STGCL.RA.90.1_Genomic DNA Extraction

advertisement

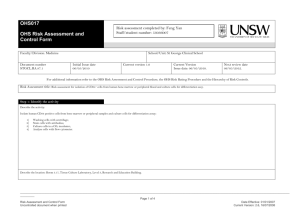

OHS017 OHS Risk Assessment and Control Form Risk assessment completed by: Raymond Clarke Staff/student number: s8503611 Faculty/Division: School/Unit: Medicine STG – Radiation Oncology Document number Initial Issue date 07/05/2010 STGCL.RA.90.1 Current version 1.0 Current Version 07/05/2010 Next review date May 2012 For additional information refer to the OHS Risk Assessment and Control Procedure, the OHS Risk Rating Procedure and the Hierarchy of Risk Controls. Risk Assessment title: Genomic DNA extraction using Sigma GenElute Blood Genomic DNA Kit Step 1: Identify the activity Describe the activity: This Risk Assessment describes the extraction of genomic DNA using extraction kit from Sigma Describe the location: Cancer Care Lab, Rm 3.20, Level 3., Research & Education Centre, 4-10 South St., Kogarah. NSW 2217. Step 2: Identify who may be at risk by the activity The person carrying out these procedures are at risk. Steps 3 to 7: Identify the hazards, risks, and rate the risks 1. An activity may be divided into tasks. For each task identify the hazards and associated risks. 2. List existing risk controls and determine a risk rating using the UNSW Risk Rating Procedure. 3. Additional risk controls may be required to achieve an acceptable level of risk. Re-rate the risk if additional risk controls used. __________________________________________________________________________________________________________________________________________________________________________ _________ Page 1 of 5 Risk Assessment and Control Form Date Effective: 01/01/2007 Uncontrolled document when printed Current Version: 2.6, 16/07/2008 Tasks Hazards Associated risks (Step 3) (Step 4) Risk rating with existing controls * Additional risk controls required Risk Rating with additional controls * (Step 5) (Step 6) (Step 7) Existing risk controls C L R Addition of relevant antibiotics to Lauria Bertani (LB) broth culture. Hazardous substances The antibiotics used as selection agents are hazardous substances. MSDSs are available. Wear suitable protective clothing and gloves. 2 D L Handling of cell culture. Biological exposure Handling of cells outside of a Class I Biohazard Safety Cabinet risks generating aerosol particles which may be inhaled or ingested An SWP has been prepared. External and internal PC-2 training is compulsory. Conduct Bacteria work in a Class I Biohazard Safety Cabinet Wear suitable protective clothing, goggles and gloves. 3 E M Handling of 70% ethanol and 95% ethanol Classified as dangerous goods class 3. Ethanol is highly flammable and irritating to eye. MSDSs are available. Wear suitable protective clothing, goggles and gloves. Keep away from sources of ignition. Do not breathe vapor. Keep container tightly closed. 3 D M Handling of isopropanol Hazardous substances, Classified as dangerous goods class 3. Highly flammable. Irritating to eyes. Vapours may cause drowsiness and dizziness. MSDSs are available. Wear suitable protective clothing, goggles and gloves. Keep away from sources of ignition. Do not breathe vapor, mist or gas. Keep container tightly closed. 3 D M Cell Lysis Solution (CLA) Hazardous substances Irritant to eyes and skin. MSDSs are available. Wear suitable protective clothing, goggles and gloves. 2 D L (Apply the hierarchy of risk controls) C L R __________________________________________________________________________________________________________________________________________________________________________ _________ Page 2 of 5 Risk Assessment and Control Form Date Effective: 01/01/2007 Uncontrolled document when printed Current Version: 2.6, 16/07/2008 Proteinase K Hazardous substances Harmful. Irritant to skin and respiratory system. MSDSs are available. Wear suitable protective clothing, goggles and gloves. 2 D L RNAse A Hazardous substances Harmful if swallowed and irritant to eyes and skin. MSDSs are available. Wear suitable protective clothing, goggles and gloves. 