Brenda Coleman - The Manufacturing Alliance of Philadelphia

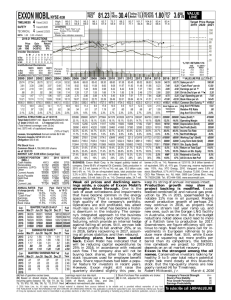

advertisement

4500 Worth Street Philadelphia, PA 19124 Phone: 215.948-9285 Ext 104 Fax: 215.948-9284 Email: CharlesM@manufacturingonline.org Web: www.manufacturingonline.org James Y. Nash I am dependable and hard-working, and enjoy working as part of a team, but also appreciate working independently. EMPLOYMENT: Branch Medical, Eagleville, PA, June 2014 To Present Maintenance Technician Responsible for the completion of all maintenance service requests as assigned. Maintain inventory controls for cost effective operations. Schedule and complete the "Preventative Maintenance Program". Assist in monitoring all work being performed by outside contractors. Performs minor electrical maintenance to include but not be limited to replacement or repair of fixtures using appropriate hand, power and specialty tools. Performs minor plumbing maintenance Allied Tube & Conduit, Philadelphia, PA, 2001-2013 Welder / Mill Operator / General Laborer Lead position as a TIG welder. Welded coils together keeping the main mill processing. Some experience as a MIG welder. Operated the mill that made a 1,000 feet of pipe per minute while performing quality insurance checks of the manufactured product. Zinc pot operator – added blocks of zinc to keep the temperatures correct for the pipe to flow through the mill. Maintained the equipment as well as monitored temperature gauges and made adjustments as needed. Managed crew during changeovers of equipment for different size piping. Performed all maintenance on steel mill, changed bearings and drive shafts and reconstructed them, changed cut off die when broken. Executed all preventative maintenance work whenever the mill was down in order to avoid future down time. Completed all change overs. Disassemble mill and put back together. Aldan Rubber Industries, Philadelphia, PA, 1986-2001 Quality Control / Spreader / Head Heater Man / Fabric Control Supervised as well as performed positions above – managed and lead crew in troubleshooting and correcting factory quality problems. Provided production line training, leadership and development of workers. Evaluated employee efficiency and made corrections as required. Set blade adjustments on the machine for coating purposes and analyzed cloth and rubber for problems or defects. Prepared machinery for shifts; maintained temperature of machines and areas of production heaters. 4500 Worth Street Philadelphia, PA 19124 Phone: 215.948-9285 Ext 104 Fax: 215.948-9284 Email: CharlesM@manufacturingonline.org Web: www.manufacturingonline.org Maintenance - Performed all main duties, including changing gears on all machines, changing drum belts and air lines and bearings, changing and replacing drive shafts. Performed preventative maintenance to all machinery in factory for last five years of employment. Education: Frankford High School / Swenson Skill School 1979-1982 Coursework: Sheet Metal / Aviation / Maintenance / Blue Print Reading Certifications: TIG Welder Other OSHA Certified Forklift Operator Experience: Knowledgeable in building and home maintenance and repair, some electrical work, general plumbing, drywall and framing experience. Board Member, Leprechaun Sports’ Association, Assistant Football Coach Scanlon In-House League, Head Coach of Ice Hockey Referee for Northeast Suburban Athletic Conference