Quality Management Plan 1

advertisement

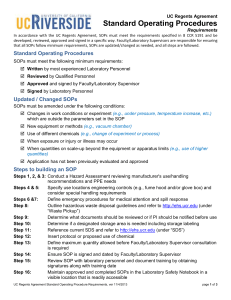

CONFIDENTIAL Facility Name Facility Address Facility Phone Number QA:1.6 Page 1 of 14 QUALITY ASSURANCE PROGRAM Implementation date: 10/15/07 Obsolete date: QA Initials: Review dates: Revision dates: 01/16/09 10/07/09 PRINCIPLE: The … Facility . performs various steps in the manufacture of human cells, tissue and tissue-based products (HCT/Ps) and maintains a detailed Quality Assurance Program (QA Program hereafter). The QA Program specifically focuses on FACT-JACIE International Standards for Cellular Therapy Product Collection, Processing and Administration and the FDA’s 21 CFR 1271 (cGTP) guidelines. The overall goal of the QA Program is to prevent the introduction, transmission, or spread of communicable diseases through the manufacturing and use of HCT/Ps and to assure HCT/Ps have the required safety, purity, potency and effectiveness. …’s Quality Plan identifies and monitors specific operational systems in the QA Program. The Program is an integral part of the BMT Total Quality Management (TQM) Program. QA monitors implemented systems to ensure the goals and objectives are consistent with the Program as well as University. The QA Program ensures integration and participation with the BMT and all other contracted client quality programs. Facility Mission Statement: Consistently provide high quality stem and progenitor cells for target disease treatments and novel cellbased therapies. PURPOSE: Outline the Quality Plan, including key personnel and procedures integral to Quality Assurance SCOPE: The QA Program is designed to encompass all aspects of operations. The Quality Manager, QA Supervisor, Technical Supervisor/Manager and Lab Director will ensure it’s adherence throughout all laboratory activities. SPECIMEN REQUIREMENTS: N/A REAGENTS, STANDARDS, MEDIA, AND SPECIAL SUPPLIES REQUIRED: N/A INSTRUMENTATION: Personal Computer loaded with Q-Pulse Quality Management System FORMS, WORKSHEETS AND LABELS: N/A CALIBRATION: N/A CONTROLS: N/A QA:1.6 Page 2 of 14 PROCEDURE: A. Quality Assurance Program -- The QA Program establishes and maintains ongoing, systematic monitoring for critical lab processes, procedures and equipment. It also identifies and resolves problems in a productive and timely manner. Program elements: 1. Organizational Structure – (see ATTACHMENT 1) a. Organization chart indicates key personnel and the reporting structure b. Processing/Collections Facility Director: Responsible for QA Program as it pertains to the facility 1) Director designates Quality Assurance Manager to establish and maintain the QA Program a) Manager works with QA department staff to perform all program aspects (1) QA staff may not quality review their own tasks performed b) QA Manager (with Technical Manager) assign QA responsibilities to ... staff as needed c) QA compiles quality data and reports the results to ..., all program BMT and (quarterly minimum) 2) Director and QA determine monitored indicators requiring audits 3) Director, QA Manager and/or BMT Program Director work together on corrective/preventive action (CAPA) and follow up as needed c. Designees assigned in the order listed: 1) Director a) General: Technical Manager serves as designee when Director is not available b) Infusion orders/medical orders/Urgent Medical Need: Technical Manager, Technical Supervisor, Apheresis Supervisor, Lead Stem Cell Technologist, QA Supervisor c) QA Functions (Planned Deviations): QA Manager, QA Supervisor 2) Technical Manager a) General: Technical Supervisor/Lead Stem Cell Technologist b) Chart Review: Apheresis Supervisor, Technical Supervisor/Lead Stem Cell Technologist, QA Supervisor 3) QA Manager a) General: QA Supervisor 4) Regenerative Medicine (RM) Project Development Manager a) General: RM Supervisor, Lead RM Technologist 5) RM Supervisor a) General: Lead RM Technologist Related SOPs/documents: Job Descriptions for positions noted above Annual Quality Indicator Review Annual QA Summary Organizational Chart 2. Personnel a. Staff Training and Competency binder in the Program Coordinator’s office includes: 1) Current Job Description for all facility positions (also describes initial qualifications) 2) Orientation and initial facility training and re-training if applicable a) Includes HIPPA training, covering donor and recipient confidentiality 3) Competency for all job duties performed (initial and annual) 4) Continuing education b. Policy for personnel training and competency assessment 1) Includes trainer qualifications with a uniform staff training plan c. Sufficient personnel with adequate education, experience and training to competently perform duties/services required while achieving the highest product quality d. Sufficient staffing to ensure