window. Nevertheless, light striking the glass at an angle bends as it slows down within the glass, and then bends again as it speeds up when leaving the glass. You can see this phenomenon clearly if you slide a piece of flat glass over the print in a book or newspaper. Any substance that light can travel through will exhibit this phenomenon to some extent. Glass happens to be a very practical choice for optical fiber because it is reasonably strong, flexible, and has good light transmission characteristics. The question to be answered now is, "How can we use this phenomenon to keep the light inside the glass, especially if we want to bend the glass (with the light still inside) around corners?" Now, consider looking into a glass of water from below the surface of the water. If you look up through the bottom of the glass, you will see a somewhat distorted view of the ceiling or whatever is above the glass. However, if you look in from the side of the glass and observe the underside of the top surface, you will begin to note an interesting and useful effect. If you are looking up from a steep angle, the light you see entered the top surface of the water at a shallower angle, as shown on the left. However, as you look at the underside of the top surface from a shallower angle, as shown on the right, you will find a point at which light can't enter the top surface at a yet shallower angle. At this point, the top surface of the water looks like a perfect mirror, even though you know it isn't. Now, the light you see is reflected from the surface, rather than being refracted through it. This effect persists for all angles shallower than the critical angle at which the phenomenon first appears. As you might expect, the same phenomenon is exhibited by glass or any other material through which light might pass. Consider a single glass fiber, such as the one shown in an enlarged view here. The actual fiber is so thin that light entering one end will experience the "mirror effect" described earlier in this discussion every time it touches the wall of the fiber. As a result, the light will travel from one end of the fiber to the other, bouncing back and forth between the walls of the fiber. This is the basic concept of optical fibers, and it correctly describes the fundamental operation of all such fibers. Unfortunately, it is not possible to use fibers of this basic construction for any practical application. The reason for this has to do with the physical realities of the phenomenon of reflection within the fiber, and how the parameters involved will change under different conditions. The basic fact governing the reflection of light within the fiber has to do with the speed of light inside the fiber, and the speed of light in the medium just outside the fiber. Every possible material through which light can pass has a characteristic called the refractive index, which is a measure of the speed of light through that material as compared to the speed of light in open space. We won't get into the mathematics in this demonstration; it is only necessary for you to understand this concept. One of the requirements of an optical fiber is that its diameter remain constant throughout its length. Any change in the thickness of the fiber will affect the way light reflects from the inner walls of the fiber. In some cases, this could even mean that the reflected light could exceed the critical angle required for total reflection, and so be lost through the walls of the fiber. Unfortunately, the same effect will be noticed if the characteristics of the medium outside the fiber should change. For example, if the fiber gets wet (as it would in rain, fog, or some underground situations), the characteristics of the boundary between the inside and the outside of the fiber will change, and hence the effective shape of the fiber will change, and will keep changing as drops of water move along the surface of the fiber. The question now is, "How can we make the fiber so the boundary layer is permanently fixed and precisely predictable?" The easiest way to ensure that the boundary between the inside of the fiber and the outside of the fiber remains constant and unchanging no matter what is to create a permanent boundary of known characteristics. The practical approach is to surround the glass fiber with another layer of glass, while making sure that the speed of light in the outer layer remains faster than the speed of light in the inner fiber. The result is shown here. In this figure, the original fiber is now the core of a two-layer construct. The diameter of the core is kept constant, at approximately 50 to 60 µm (micrometers, at one time designated "microns") and its surface is kept as perfectly smooth as possible. The outer layer, known as cladding, is bonded at all points to the surface of the core. To the outside world, this construction is effectively one solid piece of glass, even though it is constructed of two different types of glass. Thus, it is impervious to water, dirt, and other materials. If the outer surface gets wet, that makes no difference because it still doesn't affect the boundary between the core and the cladding. The whole composite fiber may be covered with rubber or plastic for easier handling and visibility. This type of optical fiber is known as a multi-mode step-index fiber, because of the fixed and definite boundary, or step, between the core and the cladding, as well as the fact that light traveling through the fiber may assume any of several possible electromagnetic "modes." This is the first successful type of optical fiber that was developed. Since then, more advanced types of optical fibers, such as graded-index and single-mode fibers have been produced.