2 D L * C = consequence L = likelihood R = risk rating from the UNSW Risk Rating Procedure Step 8 Documentation and supervisor approval Completed by: (name) Raymond Clarke (signature) Authorised by: (signature) Date: Reviewed by: name) (signature) Authorised by: (signature) Date: Reviewed by: name) (signature) Authorised by: (signature) Date: Reviewed by: name) (signature) Authorised by: (signature) Date: Reviewed by: name) (signature) Authorised by: (signature) Date: Reviewed by: name) (signature) Authorised by: (signature) Date: Step 9: Implement the additional risk controls identified Indicate briefly what additional risk controls from Step 6 above were implemented, when and by whom. Risk control: Date: Implemented by: Risk control: Date: Implemented by: Risk control: Date: Implemented by: Risk control: Date: Implemented by: Risk control: Date: Implemented by: Step 10: Monitor and review the risk controls It is important to monitor risk controls and review risk assessments regularly. Review is required when there is a change in the process, relevant legal changes, and where a cause for concern has arisen. Reviews could be scheduled on an annual basis. If the risk assessment has substantially changed a new risk assessment is warranted. Review date: Reviewed by: Authorised by: Review date: Reviewed by: Authorised by: __________________________________________________________________________________________________________________________________________________________________________ _________ Page 3 of 5 Risk Assessment and Control Form Date Effective: 01/01/2007 Uncontrolled document when printed Current Version: 2.6, 16/07/2008 Review date: Reviewed by: Authorised by: Review date: Reviewed by: Authorised by: Documentation It is a requirement that legal and advisory documentation that supports this risk assessment be listed. Such documentation includes Acts, Regulations, Australian Standards and Codes of Practice, where applicable. Australian/New Zealand Standard, Safety in Laboratories Part 3: Microbiological aspects and containment facilities 2002 (AS/NZS 2243.3: 2002) MSDSs for all the listed chemicals. __________________________________________________________________________________________________________________________________________________________________________ _________ Page 4 of 5 Risk Assessment and Control Form Date Effective: 01/01/2007 Uncontrolled document when printed Current Version: 2.6, 16/07/2008 UNSW Concise OHS Risk Rating Table OHS697 What you need to do 1. Consider what can go wrong that can hurt someone 2. Determine what the most likely outcome would be - Consequences 3. Determine how likely those consequences are - Likelihood 4. Calculate the risk rating 5. Required action How severely could someone be hurt death or permanent disability to one or more persons hospital admission required medical treatment required first aid required injuries not requiring first aid CONSEQUENCES: Severe Major Moderate Minor Insignificant How likely are those consequences? expected to occur in most circumstances will probably occur in most circumstances could occur at some time is not likely to occur in normal circumstances may occur only in exceptional circumstances LIKELIHOOD: Almost certain Likely Possible Unlikely Rare CONSEQUENCES Insignificant 1 Minor 2 Moderate 3 Major 4 Severe 5 M H H VH VH M M H H VH Possible C L M H H VH Unlikely D L L M M H Rare E L L M M M LIKELIHOOD Almost certain A Likely B Risk level Very high High Medium Low Required action Act immediately: The proposed task or process activity must not proceed. Steps must be taken to lower the risk level to as low as reasonably practicable using the hierarchy of risk controls. Act today: The proposed activity can only proceed, provided that: (i) the risk level has been reduced to as low as reasonably practicable using the hierarchy of risk controls; (ii) the risk controls must include those identified in legislation, Australian Standards, Codes of Practice etc. (iii) the risk assessment has been reviewed and approved by the Supervisor and (iv) a Safe Working Procedure or Safe Work Method has been prepared. (v) The supervisor must review and document the effectiveness of the implemented risk controls. Act this week: The proposed task or process can proceed, provided that: (i) the risk level has been reduced to as low as reasonably practicable using the hierarchy of risk controls; (ii) the risk assessment has been reviewed and approved by the Supervisor and (iii) a Safe Working Procedure or Safe Work Method has been prepared. Act this month: Managed by local documented routine procedures which must include application of the hierarchy of controls. ______________________________________________________________________________________________________ Page 5 of 5 UNSW Concise OHS Risk Rating Table Effective date: 01/01/2007 Uncontrolled document when printed Current Version: 2.6,16/07/2008