compliance with regulatory agencies Related SOPs/documents: CONFIDENTIAL QA:1.6 Page 3 of 14 GP: 3 Personnel Training, Competency and Proficiency Testing 3. Protocol Development and Review – Process for protocol development, validation, approval, implementation, review, revision and archiving a. Established and maintained protocols/procedures describing all operational aspects b. Procedures designed to prevent the risk of introduction, transmission or spread of communicable diseases through the use of HCT/Ps c. Critical procedures are validated and/or verified prior to implementation d. The Director reviews and approves all SOPs before implementation, and annually thereafter 1) Medical Director reviews and approves collection SOPs before implementation e. Procedures are readily available to personnel in operational areas to which they relate, or in a nearby area if such availability is impractical f. A defined improvement plan is in place to allow recognition, investigation and CAPA when deficiencies arise in existing processes Related SOPs/documents: GP:2 Standard Operating Procedures Preparation QA:8 Documenting Deviations, Addendums, Complaints and Accidents QA:9 Validation Procedures 4. Document Control -- System for document control and records review relating to processing, storage, release and transportation a. Any requirement for documentation requires that a record be created b. Document Control system includes: 1) Current listing of all critical documents in the control system a. Standard Operating Procedures (SOPs) b. Worksheets – Process documents (i.e. Daily QC, apheresis collection, processing, etc.) c. Forms -- Consents, orders, tracking, distribution, notification, eligibility, and adverse events/reactions d. Labels used to identify and track products from collection to distribution 2) Unique alpha/numeric identifier for each document regulated within the system 3) A procedure for document approval, including the date and signature of approving individuals (SOPs) and the effective date of the document 4) A method to ensure that documents cannot undergo accidental or unauthorized modification 5) For SOPs, training documentation associated with initial activation and subsequent revisions 6) A method for document change control a. Includes change description, approving individuals signature (SOPs) and effective date 7) A method for obsolete document retraction to prevent unintended use 8) A method for record creation, assembly, storage, archival and retrieval c. Q-Pulse 1) Document control activities are managed by Q-Pulse Quality Management software d. General Document/Record Attributes 1) Accurate, indelible, and legible, written in blue or black ink 2) Identify the person performing the work and date completed 3) Documentation errors are corrected by a single horizontal line through the error, recording the correct entry with date/initials next to the correction 4) Records provide a complete history before product distribution 5) Records pertinent to HCT/P manufacture (labeling/packaging procedures and equipment logs, etc) are also maintained and organized under the record management system 6) The record management system allows prompt document identification, location and retrieval if maintained in more than one location 7) Records are maintained electronically, in original hard copy, and/or photocopies 8) Equipment necessary to obtain legible records (i.e. computers) are readily available 9) Electronic records are backed up daily 10) All records are maintained for 10 years after their creation, unless stated otherwise CONFIDENTIAL QA:1.6 Page 4 of 14 11) A contracts list, with names and addresses, including responsibilities, is also maintained Related SOPs/documents: GP:13 Patient Chart Preparation and Review CP:14 Product Labeling GP:2 Standard Operating Procedures Preparation Policy QA:2 Quality Control Procedures, Cleaning and Maintenance QA:12 Worksheet, Form and Label Preparation 5. Written Agreements a. The QA Program incorporates policies and procedures for the establishment and maintenance of written agreements with third parties whose services impact ...’s products 1) A third party facility must comply with applicable laws, regulations and standards equal to ... 