Proposal for research on optimization of heat transfer in thin slab

advertisement

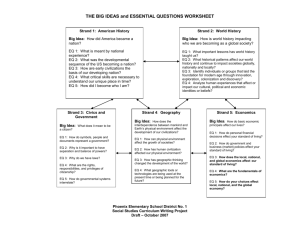

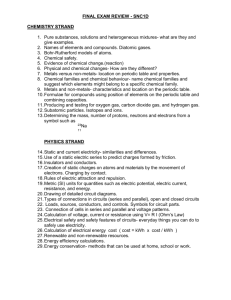

Proposal for research on optimization of heat transfer in thin slab continuous casting processes of steel. 1. Introduction 1.1Technology review Continuous casting is a process used to solidify molten steel into billets, blooms or slabs for rolling in the finishing mills. Since its introduction in the 1950s the continuous casting process has allowed for improvements in yield, quality, productivity and cost in the steel industry. In this process (Figure1), the molten steel is continuously cast via a vessel called tundish into a water cooled mold causing a thin shell to solidify next to the mold walls [1]. The resulting strand is then withdrawn through a set of guiding rolls and cooled by spraying with a fine water mist. Since the bulk of the metal within the walls of the strand is still molten, the rollers act as support against the static pressure of the stillsolidifying liquid within the strand. The spraying helps increase the rate of solidification by extracting heat from the strand surface. The strand becomes completely solidified when it reaches the metallurgical length. Depending on the design of the casting machine, a wide range of strands dimensions can be cast (Figure2), ‘slabs’ for flat products such as plate and strip, ‘blooms’ for sections such as beams, and ‘billets’ for long products such as wire. However, the thin shell of the strand can break causing the molten metal in the strand to spill out and stopping the operation. This is mainly due to a high withdrawal rate or the metal being too hot. In general the strand will break if final solidification takes place below the straightening rolls. The breakout has been addressed by vertically oscillating the mold to separate the solidified steel from the mold walls, in addition additional separation has been achieved by introducing a powder that acts as a lubricant between the strand and the mold. In addition, the solidification of steel has always faced the problem of segregation and continuous casting has not been immune to it. Dissolved elements generally have a higher solubility in the liquid phase than in the solid and therefore will tend to come out of the solution ahead of the solidification front [2]. As the strand solidifies, chunks of solidified pieces will migrate to the centerline of the strand. This can make the product brittle along the centerline and result in failure during processing as well as poor product quality. Thin slab casting in particular has the potential of further improving productivity. Unlike the conventional casting that produces a slab up to a 10” section; thin slab casters can produce a slab 2”-3.5” thick. This eliminates the large roughing mills required to work the thick slabs, and integrates slab production with sheet and strip rolling, greatly reducing reheating requirements [3]. Recently the use of soft-reduction has allowed a reduction in the centerline segregation. For soft reduction to have any effect, casting speed and secondary cooling rate must be chosen so that the metallurgical length is in the soft reduction zone [4]. 1.2 Objective of the study The main objective of this study is to optimize of the heat transfer in thin slab continuous casting processes of steel. The proposed study will look at how using soft reduction can help improve both productivity and material quality at high casting speeds. In order to reach this goal, we will develop an algorithm that allows us to determine the heat flux requirements for a desired temperature along the strand thickness. 2. Model formulation 2.1 Heat transfer solidification model The mathematical model for the heat transfer during the solidification of the strand is based on the general heat equation for conduction [5]. For a three dimensional heat flux T kT q (1) where is the material in unsteady state it is given as: c p t J kg W ; k is the thermal conductivity density 3 ; c p is the specific heat ; T is m mK kg K the temperature (K), t is the time (s) and q represents the term associated to internal heat generation due to the phase change. However, we will mainly use the two-dimensional 2T 2T T assumption for this optimization model c k 2 2 q (2). Furthermore t y x 2T 2T steady state conditions will be assumed reducing (2) to q k 2 2 (3). y x 2.2 Optimization model Alternatives for optimization modeling (gradient methods, particle swarm methods, genetic algorithms) 3. Milestones and Deadlines Literature review September 30 Heat transfer model July 30 Optimization model August 30 Testing, verification, validation, production runs October 30 Final report December15 4. References [1] [2] A. Scholes, A.W. Smith, S. Riaz, B. Patrick, B. Barber, M.I. McDonald, G. Stephen… Segregation in continuous casting, Ironmaking & Steelmaking, April 2005, 32, 2, ABI/INFORM Trade & Industry pg. 101 [3] [4] 5. Figures Figure1. Continuous Casting Machine Figure2. Continuous Casting Products