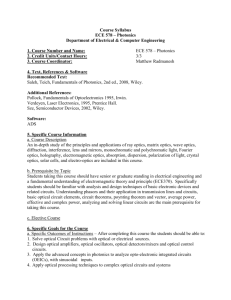

optics diameter

advertisement

17.02 Astrophysical Observing Systems Lead Center: GSFC Participating Center(s): JPL, LaRC, MSFC The NASA Space Science Enterprise is studying future missions to explore the Structure and Evolution of the Universe, which will require very large space observatories. In order to understand the Structure and Evolution of the Universe, a variety of observatories are necessary to observe cosmic phenomena from radio waves to the highest energy cosmic rays. These observatories will peer farther and view objects more fainter than current Earth-based or space-based observatories and therefore will have increased resolution and light-gathering ability by greatly increasing the aperture size. It also will be necessary to operate some of these telescopes at cryogenic temperatures and at a substantial distance from the Earth. Apertures for normal incidence optics are required in the range of 20 - 40 m in diameter, while grazing incidence optics are required to support apertures up to 10 m in diameter. For some missions, these apertures will form a constellation of telescopes operating as interferometers. These interferometric observatories will have effective apertures in the 100 - 1000 m diameter range. The observatories required for many future SEU missions will also be operated at cryogenic temperatures (30 K) and at a substantial distance from the Earth. Therefore, low mass of critical components such as the primary mirror and support and/or deployment structure is extremely important. It is also essential to develop actuators, deformable mirrors and other components for operation in a cryogenic environment. In order to meet the stringent optical alignment and tolerances necessary for a high quality telescope and to provide a robust design, there are potential significant benefits possible from employing systems that can adaptively correct for image degrading sources from inside and outside the spacecraft. This subtopic also includes correction systems for large aperture space telescopes that require control across the entire wavefront, typically at low bandwidth. The following technologies are sought: Large, ultra-lightweight optical mirrors including membrane optics for very large aperture space telescopes and interferometers. Large, ultra-lightweight grazing incidence optics for X-ray mirrors with angular resolutions less than 5 arcsec. Ultra-precise, low mass deployable structures to reduce launch volume for largeaperture space telescopes and interferometers. Segmented optical systems with high-precision controls; active and/or adaptive mirrors; shape control of deformable telescope mirrors; image stabilization systems. Advanced, wavefront sensing and control systems including image based wavefront sensors. Shape measurement and control of large aperture membrane optics. Wavefront correction techniques and optics for large aperture membrane mirrors and refractors (curved lenses, fresnel lenses, diffractive lenses). Cryogenic optics, structures, and mechanisms for space telescopes and interferometers. Nanometer and picometer metrology for space telescopes and interferometers. High-precision pointing and attitude control systems for large space telescopes and interferometers. Space-fabricated optics and techniques including fabrication from raw materials or blanks, coatings, assembly of components, metrology, and system testing. High-performance materials and fabrication processes for ultra-lightweight, high performance optics. Advanced analytical models, simulations, and evaluation techniques and new integrations of suites of existing software tools allowing a broader and more indepth evaluation of design alternatives and identification of optimum system parameters including optical, thermal, and structural performance of large space telescopes and interferometers. Advanced, low cost, high quality large optics fabrication processes and test methods including active metrology feedback systems during fabrication, and artificial intelligence controlled systems. Technologies for testing new mirror materials and shapes in relevant environments including cryogenic testing. New coatings and methods for applying them. Long path length measurement techniques. Innovative solutions to detect and correct errors in deployed optical systems. Deployable optical benches to achieve reference baseline dimensions greater than those of the payload envelope. High resolution (2 nm) long stroke (6mm) cryogenic actuators. Wide field of view optics using square pore slumped micro-channel plates or equivalent. Coded masks for 5 mm x 5 mm x 5 mm pixels of high-Z passive metal (Pb or W) and ~4 m^2 area. Grazing incidence focusing mirrors with response up to 150 keV. Develop fabrication techniques for ultra-thin-flat silicon (or like material) for grating substrates for X-ray energies < 0.5 keV. Large area thin blocking filters with high efficiency at low energy X-ray energies (< 600 eV). Novel optical materials, specialized optical fabrication techniques, and new optical metrology instruments and components for Earth- and space-based applications are needed, as follows: Develop novel materials and fabrication techniques for producing ultralightweight mirrors, high-performance diamond turned optics, and ultra-smooth (2-3 angstrom rms) replicated optics that are both rigid and lightweight. Lightweight silicon carbide optics and structures are also desired. Develop optics for focusing EUV and X-ray radiation, where reductions in fabrication time and cost are sought. Developments are also needed in the areas of surface roughness and figure characterization of EUV and curved X-ray optics, especially Wolter systems. Develop novel materials and fabrication techniques for producing cryogenic optics. Testing techniques, including both full- and sub-aperture testing, for cryogenic optics are needed. Also desired are techniques for testing the durability of and stress in coatings used in harsh environments, particularly cryogenic optics. Develop novel techniques for producing and measuring coatings and polarization control elements. Optical coatings for use in the EUV, UV, visible, IR and far IR for filters, beamsplitters, polarizers, and reflectors will be considered. Broadband polarizing- and non-polarizing cube-type beamsplitters are also needed. Perform development related to fabrication of X-ray, gamma-ray, and neutron collimators that have the precision necessary to achieve arcsecond or subarcsecond imaging in solar physics and astrophysics when used in stationary multi-grid arrays or as rotating modulation. Develop portable and miniaturized state-of-the-art optical characterization instrumentation and rapid, large-area surface-roughness characterization techniques are needed. Also, develop calibrated processes for determination of surface roughness using replicas made from the actual surface. Traceable surface roughness standards suitable for calibrating profilometers over sub-micron to millimeter wavelength ranges are needed. Develop instruments capable of rapidly determining the approximate surface roughness of an optical surface, allowing modification of process parameters to improve finish, without the need to remove the optic from the polishing machine. Techniques for testing the figure of large, convex aspheric surfaces to fractional wave tolerances in the visible are needed. Develop efficient, analytical, optical modeling and analysis programs capable of determining the ground-based and space-based performance of complex aberrated optical telescopes and instrument systems will be considered. Also, simple, well documented, flexible programs which generate commands to operate a numerically controlled polishing machine, given the tool wear profile and surface error map are desired. Develop very low scattered light optical material thin film mirror coatings or mirrors for broad-band white light applications to planet detection space telescopes. Develop a novel material for producing doubly curved, ultra-thin, unsupported shell optical quality telescope mirrors which are capable of being rolled for storage and transport. These mirrors will exceed one meter in diameter, have an areal density of < 1.5 kg/m2, and have sufficient "memory" to enable it to return to its original configuration when unfurled. Fine adjustment will be achieved using actuator material embedded within the shell mirror or with a two-stage optics system or both. The reflective surface would not be damaged when the mirror is rolled. This material must tolerate the space environment without dimensional changes, stiffness changes, or loss of mechanical integrity.