2) The agreement will define the roles and responsibilities for critical tasks 3) ... ensures compliance a) Confirmed by vendor qualification and/or audits as needed Related SOPs/documents: QA:11 Vendor Qualification 6. Outcomes Analysis -- Process for documentation and review of product efficacy following administration a. BMT program coordinator offices (…) provide engraftment data as it becomes available 1) QA Supervisor inputs data into Sigma Plot™ and graphs data based on a product type a) All data is analyzed based on the product type mean ±2 standard deviations b) Graphs consist of a minimum three months of data for tracking and trending purposes 2) If delayed engraftment is evident, outside standard deviation range, a process for cause analysis and CAPA is documented, if applicable 3) Data is reported to the Facility Director and respective BMT programs quarterly b. Criteria for non-HPC product efficacy is determined and reviewed at regular intervals as needed Related SOPs/documents: ... QA Reports 7. Quality Audits – ... conducts independent quality audits and indicator reviews to confirm compliance with regulatory, FACT or institutional requirements a. Audit performed by staff with expertise in the process but not solely responsible for its performance b. Results used to recognize problems, detect trends and improve processes 1) Reported at least quarterly to the Lab Director NOTE: Audit results which identify the potential for introduction, transmission, or spread of communicable diseases or harm to the donor or recipient are discussed immediately when discovered c. Deviations are managed per SOP QA:8 d. CAPA completed, tracked and documented as needed e. Documentation maintained and permanently archived 1) Audit results are used to illuminate problems, identify trends and implement improvement f. Indicators and audits include the following: 1) Indicator Reviews (Frequency) a) Unit number (Monthly): All unit numbers are accounted for (1) Each product, upon receipt, is assigned a unique unit number which relates any component to its donor, the donor’s medical record, and all records describing handling and final component disposition b) Donor infectious disease marker– Monthly (ID marker test/ timely completion): (1) HPC (apheresis, BM, Cord Blood): 30 days before collection CONFIDENTIAL QA:1.6 Page 5 of 14 (2) Therapeutic cells/DLI (apheresis or whole blood): 7 days of collection c) Microbiology Testing (Monthly): Confirm no positive cultures observed (1) Positive tests are investigated for root cause d) Processing Logs (Monthly): Product related logs/worksheets (workload, sign-in, distribution, flow cytometry, etc.) are accurate, legible, complete and initialed by responsible tech e) QC (Monthly): Review all QC logs and forms for completeness, accuracy and tech initials (1) Also confirm aberrant results were investigated, corrected and re-validated as required by QA Manager or Director f) Freezerworks (Monthly): Ensure product inventory software is correct and up to date with current patient chart information g) Engraftment (quarterly): See 6 above 2) Audits a) Internal Focus Audits (Frequency) (1) QA Manager/Lab Director Discretion (2) Based on identified trends and/or deviations (3) Indicators, frequency and duration determined according to specific situational needs (4) Initial duration will usually be one year. b) Electronic documents not validated (1) Infusion Orders- created on excel spreadsheet which performs automatic calculations (a) Calculations manually completed by Stem Cell Technologist prior to product release (b) These documents are also reviewed by the Facility Director and Technical Manager (2) Summary Sheets- created on excel spreadsheet which performs automatic calculations (a) All data input is based off of worksheets in which calculations have all been performed manually and checked by a secondary technologist. (b) Values on this sheet are compared with those values on the worksheets 3) External Audits a) CFT allows facility , protocol, document, QC, adverse reaction and deviation audits from 3rd parties for whom ... provides services or their representative auditors b) FACT (Foundation for the Accreditation of Cellular Therapy) (1) Tri-annual inspection, entire university BMT program involved (2) Lab is responsible for specific standards (3) FACT audit results are documented and reviewed by ... staff (a) Corrective action is implemented (as applicable) and documented (b) The corrective action report is archived c) College of American Pathologists (CAP) Audits (1) Pre-inspection -- Internal audit a few months prior to the scheduled CAP inspection (2) CAP non-inspections year- Bi-annual internal audit to assess CAP compliance (continuing accreditation terms) (3) CAP audit results are documented and reviewed by ... staff (a) Corrective action is implemented (as applicable) and documented (b) The corrective action report is archived Related SOPs/documents/systems: Q-Pulse Quality Management Software QA:2 Quality Control Procedures, Cleaning and Maintenance QA:8 Documenting Deviations, Addendums, Complaints and Accidents Quality Indicator Audit Summaries ... QA Reports GP:13 Patient Chart Prep and Review 8. Products with Positive Microbial Culture Results a. When positive culture results are received, the following are notified: 