World Journal of Engineering EFFECT OF MODIFIED

advertisement

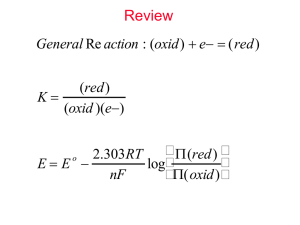

World Journal of Engineering EFFECT OF MODIFIED-MONTMORILLONITE AND POSS ON ELECTRICAL PROPERTIES OF SOLID POLYMER ELECROLYTES Keun-Byoung Yoon1 and Dong-ho Lee2* 1 Department of Polymer Science & Engineering, Kyungpook National University, Daegu 701-702, Korea 2 Dongyang Mirae University, Seoul 152-714, Korea Introduction in this work. A solid polymer electrolyte (SPE) is a solid medium that permits ion transport. An SPE in its original sense is a (liquid) solvent-free system where the ionically conducting phase is formed by dissolving salts in a high-molecular-weight polymer matrix. A polymer that strongly coordinates with cations is necessary for SPE formation. Among a variety of polymers that solvate lithium salts, the poly(ethylene oxide) (PEO)based systems are the most comprehensively investigated due to the beneficial structure for supporting fast ion transport. The main reason for the use of PEO is its ability to show a higher conductivity than any commercially available polymer. Conventional PEO–Li salt complexes show conductivities of the order of 10−4 S/cm at about 100 ◦C; however, widespread applications of these electrolytes require a conductivity of about 10−4 S/cm at ambient temperature. A high crystalline phase concentration limits the conductivity of PEO-based electrolytes, so an important amorphous phase is desired. Apart from high crystallinity, PEO-based electrolytes suffer from low cation transport number t+, ion-pair formation and inferior mechanical properties. To counter these problems various chemical and physical modifications have been tested, aimed at reducing the crystallinity. One such approach is to add plasticisers to polymer–salt complexes such as poly(ethylene glycol) (PEG) and propylene carbonate (PC). The problem encountered with such systems is that higher conductivities are obtained at very high plasticiser concentration, which in turn leads to poorer mechanical properties and reduces the compatibility of the electrolyte film with the electrode. Chu et al. reported the modification of PEO with a phenolic resin to improve the mechanical properties and conductivity. The study reported in the present work aimed at the synthesis and characterisation of PEO/MMT/POSS nanocomposite electrolytes using apolar alkylammonium cation modified nanoclay. The characterisation of the nanocomposite electrolyte samples using XRD and DSC and the evaluation of the electrical properties of such composites as SPEs are presented Experimental Materials and Procedures PEO (Mw=20,000 and 400,000, Aldrich), Na+MMT(Southern Clay) and POSS (1,3,5,7,9,11,14heptaisobutyltricycloheptasiloxane-endo-3,7,14-triol (Hybrid Plastics) were uses. An organo-modified MMT made using an ion exchange method. The electrolytes were prepared by coratating twinscrew mixer (MiniLab, Hakke Rheomex) on pre-dried PEO, organo-modified MMT, POSS and LiClO4 ([EO]/[Li+]=8) under a nitrogen blanket. Characterization XRD experiments were conducted using a Philips X’pert Pro X-ray diffraction instrument that employed Kα radiation (λ = 1.5405A° ). Scans were carried out from 0◦ to 30◦ at a scanning rate of 0.2◦ min−1. The thermal behaviour of electrolytes was characterized using a DSC(TA Q100). The crystallinity of the samples was calculated as the ratio of the heat enthalpy of the crystalline phase to the heat enthalpy of pure crystalline PEO. The ionic conductivity of the electrolyte films was measured using alternating current (AC) impedance spectroscopy. Measurements were conducted by a frequency response analysis (Autolab from Eco Chemie). The experiments