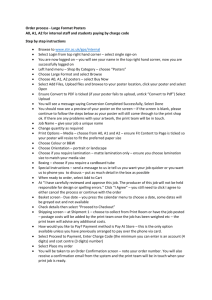

during solvent-based lamination of ceramic green tapes

advertisement

ROLES OF POLY(PROPYLENE GLYCOL) DURING SOLVENT-BASED LAMINATION OF CERAMIC GREEN TAPES Nitinat Suppakarn,* Hatsuo Ishida,* and James D. Cawley*. *Department of Macromolecular Science and **Department of Materials Science and Engineering, Case Western Reserve University, Cleveland, Ohio 44106 Abstract Solvent lamination of alumina green tapes is readily accomplished using a mixture of ethanol, toluene, and poly(propylene glycol), or PPG. After lamination, the PPG is clearly present as a discrete film at the interface between the laminated tapes, and direct particle-particle contact does not, in general, exist across the joined surfaces. This condition, however, does not generate delamination during firing. Instead, stacks of green tapes laminated using this mixture routinely sinter to full density and no evidence of original joint persists through the firing process. This paper presents the results of experiments undertaken to determine the role of PPG in the lamination process and, specifically, the mechanism by which it is redistributed during subsequent processing. PPG slowly diffuses through the organic binder film at room temperature. The PPG diffusion rapidly increases as the temperature is in creased to 80C. The key to the efficiency of adhesives during green-tape lamination is mutual solubility of the nonvolatile component of the glue and the base polymeric binder. Published in Journal of the American Ceramic Society, 84(2), 289, 2001 J. Am. Ceram. Soc., 84(2), 289, 2 0 0 1 . PHASE DISTRIBUTION WITHIN THE ORGANIC CONSTITUENTS OF CERAMIC GREEN TAPE AND RELATION TO PHYSICAL PROPERTIES Nitinat Suppakarn*, Hatsuo Ishida, and James D. Cawley* *Department of Macromolecular Science **Department of Material Science and Engineering Case Western Reserve University Cleveland, OH 44106 Abstract Dynamic mechanical analysis (DMA) and tensile testing are used to study the properties of a commercial ceramic green tape. Particular emphasis is placed on analyzing the physical state of the organic subcomponent, i.e., the binder system. Rather than the expected compatible or single-phase, organic system marked phase separation is observed at room temperature. This information can be used to explain the complex mechanical behavior of this ceramic green tape that is dependent on aging time at room and elevated temperatures. To be Published in Journal of the American Ceramic Society. POLYMER ASSISTED LAMINATION OF CERAMIC GREEN TAPE Nitinat Suppakarn,* Zhien Liu and James D. Cawley** *School of Polymer Engineering, Suranaree University of Technology Nakhonratchasrima 30000, Thailand **Department of Materials Science and Engineering Case Western Reserve University Cleveland, OH 44106, USA Abstract Multilayer manufacturing processes allow easy fabrication of large or, more often, complex ceramic components. Commonly in this process, a sheet-like powder-compact or “green tape” is first prepared. Then, the sheet materials are cut or punched into the desired shapes before joining together and sintering to obtain the final ceramic component with useful properties. Solvent lamination for alumina green tapes has been readily accomplished using a mixture of ethanol, toluene and poly(propylene glycol), PPG. However, the role of nonvolatile component, PPG, during the lamination process was not clearly understood. The purpose of the work reported herein is to determine the redistribution of the PPG during subsequent processing of green tape lamination. Based on these results, the environmentally friendly, solvent free system, f o r g r e e n t a p e l a m i n a t i o n w a s d e v e l o p e d . Published in “The First Thailand Materials Science and Technology Proceedings,” MTEC, T h a i l a n d , 3 6 4 , 2 0 0 0 . COATED FEEDSTOCK FOR FABRICATION OF CERAMIC PARTS BY CAM-LEM Zhien Liu**, N. Suppakarn*, and James D. Cawley** *Department of Macromolecular Science **Department of Materials Science and Engineering Case Western Reserve University 10900 Euclid Avenue Cleveland Ohio 44106-7204 Abstract In laminated object manufacturing of ceramic components, lamination is one of the most important materials issues. Good lamination can ensure monolithic finished component. Otherwise, lamination defect will occur in the parts, which will affect the properties of ceramic components. Adhesive (both liquid and non-liquid) lamination were developed for the cut-thenstack (CAM-LEM) procedure. Especially, the non-liquid adhesive lamination was discussed in m o r e d e t a i l s . Published in “Solid Freeform Fabrication Symposium Proceedings, Edited by D. Bourell, J.J. Beaman, R. Crawford, H.L. Marcus, and J.W. Barlow, University of Texas, Austin, TX, 393, 1999.