1) Recipient physician, collection facility, or other processing facility as applicable a) Clinical staff follows up with the donor/recipient according to their protocols 2) ... Facility Director, Technical Manager/Supervisor, Apheresis Supervisor, and QA CONFIDENTIAL b. c. d. e. f. g. QA:1.6 Page 6 of 14 Notification is recorded on Notification of Pending Results to Physician form and placed in the patient’s chart The product is relabeled and relocated to appropriate storage location per SOP All necessary documents are changed QA performs investigation and a deviation report is initiated if applicable 1) If no deviation, a staff note documenting investigation results will be placed in the patient’s chart Product may be released by authorized personnel after release criteria are met QA will report the incident to regulatory agencies if applicable Related SOPs/documents: GP:26 Positive Sterility Culture Product Handling QA:8 Documenting Deviations, Addendums, Complaints and Accidents 9. Detecting and Reporting Errors, Accidents, Adverse Events and Complaints: a. Deviations from SOP are investigated and documented, to include root cause analysis and CAPA 1) Planned deviations are pre-approved by the QA Manager and ... Director (BMT Medical Director notified as deemed necessary by Director) b. Adverse reactions (donor or recipient) and subsequent CA are reviewed by ... and Medical Directors 1) Adverse reaction written evaluation is included in the patient file and available to the patient/donor’s physician 2) Where applicable, the adverse events are reported to appropriate local, state and federal regulatory agencies a) When an adverse reaction is caused by a collection procedure or infused cell component, the written report generated by ... is forwarded to and maintained by the collection and/or transplant facilities, as requested IMPORTANT: ANY adverse reaction involving communicable disease related to an HCT/P made available for distribution MUST be investigated and reported if: fatal life-threatening results in permanent body function impairment/permanent body structure damage; or necessitates medical/surgical intervention, including hospitalization If a deviation causes an increased risk of contamination or communicable disease transmission of a collected product, documentation and follow-up is required Follow FDA reporting guidelines outlined in 21 CFR 1271.350 c. Complaints are communicated to the Technical Manager, QA and Director immediately 1) Management will investigate the issue with all involved parties and document findings in Q-Pulse to facilitate CAPA and tracking d. All deviations, adverse reactions and complaints are presented in ... staff meeting as soon as possible for information and input 1) Additional CAPA may be defined and implemented as needed e. QA will determine deviation or event reporting in BMT QA meetings as well as regulatory reporting 1) QA will be responsible for reporting with Director input as needed f. Employee concerns about quality and safety may be communicated during staff meetings open discussion 1) Concerns and follow-up are recorded in the meeting minutes 2) Other methods in which staff can communicate their concerns which will then be discussed in the next staff meeting: a) Q-Pulse b) All management, to include QA, Technical Manager and Lab Director g. Process Improvement 1) Anyone who sees improvement opportunities, whether in a process (SOP), form or worksheet CONFIDENTIAL QA:1.6 Page 7 of 14 input a Change Request (CR) into Q-Pulse on the applicable document Record 2) CRs are sent by Q-Pulse to the document owner and author for review a) They decide whether the change is high impact, warranting immediate revision, or can wait until the next annual review b) CRs will be discussed with staff c) Reasons for not implementing a CR will be reviewed with the submitter Related SOPs/documents: QA:8 Documenting Deviations, Addendums, Complaints and Accidents GP:5 Progenitor Cell Infusion Reaction Workup CC:7 Management of Adverse Reactions in HPC Donors QA:12 Form, Label and Worksheet Preparation GP:2 Standard Operating Procedures Preparation Policy 10. Product Tracking -- The QA Program includes product tracking from donor to recipient/final distribution and visa versa a. Each HCT/P is assigned and labeled with a unique identification 1) The unique ID facilitates HCT/P tracking from the donor to the recipient and back 2) All HCT/P records contain the unique ID 3) The unique ID does not include name, social security number or medical record number (MRN) b. Another unique ID may be adopted by another manufacturing facility 1) The new ID will be documented in the patient record to relate to the old ID c. SOP dictates to record and document the unique ID code, HCT/P type and disposition when