III. Resin Cost of Ownership

advertisement

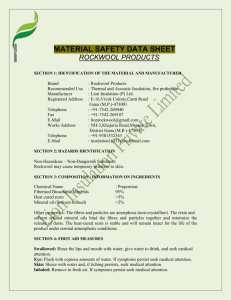

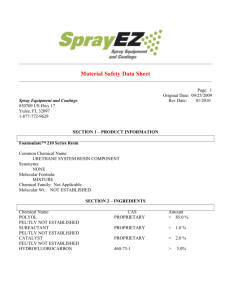

Advances in Compound Semiconductor Processing Joseph Sweeney, James Dietz, Karl Olander, Paul Marganski, Josep Arnó ATMI, Inc.; Danbury, Connecticut, USA jsweeney@atmi.com phase since neither gas is soluble in or reactive with water alone. The benefit of gas absorption is its low operating cost. Although water usage is being scrutinized more and more, its cost is still relatively low. In addition, the cost of an oxidizing agent like sodium hypochlorite is not high. A disadvantage of gas absorption is its dependence on moving parts, e.g. pumps, in order to maintain an effective gas removal rate. The most notable disadvantage, however, is the large volume of arsenic laden aqueous waste that is produced. Not only must this waste be specially treated, it represents an elevated risk within the fab. For example, if a gas absorption system were to suffer a large leak, the cleanup costs could be significant due to arsenic contamination. Abstract—Compound semiconductor manufacturers employ a variety of techniques for managing toxic gases and solids in the effluent of MOCVD reactors. For gas abatement, chemical wet scrubbers, chemical dry scrubbers, and burners have been employed with varying degrees of success. Wet scrubbers and burners have become popular solutions due to their lower operating costs. Unfortunately, these systems can require frequent maintenance and generate large volumes of secondary waste, e.g., arsenic laden waste water in the case of chemical wet scrubbers. Dry scrubbing is the simplest and perhaps least maintenance intensive solution for compound semiconductor abatement of arsine and phosphine; however, efficiency challenges at high flow rates, thermal issues due to hydrogen reduction reactions, and material costs have limited their use. This paper discusses new options for simplifying and improving the abatement of gases from MOCVD reactors depositing GaAs and InP films. The performance of several new dry scrubber materials is presented and proven to reduce materials costs and total operating costs when compared to existing treatment solutions. TABLE I. Gas Keywords-Compound semiconductor; abatement; effluent treatment; chemisorption; gas adsorption, cost of ownership, arsine, phosphine I. EXPOSURE GUIDELINES FOR TYPICAL COMPOUND SEMICONDUCTOR GASES Concentration Limits TLV-TWA (ppm) [1] IDLH (ppm) [2] Arsine (AsH3) 0.05 3 Phosphine (PH3) 0.3 50 Hydrogen Chloride (HCl) 5 50 INTRODUCTION Various effluent treatment challenges arise in compound semiconductor applications. First, the process gases used typically have multiple hazards associated with them. For example, two of the most widely used deposition gases, the hydrides arsine and phosphine, are extremely toxic as indicated by their respective threshold limit values (TLV’s) and immediately dangerous to life or health values (IDLH’s); see Table 1. In addition, phosphine is pyrophoric, meaning that it will ignite spontaneously in air, while arsine is flammable. Occasionally, it is necessary to use hydrogen chloride gas (toxic and corrosive) to clean the tool chamber of unwanted deposits. Such hazards require effective and efficient abatement methods. Thermal oxidation coverts toxic and hazardous effluent gases to their respective oxides through a reaction with oxygen at elevated temperatures. For example, arsine is converted to arsenic(III) oxide (As2O3), while phosphine is converted to phosphorus pentoxide (P2O5). These oxides are still hazardous and must be collected prior to venting to the atmosphere. A typical collection technique is to filter the solids from the gas stream (e.g. with a bag house filter system). As with gas absorption, the main advantage of such a system is its relatively low operating costs, which include fuel or electricity to operate the oxidizer as well as the need to potentially replace filter elements. The major disadvantage is the need to perform frequent maintenance. The significant quantity of solids produced in the oxidation process leads to arsenic contamination within the exhaust ducting and may also require frequent replacement of the filter elements. In addition, the oxidizer unit itself may require frequent maintenance due to solids accumulation. Another effect of using a thermal oxidizer (which may be viewed as a positive or negative depending on the user) is that in addition to treating the hydrides, it will also react the hydrogen present in the gas stream. Because the hydrogen flow rate is commonly very high (50 – 120 slpm is typical), the oxidizer may require active cooling in the form of large amounts of dilution air or cooling water, both