Corporate ESD Specification - Universal Instruments Corporation

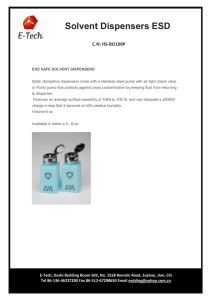

advertisement

Corporate ESD Specification 3 May 2010 MAKE150006 Rev I IMPORTANT: The attachment/text below also appears on the UIC external web site. If you alter the attachment/text below, you must also change the copy contained in the image library WCMS2 Images (see folder "Suppliers"). Purpose The purpose of this document is to establish uniform Electrostatic Discharge (ESD) Control methods. Scope This document applies to all Universal Instruments manufacturing facilities and to field activities at any location worldwide. Responsibility/Authority The authority to review and approve this procedure resides with the Product Safety & Code Compliance Engineer. It is the responsibility of the Vice President, Quality and Reliability, and the local area supervision to ensure the ESD control program is in place and that all employees who work with ESD sensitive components and assemblies are trained and comply with this standard. Audit Responsibility ESD Audits may be conducted as part of the on-going Quality System audit process or as deemed appropriate by the ESD Specialist or when requested by manufacturing. Audits may be performed on an as needed basis. Description Note: The policy items listed are a top level description. For detailed information concerning these ESD control items, see UIC Part Numbers 41078411 and 42363901. 4.1 CONTROLLING ESD Unless otherwise stated, assume all electronic components, subassemblies, and assemblies are ESD sensitive (ESDS). Mechanical Assemblies with electronics attached are ESDS assemblies Universal Instruments UNCONTROLLED COPY Page 1 of 6 Corporate ESD Specification 4.1.1 3 May 2010 MAKE150006 Rev I IN RECEIVING Electrostatic Discharge Sensitive (ESDS) components, subassemblies, or assemblies, shall be handled using proper ESD handling controls at an approved ESD Work Station or Area must be used. See Handling, 4.1.5. 4.1.2 PACKAGING ESDS devices and assemblies should be packaged to promote ESD protection (static shielding), as well as structural integrity. At a minimum, populated PC Boards shall be in transparent static shielding bags with an industry-standard ESD awareness warning label ((JDEC-14 or RS471) on the bag which identifies ESD sensitive devices that require static safe handling. The bag should be large enough to cover the board and close easily without stress. If a non-zip lock static shielding bag is used, it should be large enough to allow at least two inches folded over the end to form a seal without stress, and held in place with an industry-standard ESD warning label. No staples or scotch tape are allowed to seal the bag. Anti-static (pinkpoly) bags are not allowed for ESD devices. Static generating materials are not allowed to be used as sealing or labeling.. See UIC Part Number 41078411. ESDS Assemblies too large for static shielding bags shall be packaged in approved static protection packaging ESDS PC Boards that can puncture the static shielding bag should be packaged with conductive foam on the pins or other sharp protrusions prior to being placed in the static shielding bag. Individual ESDS components such as ICs, SIPs, and DIPs shall be placed in sulfur free conductive foam. The foam and components shall be placed in a static shielding bag or box. The bag or box shall be labeled using standard ESD warning labels. Bulk ESDS components such as ICs, SIPs, and DIPs will be packaged in anti-static tubes or conductive trays. ESDS components packaged in anti static packaging shall be enclosed in static shielding bags or boxes. The bags or boxes shall be labeled with an industry-standard ESD warning label, and part number. 4.1.3 SHIPPING UIC machines, assemblies, and sub-assemblies are ESD sensitive assemblies. Do not use static generating material as shipping restraints, brackets, or to wrap the machines unless approved by the ESD Specialist. All foams used to ship exposed ESDS assemblies shall be anti static foam. Universal Instruments UNCONTROLLED COPY Page 2 of 6 Corporate ESD Specification 4.1.4 3 May 2010 MAKE150006 Rev I STORAGE All ESDS devices should be stored in sealed static shielding packaging until the time they are required for use in the manufacturing process. These items should be protected from all static generating activity or material prior to and during the manufacturing process. ESDS devices are counted or dispensed for kitting shall be done at an approved ESD area or workstation. Storage of PC Boards in static shielding bags shall be placed on grounded shelves or if in boxes or other non-static generating materials on non-static generating materials. 4.1.5 HANDLING All handling of unprotected ESDS devices shall be completed at an approved ESD Area, workstation, or approved field service portable workstation while properly grounded. 