distributed to a consignee to enable tracking d. Consignee is informed in writing of these requirements and the product distribution tracking system Related SOPs/documents: CP:14 Product Labeling GP:4 Issue, Release and Return of Products Intended for Transplant GP:7 Receipt and Handling of HPC Products GP:8 HPC/T Transfer and Transport GP:19 Product Release for Research or Disposal 11. Continuous operations when electronic systems are inoperable a. Immediately notify the appropriate electronic system personnel and proceed as listed below until the system is fixed b. Electronic systems used in daily ... activities are backed during operational down times as follows: 1) Freezerworks – Product Inventory Software a) Hard inventory location copies and disposition in each patient file b) QA Supervisor prints a list of available freezer space every week c) All electronic files are automatically backed up daily 2) REES – Environmental Monitoring System a) All readings are automatically backed daily b) In case of malfunction, QA will immediately implement needed manual daily QC or equipment verification to ensure environmental stability 3) Q- Pulse Document Control System a) All SOPs, Worksheets, and Forms exist as hard copies and can be copied as needed b) All electronic files are automatically backed up daily 4) ... Laboratories - laboratory values needed for collection and distribution a) ... Stat Lab will be called for the values as needed b) Values should be faxed unless system is down in which case values may be communicated by phone (1) Communicated values must be repeated to ... representative to ensure accuracy (2) A staff note is created explaining the circumstances and communication CONFIDENTIAL QA:1.6 Page 8 of 14 Related SOPs/documents: GP:9 REES Scientific E-Centron EM System GP:22 HCT/P Inventory Using Freezerworks QA:12 Form, Label and Worksheet Preparation GP:2 Standard Operating Procedures Preparation Policy 12. Qualification and Validation of Facilities, Reagents, Supplies, Suppliers, Equipment and Procedures a. Suppliers of critical supplies, reagents, services, and equipment are qualified according to SOP QA:11, Vendor Qualification, to ensure they are complaint with applicable laws and regulations b. ... employs documented review and acceptance by the QA Manager and Facility Director of all validation studies 1) Process changes are validated or verified to ensure they do not impact other operations 2) In-house reagent manufacturing must be validated c. The following critical areas will either be qualified or validated to ensure proper operation and use: 1) Facilities a) Suitable size, construction and location to ensure orderly HCT/Ps handling without mix-ups b) In good repair with adequate lighting, ventilation, plumbing, drainage and sink/toilet access c) Maintained in a clean, sanitary and orderly manner d) Sewage, trash and biological waste disposed of in a timely, safe and sanitary manner e) Defined areas of adequate size for each facility operation f) Establish control systems to prevent improper labeling, product mix-ups, contamination, cross-contamination and accidental exposure of HCT/Ps to communicable disease agents g) Established/maintained cleaning and sanitation policies (1) Procedures assign sanitation responsibility, giving detailed descriptions of cleaning schedule and methods h) Cleaning and sanitation records retained for 10 years i) Gloves and protective clothing (lab coat, cryo gloves, safety goggles; collectively PPE) is worn while handling biological specimens (1) PPE is not worn outside the work area (i.e. admin areas) Related SOPs/documents: CR:3 GMP Lab Cleaning GP:11 Biohazard Waste Disposal QA:2 Quality Control Procedures, Cleaning and Maintenance QA:11 Vendor Qualification Clean Room Validation Plan Facility Blueprints and Construction Documents 2) Environmental Control a) Environmental conditions controlled to minimize product/equipment contamination or crosscontamination and HCT/Ps exposure to communicable disease agents b) Controls include: temperature, humidity, ventilation/air filtration, room/equipment cleaning/disinfecting and equipment maintenance (BSCs, HVAC, HEPA filters, etc.) c) Inspected periodically to verify system and equipment adequate and functioning properly d) Corrective action taken when aberrations occur e) Environmental monitoring where HCT/P contamination/cross-contamination potential exists f) Monitoring records established and maintained indefinitely Related SOPs/documents: GP:9 REES Scientific E-Centron Environmental Monitor System QA:2 Quality Control Procedures, Cleaning and Maintenance QA:10 Environmental Monitoring QA:11 Vendor Qualification Clean Room Validation CONFIDENTIAL QA:1.6 Page 9 of 14 3) Reagents, Supplies and Suppliers a) Reagents and