of which Traditionally, there have been three common abatement methods used in the treatment of effluent gases from compound semiconductor processes. These are gas absorption (water scrubbing), thermal oxidation, and gas adsorption (dry scrubbing). Gas absorption entails contacting the gas stream with an aqueous stream typically over a packed bed. Although such a system is ideal for HCl abatement, in order to effect the removal of arsine and phosphine gases, a strong oxidizing agent (e.g. sodium hypochlorite) must be added to the aqueous 1 add to the cost of ownership. A final disadvantage of a thermal oxidizer is that it will not abate HCl. If left untreated, the HCl has the potential to cause corrosion within the house exhaust system. scrubbing solution, as well as to further enhance our resins’ resistance to the secondary hydrogen reduction reaction. In order to avoid using a filter unit to remove the solid byproducts emitted from a thermal oxidizer and in order to treat HCl, an integrated scrubber system containing a thermal oxidizer followed by a wet gas absorption column can be employed. Such a solution can significantly reduce the footprint compared to a thermal oxidizer used in conjunction with a filter system. Although an oxidizing agent is not required, the problem and risk associated with aqueous arsenic containing waste is the same as described for the stand-alone gas absorption system. In addition, care must be taken in the design such that even very small particles of arsenic oxide are captured in the absorption column. For example, a typical gas absorption column will only remove particles down to 2-10 microns, depending on specific process conditions [3]. Additional separations techniques may be necessary to remove smaller particulate. Such technologies may increase the capital cost and complexity of the equipment. Finally, as with the thermal oxidizer solution, the integrated scrubber will require significant cooling to manage the heat liberated from the abatement of hydrogen gas. In order to reduce the cost of ownership of dry scrubbing, the focus was placed on significantly improving the capacity (lifetime) of the chemisorbent resin media. This challenge was tackled in three steps. First a program was developed to screen resins of various chemistries. Second, the top performing materials from the screening experiments were characterized more thoroughly to determine the effect of process parameters on the resins’ capacity and operating temperature. Third, resin optimization techniques were evaluated. II. RESIN DEVELOPMENT PROGRAM Most of the resin experiments were performed using a test cell (Figure 1) with the following characteristics: The final major technology used is gas adsorption – specifically chemisorption. In chemisorption (often referred to as dry scrubbing), the effluent gas stream is contacted with a fixed bed containing solid particles having very high surface areas. The chemistry of the solid material is such that a reaction occurs when the effluent gas molecules adsorb onto the surface. Byproducts of the reaction are non-volatile solids and cannot be desorbed from the surface. A major benefit of such a system is its simplicity. The system does not require moving parts, fuel, or water, and consumes minimal electricity. The system is passive in operation, meaning that the only requirement for abatement is the presence of the chemisorbent material itself. This is in stark contrast to other methods of treatment where loss of water, air, fuel, or electricity can mean a partial or total loss of abatement efficiency. In addition, a dry scrubbing system contains the arsenic, phosphorus, and hydrogen chloride waste in an isolated, well contained, and compact vessel. The biggest disadvantage of gas adsorption systems is their cost of operation. This arises from the need to replace the vessels containing the chemisorption media (from hereafter to be termed resin) on a basis prescribed by the capacity of the given resin material in conjunction with the total gas loading onto the resin. In addition, the relatively large effluent flow rate common to most compound semiconductor processes tends to reduce a resin’s capacity due to the shorter residence time the effluent stays within the media bed. Added to this challenge is another in which a secondary reaction can occur between hydrogen and common metal oxide resins if the bed temperature rises above 110-120°C. This hydrogen reduction reaction of the resin is undesirable simply due to the large flow of hydrogen. Not only can the resin capacity be used up, the temperature of the bed can increase significantly. 