4.1.6 WORKSTATIONS The workstation must be approved by the ESD Specialist. For approved workstation configuration, refer to UIC Part Number 46165901 4.1.7 PERSONNEL GROUNDING Personnel must be grounded used personal grounding devices prior to removing the product from ESD protective packaging or working on ESDS devices or assemblies. If working on an ESD dissipative floor: (Excluding WPSD area) All personnel must wear heel or toe straps or conductive footwear on both feet. Heel straps or conductive footwear does not preclude the use of a wrist strap. Prior to use, all personnel shall test personal ESD control devices at least daily. Wrist straps when used with a constant wrist strap monitor need not be tested. Heel straps are not required in aisle ways defined by red tape stripes on the floor. When working on machines or when positioned that the heel straps are not in contact with the floor, wrist straps shall be worn. Universal Instruments UNCONTROLLED COPY Page 3 of 6 Corporate ESD Specification 4.1.8 3 May 2010 MAKE150006 Rev I Proper Method for Testing ESD Straps/Footwear Proper application of straps: It is important that heel or toe straps are worn correctly in order to pass the test at ESD test stations. The strap must be situated under your shoe so that it makes full contact with the floor. The conductive ribbon can be tucked in between your sock and skin or between your shoe and your sock. You may have to try both methods in order to pass the ESD test station. Testing the straps/footwear: 1. With both feet on the test mat, depress and hold the button on the test station, the Green LED should illuminate. 2. While still pressing the test button, lift your right foot away from the test mat. The Green LED should stay illuminated. 3. Place your right foot back on the test mat and pick up your left foot while still pressing the test button. The Green LED should stay illuminated. 4. Place both feet on the floor off of the test mat while still pressing the test button. The Green LED should go off and the Red LED should illuminate. 5. If the outcome of above tests is as defined above, the straps/footwear has passed the test. Sign the log next to the station and initial the appropriate day or date column. Test Failure: 1. If the high resistance RED LED should illuminate, reposition the effected strap on the shoe and the ribbon in the shoe or the sock. Retest the strap. 2. If no improvement, your skin may be too dry. Use IC Lotion or other skin moisturizer and situate the ribbon. If placing the ribbon between your shoe and sock, your sock may be too dry. Some people require a longer period of time before there is enough moisture from the foot to make the strap work. Place the ribbon in your sock until there is enough moisture in the sock. Retest the strap. Universal Instruments UNCONTROLLED COPY Page 4 of 6 Corporate ESD Specification 3 May 2010 MAKE150006 Rev I 3. If there is still no improvement, obtain a new strap and retest. If there is no improvement, see supervisor immediately prior to entering an area inside the red taped lines on the manufacturing floor. 4.1.9 Proper Method for Testing ESD Wrist Straps Proper application of Wrist Straps: It is important for the second part of the wrist strap test that the wrist strap fits properly. The wrist straps should fit snug but not tight. The elastic band should be stretched to obtain the snug feeling. Testing the Wrist Straps: 1. Remove the foot wear test pad jack from the tester jack and plug in the wrist strap. 2. With the wrist strap held by the band opposite of the snap between the fore finger and the thumb of one hand, touch the button of the tester with the other hand. The Green LED should illuminate if the resistance of the wrist strap is satisfactory. 3. While still holding the band and touching the button, wiggle the band and cord making sure the Green LED remains illuminated. 4. With the wrist strap properly worn on a wrist, touch the test button with the fore finger of the opposite hand from the wrist strap. The Green LED should illuminate. 5. If the outcome of above tests is as defined above, the wrist strap has passed the test. Sign the log next to the station and initial the appropriate day or date column. Remove the wrist strap from the tester and replace the mat jack. Test Failure: 1. If the Red LED illuminates indicating a high resistance following Steps 2 and 3 of the Wrist Strap Test, obtain new wrist strap and test it in the same manner. Universal Instruments UNCONTROLLED COPY Page 5 of 6 Corporate ESD Specification 3 May 2010 MAKE150006 Rev I 2. If the wrist strap passed steps 2 and 3 and fails step 4, remove the wrist strap, use moisturizer cream on the wrist strap area of the wrist. Put wrist strap back on and retest. The Green LED Should illuminate. If the Red LED Illuminates remove wrist strap and obtain new unit. 4.2 Product Grounding: Populated PC Boards shall be placed inside covered static-shielding totes or in individual static-shielding bags prior to transfer from one place to another. When carts or bread racks are used to transport unprotected assemblies or sub-assemblies, the shelves shall have dissipative surfaces that must be connected electrically to each other and ground,. All ESDS devices must maintain contact with the dissipative surface on the rack. If card holders are used on the rack, they must be dissipative / conductive and electrically connected to the cart. Racks used for storage of sensitive devices and assemblies shall be grounded. Prior to removing ESDS devices and assemblies from ESD Protective packaging, personnel handling such devices are required to wear properly fitting grounding devices connected to ground. References 5.1 5.2 5.3 5.4 5.5 5.6 5.7 MAKE015 Handling, Storage, Packaging and Delivery 41078411 Suggested ESD Design Guidelines 42363901 Handling Specification for Maximum Reliability of Electronic Components and Assemblies 46165901 ESD Audit Checklist ATT Electrostatic Discharge Control Handbook Electrostatic Discharge and Electronic Equipment IEEE Press CORP006 Internal Assessment Process End of Document Universal Instruments UNCONTROLLED COPY Page 6 of 6