supplies are not used until verified to meet specifications b) Verification by end user, supplier or manufacturer (documentation required for the latter two) c) Processing and preservation reagents/supplies must be sterile d) In-house reagents validated e) Reagents and supplies stored and used according to manufacturer’s recommendations f) System to track critical reagents and supplies g) Non-disposable supplies cleaned/sterilized by validated procedure to remove infectious agents h) System in place to prevent expired reagent or supply use Related SOPs/documents: GP:15 Supply/Reagent Ordering, Receipt and Inventory Management. QA:9 Validation Procedures GP:25 Autoclave Operation and Maintenance QA:11 Vendor Qualification 4) Equipment a) Operate so as to prevent (1) Product mix-ups (2) Contamination/cross-contamination (3) Compromising cellular therapy product function and integrity b) Standardized and calibrated periodically per SOP and manufacturer’s recommendations c) Unique identification and tracking system of all critical equipment used in processing d) All equipment is located to facilitate cleaning, calibration and maintenance (1) maintained in a clean and orderly manner e) Routine equipment inspection for cleanliness, sanitation, and calibration to ensure adherence to maintenance schedules Related SOPs/documents: QA:2 Quality Control Procedures, Cleaning and Maintenance QA:9 Validation Procedures QA:11 Vendor Qualification 5) Procedures a) Since process results cannot always be fully verified at distribution, the process must be validated according to standard procedures b) Written representation that the processing method reduces communicable disease transmission risk based on a validated process c) Validation activities, results and conclusions are documented, including approving authority signature and date Related SOPs/documents: QA:9 Validation Procedures GP:2 Standard Operating Procedures Preparation 13. Inventory Control a. System to identify and track all critical reagents, supplies, and labels used to manufacture HCT/Ps b. Each supply and reagent used to manufacture and administer HCT/Ps is examined visually for damage or evidence of contamination upon receipt or printing (labels) Related SOPs/documents: GP:15 Supply/Reagent Ordering, Receipt and Inventory Management CP:14 Product Labeling Reagent and Supply inventory Log CONFIDENTIAL QA:1.6 Page 10 of 14 Research Inventory Log 14. Process Control and Changes –The QA Program includes controlling and monitoring cellular therapy product manufacturing to ensure products meet predetermined release specifications IMPORTANT: FDA Regulations stipulate, HCTP/s must be processed in a manner that does not cause contamination or cross-contamination during processing and prevent the introduction, transmission, or spread of communicable disease a. Human cells or tissues from two or more donors must not be pooled during manufacturing b. In-process tests and controls are used to measure and assess products during manufacturing c. In-process controls ensure each processing step is met and verified to guarantee product safety, viability and integrity and to document products meet predetermined release specifications d. Process changes are verified/validated to ensure the change does not adversely impact operations e. Changes are approved by the Lab Director, Technical Manager and/or QA Manager prior to implementation f. Changes are communicated to all relevant staff in a timely manner g. All test and procedure results become a permanent part of the product record h. Communicable disease testing is performed using FDA approved tests in an FDA registered laboratory accredited or licensed in accordance with applicable governmental regulations i. Tests not performed by ... are performed by a laboratory certified by CMS, CAP or CLIA j. Proficiency testing is documented for tests performed at ... as designated by the Lab Director 1) Proficiency test results reviewed by the Lab Director/designee and outcomes reviewed with staff k. Staff hand-off communication (staff handing off a task to another) 1) Present and review documentation, where in the protocol the specimen or product is at with any other pertinent details required to complete processing or testing 2) Staff receiving the information should repeat details back as needed for complete understanding Related SOPs/documents: ... SOPs and documents, including the Quality Program, are designed toward this end 15. Donor Eligibility Determination: QA Program has a mechanism in place to ensure donor eligibility determination is performed for all allogeneic HCT/P donors a. ... does not currently perform donor eligibility activities for standard BMT Program 1) DE performed for some projects and governed by individual SOPs for those