1” or 2” outer diameter (0.065” wall thickness) 8” resin bed height 5-point thermocouple centered within cell ~ 1” thick insulation surrounding cell Stainless steel construction 5-point thermocouple Gas Out Resin Bed Thermocouple locations (in red) Screen Gas In Figure 1. Test Cell used to Determine the Effectiveness of Various Resins Tests were performed flowing either arsine or phosphine gas in a ballast stream composed of 80% hydrogen and 20% nitrogen by volume (this ballast stream was meant to approximate the actual conditions in the field). All gases were It is in this light that the authors have embarked on a major effort to improve the cost of ownership of ATMI’s dry 2 delivered to the test cell using mass flow controllers. The effluent of the test cell flowed through a MIDAC G2000 FTIR (Fourier Transform Infrared Spectrometer) with a 10 cm pathlength in order to determine the shape of the arsine or phosphine breakthrough curve (i.e., the effluent concentration of hydride gas as a function of time). In addition, a portable gas detector sampled the exhaust stream to monitor for TLV breakthrough, while a Fluke Hydra Databucket logged cell temperatures during the experiments. Figure 2 is a simple block diagram of the setup. Test Cell FTIR TLV Monitor PH3 + MOx MyPz + P + H2O unbalanced (2) HCl + MOx MyClz + H2O unbalanced (3) where “M” stands for a generic metal. Although chemistry of the resin is very important in terms of dictating the resin’s capacity, so is surface area, pore structure, density, water content, etc. In fact, a resin screening study could be almost limitless due to the large number of resin property variations one could imagine. For practical purposes, we chose to focus on only a handful of carefully selected candidates. Because HCl flow rates are usually much smaller than the hydride challenges in compound semiconductor processing, the focus of this project was on the hydrides, notably arsine. In addition, resins that abate HCl are typically lower in cost and tend to have higher capacities than their hydride resin counterparts. Therefore, hydride capacity improvements have a much larger impact on cost of ownership. Hood Dry Scrubber Gas In TABLE II. RESIN SCREENING EXPERIMENTS Resin Capacity (moles gas per liter resin) Figure 2. Major Components of the Experiment Resin The performance of any given resin was evaluated by three criteria: TLV Capacity Dynamic Theoretical Capacity Maximum Temperature A B C D E F G H I TLV capacity was defined as the amount of gas taken up per unit volume of resin at the time when the effluent concentration reached TLV levels as determined by the portable gas monitor. (Note that many commercially available gas adsorption systems are outfitted with a sensor that detects TLV breakthrough from the fixed resin bed. At this point, the resin bed is replaced with a new vessel containing fresh resin. Therefore TLV capacity is directly related to cost of ownership). Dynamic theoretical capacity was determined by recording the full breakthrough curve using the MIDAC FTIR. The term “full breakthrough curve” means the test was run until the outlet concentration approached 50%+ of inlet concentration. The area above this curve was used to determine the total amount of hydride gas that had been chemisorbed by the resin (note that the curve slope was extrapolated for calculation puposes). Finally, we monitored and logged the temperature of the cell interior at various depths in the resin bed. For each test, we recorded the maximum value attained. Theoretical 1.16 0 2.47 1.00 1.02 0 0.16 0.82 0.55 3.10 NA 4.87 3.89 1.44 NA 1.53 1.13 0.82 Table II lists the results of the screening tests. Note that resin “A” represents the material ATMI sells today for arsine and phosphine abatement. All tests were performed using arsine as the hydride gas; the inlet concentration was 4%, while the superficial linear velocity through the cell was 4 cm/sec. These test conditions are quite challenging and were chosen mainly to decrease the testing time during the screening program. Actual field conditions are typically 0.5% - 2% inlet gas concentration with a linear velocity of less than 1 cm/sec (although this is dependent on the specific design of the resin containing vessel). Three resins were chosen for further study based on the results of the screening program. These materials are shaded in gray in Table II: resins A, C, and D. It is noteworthy that a significant portion of the resins’ chemistry remained available for further reaction at TLV breakthrough. This is evidenced by the theoretical capacities being 2-4 times higher than TLV capacities for the three top performers. As an example, Figure 3 plots the exhaust concentration (breakthrough curve) from the test cell as a function of time for resin “A”. Whereas TLV breakthrough occurred