P265 - World Journal of Engineering

advertisement

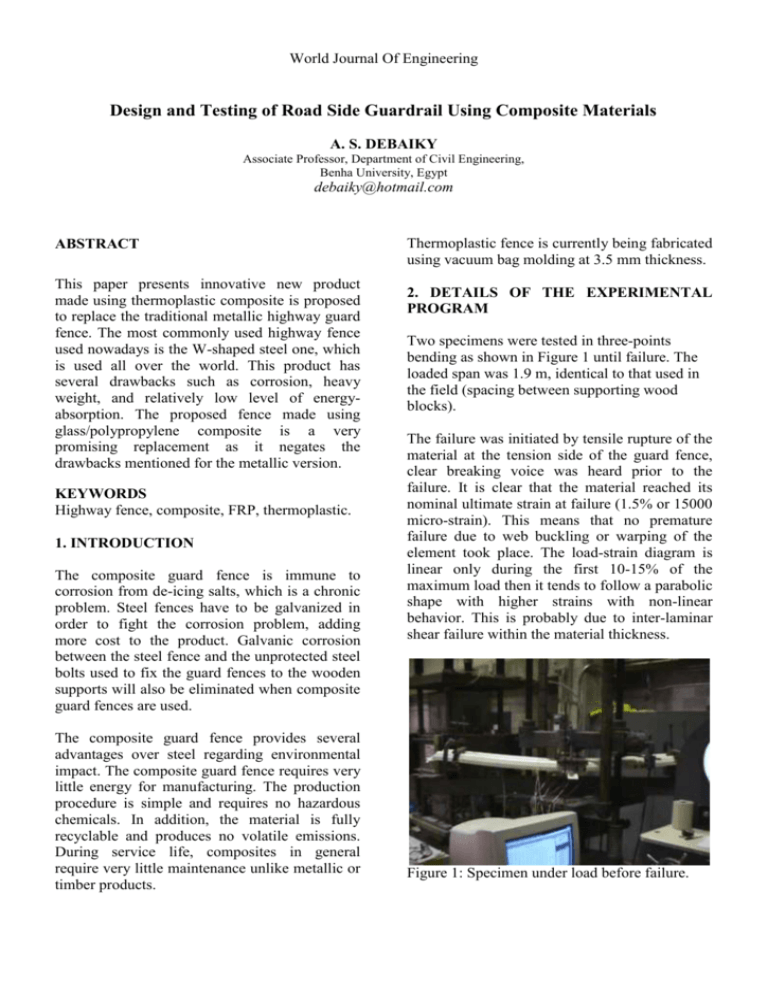

World Journal Of Engineering Design and Testing of Road Side Guardrail Using Composite Materials A. S. DEBAIKY Associate Professor, Department of Civil Engineering, Benha University, Egypt debaiky@hotmail.com ABSTRACT This paper presents innovative new product made using thermoplastic composite is proposed to replace the traditional metallic highway guard fence. The most commonly used highway fence used nowadays is the W-shaped steel one, which is used all over the world. This product has several drawbacks such as corrosion, heavy weight, and relatively low level of energyabsorption. The proposed fence made using glass/polypropylene composite is a very promising replacement as it negates the drawbacks mentioned for the metallic version. KEYWORDS Highway fence, composite, FRP, thermoplastic. 1. INTRODUCTION The composite guard fence is immune to corrosion from de-icing salts, which is a chronic problem. Steel fences have to be galvanized in order to fight the corrosion problem, adding more cost to the product. Galvanic corrosion between the steel fence and the unprotected steel bolts used to fix the guard fences to the wooden supports will also be eliminated when composite guard fences are used. The composite guard fence provides several advantages over steel regarding environmental impact. The composite guard fence requires very little energy for manufacturing. The production procedure is simple and requires no hazardous chemicals. In addition, the material is fully recyclable and produces no volatile emissions. During service life, composites in general require very little maintenance unlike metallic or timber products. Thermoplastic fence is currently being fabricated using vacuum bag molding at 3.5 mm thickness. 2. DETAILS OF THE EXPERIMENTAL PROGRAM Two specimens were tested in three-points bending as shown in Figure 1 until failure. The loaded span was 1.9 m, identical to that used in the field (spacing between supporting wood blocks). The failure was initiated by tensile rupture of the material at the tension side of the guard fence, clear breaking voice was heard prior to the failure. It is clear that the material reached its nominal ultimate strain at failure (1.5% or 15000 micro-strain). This means that no premature failure due to web buckling or warping of the element took place. The load-strain diagram is linear only during the first 10-15% of the maximum load then it tends to follow a parabolic shape with higher strains with non-linear behavior. This is probably due to inter-laminar shear failure within the material thickness. Figure 1: Specimen under load before failure. 450 900 Load [lbs] 1350 1800 The comparison with traditional steel guard with respect to strength & ductility is simpler than was initially thought. The ultimate strengths of the mild steel and the glass composite are about 370 and 189 MPa, respectively. This makes the failure load of steel guard about twice that of composite guard (for the same section properties). Since The profile of the traditional steel guard was obtained by highway research engineers after years of tests and trials, the choice was to adopt the same profile for the composite guard. The thickness of the composite guard was then chosen to be 3.5 mm to obtain the same failure moment of the traditional 2.0 mm thick steel guard. 0 Microstrain 0 5000 10000 15000 20000 On another note, the composite guard offers much higher deformation compared to steel guard due its very low elasticity modulus (~10 GPa versus 200 GPa). This means 20 times the deflection value. Numerically, the steel guard will suffer only 4.0mm deflection (instead of the obtained 80mm in composite). This reduction means much less energy absorption in the case of vehicle impact. This is the topic of another research paper. Figure 2: Load-strain relationship at mid-span on tension side. For a continuous fence, the failure load is expected to be around 3,000 lb (13.35 kN). 3. NUMERICAL MODELING Finite Element method was used to simulate the behavior of the composite guard fence, and to evaluate its efficiency. The modeling was made assuming a central load simulation maximum flexure effect of car impact. Figures 3 shows stress distribution along the length of the panel under the maximum load. 4. CONCLUSIONS 1. Innovative highway guard fence made of thermo-plastic glass fibre/Polypropelene is a promising alternative to traditional steel guard. 2. The new product is immune to corrosion, light weight, 100% recyclable, and environmental friendly. 3. (failure) stable and almost linear behavior in 3-points Max comp. stresses bending test is obtained. Deflection and stress levels at critical location are consistent with theoretical values. 4. The composite guard fence is much more flexible than the traditional steel counterpart, enabling higher energy absorption that is much desired in highway fence elements. 5. Improved product shall be obtained by using continuous thermo-pressing technique rather Figure 3: Maximum stresses distribution than the current vacuum bag method. The latter does not fully ensure full bond between the different layers of the material. 4. COMPARISON WITH STEEL FENCE 266