activities b. The BMT programs for whom ... is processing performs donor eligibility and supplies ... with documentation showing all requirements are met 1) Document is signed by the BMT attending physician who accepts regulatory responsibility IMPORTANT: It is ...’s responsibility, for any product collected or manufactured, to ensure all donor eligibility criteria has been met according to 21 CFR 1271 Subpart C prior to product distribution 16. Labeling a. Accuracy, legibility and integrity verified b. Every product is labeled according to standard operating procedures c. HCT/Ps are labeled with an expiration date and time Related SOPs/documents: CP:14 Product Labeling 17. Product Receipt, Storage, Distribution and Transportation a. Storage areas controlled to prevent HCT/P contamination/cross-contamination b. Quarantine protocols are in place to prevent HCT/Ps from improper/premature distribution c. Storage temperatures recorded, reviewed and maintained CONFIDENTIAL QA:1.6 Page 11 of 14 d. HCT/Ps have acceptable storage temperature limits for each manufacturing step e. HCT/P receipt includes inspection for: 1) Damage 2) Evidence of contamination 3) Evaluation for acceptance, rejection or quarantine f. Transfer within an establishment performed in quarantine to avoid communicable disease transmission (if ID marker testing or donor history screening is incomplete or pending) g. Manufacturing records are reviewed before HCT/P distribution h. Documentation that release criteria is met prior to HCT/P distribution i. Documentation by a responsible individual that a product is available for distribution j. Allogeneic HCT/P is not made available for distribution if in quarantine, contaminated or recovered from an ineligible donor 1) If attending physician requests release, urgent medical need MUST be documented k. HCT/P is not distributed if a deviation from SOP occurs unless authorized and deviation has not increased the risk of communicable disease transmission l. Every product made available for distribution is accompanied by documentation of donor eligibility m. Shipping conditions established and maintained for HCT/P transport n. HCT/P return requirements determined and outlined in SOP Related SOPs/documents: CP:14 Product Labeling CP:23 Thermo CRF Operation CP:28 Liquid Nitrogen Storage Freezers CP:29 MVE Cryo-Shipper Care and Use GP:4 Product Issue, Release, Return and Recall GP:7 Receipt and Handling of HCT/Ps GP:8 HCT/P Transfer and Transport GP:9 REES Scientific E-Centron EM System GP:17 Storage and Expiration of HPC Products GP:19 Release of Products for Research or Disposal QA:6 Standardization and Calibration of Thermometers 18. ... Registrations and Accreditation -- ... is currently registered or accredited with the following a. FDA Registered b. FACT, since 2000 c. CAP 1) CAP accreditation terms (GEN:26791) require ... must notify CAP in the following circumstances: a) Investigation by a government entity or adverse media attention (1) Notification must occur within 2 working days after the occurrence b) Change in laboratory test menu (1) Notification must occur prior to implementation of new patient testing c) Change in location, ownership or directorship (1) Notification must occur prior to change, if change unexpected notification must occur within 2 days after change d. CLIA CALCULATIONS: N/A RESULTS REPORTING: N/A LIMITATIONS: All QA reports should include the following disclaimer: CONFIDENTIAL: This material is prepared pursuant to Code Annotated, § 26-25-1, et. seq., and 5812-43 (7,8 and 9), for the purpose of evaluating health care rendered by hospitals or physicians and is NOT PART of the medical record. It is also classified as “protected” under the Government Records CONFIDENTIAL QA:1.6 Page 12 of 14 Access and Management Act, Code Annotated § 63-2-101 et. seq. EXPECTED RANGES: N/A REFERENCES: International Standards for Cellular Therapy Collection, Processing and Administration -- Foundation for the Accreditation of Cellular Therapy, Fourth Edition, 2008 Quality Program Manual Volumes 1 and 2, American Association of Blood Banks, 1994 .../University of … Department of Pathology Quality Assurance Program Policy, ..., SLC, UT Total Quality Management Program for Clinical and Collection Programs, SOP# TQM: 401, UBMT Program, Policy and Procedure Manuals, University of … Hospital and Clinics Code of Federal Regulations, 21 CFR, Part 1271, May 25, 2005 CONFIDENTIAL QA:1.6 Page 13 of 14 APPROVALS: Written by : 10/15/07 Date Approved by: Supervisor Date Laboratory Director Date Quality Assurance Manager Date ANNUAL DIRECTOR REVIEW: Laboratory Director Date Laboratory Director Date Laboratory Director Date Laboratory Director Date Laboratory Director Date CONFIDENTIAL QA:1.6 Page 14 of 14 ATTACHMENT 1 CONFIDENTIAL