at t = 60 minutes, the outlet had not reached 50% of the inlet concentration by t = 140 minutes. A. Resin Screening Study Resin screening consisted of testing various materials to quickly determine those that showed promise. Generally, resins are composed of various metal oxides that react with arsine, phosphine, and HCl gases in the following fashion: AsH3 + MOx MyAsz + As + H2O unbalanced TLV (1) 3 test cases. The technique developed will be discussed in the next section. . Concentration (ppm) 40000 Notes (1) Resin "A" (2) Column diameter = 0.87" ID (3) Resin bed height = 8" (4) Thermocouple (1/8" diameter) centered in bed (5) AsH3 flow = 34.2 sccm (6) 80%/20% H2-N2 mix flow = 840 sccm 30000 20000 Arsine in bypass TABLE III. Test Parameters Test 1 2 3 4 5 6 10000 MDA TLV (50 ppb, 59.5 min) 0 0 20 40 60 80 100 RESIN CHARACTERIZATION: EFFECT OF LINEAR VELOCITY AND INLET CONCENTRATION ON CAPACITY 120 140 160 Time (min) Conc. % 4 4 4 2 1 1 Vel. cm/sec 1 2 4 4 4 1 Resin Capacity for Arsine (TLV; Theoretical)1,2 A C D NA; 4.77 1.60; 3.69 1.16; 3.10 1.05; 2.07 0.85; 1.73 1.94; NA NA; 3.49 2.26; 4.48 2.47; 4.87 1.35; 3.75 1.01; 3.66 ---- ------1.00; 3.89 ------2.95; NA 1) Resin capacity is defined as the moles of gas treated per liter of resin. 2) All tests performed with a 1” diameter cell except for the last set, which were done with a 2” cell. Figure 3. Breakthrough Curve for Resin “A” TABLE IV. RESIN CHARACTERIZATION: EFFECT OF LINEAR VELOCITY AND INLET CONCENTRATION ON MAXIMUM TEMPERATURE RISE B. Resin Characterization To characterize the performance of the three candidate resins, a simple test matrix was created to evaluate the effect of inlet concentration and linear velocity on resin capacity and operating temperature. In the field, the effluent flow rate is dictated by the process recipe. Once an abatement system is in place, there is little control over the hydride concentration or the linear velocity of the gas as it passes through the resin bed. Of course, in a product development sense, it is possible to modify the resin bed geometry or add dilution nitrogen to reduce the gas concentration. Therefore, we felt it worthwhile to understand how these two variables affected the resins’ performance. Test Parameters Test 1 2 3 4 5 6 Test results for various inlet concentrations and linear velocities are tabulated in Tables III and IV. Table III shows how the capacities of the three candidate materials varied based on process conditions. For example, the TLV and theoretical capacities of resin A were observed to decrease with higher linear velocity. In addition, for a given velocity, the capacity is better for higher inlet arsine concentrations. For resin system C, the effect of linear velocity was opposite that of resin A – TLV and theoretical capacities actually increased with higher linear velocities. The inlet concentration dependence was analogous to resin A. Only one test was completed for resin D in this stage of the project (test #6). This was not for lack of interest in this material. Rather, the results from resins A and C (as well as the screening test point for D) suggested that changes in linear velocity and concentration only moderately affected the TLV capacities relative to the theoretical values. Furthermore, the dependence upon inlet concentration was opposite to that which would be desirable from a control standpoint. That is, the capacities decreased with lower inlet concentration. Unfortunately, it would be much easier from an abatement standpoint to decrease the concentration of effluent species coming from the tool via simple dilution, as opposed to increasing the concentration by special design and process techniques. Something other than control techniques or design modifications was needed to narrow the gap between the TLV and theoretical capacities, which were quite large for nearly all Conc. % 4 4 4 2 1 1 Vel. cm/sec 1 2 4 4 4 1 Maximum Temperature Rise (°C)1 A C D 29 50 46 39 26 24 27 49 77 41 23 ---- ------53 ------27 (1) All tests performed with a 1” diameter cell except for the last set, which were done with a 2” cell. (2) Temperature rise is defined as the maximum observed temperature minus the room temperature at the time of the experiment. Figure 4. Average Ratios for Capacity and Temperature Rise Between Candidate Resins and Resin A As discussed in the introduction, high operation temperatures in a dry scrubber can promote an unwanted secondary reaction with hydrogen. In addition to improving resin capacity, it was a second goal of this project to identify a resin with higher resistance to a reaction with hydrogen. Table IV shows the corresponding maximum temperature rise within 4 the test cell for each experiment. When averaged over