Supplemental_Material

advertisement

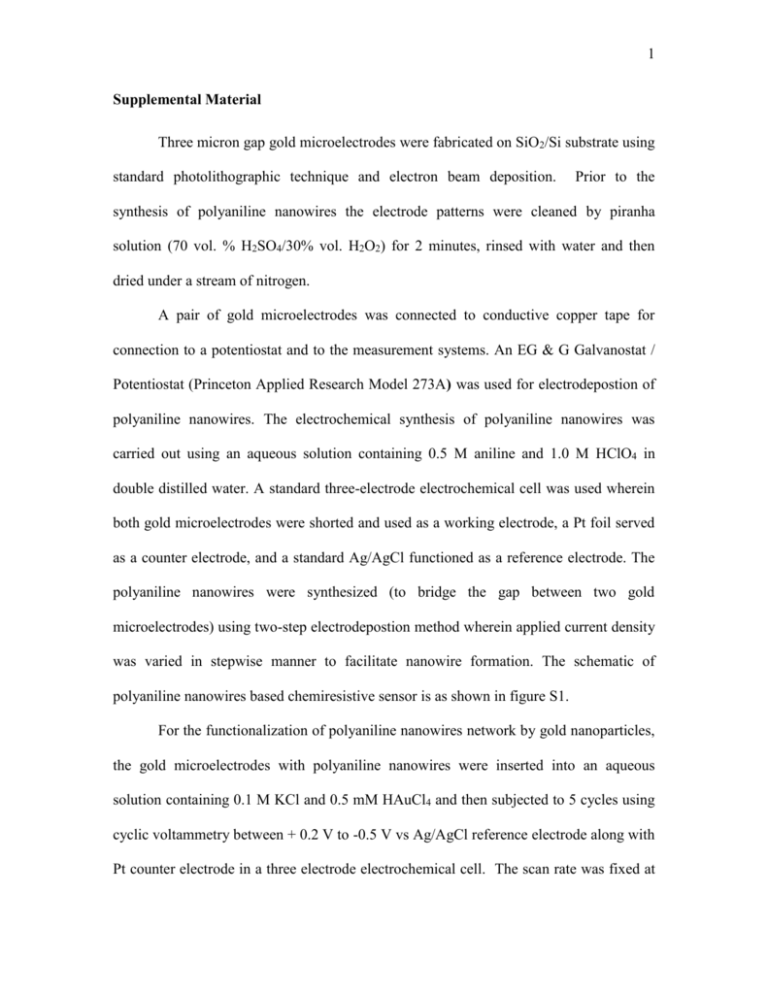

1 Supplemental Material Three micron gap gold microelectrodes were fabricated on SiO2/Si substrate using standard photolithographic technique and electron beam deposition. Prior to the synthesis of polyaniline nanowires the electrode patterns were cleaned by piranha solution (70 vol. % H2SO4/30% vol. H2O2) for 2 minutes, rinsed with water and then dried under a stream of nitrogen. A pair of gold microelectrodes was connected to conductive copper tape for connection to a potentiostat and to the measurement systems. An EG & G Galvanostat / Potentiostat (Princeton Applied Research Model 273A) was used for electrodepostion of polyaniline nanowires. The electrochemical synthesis of polyaniline nanowires was carried out using an aqueous solution containing 0.5 M aniline and 1.0 M HClO4 in double distilled water. A standard three-electrode electrochemical cell was used wherein both gold microelectrodes were shorted and used as a working electrode, a Pt foil served as a counter electrode, and a standard Ag/AgCl functioned as a reference electrode. The polyaniline nanowires were synthesized (to bridge the gap between two gold microelectrodes) using two-step electrodepostion method wherein applied current density was varied in stepwise manner to facilitate nanowire formation. The schematic of polyaniline nanowires based chemiresistive sensor is as shown in figure S1. For the functionalization of polyaniline nanowires network by gold nanoparticles, the gold microelectrodes with polyaniline nanowires were inserted into an aqueous solution containing 0.1 M KCl and 0.5 mM HAuCl4 and then subjected to 5 cycles using cyclic voltammetry between + 0.2 V to -0.5 V vs Ag/AgCl reference electrode along with Pt counter electrode in a three electrode electrochemical cell. The scan rate was fixed at 2 50 mV/s. Optical microscopy (Hirox HI-Scope Advanced KH-3000, River Edge, NJ, USA) was used for visual verification of polyaniline nanowires bridging two gold electrodes. Polyaniline nanowires network before and after functionalization with gold nanoparticles was also characterized by scanning electron microscope and Energy Dispersive X-ray analysis (EDAX) (SEM, Leo SUPRA 55, Model 1550). For gas sensing studies, the electrodes were wire-bonded to a chip holder and each electrode was connected in series with a load resistance of comparable value to the resistance of the sensor in order to optimize resolution1. The circuit was subjected to 0.5 V DC potential and the current was continuously monitored with sample rate of five samples per second. Electrical resistance of the sensor was determined by continuous monitoring the voltage over the load resistor and applying Ohm’s Law. A 1.3 cm3 glass chamber with inlet and outlet ports was positioned over the microfabricated chip with a sandwiched O-ring and sealed by using a clamp. Gas at 200 std. cm3 min-1 flowed through the glass chamber. Dry air (purity: 99.998%) and H2S (purity: 99.99%) were used as the carrier and analyte gases, respectively (Air gas Inc., Riverside, CA, USA). The carrier gas was diluted with the analyte gas to obtain different H2S concentrations. Analyte and carrier gas flow rates were regulated by mass flow controllers (Alicat Scientific Incorporated, Tucson, AZ). A custom LabView computer program was developed to control and monitor the voltage of the nanowire circuit using a Field Point analog module from National Instruments (Austin, TX, USA)1. References 1 C.M.Hangarter, M.A.Bangar, S.C. Hernandez., W.Chen, M. A. Deshusses, A. Mulchandani, and N. V. Myung, Appl. Phy. Lett. 92, Art. 073104 (2008). 3 Figure S1. Schematic of polyaniline nanowire based chemiresistive sensor.