were carried out at room temperature in the frequency range 1–10MHz. The AC amplitude was 5 mV. Samples of rectangular shape were cut and clamped between two ITO electrode having an area 1 cm × 1 cm. The resistivity was obtained from the intercept of the impedance curve with the real axis at high-frequency range. Results and Discussion In order to study their crystalline behavior and thermal properties, PEO/MMT/LiClO4 electrolytes were subjected to DSC analysis. It was found that the heat of melting decrease with addition of orfano-modified MMT. The crystallinity of electrolytes containing organo-modified MMT was 26%, whereas the 1279 World Journal of Engineering crystallinity of PEO/LiClO4 was 39%. It was observed that PEO/Li+ electrolyte showed a lower crystallinity than undoped PEO. This is because the lithium cation coordinate with the flexible CH2-O- chain of PEO. When the organo-modified MMT is loaded into the PEO/Li+ electrolyte the crystallinity slightly decreases. In order to study the effect of MMT contents on the room temperature conductivity of PEO/MMT/LiClO4 composite electrolytes, solid electrolyte films were analyzed using AC impedance analyser.(Figure 1) 10 + (a) HW PEO/LiClO4/Na -MMT (b) HW PEO/LiClO4/Dodecylamine-MMT (c) HW PEO/LiClO4/1,12-diaminododecane-MMT (f) HW PEO/LiClO4/Coisite 6A (h) HW PEO/LiClO4/Coisite 30B 10 2 4 6 8 MMT Contents (wt %) Figure 1. Ionic conductivity of PEO/LiClO4/MMT composites for various MMT contents at 30oC It is observed that ion conductivity increased with incorporation of organo-modified MMT, reaches at 5 wt% of MMT and slightly decreases with further increase in MMT content. Addition of MMT leads to a higher ionic mobility of the ions by reducing the crystallinity. Interaction of lithium cations with silicate layers disrupts the strong intra-association between lithium cations and anions. Since silicate layers cannot move, only Li+ cations move under an electric field. To reduce the crystallinity of PEO, POSS was added at PEO/LiClO4 electrolytes. Low molecular weight PEG was also used for plasticizer. The crystallinity of electrolytes is summarized at Table 1. The crystallinity of electrolyte composites was dramatically decreased by addition of POSS (5 wt%), reached at 17%. Generally, POSS and low molecular weight of PEG (LW-PEG) were well-known plasticizer for thermoplastics. Therefore, LW-PEG also added to electrolyte, the crystallinity of electrolytes decreased with increasing the amount of LW-PEG. The lowest crystallinity of electrolytes was 11%. It is observed that the plasticizability of POSS was higher than that of LW-PEG at PEO-based electrolyte composites. -48 55 39 (b) HW-PEO/LiClO4/POSS -46 52 17 -47 51 16 -46 54 15 -45 52 14 -45 53 11 The ionic conductivity changes as a function of crystallinity at 30oC was shown in Figure 2. -7 0 (a) HW-PEO/LiClO4 (c) HW-PEO/LW-PEO(5wt%) /LiClO4/POSS (d) HW-PEO/LW-PEO(10wt%) /LiClO4/POSS (e) HW-PEO/LW-PEO(15wt%) /LiClO4/POSS (f) HW-PEO/LW-PEO(12wt%) /LiClO4/POSS -5 -6 Tg(oC) Tm(oC) Xc(%) Sample Ionic Conductivity (S/Cm) Ionic Conductivity (S/Cm) 10 Table 1. Thermal properties of HW-PEO/LWPEO/POSS 5wt% Composites 10 -3 10 -4 10 -5 10 -6 10 -7 15 20 25 30 35 40 Crystallinity (Xc) Figure 2. Ion conductivity changes as a function of crystallinity of electrolyte composites. The ionic conductivity of the solid electrolyte composites increased with decreasing that of crystallinity, exhibiting a high-degree slope from 35 to 25 % crystallinity. After that point, ionic conductivity was almost constant. The highest value of ionic conductivity of solid electrolyte composite was 9.8x10-3 S/cm. This value is feasible for commercial applications. 1280 45