all tests, neither resins C nor D maintained a lower relative temperature rise. However, resin C showed good results for all tests with the exception of test #3. Because test #3 represents conditions significantly outside those present in the field, it was felt that resin C was acceptable. For the two tests performed with resin D, the temperature rise was slightly higher than resin A. However, resin D is known to resist the hydrogen reduction reaction up to temperatures in the range of 180°C – much higher than resin A (110-120°C). Therefore, it was deemed acceptable as well. Figure 4 displays the average capacity and temperature rise ratios between resins C and A, and D and A. faster resin (short MTZ) acts as a polisher. demonstrates the basic concept. Figure 5 One can perform a mathematical analysis to evaluate the effect of combining two such resins. Assume, for example that the MTZ length of the high capacity resin is ½ the entire bed length. If this is the only resin present, it stands to reason that the capacity will be 3/4th of the resin’s theoretical limit. As portrayed in Figure 6, this result is obtained by looking at the area under the curve. C/Co C. Resin Optimization As mentioned in the prior section, during both the screening and the characterization testing, there always existed a large difference between the TLV and theoretical capacities. For any given experiment, the gap was between 100%-300% (2-4x). These results indicated that a large percentage of the resins’ chemistry was left unutilized. In this phase of the project, a method was investigated for improving the TLV capacities to values closer to theoretical. MTZ/LOB = 0.5 Column Height/Location Figure 6. Idealized Mass Transfer Zone Equal to ½ the Column Length Expanding on this idea, Figure 7 shows how the resin bed utilization (defined as TLV capacity/theoretical capacity) is affected as the MTZ:bed length ratio is varied. It is apparent that a severe reduction in utilization occurs as the MTZ length increases. In fact, it is obvious that the materials in Table III all had very long MTZ lengths – some in excess of the bed length itself. This may seem impossible, but it simply implies that the MTZ length became longer as the bed media was consumed. That is, an 8” bed height was not sufficient to generate a steady state MTZ length. This corroborates data generated by Illes[4]. The authors confirmed this idea experimentally by performing tests utilizing a bed height of 22”. The results (not shown) indicated that the capacity was relatively unchanged relative to the tests performed with the 8” bed height. Had the MTZ length been constant, the use of a 22” tall bed would have moved the system to the left and upwards on the line in Figure 7, providing for dramatically improved resin utilization. As plotted in Figure 3, all resins display a characteristic breakthrough curve. It is desirable to utilize resins in which the curve is as steep (vertical) as possible so that little capacity remains after TLV breakthrough. Said another way, there must be a short mass transfer zone within the resin. Mass transfer zone (MTZ) is defined as the length of adsorbent required to remove the target contaminant from its incoming concentration level to the level defined as the breakthrough level (TLV). Cinlet Breakthrough C=0 Slow Resin Cinlet Breakthrough C=0 Fast Resin Cinlet Breakthrough C=0 Slow Resin Fast Resin Figure 5. Mass Transfer Zone Shape Through Slow and Fast Resins Unfortunately, resins that have both high capacities and short MTZ’s, will operate very hot and are susceptible to a reduction reaction with hydrogen. Resins with short MTZ’s and low capacities operate at acceptable temperature ranges, but obviously do not last long. Finally, resins that have long MTZ’s and high capacities tend not to be utilized well (as indicated in Table III). The solution to this problem is to combine a high capacity/long MTZ resin with a low capacity/short MTZ material. Such an arrangement allows the high capacity material to be utilized more fully because the Figure 7. Effect of Mass Transfer Zone Length on Bed Utilization. Therefore, the only way to attack this problem was to somehow decrease the effective mass transfer zone of the resin. However, because a resin that exhibits both high capacity and short mass transfer zone tends to operate at rather high temperatures, a different method had to be employed. This 5 TABLE V. method as described earlier (and shown graphically in Figure 5) is to layer a small amount of “fast” polishing resin (i.e. short MTZ) over a bed of high capacity, “slow” material. A search began to find appropriate resins that would act as effective polishers to the three candidates identified from the screening study. In addition, the correct ratio in which to use the two resins was investigated. Resin Configuration Using polish resin S improved the capacity of resin A by 51%. Although a significant improvement, it was below the theoretical value of 3.1 (see Table III). Resin V was also effective as a polishing agent when used with resin A. The capacity of 3.12 moles/liter could not be directly compared to a test in which TLV capacity was measured for process conditions of 4% arsine and 1 cm/sec velocity. However, the data and trends displayed in Table III suggest such a comparative data point would be < 1.94 moles/liter. Using polish resin S with resin C actually decreased capacity relative to C alone. Clearly, S was not effective in this case. It is possible that certain byproducts from the reaction of arsine with resin C were incompatible with resin S. Assuming S contributed little, the lower capacity was likely due to the smaller quantity of C present in the test cell (compared to the test of C by itself). Utilizing polisher V with resin C produced the best capacity result of the program – almost 2x higher than the next best result shown here. It is noteworthy that the capacity far exceeded the theoretical value shown in Table III. The reason for this is not completely understood. However, it is suspected that the method of calculating the dynamic theoretical capacity by extrapolating the slope of the breakthrough curve led to underestimated values. In fact, one can calculate an absolute theoretical capacity simply by looking at the reaction stoichiometry. For resin C, this value is between 9 and 10 moles/liter. Tests using resin D indicated that polishing agents T, U, and V all provided significant improvements over resin D by itself. For example, the D/V combination was 2.5x better than D alone. The theoretical capacity at these process conditions of 3.89 moles/liter (Table III) indicates that there may be even more room to improve. Resin D displayed similar performance for the abatement of phosphine as it did for arsine. In addition, other test results (not included here) indicated that the capacity for phosphine was always approximately the same as for arsine. Test Parameters1,2,3 Performance A A A Polish Bed ---S V Conc. (%) 4 4 4 Vel. cm/sec 4 4 1 C C C ---S V 4 4 4 4 4 1 2.47 2.20 6.97 D D D D D D D ---J V U U U T 4 4 4 4 4 4 1 4 4 4 4 1 1 1 1.00 0.94 2.49 2.04 3.39 3.28 3.67 Main Bed Various tests were performed using each of the three main resin candidates in which the effect of using different polishing resins was evaluated. The results are shown in Table V. A number of comments can be made regarding these data. THE SEARCH FOR A POLISHING RESIN TLV Capacity (1) Grayed row denotes a test in which phosphine was used instead of arsine (2) Percent polisher was 20% for all tests (3) TLV Capacity defined as moles gas abated per liter resin 1.16 1.75 3.12 The next step in the resin development program was to evaluate the effect of varying the amount of polish material. For this we chose resin D with polisher U. We set up a simple 2 level, 2 factor design of experiments in which we varied the resin bed height and the percentage of polisher. The test results are plotted in Figure 8. The data show a major dependence on the quantity of polisher present within the bed, and a small dependence on the bed height. An optimum polish layer percent is known to exist because the capacity of the polishing resin itself (100% polish) was less than any of the four points plotted in Figure 8. The actual maximum location cannot be determined from these data; other test results (not presented here) suggest it is somewhere in the 20-30% range. Figure 8. Effect of Polish Layer Percent and Bed Height on TLV Capacity. D. Resin Development – Concluding Remarks Through the resin screening, characterization, and optimization efforts, significant achievements were made in 6 identifying new resins with improved capacities and better thermal characteristics. Resin combination D/V had a maximum capacity of 3.67 moles/liter, while C/V achieved a value of 6.97. This compares to a capacity of 1.94 moles/liter for a standard material available today. III. The model provides a useful basis for understanding the relative cost of using carbon resin in the TGA system as well as the targeted cost for new chemisorption resins under development. As Figure 10 shows, the model predicts the mean cost of carbon abatement to be $12.81 per mole hydride treated. Depending on the particular conditions, the range in carbon abatement costs is approximately $8.60 – $18.37 per mole hydride abated, at a 90% confidence level. Therefore, from the end-user standpoint, the cost of the C/V or D/V resins must be equivalent or better to this distribution of existing carbon costs. The development of C/V and D/V resins included the specific target to achieve a 10-20% improvement in TCO for TGA carbon users, based upon new resin pricing and reduction of disposal quantities, labor, and time. For the beta versions of C/V and D/V resins, this appears to be entirely possible. RESIN COST OF OWNERSHIP Two key customer deliverables of resin development were improving the Total Cost of Ownership (TCO) for existing users of chemisorption abatement systems and providing existing users of carbon abatement systems a higher performing, cost-effective alternative. The C/V and D/V resin combinations show good promise to meet these goals. For the purpose of this discussion, we focus on the potential TCO improvements for existing users of carbon treatment systems for arsine and phospine abatement of III-V processes. Forecast: Carbon Cost A TCO model was developed to analyze the impact of switching from carbon to C/V and D/V layered resins. The model incorporates the main variables that were thought to impact resin consumption, maintenance, and tool downtime based upon the operation of the so-called “Toxic Gas Absorber” (TGA) carbon systems on the Emcore toolset. The main variables, assumptions cells, were: 1,000 Trials Hydride gas flow (both arsine and phosphine) Hours of operation per day using arsine and phosphine Process conversion of arsine and phosphine TGA carbon change out time (days) Tool downtime per TGA change Carbon cost Disposal costs Labor costs Frequency Chart 988 Displayed .025 25 .019 18.75 .013 12.5 .006 6.25 M ean = $1 2.81 .000 0 $6.55 $10.10 $13.64 $17.18 $20.72 $ / m ol hy dri de treated Figure 10. Distribution of carbon costs ($ / mol hydride treated) The results of the model show several advantages of C/V and D/V resins over carbon in the operation of the TGA. Regarding disposal volumes, the increased capacities of the C/V and D/V resins result in a decrease in average disposal volumes of approximately 72.7%, which allows for significant environmental and safety benefits. Figures 11 and 12 present the pertinent output data from the model regarding carbon versus C/V and D/V resin disposal volumes. In addition to reducing disposal volumes, labor and time savings are realized, the latter of which can lead to additional tool time for production, if need be. Figure 13 presents the additional tool time gain, or downtime savings when switching from carbon resin to D/V resin. Based upon these assumptions and known parameters, the model was used to determine the operating cost of the TGA, i.e., $ per mole hydride treated, using a static model of single point estimates for the assumption cells and a dynamic model using Monte-Carlo simulation. For the Monte-Carlo simulation, Crystal Ball, an Excel add-in, was used to generate distributions of likely values for the assumption cells (Figure 9). Likewise, the same base model was used to assess the operating cost of using C/V and D/V resins in place of carbon in the TGA system. Forecast: Carbon disposal v olume 1,000 Trials Frequency Chart 999 Displayed .022 22 .017 16.5 .011 11 New resin cap acity (mo l h yd rid e / liter) .006 5.5 Mean = 3,655 .000 0 2,927 3,271 3,615 3,959 Liters 3 .0 3 .5 4 .0 4 .5 5 .0 Figure 11. Carbon Disposal Volume (liters) Figure 9. Distribution of expected new resin capacity (mol / liter) 7 4,303 IV. Forecast: Total v olume of resin 1,000 Trials Frequency Chart Through an extensive test program involving resin screening, characterization, and optimization aspects, significant improvements were made in treatment capacity for hydride gases. Specifically, a resin layering technique was developed and optimized that improved resin capacities approximately 2-3½ times. 988 Displayed .029 29 .022 21.75 .015 14.5 .007 7.25 Using a Monte-Carlo simulation, the two top candidate resins appear to enable reductions in Total Cost of Ownership for current users of carbon treatment systems. Mean = 996 .000 0 440 731 1,022 1,312 1,603 REFERENCES Figure 12. Chemisorption Resin Disposal Volume (liters) [1] [2] . Forecast: Annual dow ntime sav ings 1,000 Trials Frequency Chart 988 Displayed .029 29 .022 21.75 .015 14.5 .007 7.25 [3] [4] .000 0 10.6 27.2 43.7 60.3 CONCLUSION 76.8 (hours) Figure 13. Annual Downtime Savings (hours) – chemisorption over carbon 8 American Conference of Governmental Industrial Hygienists (ACGIH) website, http://www.acgih.org. National Institute for Occupational Safety and Health (NIOSH) website, http://www.cdc.gov/niosh/homepage.html. Calvert, S., Goldshmid, J., Leith, D., and Mehta, D., Wet Scrubber System Study, Scrubber Handbook, vol. 1, Report No. EPA-R2-72118a, PB 213 016. Illes, V., MAFKI Report 233, 1961.